For anyone who relies on agricultural machinery, having access to comprehensive resources for upkeep and troubleshooting is essential. These documents serve as invaluable tools, providing step-by-step instructions that help users navigate the complexities of their machinery. Whether you’re a seasoned farmer or a newcomer to the field, understanding how to maintain and repair your equipment can significantly enhance its longevity and performance.

These resources encompass a wide array of topics, including operational guidelines, detailed schematics, and diagnostic procedures. With clear illustrations and precise explanations, they empower users to tackle common issues and perform routine maintenance tasks with confidence. Mastering this knowledge not only ensures optimal functionality but also contributes to a safer working environment.

As the agricultural industry evolves, so does the need for effective maintenance strategies. Access to these instructional materials allows operators to adapt to new technologies and practices. By investing time in learning about their equipment through these guides, users can reduce downtime and improve productivity in their operations.

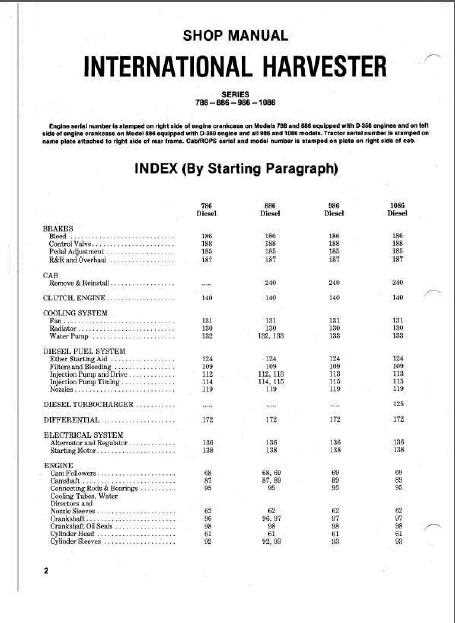

Understanding International Harvester Models

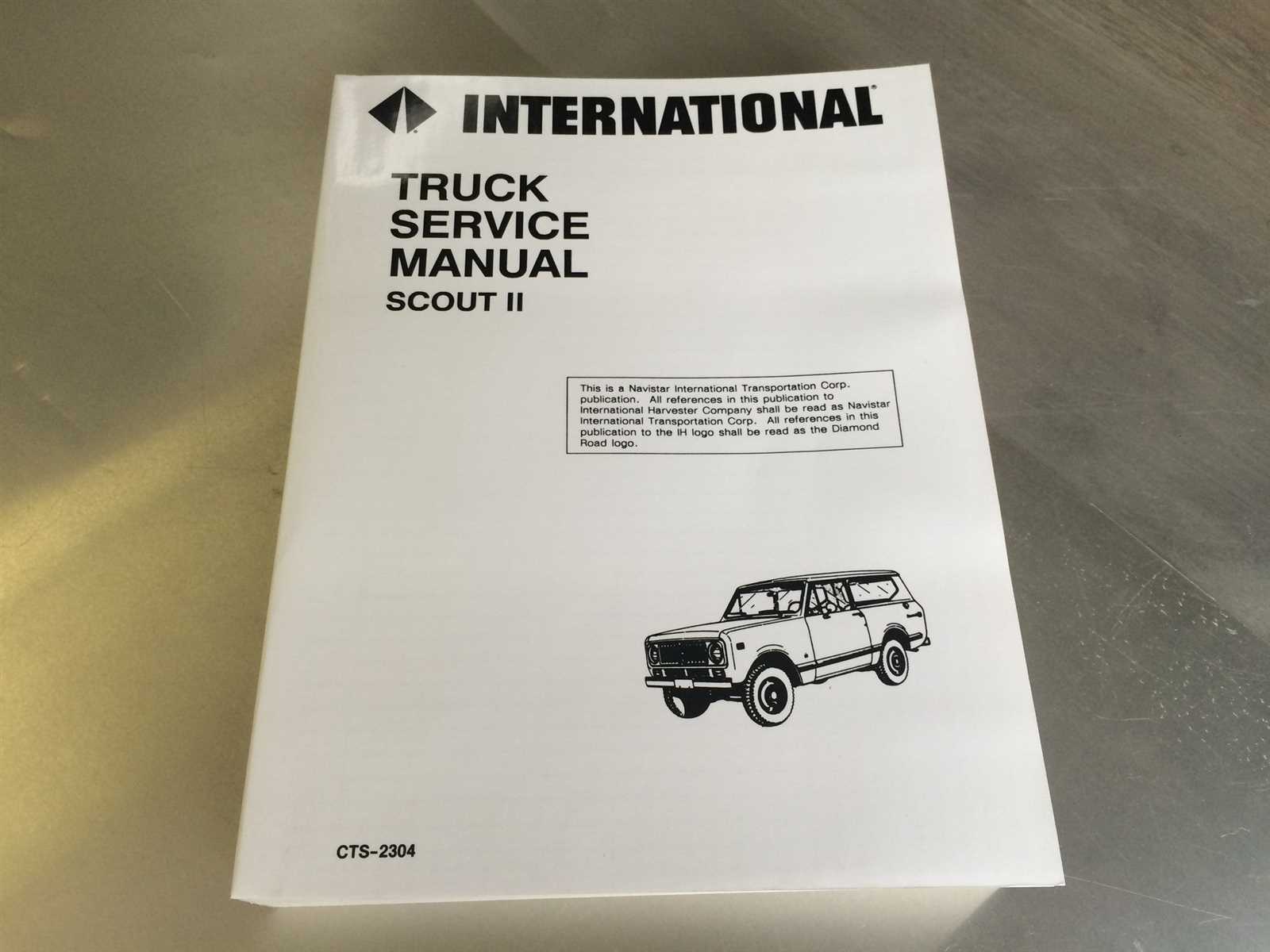

Comprehending the various models produced by a notable agricultural machinery manufacturer involves recognizing the distinct characteristics and specifications that differentiate each unit. Each design serves specific functions and caters to diverse needs within the farming community. This section delves into the classifications and unique attributes of these machines, providing insights into their operational efficiency and applications.

Categories of Machinery

The product line can be categorized into several groups, each tailored for particular tasks in the field. Below is a summary of the main categories and their primary purposes:

| Category | Description |

|---|---|

| Tractors | Heavy-duty vehicles designed for pulling and powering various implements. |

| Harvesting Equipment | Machines specifically built for efficiently gathering crops at harvest time. |

| Tillage Tools | Implementations used to prepare the soil for planting by turning and aerating it. |

| Planting Equipment | Devices aimed at accurately placing seeds in the soil for optimal growth. |

Model Identification

Identifying the specific model of machinery is crucial for maintenance and performance optimization. Each model features a unique identification number and specifications that reflect its capabilities. Understanding these details aids users in selecting the right equipment for their specific agricultural needs.

Importance of Repair Manuals

Understanding the significance of comprehensive documentation is crucial for maintaining machinery and equipment. Such guides serve as essential resources that aid users in troubleshooting, servicing, and optimizing performance, ultimately ensuring longevity and efficiency.

Benefits of Using Documentation

- Guided Troubleshooting: Step-by-step instructions enable users to identify and resolve issues effectively.

- Time Efficiency: Accessing relevant information quickly reduces downtime during maintenance.

- Enhanced Safety: Proper guidelines help prevent accidents and injuries by promoting safe practices.

- Cost-Effective Repairs: Users can often perform maintenance tasks themselves, saving on professional service fees.

Key Features to Look For

- Illustrations and Diagrams: Visual aids assist in understanding complex components.

- Maintenance Schedules: Regular upkeep recommendations ensure optimal performance.

- Parts Lists: Detailed inventories make sourcing replacements easier.

- Common Issues and Solutions: Highlighting frequent problems allows for quicker resolutions.

Common Issues in International Harvester Equipment

Understanding the frequent challenges faced by agricultural machinery is crucial for maintaining optimal performance. Various mechanical and operational issues can arise, affecting efficiency and productivity. Recognizing these problems early on can lead to effective solutions and prolong the life of the equipment.

Engine Performance Problems

One of the most prevalent concerns involves the engine, where issues such as poor fuel efficiency, starting difficulties, or abnormal noises may occur. These symptoms often stem from fuel system blockages, worn components, or ignition failures. Regular inspections and timely maintenance can mitigate these risks.

Hydraulic System Failures

Another common area of concern is the hydraulic system, which plays a vital role in the functionality of various attachments. Leaks, inadequate pressure, and unresponsive controls can hinder performance significantly. Regular checks for fluid levels and inspecting seals and hoses can help identify problems before they escalate.

How to Locate Repair Manuals

Finding the right documentation for maintenance and troubleshooting can significantly enhance your efficiency and understanding. Whether you’re a seasoned technician or a dedicated enthusiast, knowing where to search for this essential information is crucial.

Here are several effective strategies to help you uncover the needed resources:

- Online Platforms: Numerous websites specialize in offering comprehensive guides and resources. Use search engines with specific terms related to your needs.

- Manufacturer Websites: Check the official sites of the brands you are interested in. They often provide digital copies or purchasing options for their documents.

- Forums and Communities: Join relevant online groups or discussion boards. Members frequently share links, recommendations, and even personal copies of useful documents.

Additionally, consider the following methods:

- Local Libraries: Many libraries maintain a collection of technical documents and resources that may be available for public access.

- Second-Hand Stores: Thrift shops and online marketplaces often have physical copies that can be purchased at a low cost.

- Networking with Professionals: Connecting with local mechanics or technicians can provide insights into where they source their materials.

By utilizing these avenues, you can enhance your ability to find valuable documentation for any maintenance or troubleshooting task.

Step-by-Step Repair Processes

Understanding the process of fixing machinery is essential for maintaining optimal performance and longevity. This section outlines a clear, sequential approach to troubleshooting and addressing common issues, ensuring that users can confidently tackle repairs on their equipment.

1. Diagnosis: Begin by identifying the symptoms. Observe any unusual sounds, leaks, or performance drops. Take detailed notes to guide your troubleshooting.

2. Preparation: Gather all necessary tools and replacement parts. Ensuring you have everything on hand will streamline the workflow and minimize downtime.

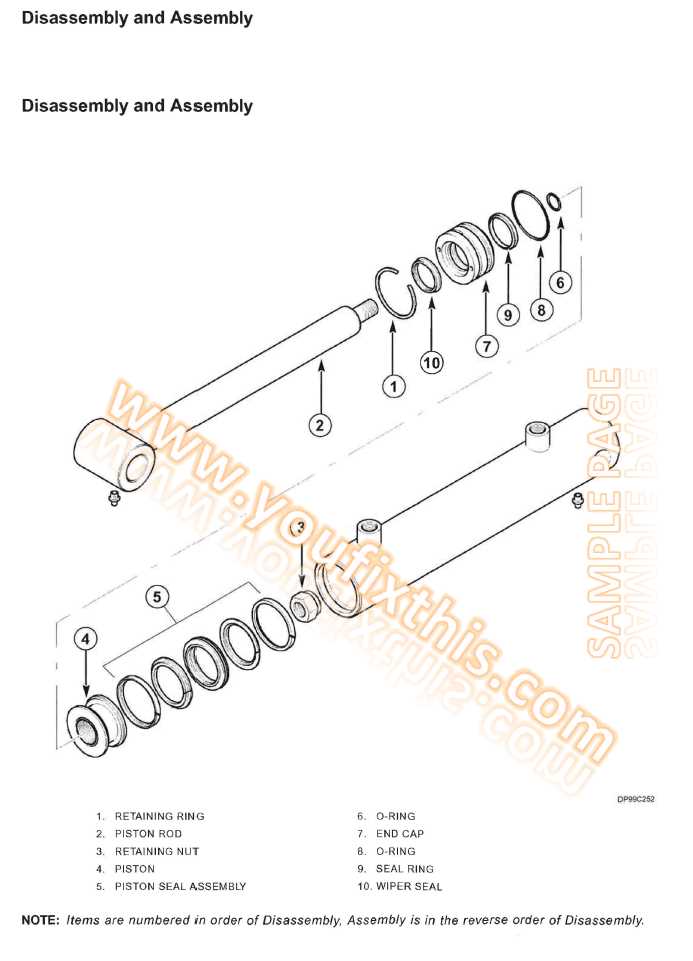

3. Disassembly: Carefully take apart the affected components. Follow a systematic order to avoid losing parts or causing damage. Document each step with photographs or notes.

4. Inspection: Examine each component for wear, damage, or blockage. Look for cracks, corrosion, or any signs of failure. This step is crucial for determining what needs to be replaced or repaired.

5. Replacement: Swap out any faulty parts with new or refurbished ones. Ensure that each piece is compatible with your specific model to avoid future issues.

6. Reassembly: Reconstruct the machinery in the reverse order of disassembly. Double-check all connections and fasteners to ensure everything is secure and correctly positioned.

7. Testing: Once reassembled, run the equipment to confirm that the issue has been resolved. Monitor performance closely to ensure stability and efficiency.

8. Documentation: Keep detailed records of the repair process, including parts used and any observations. This information will be valuable for future maintenance and repairs.

By following these steps, users can effectively address issues and maintain their equipment in peak condition, ensuring reliability and efficiency for years to come.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and restoration tasks. A well-equipped workspace not only enhances efficiency but also ensures safety while addressing various challenges. Familiarizing yourself with indispensable instruments can significantly streamline the process and yield satisfactory results.

Basic Hand Tools: A collection of hand tools forms the foundation of any toolkit. Items such as wrenches, screwdrivers, and pliers are essential for various fastening and adjustment tasks. Investing in high-quality options can make a notable difference in performance and longevity.

Power Tools: For larger jobs, power tools can provide the extra muscle needed to tackle stubborn components. Drills, saws, and grinders offer speed and precision, significantly reducing manual effort. It’s important to select tools that match the specific requirements of your project.

Measuring Instruments: Accurate measurements are vital for successful outcomes. Tools like tape measures, calipers, and levels help ensure that everything fits and aligns properly. Always double-check measurements to avoid costly mistakes.

Safety Gear: Protecting yourself should be a top priority. Appropriate safety equipment, including goggles, gloves, and masks, is essential to safeguard against potential hazards. Never compromise on safety while working.

Storage Solutions: Keeping your tools organized can save time and frustration. Toolboxes, pegboards, and drawer organizers help maintain order and make it easier to find what you need when you need it. A tidy workspace can enhance productivity.

By equipping yourself with these fundamental tools and ensuring proper organization, you’ll be well-prepared to tackle any maintenance task with confidence and ease.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires consistent attention and care. By implementing regular upkeep practices, you can enhance performance and extend the lifespan of your machinery. Below are essential strategies to help you maintain optimal functionality over time.

Regular Inspections

Conducting frequent evaluations is crucial for identifying potential issues early. Here are key areas to focus on:

- Check fluid levels and top up as necessary.

- Inspect belts and hoses for wear and tear.

- Look for signs of leaks around critical components.

- Examine tires for proper inflation and tread wear.

Proper Cleaning and Storage

Maintaining cleanliness and appropriate storage conditions can significantly impact the longevity of your machinery. Consider these tips:

- Wash your equipment regularly to remove dirt and debris.

- Store in a sheltered area to protect from harsh weather.

- Use covers when not in use to prevent dust accumulation.

- Ensure all moving parts are lubricated to reduce friction.

DIY vs. Professional Repairs

When faced with equipment issues, individuals often grapple with the choice between tackling the problem themselves or seeking expert assistance. Each approach has its own set of advantages and challenges that can influence the outcome and overall satisfaction.

Advantages of DIY Approaches

- Cost savings by eliminating labor fees.

- Flexibility in scheduling repairs at your convenience.

- Opportunity to gain hands-on experience and knowledge.

Benefits of Professional Assistance

- Expertise and specialized tools that ensure quality work.

- Time efficiency, as professionals can often complete tasks more quickly.

- Warranty protections and guarantees on their work.

Ultimately, the decision between self-service and hiring a pro should consider factors like complexity, personal skill level, and available resources.

Finding Replacement Parts

Locating suitable components for agricultural machinery can be a challenging task. Understanding where to search and what resources are available can make this process significantly easier. By utilizing various channels, you can ensure that you find the exact parts needed to keep your equipment running smoothly.

Online Retailers are among the most convenient options for sourcing replacement components. Numerous websites specialize in providing a wide range of items, often including detailed specifications and compatibility information. This can help streamline your search and save valuable time.

Local Dealerships can also be a valuable resource. Many dealers maintain extensive inventories and have knowledgeable staff who can assist in identifying the correct parts. Building a relationship with a local dealer can often lead to better service and more reliable access to essential components.

Salvage Yards offer another avenue for finding hard-to-get parts. These facilities often have a variety of machinery, and you may be able to salvage the exact components you need at a fraction of the cost. However, this approach requires some expertise to ensure the quality of the parts obtained.

Community Forums and online groups can provide insights and recommendations from other equipment owners. Engaging with these communities can lead to valuable tips on where to find parts and which suppliers are trustworthy. Moreover, sharing your own experiences can contribute to a collective knowledge base that benefits everyone.

By exploring these avenues, you can enhance your chances of finding the necessary components to maintain your machinery efficiently.

Safety Precautions During Repairs

Ensuring a secure environment while conducting maintenance work is crucial for both the individual and the equipment involved. Proper precautions can significantly reduce the risk of accidents, injuries, and damage to machinery. Adopting a methodical approach to safety enhances efficiency and promotes a culture of awareness in the workspace.

Personal Protective Equipment

Wearing appropriate personal protective gear is essential when engaging in maintenance tasks. This includes items such as gloves, goggles, and steel-toed boots, which serve to protect against potential hazards. Ensuring that all equipment fits well and is in good condition can further mitigate risks associated with unexpected incidents.

Workspace Organization

A well-organized workspace contributes to safety during maintenance activities. Keeping tools and materials in designated areas helps prevent trips and falls. Additionally, ensuring that the area is well-lit and free of clutter minimizes the chances of accidents. Regularly inspecting the workspace for hazards, such as leaks or unstable surfaces, is a vital practice for maintaining a secure environment.

Utilizing Online Resources Effectively

In today’s digital age, leveraging web-based tools can significantly enhance your knowledge and skills in various technical areas. The abundance of information available online allows users to find solutions, guidance, and support for their projects. However, knowing how to navigate and utilize these resources is crucial for maximizing their benefits.

Here are some effective strategies for making the most of online resources:

- Identify Reliable Sources: Seek websites, forums, and databases known for their credibility. Look for user reviews and recommendations to gauge the reliability of the information.

- Utilize Search Engines Wisely: Use specific keywords related to your topic. Incorporate terms that describe your needs to filter results more effectively.

- Join Online Communities: Participate in forums or social media groups where enthusiasts and professionals share insights. Engaging with others can provide valuable support and answers to your queries.

- Explore Video Tutorials: Visual content can simplify complex concepts. Platforms like YouTube offer numerous instructional videos that can enhance your understanding.

- Bookmark Useful Pages: Keep a record of valuable sites for future reference. Organizing your bookmarks can save time when revisiting important information.

By applying these techniques, you can effectively harness the power of online resources to expand your skills and troubleshoot various challenges in your projects.