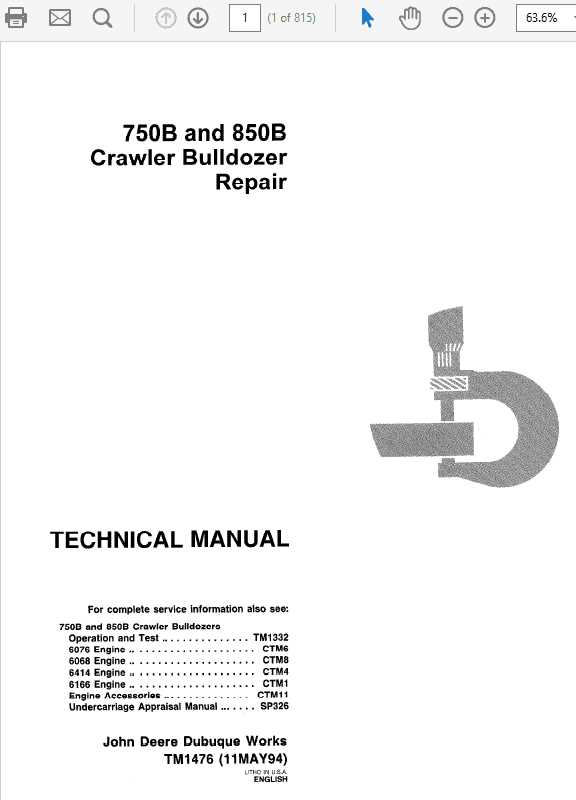

Maintaining the integrity and functionality of agricultural machinery is essential for ensuring optimal performance in the field. Over time, even the most robust farming tools may encounter wear, requiring careful inspection and adjustments to bring them back to peak condition. This section provides a thorough overview of methods and best practices for restoring machinery effectively, focusing on accessible solutions for all users.

Whether you’re addressing minor malfunctions or conducting a complete overhaul, understanding each component’s role and proper maintenance techniques can significantly extend equipment lifespan. Here, we outline essential steps, insights, and tips for keeping your tools in reliable working order, helping you tackle even complex mechanical challenges with confidence.

Explore in-depth procedures, troubleshooting tips, and essential maintenance routines to ensure your equipment is ready for any task. Our aim is to equip you with the knowledge and tools to enhance productivity and reliability in every operation.

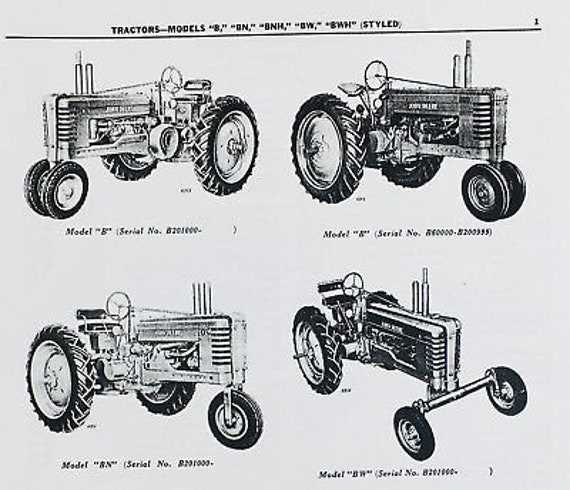

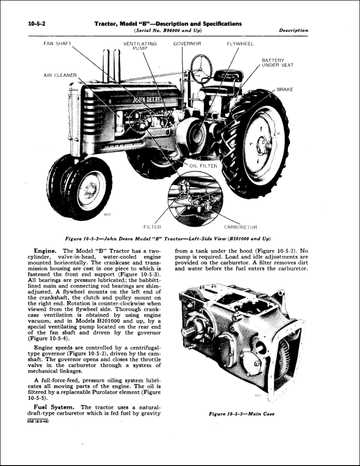

Overview of John Deere B Model

The Model B series was a cornerstone in agricultural machinery, designed to meet the needs of smaller farms while providing reliable power and versatility. Known for its durability and efficient performance, this model supported a wide range of tasks, from plowing fields to powering auxiliary equipment.

Main Features and Capabilities

- Compact build, suited for small to mid-sized farming areas

- Durable engine designed to withstand extensive use

- Fuel-efficient, enabling long hours of operation with minimal refueling

Advantages of the B Series Model

- Enhanced handling and maneuverability on varied terrains

- Adaptable to multiple attachments, increasing operational versatility

- Constructed with user-friendly maintenance in mind, ideal for owners with basic mechanical knowledge

Overall, the Model B represents a blend of efficiency and simplicity, making it a lasting choice for many small-scale agricultural needs.

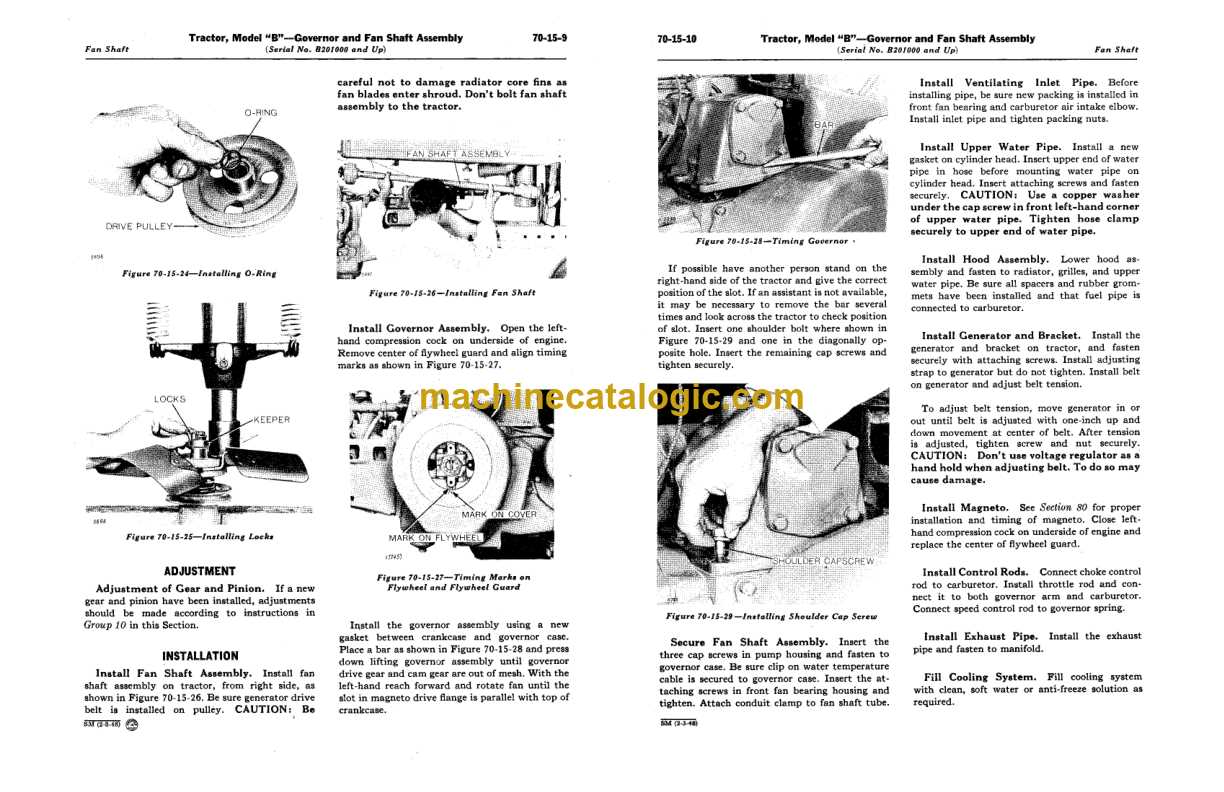

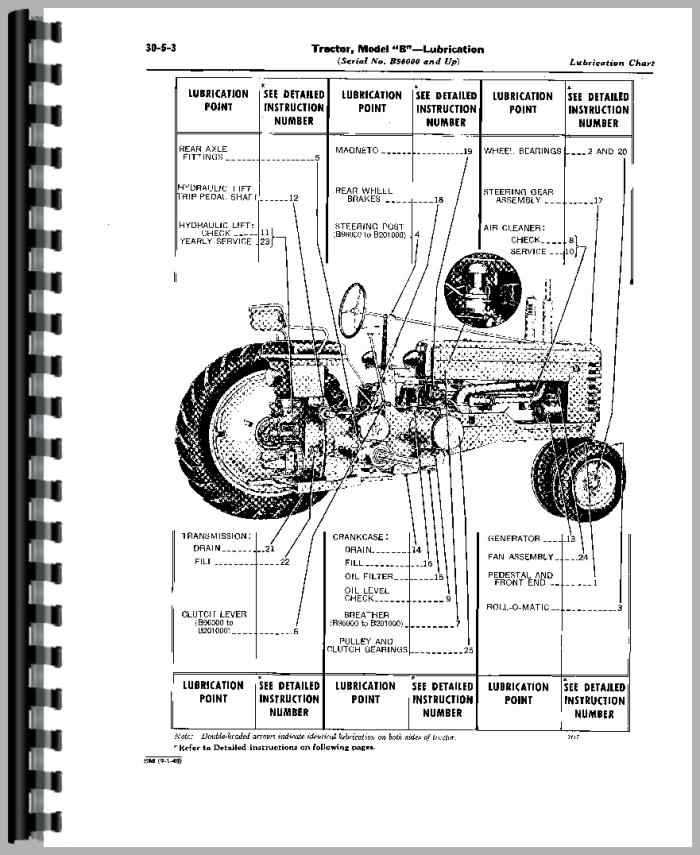

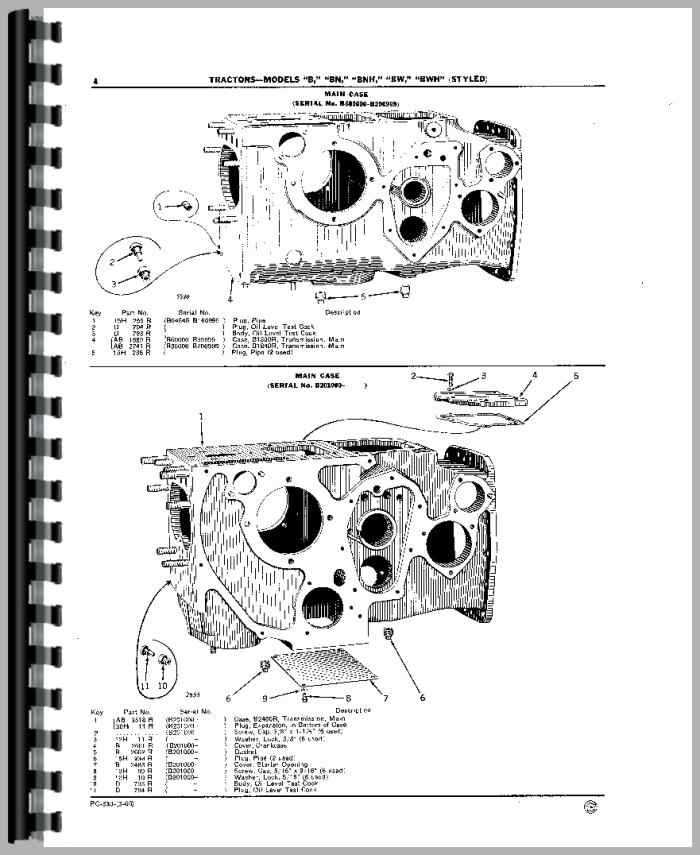

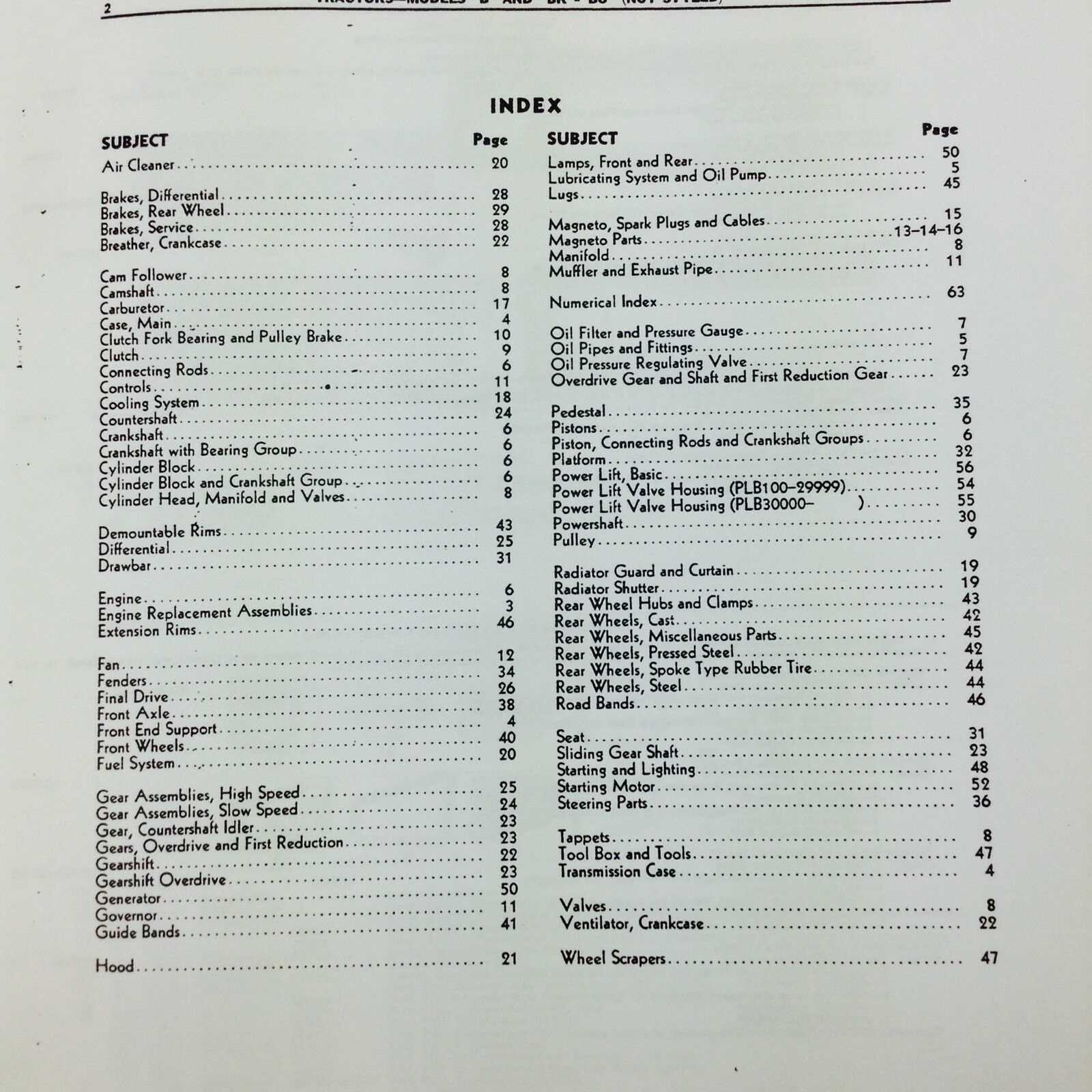

Key Components and Their Functions

Understanding the primary elements and their roles within agricultural machinery is essential for efficient maintenance and enhanced performance. These machines incorporate a range of integral parts, each contributing to specific operations and overall functionality. This section provides insights into key components and highlights their roles in the seamless operation of the equipment.

Engine System

The engine is the powerhouse, generating the necessary energy to drive all mechanical functions. It converts fuel into motion, ensuring other systems operate effectively. Regular inspection and maintenance of the engine can prevent major disruptions and extend the machine’s lifespan.

Transmission and Drive

This system manages power distribution from the engine to the wheels, enabling movement across various terrains. It also allows operators to control speed and torque, which is essential for both performance and safety. Smooth operation of this component ensures reliable handling and maneuverability.

| Component | Function | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hydraulic System |

Preparing Tools for Effective RepairsEffective maintenance requires having the right tools organized and ready for use. A well-prepared toolkit not only saves time but also ensures that each task is approached with precision and efficiency. Properly selected and arranged tools reduce the chances of errors, providing a streamlined workflow and enhancing productivity. The following table outlines some essential tools and their specific functions to support an efficient maintenance process:

Ensuring each Common Engine Issues and Solutions

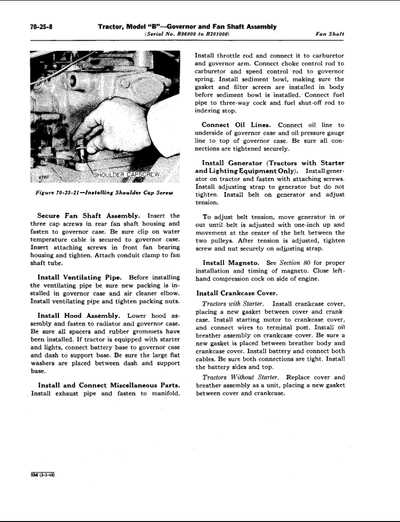

Understanding frequent engine challenges and their effective remedies is essential for maintaining smooth and efficient performance. Regular inspection and early detection of potential issues can significantly reduce downtime and prolong engine life. Below, we discuss several common complications, along with straightforward solutions to address each one. 1. Starting Problems: One prevalent issue involves difficulty in starting the engine, often due to battery power loss, clogged fuel filters, or faulty ignition components. Solution: Check and recharge the battery, replace filters, and inspect ignition parts to ensure optimal function. 2. Overheating: Overheating can arise from low coolant levels, radiator obstructions, or malfunctioning fans. Solution: Regularly verify coolant levels, clear any debris from the radiator, and examine the fan’s operation for steady airflow and cooling. 3. Excessive Smoke: Excessive smoke emissions may indicate fuel system imbalance, oil contamination, or worn gaskets. Solution: Inspect fuel injectors for proper adjustment, change the oil if needed, and replace any compromised gaskets to prevent leakage. By addressing these common issues promptly, engine performance can be maintained efficiently, reducing unexpected interruptions and extending the equipment’s overall operational lifespan. Step-by-Step Carburetor Adjustment GuideProper adjustment of a carburetor is essential for optimal engine performance and efficiency. This guide provides clear steps to ensure your engine receives the correct fuel and air mixture, reducing issues with stalling, rough idling, or fuel waste. Tools and Preparations

Adjustment Process

|