Understanding how to maintain and service essential agricultural machinery is crucial for optimal performance in the field. This guide provides in-depth insights into addressing common issues and fine-tuning your equipment, ensuring it operates smoothly across various conditions. Whether you are a professional or an enthusiast, gaining knowledge about essential components, settings, and adjustments can enhance both the lifespan and efficiency of your machinery.

In this resource, you’ll find detailed instructions for routine inspections, adjustments, and troubleshooting tips to tackle any mechanical challenges. Each section is designed to walk you through specific tasks with clarity, focusing on practical solutions that help you identify potential wear points and address them promptly. Armed with this guidance, you can keep your machinery running reliably, minimizing downtime and maximizing productivity.

Explore essential maintenance steps that cover a wide range of areas, from the power unit to the steering system, to ensure a comprehensive understanding of your equipment. This structured approach will allow you to handle complex maintenance tasks confidently, making your work more efficient and productive.

John Deere X720 Repair Manual Overview

This guide provides a detailed look into maintenance and troubleshooting strategies tailored for enhancing the durability and performance of your equipment. It covers systematic approaches, diagnostics, and essential checks to keep machinery running smoothly across various tasks.

- Detailed inspection processes to identify wear and tear

- Step-by-step instructions for part replacements and adjustments

- Preventative measures to extend equipment lifespan

- Instructions for routine lubrication and cleaning tasks

Following these comprehensive guidelines will support efficient operation and timely issue resolution, ensuring that the equipment functions optimally under diverse conditions.

Common Issues and Their Solutions

Understanding frequent challenges encountered with equipment and the best ways to address them is essential for ensuring smooth operation and prolonging the lifespan of the machinery. This section provides insights into typical problems that may arise and offers effective solutions to maintain optimal performance.

Engine Starting Difficulties

One common issue users face involves starting difficulties, which can often be traced to the fuel system or battery. Ensure the battery is fully charged and that all connections are secure. Additionally, inspect the fuel filter and fuel lines for potential blockages or wear, as these can impede fuel flow and cause irregular performance.

Hydraulic System Troubles

Hydraulic systems may experience reduced efficiency due to leaks or blockages. Regularly check hydraulic hoses and seals, as aging components may develop cracks or tears, leading to pressure loss. Cleaning and maintaining these parts can prevent further issues and help maintain steady power in the system.

Understanding the Engine Components

The engine serves as the core powerhouse, converting fuel into mechanical energy to drive machinery. To ensure optimal function, it is essential to familiarize oneself with the primary components and their roles in the overall performance.

Cylinder Block: This foundational part houses the cylinders, where fuel combustion occurs to generate power. It is crafted to withstand high temperatures and pressure, acting as the framework for various moving parts.

Pistons and Crankshaft: Pistons move within each cylinder, translating the energy from combustion into motion. The crankshaft then converts this motion into rotational energy, ultimately transferring power to the wheels.

Fuel and Air Systems: Precise amounts of fuel and air must mix for combustion to occur. The fuel injectors and air filters ensure a clean, efficient mixture, enhancing both power output and engine efficiency.

Cooling Mechanism: Engines generate substantial heat, necessitating a cooling system. This system prevents overheating by circulating coolant, which absorbs and dissipates excess heat, safeguarding engine integrity.

Lubrication System: Friction between moving parts generates wear. Oil circulates within the engine, reducing friction, minimizing wear, and extending the lifespan of internal components.

Understanding these components and their functions can greatly aid in diagnosing issues, enhancing performance, and maintaining the machinery’s longevity.

Hydraulic System Maintenance Guide

Regular upkeep of the hydraulic system is essential for smooth and efficient equipment operation. This guide provides a clear overview of necessary practices to maintain optimal performance and prevent wear. Focusing on the core components of the hydraulic setup, you can extend the longevity of the machinery while minimizing potential breakdowns.

To begin, ensure that the hydraulic fluid level is consistently checked and kept within the recommended range. Fluid quality plays a critical role in system function; thus, using only approved types helps prevent contamination and system strain. Additionally, inspect hoses and connections for leaks or visible wear, as even minor issues can lead to reduced efficiency.

Regularly clean or replace the hydraulic filters as part of routine maintenance. Filters are designed to trap contaminants, which, if left unchecked, could circulate through the system and cause extensive damage. Follow recommended intervals for filter replacement based on the equipment’s workload and operating conditions.

Monitoring the pressure levels within the system is also crucial. Excess pressure can indicate blockages or other issues within the hydraulic lines. Regular pressure testing will help identify any underlying problems, enabling timely repairs and adjustments.

Finally, ensure that all components are adequately lubricated to reduce friction and prevent heat build-up. Proper lubrication minimizes the chances of wear and extends the functional life of each part, contributing to overall system stability.

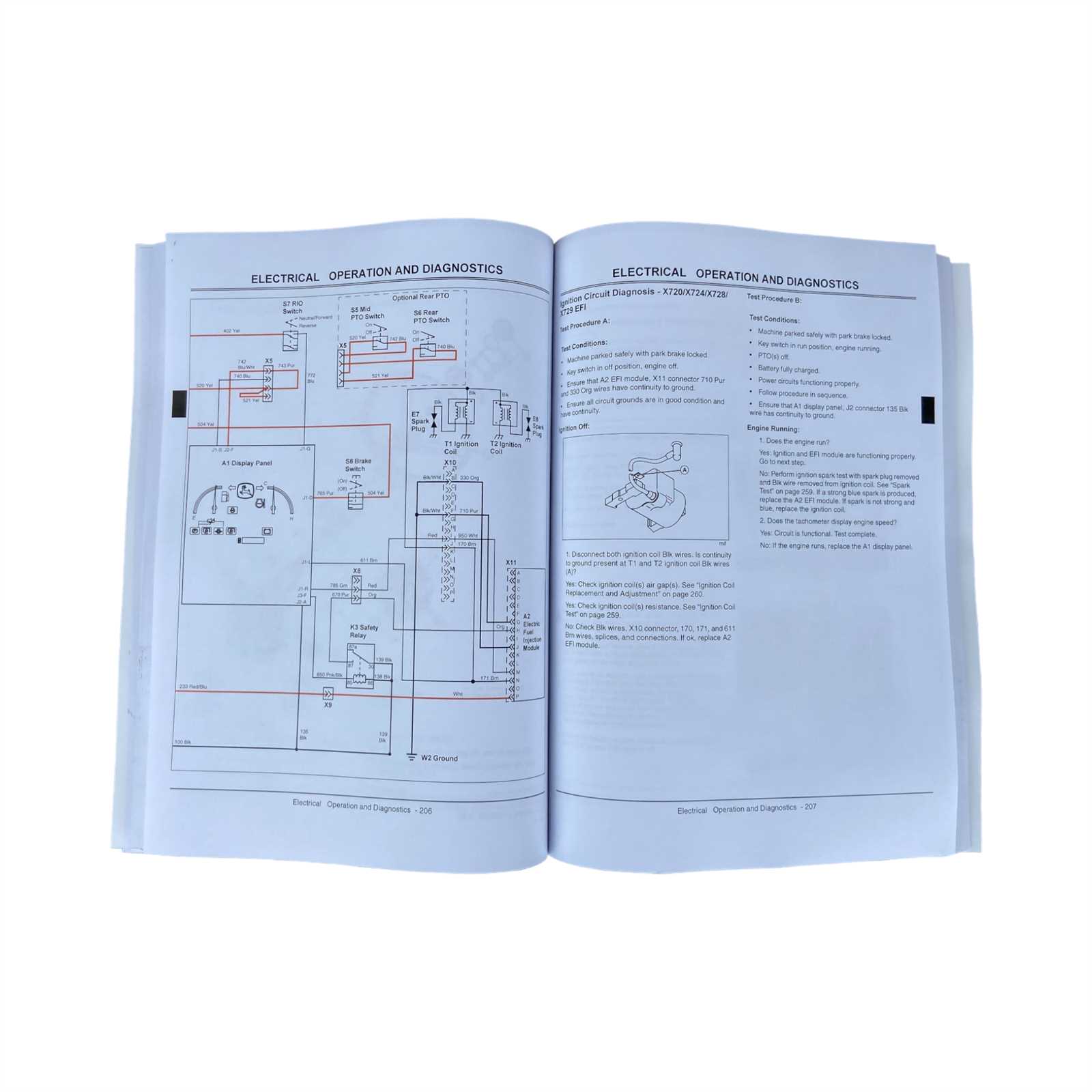

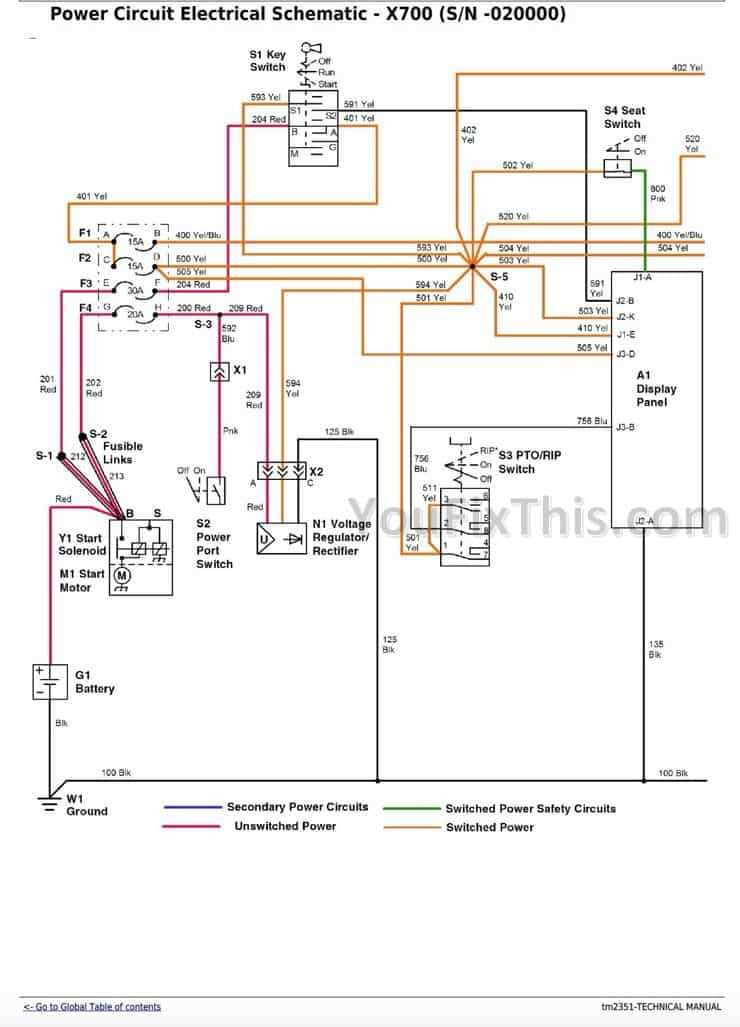

Electrical System Troubleshooting

When diagnosing electrical issues, it’s essential to follow a methodical approach to identify and resolve potential problems effectively. Understanding the flow of electricity through circuits and recognizing common symptoms of malfunctions can help in pinpointing faults within the system.

Step 1: Inspecting Connections

Begin by checking all visible connections. Ensure wires are securely fastened and free from corrosion or damage. Loose or corroded connectors can disrupt electrical flow, leading to irregular system performance or complete failure.

Step 2: Testing the Battery

A weak or depleted battery is a frequent cause of electrical issues. Use a multimeter to assess the voltage. If the reading is below optimal, recharge or replace the battery as needed to restore full functionality.

Step 3: Verifying Fuses and Relays

Examine the fuse box for any blown fuses or faulty relays. These components act as safeguards within the system. Replacing damaged fuses or relays may quickly resolve various electrical issues.

Step 4: Checking Wiring Harness

The wiring harness connects multiple components, and any break or short can lead to system malfunctions. Visually inspect the wiring for any signs of wear, cracks, or breaks. Repair or replace damaged sections to ensure a stable connection.

By following

Transmission Repair Tips and Tricks

Maintaining the functionality of your vehicle’s transmission is crucial for optimal performance. A well-functioning system ensures smooth gear transitions and extends the lifespan of the machinery. This section provides practical advice and techniques to assist you in addressing common transmission issues, enhancing efficiency, and promoting longevity.

Regular Maintenance Practices

Implementing routine maintenance is essential for preventing significant complications. Regularly checking fluid levels and replacing worn components can avert costly breakdowns. Always ensure that the fluid is clean and at the correct level, as this is vital for lubrication and cooling.

Common Issues and Solutions

Familiarize yourself with typical problems, such as slipping gears or unusual noises. These can indicate underlying issues that require attention. Addressing these signs promptly can save time and resources in the long run. For instance, if you notice your vehicle struggling to shift, inspect the linkage and adjust as necessary.

Replacing Worn-Out Parts Efficiently

Maintaining machinery in optimal condition requires timely intervention, especially when components show signs of wear. Addressing these issues promptly not only extends the lifespan of the equipment but also ensures smooth operation and enhances overall performance. This section outlines effective strategies for identifying and replacing fatigued parts to keep your equipment running efficiently.

Identifying Worn-Out Components

Before initiating replacements, it’s crucial to recognize which parts need attention. Here are some common indicators:

- Unusual noises during operation

- Decreased efficiency or performance

- Visible damage or deterioration

- Frequent breakdowns or malfunctions

Steps for Efficient Replacement

Once worn components are identified, follow these steps for a seamless replacement process:

- Gather Tools and Materials: Ensure you have the necessary tools and replacement parts on hand.

- Consult Documentation: Refer to technical guides for specific instructions related to your equipment.

- Remove the Affected Part: Carefully detach the worn component, following safety protocols.

- Install the New Part: Position the new piece accurately and secure it properly.

- Test Functionality: Run the equipment to ensure the new part operates correctly and efficiently.

By adhering to these guidelines, you can effectively manage part replacements, enhancing the reliability and functionality of your machinery.

Fuel System Cleaning and Care

Maintaining the integrity of the fuel system is essential for optimal performance and longevity of any machinery. Regular cleaning and care can prevent clogs and ensure that the engine receives a steady supply of clean fuel. This section focuses on best practices and procedures for keeping the fuel system in top condition.

Inspection is the first step in fuel system maintenance. Periodically check all components, including the fuel tank, lines, and filters, for any signs of wear or contamination. Look for rust, dirt, or debris that may hinder fuel flow.

It is crucial to clean the fuel filters regularly. These filters trap impurities that can lead to performance issues. Replace them according to the manufacturer’s recommendations or more frequently if you notice a decrease in efficiency.

Another important aspect is ensuring that the fuel being used is of high quality. Using clean, fresh fuel minimizes the risk of deposits forming in the system. If possible, avoid leaving fuel in the tank for extended periods, as this can lead to the degradation of fuel quality.

Finally, consider using fuel additives designed to clean the system and enhance performance. These products can help dissolve deposits and improve fuel combustion, leading to better efficiency and reduced emissions.

Routine Inspections for Longevity

Regular assessments are essential for ensuring the extended lifespan and optimal performance of machinery. Implementing a structured approach to routine checks can help identify potential issues before they escalate, allowing for timely maintenance and repairs.

Visual Checks: Begin with a thorough visual inspection of the equipment. Look for signs of wear, damage, or leaks. Ensure that all components are secure and free from obstructions.

Fluid Levels: Monitoring fluid levels is crucial. Regularly check oil, coolant, and hydraulic fluid to ensure they are within the recommended ranges. Low levels can lead to overheating and mechanical failure.

Belts and Hoses: Inspect belts and hoses for signs of cracking or fraying. Proper tension and condition of these components are vital for efficient operation.

Tire Condition: Examine the tires for proper inflation and tread wear. Maintaining correct tire pressure is important for stability and traction, while worn tires can affect handling and safety.

Battery Health: Ensure the battery terminals are clean and securely connected. Regularly test the battery’s charge and inspect for any signs of corrosion.

By adhering to these routine inspections, you can significantly enhance the durability and reliability of your equipment, ultimately leading to improved performance and reduced downtime.

Essential Tools for DIY Repairs

For anyone looking to tackle maintenance tasks at home, having the right instruments is crucial. Proper tools not only streamline the process but also enhance safety and efficiency. Whether you’re fixing minor issues or conducting more extensive work, a well-equipped toolkit can make all the difference.

Wrenches are among the fundamental items every DIY enthusiast should possess. These come in various sizes and types, including adjustable and socket wrenches, enabling you to handle a wide range of fasteners with ease.

Screwdrivers are another essential addition, available in both flathead and Phillips varieties. A quality set will allow you to tackle screws of different shapes and sizes, which are common in various assemblies.

Pliers are invaluable for gripping, twisting, and cutting tasks. With options like needle-nose and slip-joint pliers, they provide versatility for various applications.

Safety Gear should never be overlooked. Basic protective equipment, including gloves and goggles, is vital for ensuring personal safety while performing hands-on tasks.

Finally, a reliable toolbox is essential for organizing and storing your equipment. Keeping tools neatly arranged not only saves time but also helps prevent damage or loss.

Preventive Maintenance Practices

Implementing regular upkeep routines is essential for enhancing the longevity and efficiency of your equipment. These practices not only prevent unexpected breakdowns but also ensure that the machinery operates at peak performance. Consistent attention to maintenance tasks can lead to significant savings in both time and costs associated with repairs.

Key Maintenance Activities

- Regularly inspect and clean air filters to maintain optimal airflow.

- Check fluid levels, including oil, coolant, and fuel, ensuring they are within recommended ranges.

- Examine belts and hoses for signs of wear or damage, replacing them as necessary.

- Sharpen blades and tools to improve cutting efficiency and reduce strain on the engine.

Seasonal Maintenance Checklist

- Spring:

- Inspect tires for proper inflation and tread wear.

- Replace any worn or damaged parts before heavy use.

- Summer:

- Monitor coolant levels to prevent overheating during extended use.

- Clean debris from undercarriage and engine compartments to avoid overheating.

- Fall:

- Prepare equipment for winter storage by cleaning and lubricating parts.

- Perform a thorough inspection to identify potential issues before inactivity.

- Winter:

- Check battery condition and keep it charged during cold months.

- Cover machinery to protect it from snow and ice accumulation.

Identifying and Fixing Fluid Leaks

Detecting and addressing fluid leaks is essential for maintaining optimal performance and longevity of equipment. These issues can lead to serious complications if left unresolved, affecting both functionality and safety. By learning to recognize the signs of leaks and implementing effective solutions, operators can ensure their machinery runs smoothly and efficiently.

Common Signs of Fluid Leaks

Fluid leaks often manifest through visible puddles or spots beneath the machinery. Additionally, changes in fluid levels in reservoirs or tanks can indicate a problem. Unusual smells, sounds, or performance issues may also signal a potential leak. Regular inspections and awareness of these indicators are crucial for early detection.

Steps to Fix Fluid Leaks

Once a leak is identified, the next step involves pinpointing its source. Inspect hoses, seals, and connections for wear or damage. Tightening loose fittings can sometimes resolve minor leaks. If the issue persists, replacing damaged components may be necessary. After repairs, always monitor the area for any recurring leaks to ensure the problem is fully addressed.

Winterizing and Seasonal Adjustments

Preparing your equipment for winter conditions and making necessary seasonal adjustments is essential for optimal performance and longevity. This process involves various steps that ensure all components function effectively, preventing potential issues when temperatures drop. Proper care during this transitional period helps maintain the efficiency and reliability of your machine.

During winterization, several key areas require attention. Regular maintenance checks should be conducted, including fluid levels, battery condition, and overall cleanliness. Additionally, adjusting settings to accommodate colder weather will enhance performance and ensure a smooth operation when needed.

| Task | Details | Frequency |

|---|---|---|

| Check Engine Oil | Inspect and replace oil with winter-grade if necessary. | Every season |

| Inspect Battery | Ensure connections are clean and secure; consider using a trickle charger. | Monthly |

| Fuel Stabilization | Add fuel stabilizer to prevent degradation during storage. | Before winter storage |

| Clean Air Filter | Remove debris and check for wear to ensure optimal airflow. | Every season |

| Tire Pressure | Adjust tire pressure to recommended levels for better traction. | Monthly |