Maintaining outdoor cleaning equipment can often feel daunting, especially when issues arise unexpectedly. Understanding the common challenges and solutions related to these devices is essential for ensuring their longevity and optimal performance. This section aims to provide insightful guidance to help users navigate the complexities of restoring functionality to their machines.

Regular upkeep not only enhances the efficiency of your equipment but also prolongs its lifespan. Familiarizing yourself with potential problems and their remedies can save both time and resources. From minor adjustments to more intricate fixes, having a solid foundation of knowledge is key to successful management.

As you delve into the specifics of troubleshooting and maintenance, you will discover valuable techniques and tips that empower you to handle various situations with confidence. Whether you’re dealing with a stubborn motor or a lack of pressure, understanding the mechanics behind the device will make the process much smoother.

Understanding Husky Pressure Washers

This section aims to provide a comprehensive overview of high-performance cleaning equipment designed for various tasks. These machines are known for their efficiency and versatility, making them suitable for both residential and commercial applications. Familiarity with their components and functionalities can enhance the user experience and improve maintenance practices.

Key Features and Benefits

These cleaning devices are equipped with powerful motors that deliver impressive water flow rates and pressure levels. This results in effective removal of dirt, grime, and stains from different surfaces. Users benefit from adjustable settings, allowing for tailored cleaning experiences based on the material being treated. Additionally, their portability makes them easy to maneuver, providing convenience for both small and large jobs.

Common Uses

The applications of this equipment range from simple household tasks, such as cleaning patios and driveways, to more demanding projects like preparing surfaces for painting. The ability to tackle tough cleaning challenges is a significant advantage, saving time and effort while delivering professional-grade results. Understanding the various uses can help users maximize the potential of these machines.

Common Issues with Pressure Washers

When operating outdoor cleaning equipment, various challenges may arise that can hinder performance and efficiency. Understanding these common complications can aid users in troubleshooting and maintaining their machines effectively.

1. Low Output Force: A frequent concern is the decrease in cleaning power. This can stem from clogged nozzles or filters, as well as issues with the water supply. Regular checks and maintenance of these components can help restore optimal functionality.

2. Leaking Hoses: Another prevalent issue involves leaks in hoses or connections. These leaks can lead to diminished pressure and wasted water. Inspecting hoses for wear and tear, and ensuring secure connections can mitigate this problem.

3. Engine Difficulties: Users may experience trouble starting the engine or may notice unusual noises during operation. This could indicate fuel issues, such as stale gas or blockages in the fuel line. Ensuring fresh fuel and routine checks of the engine components can resolve these concerns.

4. Unresponsive Trigger: Sometimes, the trigger may become unresponsive or sticky, affecting the user’s ability to control the flow. This issue might be caused by dirt accumulation or a malfunctioning mechanism. Cleaning the trigger assembly and inspecting for damage are essential steps for resolution.

5. Overheating: Equipment may overheat, especially during extended use. This can be due to a lack of water supply or blocked vents. Allowing the machine to cool and checking water flow can prevent further damage.

By familiarizing yourself with these common issues, you can enhance the longevity and effectiveness of your cleaning device, ensuring it performs at its best when needed most.

Tools Needed for Repairs

When tackling maintenance tasks on equipment, having the right instruments at your disposal is essential for efficiency and effectiveness. A well-equipped toolkit not only facilitates smooth procedures but also ensures that every component is handled with care, ultimately prolonging the lifespan of your device.

Essential Instruments

To begin, a set of screwdrivers in various sizes is crucial for loosening and tightening fasteners. A wrench set is equally important, as it provides the necessary leverage for bolts that may be stubborn. Additionally, a reliable socket set can simplify tasks requiring different sizes and types of nuts and screws.

Safety Gear

Before initiating any work, it is vital to prioritize safety. Ensure you have a pair of protective gloves to shield your hands from sharp edges and debris. Furthermore, safety goggles are essential to protect your eyes from flying particles, while ear protection may be necessary if working with loud machinery.

Step-by-Step Troubleshooting Guide

This guide aims to assist users in identifying and resolving common issues that may arise with their equipment. By following a systematic approach, you can efficiently diagnose problems and apply appropriate solutions.

Identifying Common Issues

- Loss of power or failure to start

- Inconsistent performance or pressure

- Unusual noises during operation

- Leaks or drips from connections

Troubleshooting Steps

- Check Power Supply:

- Ensure the device is plugged in securely.

- Inspect the outlet for functionality.

- Test with a different power source if necessary.

- Inspect Hoses and Connections:

- Examine all hoses for kinks or blockages.

- Verify that connections are tight and free of leaks.

- Examine Filters:

- Remove and clean any filters that may be clogged.

- Replace filters if they are damaged.

- Check for Air Leaks:

- Inspect seals and gaskets for wear and tear.

- Replace any damaged components as needed.

By methodically working through these steps, users can effectively pinpoint issues and take corrective action to restore optimal functionality.

How to Replace a Hose

Replacing a flexible tube can be a straightforward task that enhances the functionality of your equipment. Understanding the right steps and having the appropriate tools on hand can make the process seamless and efficient.

Step 1: Gather Your Tools

Step 2: Disconnect the Old Tube

Begin by turning off the power source and releasing any built-up pressure. Carefully detach the old tube from the connection points. If it’s stuck, gently wiggle it while applying a bit of force, taking care not to damage surrounding components.

Step 3: Prepare the New Tube

Inspect the new tube for any defects before installation. Ensure it matches the length and diameter specifications needed for your equipment. This step is crucial for optimal performance.

Step 4: Install the New Tube

Attach the new tube to the designated connectors, ensuring a snug fit. Use pliers or a wrench to secure any clamps or fittings, but be cautious not to overtighten, as this can lead to damage.

Step 5: Test the Connection

After installation, restore the power and conduct a test run. Check for any leaks or irregularities. If everything functions properly, you have successfully completed the replacement.

Following these steps will ensure your equipment remains in top condition, ready for any task at hand.

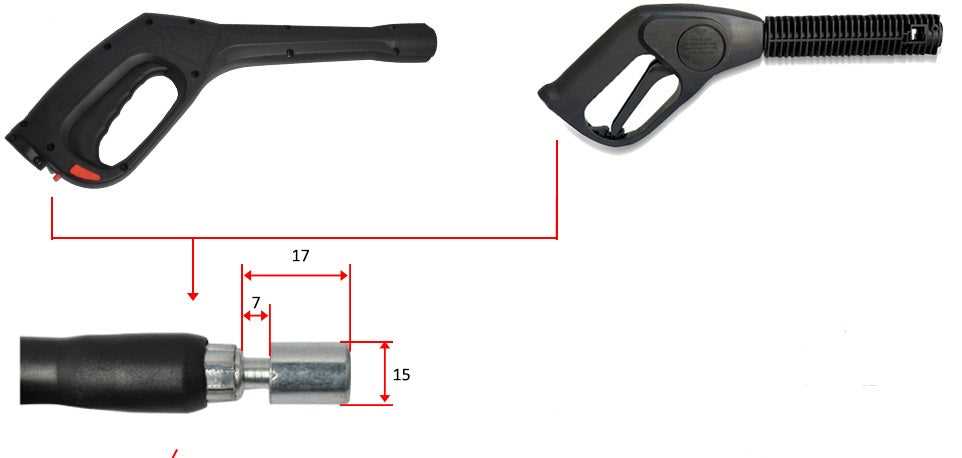

Fixing the Spray Gun Problems

When dealing with issues related to the spraying tool, it’s essential to identify and address common malfunctions. Various factors can contribute to poor performance, affecting the efficiency and quality of the task at hand. This section provides guidance on troubleshooting and resolving typical difficulties.

- Low Pressure:

- Check for any blockages in the nozzle or hose.

- Ensure that connections are tight and free from leaks.

- Inspect the water supply for sufficient flow.

- Inconsistent Spray Pattern:

- Examine the nozzle for wear or damage.

- Clean the spray tip to remove any debris.

- Adjust the settings to match the desired spray type.

- Handle Leaks:

- Tighten any loose fittings.

- Replace worn or damaged seals and O-rings.

- Test the trigger mechanism for proper function.

- Trigger Issues:

- Inspect the trigger for any obstructions.

- Lubricate moving parts to ensure smooth operation.

- Check the internal components for wear and replace if necessary.

By following these steps, users can effectively troubleshoot and enhance the performance of their spraying equipment, ensuring optimal results for various cleaning tasks.

Engine Maintenance Tips

Regular upkeep of your motor is essential for optimal performance and longevity. Proper maintenance helps prevent issues and ensures that your equipment runs smoothly. Here are some key strategies to keep in mind.

- Check the Oil Level: Regularly inspect the oil level and quality. Replace it according to the manufacturer’s recommendations to ensure efficient lubrication.

- Air Filter Maintenance: Clean or replace the air filter to prevent debris from entering the engine. A clean filter promotes better airflow and enhances performance.

- Inspect Fuel System: Examine fuel lines and connections for leaks. Replace old fuel with fresh gasoline to avoid clogging and starting issues.

In addition to these basic checks, consider the following maintenance practices:

- Spark Plug Care: Inspect and replace spark plugs as needed. Clean them to improve ignition efficiency and overall engine responsiveness.

- Regular Cleaning: Keep the engine exterior clean from dirt and debris to prevent overheating and ensure proper cooling.

- Seasonal Storage: Prepare the engine for storage during off-seasons by draining fuel and checking for corrosion.

Implementing these tips will help maintain the reliability and efficiency of your motor, extending its operational life and performance capabilities.

Cleaning the Filters Effectively

Regular maintenance of filtration systems is crucial for optimal performance. Ensuring these components are clean not only enhances efficiency but also prolongs the lifespan of the entire unit. This section outlines effective techniques for keeping filters in top condition.

Importance of Filter Maintenance

Filters play a vital role in maintaining the quality of operation. Here are some key reasons for their upkeep:

- Prevents debris buildup

- Enhances airflow and performance

- Reduces wear on internal components

- Improves safety and reliability

Steps for Effective Cleaning

Follow these steps to ensure your filtration systems are properly maintained:

- Turn off the machine and disconnect it from the power source.

- Remove the filters carefully, taking note of their orientation.

- Use a soft brush or cloth to remove loose dirt and debris.

- Rinse the filters under warm water to eliminate stubborn residues.

- Allow the filters to dry completely before reinstallation.

- Reattach the filters, ensuring they are seated correctly.

By adhering to these guidelines, you can ensure that your filtration systems remain clean and efficient, contributing to the overall performance of your equipment.

Identifying Electrical Issues

Understanding the potential electrical challenges is crucial for maintaining equipment functionality. Many problems can arise due to faulty connections, damaged components, or wear over time. Recognizing these issues early can prevent further damage and ensure optimal performance.

Start by inspecting the power source and cord for any visible signs of wear or damage. A frayed cord or loose connection can lead to insufficient power delivery. Next, check the switches and controls for any malfunctioning parts. If buttons feel unresponsive or exhibit erratic behavior, they may require further examination or replacement.

Multimeters can be invaluable tools for diagnosing electrical problems. Use one to measure voltage at various points within the system. If readings are inconsistent or absent where they should be present, it may indicate a deeper issue. Additionally, pay attention to any unusual sounds or smells during operation, as these can be indicative of electrical failures.

Lastly, reviewing the user guidelines specific to your equipment can provide insights into common electrical issues and troubleshooting steps. Being proactive in identifying these challenges can enhance the longevity and efficiency of your tools.

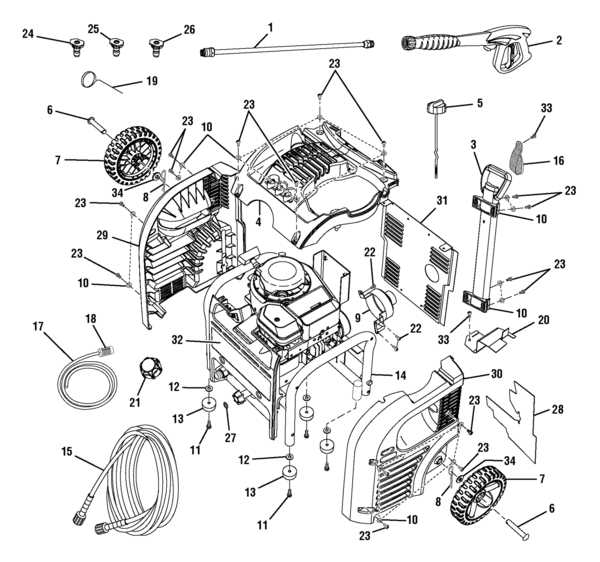

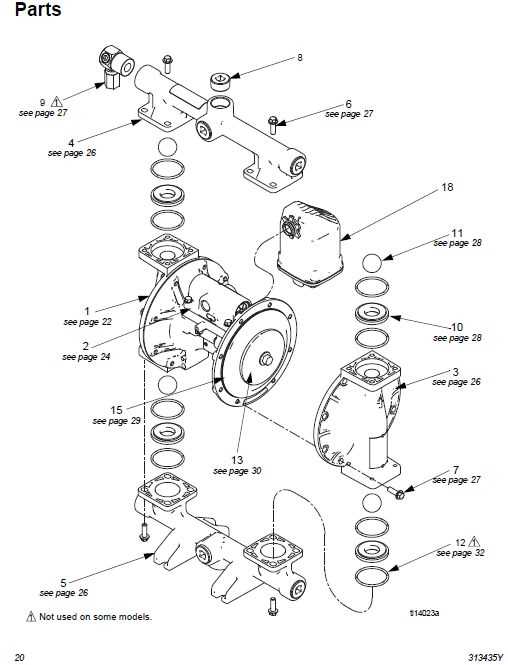

Reassembling Your Pressure Washer

When putting your cleaning equipment back together, it’s essential to follow a systematic approach to ensure all components fit securely and function optimally. This process not only enhances performance but also extends the lifespan of your device.

Begin by organizing all the parts and tools you will need. Having everything at hand will streamline the assembly and reduce the risk of missing any vital components.

| Step | Action | Notes |

|---|---|---|

| 1 | Inspect each component | Check for wear and tear before reassembly. |

| 2 | Start with the base unit | Ensure all seals and gaskets are properly positioned. |

| 3 | Attach the motor | Align it carefully to avoid misalignment. |

| 4 | Secure the hose connections | Ensure they are tight to prevent leaks. |

| 5 | Reattach any additional components | Double-check all screws and fasteners. |

| 6 | Conduct a final inspection | Make sure everything is in place before testing. |

By adhering to these steps, you will effectively restore your device to working condition, ready for efficient operation when needed.

Preventive Measures for Longevity

Maintaining the optimal performance of your cleaning equipment requires proactive care and attention. By implementing specific strategies, you can extend the lifespan and efficiency of your device, ensuring it remains in excellent condition for years to come.

- Regular Inspections: Routinely check for wear and tear on components, such as hoses and nozzles, to catch issues early.

- Clean After Use: Remove debris and buildup to prevent clogging and damage to internal parts.

- Proper Storage: Keep the equipment in a dry, sheltered area to avoid exposure to harsh weather conditions.

Adopting these habits can significantly enhance the durability and reliability of your machine.

- Check Oil Levels: Ensure lubrication is adequate to avoid friction-related problems.

- Use Quality Supplies: Utilize recommended detergents and accessories to maintain performance standards.

- Follow Manufacturer Guidelines: Adhere to the instructions provided for maintenance to optimize functionality.

By prioritizing these preventive measures, you will not only improve the performance of your equipment but also save on future repair costs.

When to Seek Professional Help

Understanding when to call in an expert can save time, money, and frustration. While many issues can be handled by the owner, certain situations require specialized knowledge and skills to ensure proper resolution.

Consider reaching out to a professional if you encounter any of the following:

- Persistent Malfunctions: If the device continues to malfunction despite following troubleshooting steps.

- Unusual Noises: Any strange sounds that weren’t present during normal operation may indicate a serious problem.

- Fluid Leaks: Visible leaks can signal a critical failure that could worsen without expert intervention.

- Electrical Issues: Any problems involving wiring or electrical components should be handled by a qualified technician.

- Performance Decline: A significant drop in efficiency, such as inadequate output or pressure, often requires a professional assessment.

In addition to these scenarios, if you lack the necessary tools or experience to perform maintenance safely, it’s wise to consult an expert. This not only ensures a thorough job but also extends the lifespan of your equipment.