Every piece of intricate craftsmanship holds a story within its design, embodying an era and a unique blend of engineering and artistry. Understanding how to maintain and rejuvenate these delicate timepieces not only preserves history but also brings back the charm of a bygone age. This guide offers an in-depth approach to revitalizing and caring for such remarkable mechanisms, ensuring they continue to function as beautifully as they were intended.

Whether you’re a seasoned hobbyist or exploring the nuances of precision maintenance for the first time, delving into this topic will introduce you to key steps and insights. By following a structured approach, you can confidently address common issues, explore techniques to restore functionality, and learn the essentials of component preservation. These methods emphasize careful attention to detail, helping maintain the elegance and performance of treasured devices for years to come.

As you explore this guide, you’ll discover both foundational methods and advanced tips to make adjustments and fine-tune performance. Each section focuses on practices that honor the original craftsmanship, ensuring that your restoration journey is as rewarding as the device’s renewed vibrancy. Embrace the satisfaction that comes from restoring something beautiful and historical with your own hands.

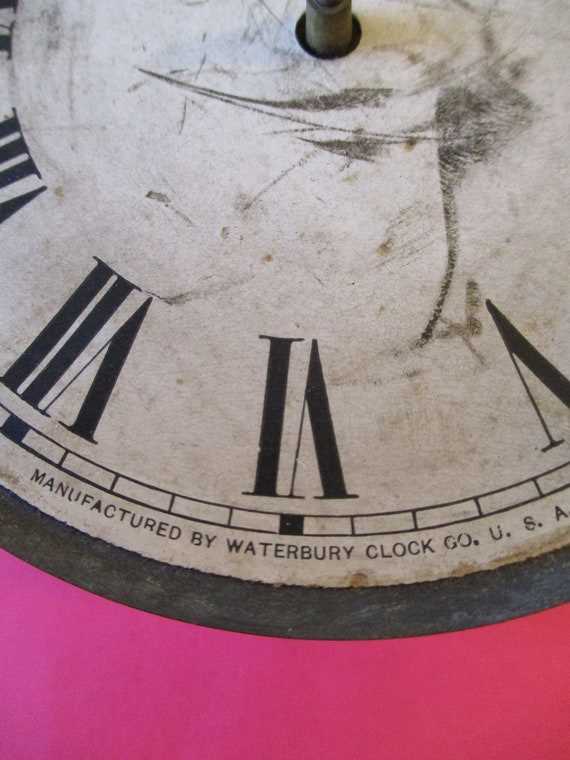

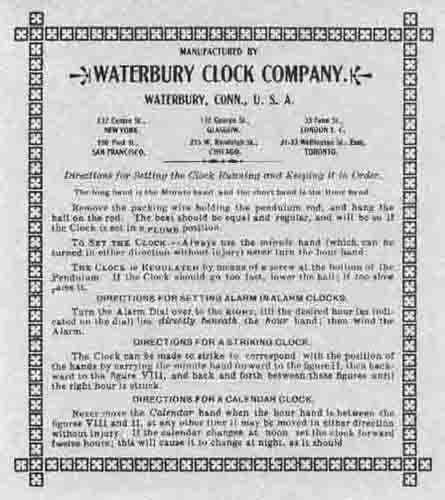

Identifying Parts of a Waterbury Clock

To understand the unique structure of these classic timepieces, one must become familiar with the primary components that drive their function and aesthetics. Each element, from the intricate mechanisms within to the decorative exterior features, plays a critical role in the overall performance and appearance. Recognizing these parts allows for better insight into both maintenance and historical appreciation.

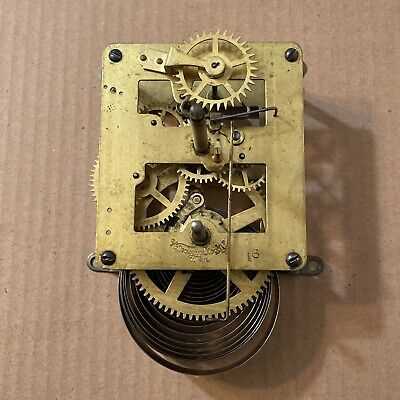

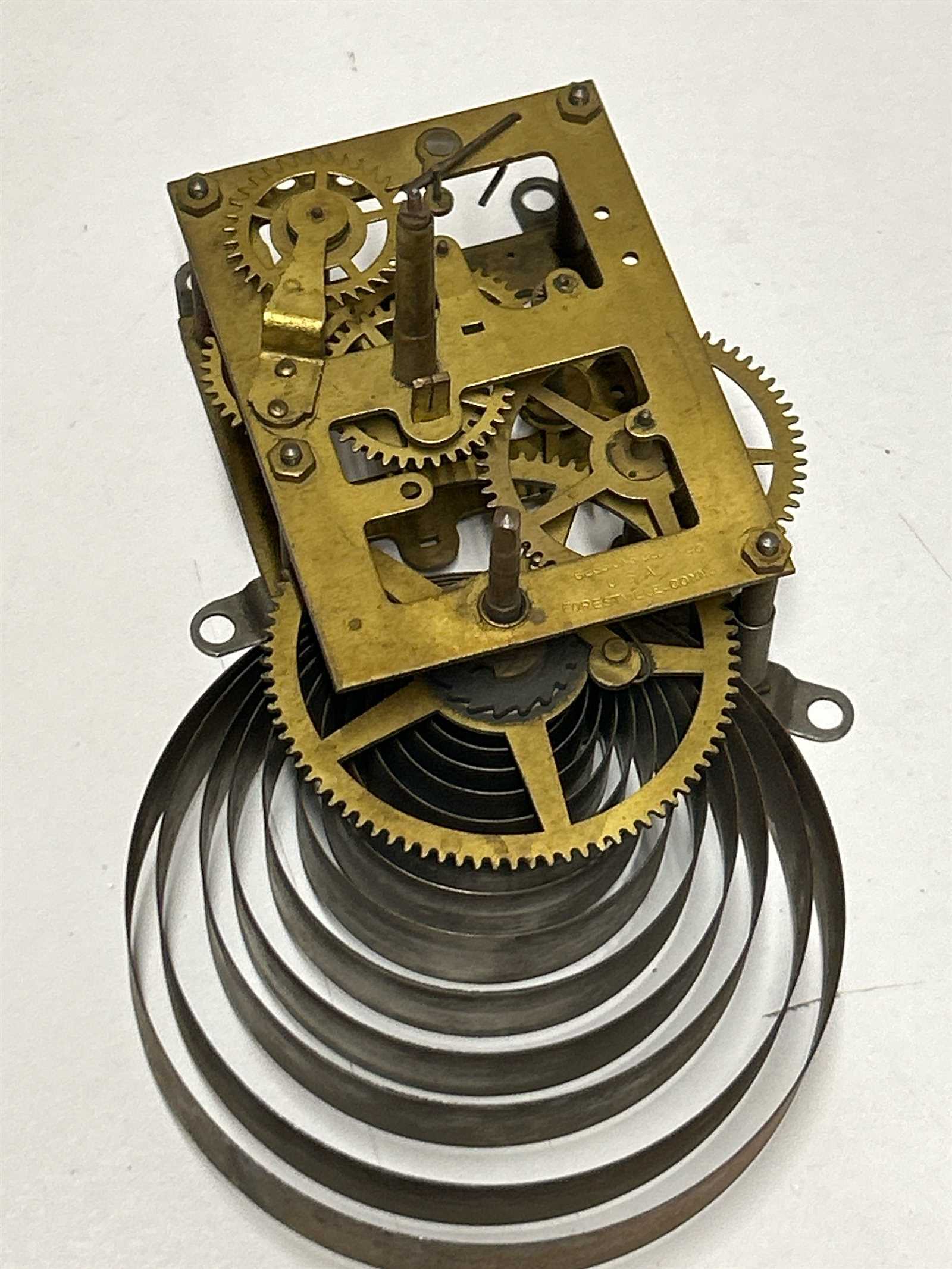

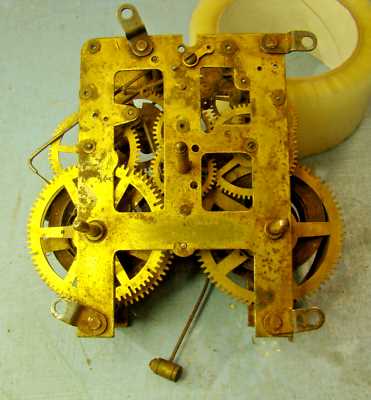

The heart of the timekeeping device lies in its gear assembly. The gears are interconnected, working in tandem to regulate movement through precise, measured rotations. Each wheel is crafted to interact smoothly with adjacent parts, creating a rhythmic motion that supports accurate time measurement.

Another essential element is the escapement, which controls the release of energy at steady intervals. This part is often considered the regulator, allowing the machinery to advance in small, consistent steps. Its carefully calibrated design ensures reliable time intervals, contributing to the piece’s accuracy.

The dial and hands provide a visible interface for reading time. The hands, typically fashioned in various shapes and sizes, move across a marked surface that indicates hours, minutes, and often seconds. Together, these elements translate th

Common Issues in Waterbury Clocks

Over time, historical timepieces often develop a range of mechanical and structural challenges. Due to the age and complexity of their inner mechanisms, these items may experience disruptions in their regular rhythm, affecting accuracy and reliability. Additionally, materials such as metal, wood, and delicate gearwork can wear down, particularly in older or frequently handled pieces.

Irregular Timekeeping

A common issue for antique mechanisms is inconsistent time measurement. This can result from worn gears, weakened springs, or dust accumulation that interferes with the smooth movement of parts. Regular use and the passage of years may also impact the tightness and alignment of internal components, affecting the steady ticking necessary for precision.

Stopping or Pausing Unexpectedly

Occasionally, these timepieces may halt without an obvious cause, leaving the hands frozen until manual adjustment. Such halts often stem from imbalances in the interior mechanism or from obstruction caused by aging lubricants that have thickened over time. In many cases, cleaning

Choosing the Right Tools for Repair

Using the correct tools is essential for ensuring quality and precision when working on delicate mechanical systems. Selecting tools suited to the task at hand not only enhances efficiency but also minimizes potential damage to intricate parts. For anyone working on these types of mechanisms, a reliable set of tools becomes an invaluable asset.

Basic Hand Tools

When handling small components, hand tools like tweezers and small screwdrivers offer control and precision. These instruments help manage detailed adjustments, making them crucial for working with fragile elements. A gentle grip and steady hand are essential when using these basic tools, as small parts require careful handling to avoid scratches or misalignment.

Specialized Instruments

Certain tools are designed specifically for intricate systems, such as movement holders and precision measuring instruments. These specialized tools assist in mainta

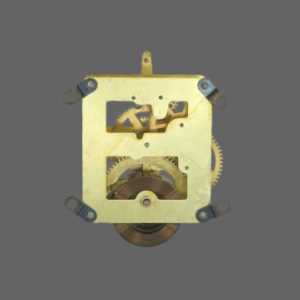

How to Disassemble the Clock Mechanism

Understanding the internal components is essential before beginning any disassembly process. Each piece plays a unique role, and removing parts in the right sequence ensures that the structure remains intact and damage is minimized. This guide will walk you through each step with a focus on precision and care.

Step 1: Start by locating the back panel, which typically provides access to the core of the mechanism. Remove any securing screws carefully, keeping them organized for reassembly. Once the back panel is off, you’ll see the primary gear system.

Step 2: Identify the power source within the mechanism, whether spring-driven or otherwise. Gradually release any tension, avoiding sudden movements to prevent injury or part misalignment. Gently detach each part connected to the main gear, noting their positions for later.

Step 3: Next, focus on the central gears. Begin with the smallest gears first, easing them out with a gentle, steady hand. Remove these in sequence, noting

Cleaning and Polishing Clock Components

Maintaining the functionality and appearance of timekeeping devices requires careful cleaning and polishing of each part. With attention to detail, this process can revitalize components, enhancing both aesthetics and performance. The approach focuses on gently removing accumulated residue while preserving the integrity of each element.

Preparing for Cleaning

Begin by identifying the type of materials in the mechanisms, as different surfaces–such as metal, glass, and wood–require tailored methods. Ensure all necessary tools are prepared, including soft brushes, mild cleansers, and cloths free from abrasive textures. Disassemble parts carefully, keeping track of each component for easy reassembly.

Polishing for Shine and Durability

Once clean, polishing brings out a refined finish. Use non-abrasive solutions designed for delicate surfaces, applying minimal pressure to avoid wear. A soft microfiber cloth is ideal for achieving a smooth, scratch-free shine, ensuring that every polished piece gleams without compromising its structure.

Fixing Pendulum and Weight Problems

When dealing with timing mechanisms, issues related to the swinging device and the associated weights can significantly affect accuracy and functionality. Understanding the fundamental aspects of these components is essential for restoring proper performance. Identifying the source of the problem, whether it be imbalance, misalignment, or wear, is the first step toward resolution.

One common issue involves the pendulum not swinging freely. This can often be attributed to a buildup of dust or debris around the pivot point. Regular cleaning and lubrication can help maintain smooth operation. Additionally, ensure that the pendulum is properly attached and hanging straight. If it appears tilted, adjusting its position can restore balance.

Weight-related complications may also arise. If the weights are unevenly distributed or if one has become detached, it can disrupt the entire mechanism. Reassessing the placement of the weights and ensuring they are securely fastened is crucial. In some cases, it may be necessary to replace worn-out cords or chains to maintain proper weight distribution and functionality.

By systematically addressing these common challenges, one can enhance the reliability and performance of the timing mechanism, ensuring it operates smoothly and accurately.

Repairing the Clock’s Gears and Springs

Maintaining the intricate mechanisms of timekeeping devices is essential for ensuring their proper functionality and longevity. A significant aspect of this process involves addressing the components that regulate movement and energy storage. Understanding how to effectively handle these parts can enhance performance and prevent further issues.

Identifying Common Issues

Before beginning any work, it is crucial to recognize typical problems that may arise with the mechanisms. Some common issues include:

- Stiffness due to old lubricant.

- Worn or broken parts leading to irregular movement.

- Misalignment that hinders proper operation.

Steps to Address the Mechanisms

To restore the functionality of the internal components, follow these steps:

- Disassemble the housing carefully to access the inner workings.

- Examine each gear and spring for signs of wear or damage.

- Clean all components using appropriate solvents to remove old lubricant and debris.

- Apply fresh lubricant to gears and springs to facilitate smooth movement.

- Replace any damaged parts with suitable replacements to ensure proper function.

- Reassemble the housing, making sure everything is aligned correctly.

Adjusting Timekeeping Accuracy

Ensuring precise time measurement is essential for the optimal performance of any timekeeping device. Small adjustments can significantly enhance its reliability and accuracy, making it crucial to understand the fundamental principles behind these modifications. By fine-tuning various components, you can achieve consistent and accurate readings, enhancing the overall functionality of the instrument.

Understanding the Mechanism

The first step in enhancing precision involves gaining insight into the internal mechanism. Familiarize yourself with the parts that influence timing, such as the gear train and escapement. Understanding how these elements interact will provide a foundation for effective adjustments. Regular maintenance can also prevent common issues that affect accuracy.

Making Adjustments

To fine-tune performance, locate the regulating mechanism, often found near the movement. Adjusting the regulator can alter the device’s speed. Moving the regulator arm towards the center will generally increase the speed, while moving it outward will decrease it. It’s advisable to make incremental changes and observe the results before proceeding further, ensuring you attain the desired level of accuracy.

Reassembling the Clock Mechanism

Reconstructing the timepiece’s inner workings requires a careful approach, ensuring each component is placed correctly to restore its functionality. This stage is crucial for achieving accurate timekeeping and smooth operation.

Begin by gathering all disassembled parts and ensuring a clean workspace. Follow these steps for a systematic reassembly:

- Inspect Components: Check each piece for any signs of wear or damage that may affect performance.

- Organize Parts: Lay out the parts in the order they were removed to facilitate easier reassembly.

- Reinsert the Main Gear: Start with the primary gear and align it with the pivot points, ensuring it moves freely.

- Attach Additional Gears: Gradually add secondary gears, making sure each one meshes properly with its corresponding counterpart.

- Secure the Frame: Once all gears are in place, carefully reattach the outer casing, ensuring it fits snugly without forcing any components.

- Test Movement: After reassembly, manually test the movement of the mechanism to confirm that all parts are functioning as intended.

Following these steps meticulously will help ensure the successful reassembly of the inner workings, bringing the timepiece back to life.

Final Testing and Calibration Tips

When restoring timekeeping devices, ensuring accurate performance is crucial. This involves a series of evaluations and adjustments to achieve optimal precision and reliability. A systematic approach can greatly enhance the functionality of these intricate mechanisms, allowing them to operate effectively over extended periods.

Evaluation of Timekeeping Accuracy

Begin by monitoring the device’s timekeeping capabilities over several days. This assessment should include daily checks to observe any discrepancies in time. Utilize a reliable reference, such as a smartphone or atomic time display, to compare and document the results. Any significant deviation from the expected time may indicate the need for further adjustments.

Adjustment Techniques

Once discrepancies are noted, adjustments can be made to enhance accuracy. This may involve regulating the mechanism or fine-tuning specific components. Small modifications can lead to significant improvements, so it is essential to make these changes incrementally and re-evaluate performance after each adjustment. Maintaining a log of changes will help track progress and identify the most effective methods for achieving desired results.