Understanding how to keep a motorized two-wheeler in top condition is invaluable for any rider. Regular attention to mechanical and electrical systems ensures a smoother, safer ride and prolongs the life of your machine. In this guide, we’ll explore the key steps to diagnosing common issues, understanding essential maintenance routines, and applying straightforward solutions to a variety of potential concerns. Whether you’re an experienced enthusiast or new to vehicle care, this guide offers practical insights for every level.

From optimizing engine performance to caring for critical parts and systems, a systematic approach to upkeep can make all the difference. This guide breaks down each aspect of vehicle maintenance into clear, accessible sections, providing actionable advice that’s easy to follow. Expect a deep dive into the specifics of engine tuning, electrical diagnostics, and parts replacement to equip you with the knowledge needed to address most challenges you may face on the road.

Enhancing your understanding of your two-wheeler’s components and functions will also empower you to prevent and address issues proactively. With a strong grasp of these foundational principles, you’ll be better prepared to handle unexpected situations and keep your vehicle running efficiently for the long term. This guide is here to support you at every step in ensuring both reliability and enjoyment in your ride.

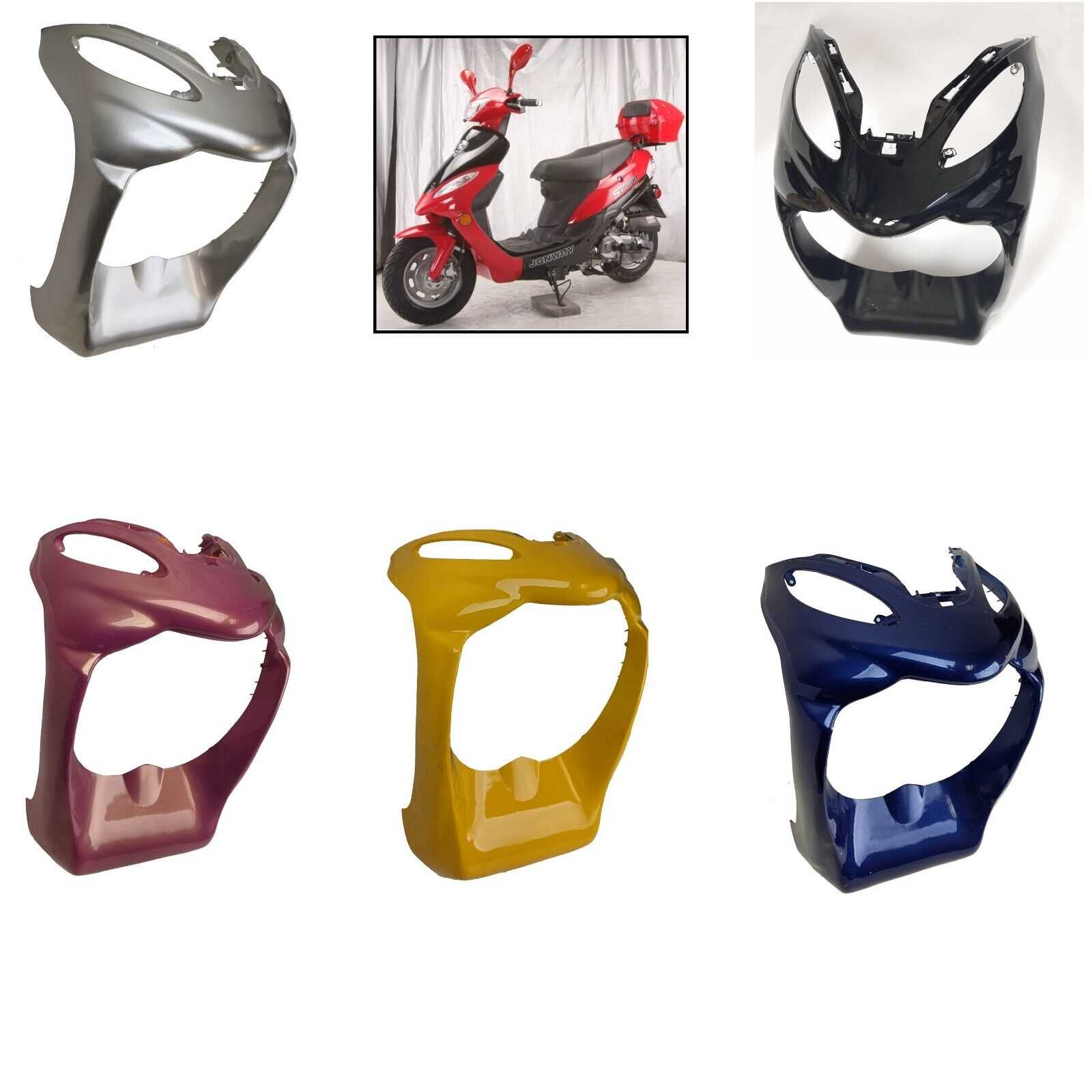

250cc Jonway Scooter Repair Guide

This section provides a comprehensive guide for maintaining and enhancing the performance of a reliable two-wheeler, aiming to ensure a smooth and safe riding experience. Covering essential aspects of upkeep, troubleshooting, and component care, the guide focuses on how to handle typical mechanical challenges while extending the vehicle’s lifespan. Understanding these details empowers riders to address common issues effectively, maintaining optimal operation and avoiding unnecessary setbacks.

Engine and Transmission Maintenance

Regular attention to the engine and transmission system is essential for sustained performance. Checking oil levels, inspecting the air filter, and replacing worn-out spark plugs contribute to a more efficient ride. It’s recommended to conduct routine inspections, ensuring that each component remains clean and operates at full capacity. These preventive steps help avoid sudden breakdowns and improve fuel efficiency.

Electrical System Overview

The electrical components require periodic inspections to ensure consistent functionality. Key areas to check include battery connections, lighting systems, and ignition wires, as these are integral to safe operation. Testing and, if necessary, replacing faulty wiring or batteries prevents unexpected interruptions and keeps critical systems responsive.

Understanding Your Jonway 250cc Engine

The heart of your vehicle is a complex system that requires a clear understanding of its key components and their functions. Recognizing how each part operates and interacts can greatly enhance the longevity and performance of your ride, allowing for smooth and efficient journeys. This section will guide you through the essential elements of the motor, helping you gain insight into maintaining its peak condition.

Cylinder and Piston: The central component where fuel combustion occurs, driving the overall motion. The piston moves within the cylinder, creating the necessary pressure for propelling the vehicle. Regular inspection of these parts can help in maintaining a stable power output.

Cooling System: Vital for regulating the temperature, this system prevents overheating by circulating coolant through the engine. A functioning cooling mechanism is essential to avoid performance issues or potential damage during prolonged use.

Ignition Mechanism: The ignition spark initiates the combustion process, generating the energy needed to start the engine. Ensuring clean connections and timely maintenance of ignition parts contributes to reliable startups and consistent performance.

Fuel Intake and Exhaust System: Managing fuel input and exhaust output is crucial for efficient combustion. The intake controls air and fuel mixture, while the exhaust releases byproducts. Keeping these pathways clear supports fuel efficiency and reduces emissions.

By gaining a solid grasp of these foundational elements, you can proactively care for your engine, anticipate issues early, and ensure a smooth and dependable riding experience.

Common Electrical Issues and Fixes

Electrical components play a crucial role in the smooth functioning of any motorized system, impacting everything from ignition to lighting. Over time, connections and circuitry may encounter wear, leading to faults that can hinder performance. This section highlights prevalent issues within these systems and provides straightforward solutions for optimal functionality.

1. Intermittent Power Supply

One of the most frequent issues is a sporadic power flow, often caused by loose connections or corroded terminals. To resolve this, inspect all wiring harnesses and terminals for any visible damage or rust. Tighten or replace any loose connectors and clean off corrosion with an appropriate electrical contact cleaner. Ensuring a secure connection minimizes the risk of power loss and improves reliability.

2. Faulty Ignition System

If starting the engine proves difficult or inconsistent, the ignition system could be compromised. Check the ignition coil, spark plug, and wiring for any signs of damage or wear. Replace the spark plug if it appears dirty or corroded, as a clean and properly connected plug ensures a stronger spark. Verifying and, if necessary, replacing these components often restores the ignition to reliable working order.

Regular inspection of these key areas prevents most common electrical malfunctions. By addressing minor issues early, users can avoid more significant repairs and maintain optimal system performance.

Fuel System Troubleshooting for Optimal Performance

Achieving smooth and consistent power delivery requires a well-maintained fuel system. This section explores common issues affecting performance and provides straightforward guidance for identifying and resolving them effectively. Addressing these components promptly helps in sustaining efficiency and prolongs the lifespan of the entire system.

Key areas of the fuel system, including filters, lines, and carburetors, can develop issues that disrupt normal function. The table below outlines common symptoms, possible causes, and recommended actions for each component to simplify the troubleshooting process.

| Symptom | Possible Cause | Recommended Action | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine sputtering or stalling | Clogged fuel filter | Inspect and replace the filter if clogged | ||||||||||||||||||||

| Fuel odor or leaks | Damaged or loose fuel lines | Check lines for cracks or looseness; replace if needed | ||||||||||||||||||||

| Difficulty starting | Carburetor blockage | Clean carburetor components thoroughly | ||||||||||||||||||||

| Weak acceleration | Incorrect fuel-air mixture | Adjust carburetor settings for optimal

Inspecting and Replacing Spark PlugsEnsuring optimal performance requires periodic examination and renewal of the ignition elements. These components are essential for efficient combustion, reliable engine starts, and overall smooth operation. Regular checks help in identifying wear or potential issues that can affect performance.

Perform Brake Maintenance for Safe RidingEnsuring that your braking system is in optimal condition is vital for maintaining safety while on the road. Proper upkeep of these components not only enhances performance but also significantly reduces the risk of accidents. Regular checks and maintenance can help identify issues before they escalate, providing peace of mind for riders. Regular Inspection

Performing routine inspections is essential for detecting wear and tear. Check the brake pads for thickness and replace them if they appear worn down. Additionally, inspect the brake lines for any signs of leaks or damage, as these can lead to serious safety hazards. Maintaining clear visibility of all components will ensure effective functioning. Fluid Levels and QualityKeep an eye on brake fluid levels, as low fluid can compromise braking efficiency. It’s important to regularly replace old fluid with fresh fluid that meets the manufacturer’s specifications. Proper hydraulic pressure is crucial for responsive braking, so make it a habit to monitor this aspect regularly. Always prioritize your safety by staying proactive in your maintenance routine. Transmission Adjustments and Gear ChecksEnsuring optimal performance of your two-wheeled vehicle involves regular maintenance and precise adjustments of the transmission system. Proper alignment and functionality of the gear components are essential for smooth operation and longevity. This section provides insights into the essential checks and adjustments that should be performed periodically. Key areas to focus on include:

Follow these steps to effectively adjust and check the transmission:

By diligently performing these tasks, you can enhance the performance and reliability of your two-wheeled vehicle, ensuring a safer and more enjoyable ride. Cooling System Maintenance and Repairs

Ensuring the optimal performance of your vehicle’s thermal management is essential for longevity and efficiency. The cooling mechanism plays a vital role in regulating engine temperature, preventing overheating, and maintaining operational integrity. Proper upkeep can enhance performance and minimize the likelihood of severe mechanical issues. Regular Inspections: Routine checks are crucial to identify any potential leaks, blockages, or damages within the cooling circuit. Pay special attention to hoses, clamps, and connections, as wear and tear can lead to failures. Look for signs of coolant leakage or corrosion, which can indicate underlying problems. Coolant Quality: Maintaining the appropriate fluid level and quality is imperative for effective heat dissipation. Use the manufacturer-recommended coolant type and replace it as advised to prevent sediment buildup and ensure efficient heat transfer. If the coolant appears discolored or has a foul odor, it may require flushing and replacement. Radiator Maintenance: The radiator must be clean and free from debris to function effectively. Regularly inspect the exterior for dirt or obstructions that could hinder airflow. Cleaning the radiator fins with a gentle stream of water can help maintain optimal cooling efficiency. Additionally, check the internal components for signs of clogs or damage. Thermostat Functionality: The thermostat regulates the flow of coolant based on temperature. If the engine runs too hot or too cold, it may indicate a malfunctioning thermostat. Testing its operation involves monitoring temperature readings and assessing the responsiveness to temperature changes. If issues arise, replacement may be necessary to restore proper function. Water Pump Condition: The water pump circulates coolant throughout the engine. Signs of failure include unusual noises, leaks, or overheating. Ensure that the pump is operating smoothly and without excessive play. If any irregularities are detected, timely replacement can prevent more significant complications down the line. Battery Care and Charging TipsMaintaining the power source of your vehicle is crucial for optimal performance and longevity. Proper care and attention can significantly enhance the lifespan and efficiency of your energy storage unit. This section provides essential guidelines to ensure your power supply remains in peak condition. Charging Best Practices

Charging your energy storage unit correctly is vital. Here are some key points to consider:

Maintenance TipsRegular upkeep is essential for prolonging the life of your energy source. Here are some practices to adopt:

How to Diagnose Starting Problems

Starting difficulties can arise from various underlying issues, making it essential to systematically identify the cause. By methodically examining different components, you can narrow down potential faults and determine the necessary actions to restore functionality. Step 1: Check the Battery – Begin by ensuring that the battery is charged and in good condition. A weak or dead battery is a common reason for starting failures. Use a multimeter to measure the voltage; it should read around 12.6 volts when fully charged. If the reading is low, recharge or replace the battery as needed. Step 2: Inspect the Fuel System – Next, examine the fuel supply. Ensure there is sufficient fuel in the tank and check for any blockages in the fuel lines. Inspect the fuel filter and clean or replace it if it appears clogged. Proper fuel delivery is crucial for starting. Step 3: Evaluate the Ignition System – The ignition system is another critical area to inspect. Check the spark plug for signs of wear or damage, such as cracks or excessive carbon buildup. Replace the spark plug if necessary. Additionally, confirm that the ignition coil is functioning correctly. Step 4: Review Electrical Connections – Faulty electrical connections can also impede starting. Examine all wiring for signs of corrosion or fraying. Ensure that connectors are secure and free from dirt. Cleaning or replacing corroded connectors may resolve the issue. Step 5: Test the Starter Motor – Finally, if previous steps do not reveal any problems, consider testing the starter motor. Listen for a clicking sound when trying to start; this may indicate a faulty starter. If the starter fails to engage, further inspection or replacement may be required. By following these steps, you can effectively diagnose starting issues and take the appropriate measures to restore your vehicle to optimal performance. Tire Care and Pressure Guidelines

Maintaining proper tire condition and pressure is crucial for the overall performance and safety of any two-wheeled vehicle. Regular inspection and adherence to recommended pressure levels can significantly enhance stability, fuel efficiency, and lifespan of the tires. This section outlines essential practices for ensuring optimal tire care and pressure management. Regular InspectionFrequent visual checks for signs of wear, damage, or foreign objects can prevent unexpected issues. Look for uneven tread wear, cracks, or bulges. Additionally, monitoring the tread depth is essential, as insufficient tread can compromise traction and handling. If any irregularities are found, addressing them promptly is vital. Maintaining Correct PressureAdhering to the manufacturer’s specifications for tire pressure is essential for safe operation. Under-inflated tires can lead to poor handling and increased fuel consumption, while over-inflation may cause a harsh ride and increased risk of blowouts. Use a reliable pressure gauge to check the tire pressure regularly, ideally when the tires are cold, and adjust as needed. Cleaning and Adjusting Carburetors

Maintaining optimal performance in small engines requires regular attention to the fuel delivery system. One of the key components in this system is the device responsible for mixing air and fuel. Proper cleaning and adjustment of this component can significantly enhance engine efficiency and responsiveness. Over time, deposits and dirt can accumulate, affecting the air-fuel mixture and leading to operational issues. Cleaning this essential part involves disassembling it to remove any blockages or residues. Start by ensuring all components are free from fuel and securely placed on a clean work surface. Use a suitable solvent to eliminate stubborn deposits, and a soft brush can help reach intricate areas. It is important to inspect gaskets and seals for wear and replace them as necessary to prevent leaks. Adjusting involves fine-tuning the air-fuel mixture to match the engine’s requirements. This can typically be done by adjusting the screws located on the device. Refer to the specifications for the correct settings, as each engine may have unique needs. After adjustments, a thorough test run is essential to ensure the engine operates smoothly and responds well to throttle input. Regular maintenance of this critical component not only prolongs engine life but also enhances performance. By incorporating cleaning and adjustment into routine checks, users can avoid more significant issues down the line and enjoy a smoother, more efficient operation. Preventing Common Belt and Pulley IssuesMaintaining the efficiency of your vehicle’s transmission system is crucial for optimal performance and longevity. Regular attention to the belt and pulley components can prevent a range of issues that might disrupt functionality. Understanding the factors that contribute to wear and tear is essential in ensuring smooth operation and extending the lifespan of these critical elements. Regular Inspections

Conduct frequent examinations of the belt and pulley assemblies to identify signs of damage or wear. Look for cracks, fraying, or unusual wear patterns on the belt, as well as any misalignment or damage to the pulleys. Addressing these issues early can prevent more significant problems down the line. Proper Tensioning

Ensure that the tension of the belt is correctly adjusted. A belt that is too loose can slip, while one that is overly tight may cause undue stress on the pulleys. Consult your manufacturer’s specifications for the recommended tension settings and use appropriate tools to make adjustments as necessary. Regular tension checks will help maintain optimal performance and reduce the risk of premature failure. |