When it comes to keeping your outdoor machinery in optimal condition, understanding the intricacies of maintenance is essential. Proper servicing not only extends the life of your equipment but also enhances its performance, ensuring a smooth and efficient operation throughout the seasons. This section aims to provide insights into the fundamental aspects of machinery upkeep.

Comprehensive knowledge of your equipment’s specifications and functionalities is crucial for any operator. Familiarizing yourself with the various components and their roles can significantly streamline the troubleshooting process, allowing for timely interventions when issues arise. Each part has its own significance, and recognizing this can lead to more effective care strategies.

Additionally, routine checks and adjustments are pivotal in preventing minor problems from escalating into major repairs. Adopting a proactive approach to maintenance not only saves time and money but also enhances the overall efficiency of your machinery. By following a systematic regimen, you can ensure your equipment remains reliable and performs at its best, season after season.

Overview of John Deere 345

This section provides a comprehensive examination of a specific model in the realm of outdoor machinery, emphasizing its features, performance, and usability. Designed for both residential and commercial use, this equipment stands out for its reliability and efficiency, making it a popular choice among users.

Equipped with advanced technology, the model is built to tackle various landscaping tasks with ease. Its ergonomic design ensures comfort during operation, while its powerful engine delivers impressive performance across different terrains.

| Feature | Description |

|---|---|

| Engine Power | Robust engine providing ample horsepower for demanding tasks. |

| Cutting Width | Wide cutting deck allows for efficient mowing in less time. |

| Durability | Constructed with high-quality materials to withstand regular use. |

| User-Friendly Controls | Intuitive controls enhance the overall user experience. |

| Maintenance | Designed for easy upkeep to extend the lifespan of the machinery. |

Overall, this model combines functionality with ease of use, making it an essential tool for maintaining beautiful lawns and gardens.

Common Issues and Solutions

This section addresses frequent problems encountered with garden machinery, offering practical solutions to enhance performance and extend longevity. Understanding these common challenges can help users effectively troubleshoot and maintain their equipment.

Frequent Mechanical Problems

Mechanical failures are a primary concern for many users. Issues may arise from wear and tear or improper maintenance. Identifying these problems early can prevent more significant complications.

| Issue | Solution |

|---|---|

| Engine won’t start | Check fuel levels and spark plugs; replace if necessary. |

| Uneven cutting | Inspect the blades for dullness and alignment; sharpen or adjust as needed. |

| Excessive vibration | Examine wheels and chassis for loose parts; tighten or replace as required. |

| Overheating | Ensure the cooling system is clear of debris; check coolant levels. |

Maintenance Tips

Regular upkeep can significantly reduce the likelihood of encountering issues. Adopting a consistent maintenance routine is essential for optimal performance.

| Maintenance Task | Frequency |

|---|---|

| Oil change | Every 50 hours of operation |

| Blade sharpening | Every 25 hours of use |

| Air filter cleaning | Monthly |

| Fuel filter replacement | Every season |

Maintenance Tips for Longevity

Ensuring the durability and efficient operation of your equipment requires regular care and attention. By implementing a few key practices, you can significantly extend the life of your machinery and enhance its performance.

- Regular Inspections: Frequently check for wear and tear, ensuring all components function properly.

- Fluid Checks: Monitor and change oil and other fluids according to the manufacturer’s recommendations.

- Cleaning: Keep the exterior and engine clean to prevent buildup that could lead to overheating.

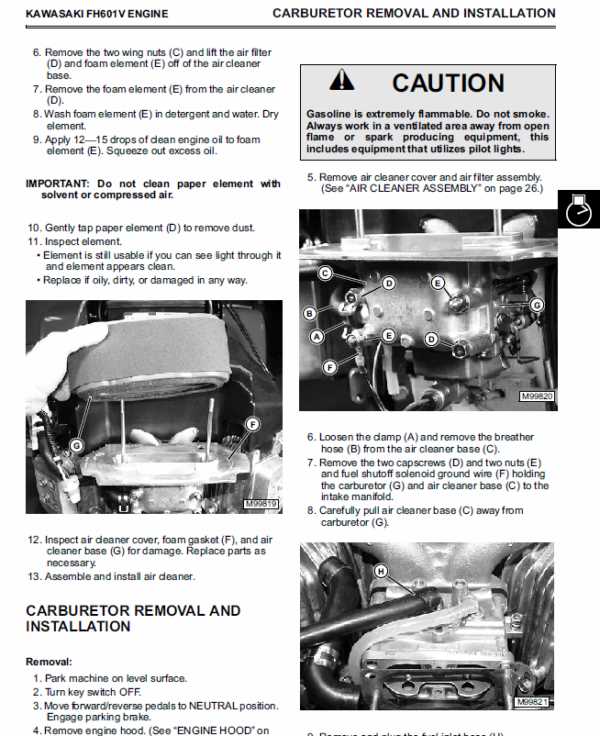

- Air Filters: Replace or clean air filters regularly to maintain optimal airflow.

- Belts and Cables: Inspect for fraying or damage, replacing them as necessary.

By following these simple yet effective strategies, you can ensure your equipment remains in excellent condition, ready for any task.

Tools Needed for Repairs

When undertaking maintenance tasks on machinery, having the right tools is essential for ensuring efficiency and effectiveness. Each task may require specific instruments to facilitate repairs and enhance performance. Below is a guide to the essential implements that will aid in these undertakings.

Essential Tools

- Wrenches: Various sizes to accommodate different bolts and nuts.

- Screwdrivers: Both flathead and Phillips for a range of fasteners.

- Socket Set: For quick and easy access to hard-to-reach fasteners.

- Pliers: Ideal for gripping, twisting, and cutting tasks.

- Torque Wrench: Ensures bolts are tightened to specified settings.

Additional Equipment

- Multimeter: Useful for electrical diagnostics and troubleshooting.

- Oil Filter Wrench: Simplifies the process of changing filters.

- Grease Gun: Ensures proper lubrication of moving parts.

- Jack Stands: Provide stability when working under equipment.

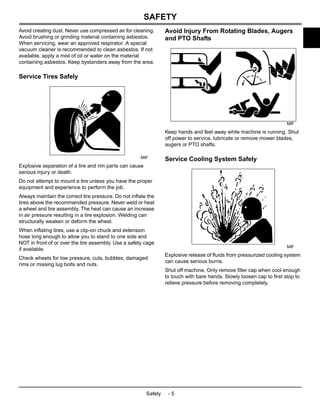

- Safety Gear: Gloves, goggles, and masks to ensure personal protection.

Equipping yourself with these tools will help streamline the maintenance process, making it easier to keep machinery in top condition.

Step-by-Step Troubleshooting Guide

This section provides a structured approach to diagnosing and resolving common issues encountered with lawn maintenance machinery. By following the outlined steps, users can effectively identify problems and implement solutions to restore optimal performance.

Identifying Common Issues

Begin by observing the equipment for any noticeable symptoms. Common problems may include unusual noises, poor performance, or failure to start. Make a list of these symptoms, as they will guide you in your troubleshooting process.

Systematic Approach to Diagnosis

Once symptoms are identified, proceed with a methodical examination. Check the fuel system for blockages or contamination, inspect electrical connections for corrosion, and assess the condition of the air filter. Taking detailed notes during this phase can aid in pinpointing the exact cause of the malfunction.

Understanding Electrical Systems

Electrical systems play a crucial role in the operation of modern machinery, providing the necessary power and control for various functions. A comprehensive grasp of these systems is essential for effective maintenance and troubleshooting, ensuring optimal performance and longevity of the equipment.

Key Components

To effectively navigate electrical systems, it’s important to familiarize oneself with the main components. Each part has a distinct function that contributes to the overall operation.

| Component | Function |

|---|---|

| Batteries | Supply power to the system and start the engine. |

| Alternators | Charge the battery and power electrical systems while the engine is running. |

| Wiring Harness | Connects various electrical components and facilitates the flow of electricity. |

| Sensors | Monitor conditions and provide feedback to the control system. |

| Relays and Fuses | Protect circuits by interrupting the flow of current in case of a fault. |

Troubleshooting Tips

Identifying issues within electrical systems requires a methodical approach. Begin by checking battery voltage and connections, followed by inspecting wiring for any signs of wear or damage. Utilizing diagnostic tools can also aid in pinpointing malfunctioning components, allowing for timely repairs and minimizing downtime.

Engine Repair Basics

Understanding the fundamentals of engine maintenance is crucial for anyone looking to enhance the longevity and efficiency of their machinery. This section delves into essential aspects of maintaining engine performance, focusing on common practices and troubleshooting techniques that can prevent larger issues down the line.

One of the first steps in maintaining engine health is regular inspection. Identifying wear and tear early can save time and resources. Key components to check include:

| Component | Function | Common Issues |

|---|---|---|

| Oil Filter | Filters impurities from oil | Clogs leading to decreased lubrication |

| Spark Plug | Ignites fuel-air mixture | Worn or fouled plugs causing misfires |

| Fuel Filter | Removes contaminants from fuel | Blockages affecting fuel flow |

| Air Filter | Prevents dirt from entering engine | Clogging leading to poor performance |

Maintaining optimal fluid levels is equally important. Regularly checking oil, coolant, and fuel can prevent overheating and ensure smooth operation. Keeping an eye on these essentials can help diagnose problems before they escalate.

Finally, familiarize yourself with basic diagnostic tools. Using items like compression testers or multimeters can help pinpoint issues quickly, allowing for timely interventions and effective solutions.

Transmissions and Drive Train Insights

Understanding the complexities of a vehicle’s transmission and drive train is crucial for maintaining optimal performance. These components work in tandem to ensure efficient power transfer from the engine to the wheels, enabling smooth operation across various terrains. An in-depth comprehension of these systems aids in diagnosing issues and implementing effective solutions.

The transmission system plays a vital role in controlling the speed and torque of the machine, while the drive train encompasses all elements that deliver power to the wheels. Below is a comparison table that outlines the key components and their functions within these systems:

| Component | Function |

|---|---|

| Transmission | Modulates engine power for optimal speed and torque delivery. |

| Drive Shaft | Transfers rotational power from the transmission to the wheels. |

| Differential | Allows wheels to rotate at different speeds, improving handling during turns. |

| Clutch | Engages and disengages the engine from the drive train for smooth gear changes. |

Maintaining these components through regular inspections and servicing can greatly enhance the longevity and reliability of the vehicle. Awareness of the intricacies involved in the transmission and drive train not only assists in troubleshooting but also fosters a deeper appreciation for the engineering that underlies powerful machinery.

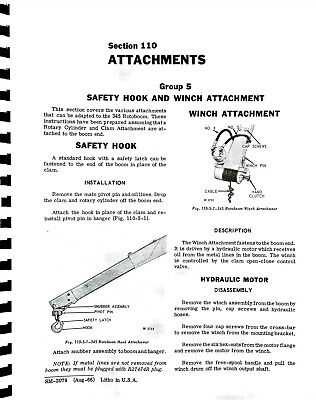

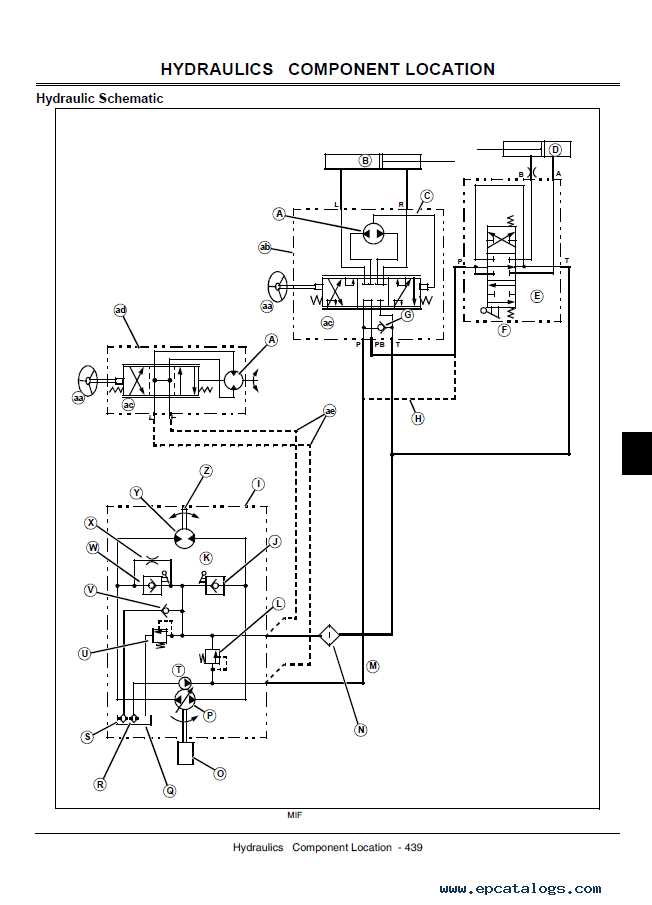

Hydraulic System Maintenance

Proper upkeep of the hydraulic system is essential for ensuring the efficient operation of machinery. Regular attention to this component can prevent costly repairs and downtime. Maintaining the hydraulic system involves monitoring fluid levels, checking for leaks, and ensuring that all connections are secure.

Fluid Checks and Changes

Regularly inspecting and replacing hydraulic fluid is crucial for optimal performance. Contaminated or degraded fluid can lead to reduced efficiency and potential damage to the system. Always follow the recommended schedule for fluid changes and use the appropriate type of fluid for your specific application.

Leak Detection and Repair

Identifying and addressing leaks promptly is vital to maintaining system integrity. Inspect hoses, connections, and seals regularly for signs of wear or damage. If any leaks are detected, they should be repaired immediately to avoid further complications and ensure the longevity of the hydraulic system.

Seasonal Care Recommendations

Proper maintenance throughout the year is crucial for ensuring the longevity and efficiency of your equipment. Each season presents unique challenges and opportunities for care, and understanding these can significantly enhance performance and reliability.

Spring Preparation

As temperatures rise, it’s essential to perform a thorough inspection of your machinery. Check the oil levels and replace any old fluids to promote optimal functionality. Additionally, examine the blades and tires for wear and tear. Ensuring all components are in peak condition will prepare you for the busy season ahead.

Winterization

Before the cold sets in, take time to winterize your equipment. This includes draining fuel and adding a stabilizer to prevent degradation. Protecting your machinery from harsh winter conditions is vital; consider storing it in a sheltered area and covering it with a tarp to shield it from moisture. Regularly checking and cleaning components during this time will help maintain efficiency when spring arrives.

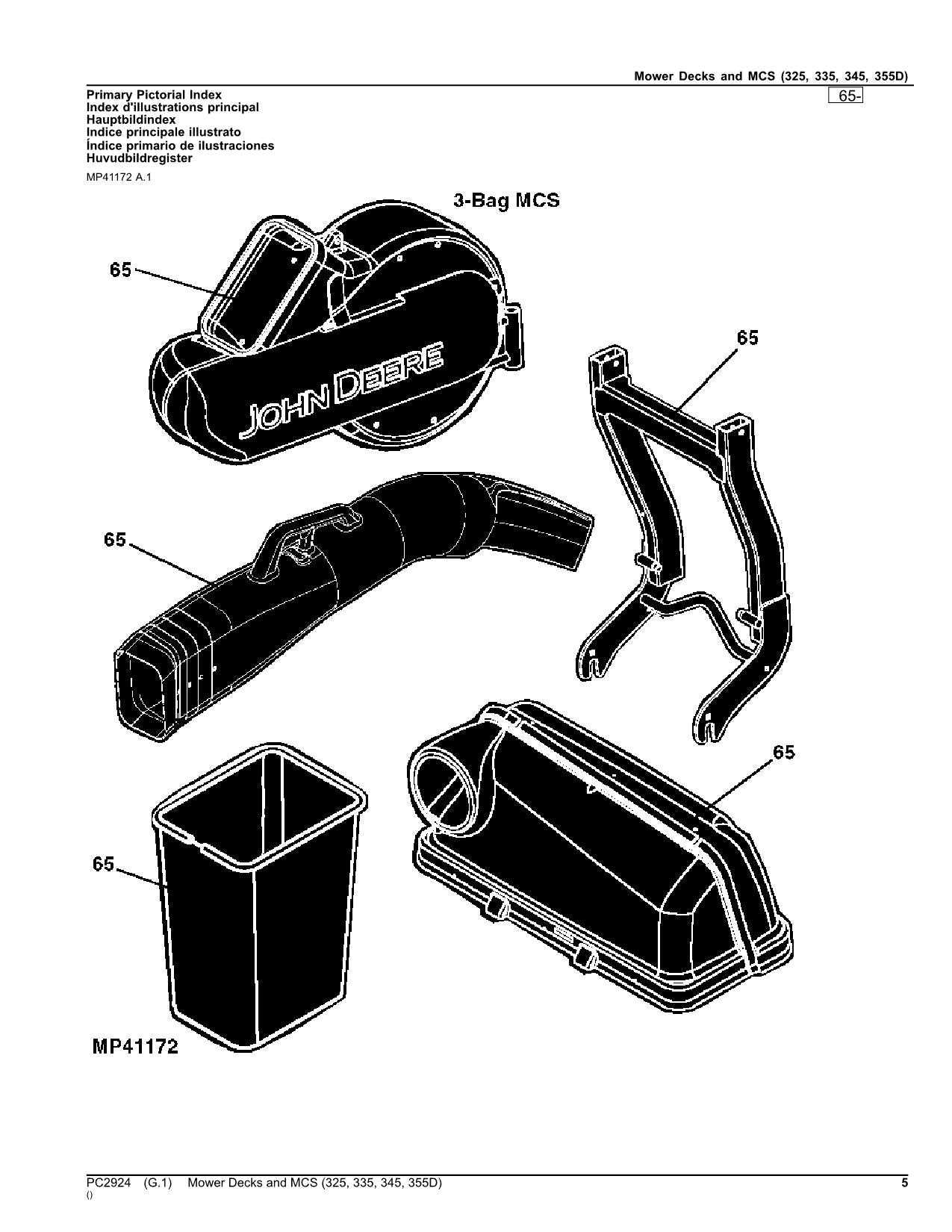

Where to Find Replacement Parts

Locating suitable components for your equipment can be a straightforward process if you know where to look. Several resources can help you find high-quality parts that meet your needs. Below are some reliable options to consider.

- Authorized Dealers: Visiting an official dealer can ensure you receive authentic parts. They often have access to the latest inventory and can provide expert advice.

- Online Retailers: Numerous websites specialize in machinery components. These platforms usually offer a wide selection and competitive prices. Popular options include:

- Amazon

- eBay

- Specialized agricultural equipment sites

By exploring these avenues, you can find the parts necessary to keep your machinery operating efficiently.