The effective upkeep of a high-performance chainsaw is essential for ensuring its longevity and optimal functioning. Understanding the intricacies of the machinery allows users to address common issues and perform routine checks, thus enhancing the tool’s reliability during operation. Proper knowledge of maintenance procedures not only extends the lifespan of the equipment but also contributes to user safety and efficiency.

In this section, we delve into comprehensive guidance on the essential practices for maintaining the 61 model. With clear instructions and insights into troubleshooting, users can gain the confidence needed to handle various scenarios, from minor adjustments to more complex tasks. The information provided aims to empower users with the skills necessary to keep their equipment in peak condition.

By familiarizing yourself with the inner workings and upkeep of the chainsaw, you can avoid common pitfalls and maximize your investment. Emphasis is placed on practical tips and detailed descriptions that facilitate understanding, ensuring that both novices and experienced users can navigate through the maintenance process with ease. This guide serves as a valuable resource, equipping you with the tools to maintain functionality and performance effectively.

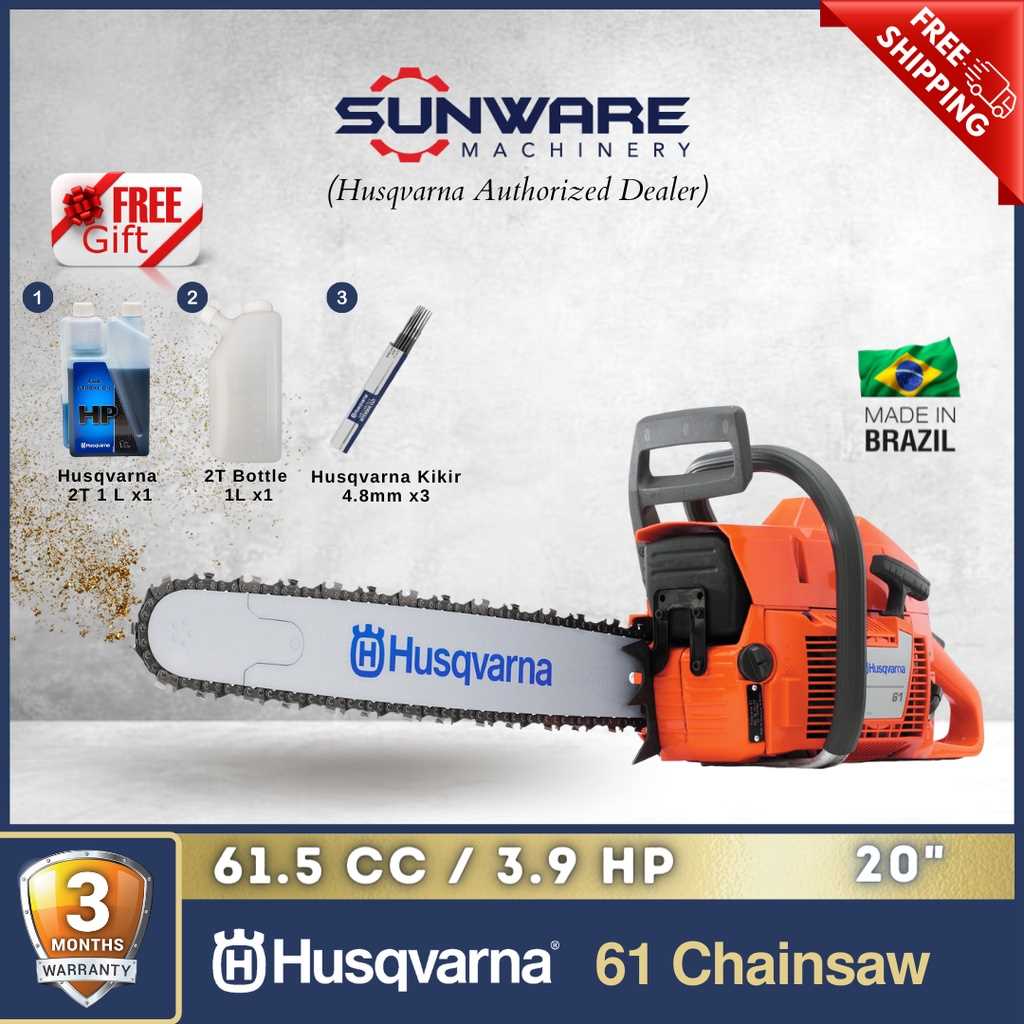

Husqvarna 61 Overview

The model in question is renowned for its reliability and performance in various outdoor tasks. Designed with a focus on durability and ease of use, this equipment is a favorite among both professionals and enthusiasts alike.

Featuring a robust engine, it offers impressive power that enables users to tackle a wide range of activities, from cutting and trimming to heavier workloads. The lightweight construction enhances maneuverability, allowing for extended use without causing excessive fatigue.

In addition, the ergonomic design ensures comfort during operation, making it accessible for users of all experience levels. Its straightforward maintenance requirements contribute to its longevity, ensuring that the device remains in peak condition for years.

Overall, this model represents an excellent choice for anyone seeking a versatile and dependable tool for outdoor projects.

Common Issues and Solutions

When operating a chainsaw, users may encounter a variety of problems that can hinder performance and efficiency. Understanding these common difficulties and their respective resolutions can help ensure optimal functionality and extend the lifespan of the equipment. Below are some frequent issues and their solutions.

Starting Difficulties

One of the most prevalent problems is difficulty starting the engine. This can be caused by several factors, including fuel issues, spark plug malfunctions, or a clogged air filter. To address this, check the fuel to ensure it is fresh and properly mixed, inspect the spark plug for wear or damage, and clean or replace the air filter as needed. Regular maintenance of these components can prevent starting issues from arising.

Poor Cutting Performance

Another common concern is insufficient cutting power, which can be attributed to a dull chain, incorrect tension, or an obstructed guide bar. To resolve this, sharpen the chain to ensure effective cutting, adjust the tension according to the manufacturer’s specifications, and clean the guide bar to remove any debris. By maintaining these elements, users can enhance cutting performance and improve overall efficiency.

Tools Needed for Repairs

When tackling maintenance tasks on outdoor power equipment, having the right set of tools is essential for effective and efficient work. This section outlines the necessary instruments that will facilitate the process and ensure optimal performance.

- Wrenches: A variety of sizes is required to handle different nuts and bolts.

- Screwdrivers: Both flathead and Phillips screwdrivers will be needed for various screws.

- Pliers: Useful for gripping, twisting, and cutting wires or components.

- Socket Set: A complete socket set will allow for quick removal and installation of fasteners.

- Fuel Mix Container: For preparing the appropriate fuel mixture for two-stroke engines.

- Safety Gear: Goggles, gloves, and ear protection should always be worn to ensure safety while working.

In addition to these tools, having a workbench and adequate lighting will help create an efficient workspace. Keeping everything organized will make the entire process smoother and more enjoyable.

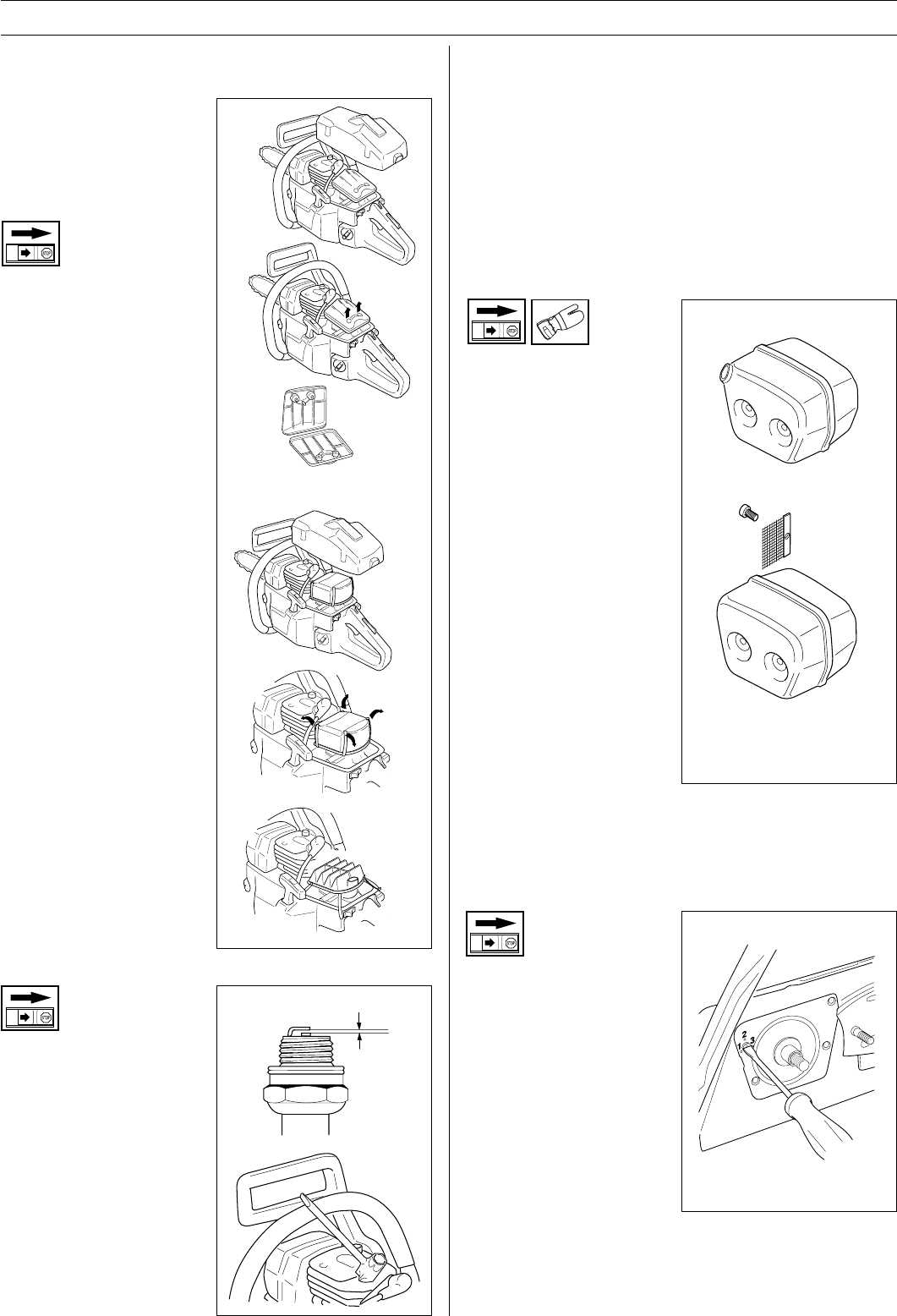

Step-by-Step Repair Instructions

This section outlines a comprehensive approach to restoring functionality to your chainsaw. By following these sequential guidelines, you can address common issues and ensure optimal performance. Each step is designed to be clear and straightforward, allowing even those with minimal experience to successfully navigate the process.

Preparation

- Gather all necessary tools: screwdriver, wrench, and cleaning materials.

- Ensure the workspace is clean and well-lit to facilitate effective handling.

- Review the specifications of your model to understand its components.

Disassembly Process

- Begin by disconnecting the spark plug to prevent accidental starts.

- Remove the housing cover by unscrewing the fasteners.

- Carefully detach the air filter for cleaning or replacement.

- Inspect the fuel lines and carburetor for any blockages or wear.

- Take out the chain and bar for maintenance, checking for damage or tension issues.

By adhering to these structured steps, you can systematically address the necessary adjustments and ensure your chainsaw operates effectively.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of your outdoor equipment. By following a few key practices, you can enhance performance and reduce the risk of malfunctions. Consistent attention to maintenance tasks not only preserves functionality but also contributes to safety and efficiency during operation.

Regularly inspecting and cleaning your tools is crucial. Remove any debris, dirt, or buildup from components, particularly after each use. This helps prevent wear and tear and maintains optimal performance levels. Additionally, pay close attention to the air filter and fuel lines, ensuring they are clear and functioning correctly.

Frequent lubrication of moving parts is another important aspect of maintenance. Use the appropriate lubricants as specified in the product guidelines to minimize friction and prevent damage. This will not only prolong the life of the equipment but also improve its overall efficiency.

Lastly, always store your equipment in a dry, sheltered place when not in use. Protecting it from harsh weather conditions and temperature fluctuations can significantly reduce deterioration. Following these straightforward practices will lead to a more reliable and durable machine.

Parts Replacement Guide

This section provides essential information for replacing components in your equipment effectively. Understanding the right procedures and tools needed for each part will ensure optimal performance and longevity. Regular maintenance and timely replacements can prevent major issues and enhance the overall efficiency of your machinery.

Common Parts for Replacement

- Air Filter

- Fuel Filter

- Spark Plug

- Chain Brake

- Bar and Chain

Replacement Steps

- Gather Tools: Before starting, collect all necessary tools including screwdrivers, wrenches, and replacement parts.

- Turn Off Equipment: Ensure that the machine is turned off and cooled down to avoid any injuries.

- Remove Old Parts: Carefully detach the old components by following the manufacturer’s specifications.

- Install New Parts: Place the new parts in their respective locations, ensuring a secure fit.

- Test Functionality: After replacement, start the equipment to check for proper operation and functionality.

Following this guide will help you maintain your machinery in peak condition and ensure smooth operation during its use.

Adjusting Carburetor Settings

Fine-tuning the carburetor is essential for optimal engine performance. Proper adjustments ensure that the fuel and air mixture is at the right ratio, which can significantly impact efficiency, power, and overall functionality.

Before proceeding with the adjustments, it’s crucial to familiarize yourself with the basic components of the carburetor, as well as the tools needed for the task.

- Flathead screwdriver

- Torque wrench

- Clean cloths

- Fuel mixture (according to specifications)

Follow these steps to effectively adjust the settings:

- Start the engine and allow it to warm up for a few minutes to reach optimal operating temperature.

- Locate the adjustment screws on the carburetor, typically labeled as the low-speed and high-speed adjustment screws.

- Turn the low-speed screw clockwise to lean the mixture or counterclockwise to enrich it. Aim for a smooth idle.

- Next, adjust the high-speed screw. Turn it clockwise to lean the mixture and counterclockwise to enrich it. Test the throttle response for optimal power during acceleration.

- After making adjustments, check the engine performance at different speeds and loads to ensure the settings are effective.

Regular maintenance and careful adjustment of the carburetor can lead to improved performance and longevity of the equipment. If issues persist after adjustment, consider consulting a professional for further diagnosis.

Chain Sharpening Techniques

Properly maintaining the cutting edge of a chainsaw chain is crucial for efficient operation and safety. Sharpening techniques can significantly enhance the performance of the tool, ensuring clean cuts and reducing wear on the engine. Understanding the fundamental principles of chain sharpening is essential for both novice and experienced users.

Understanding Chain Anatomy

Before diving into sharpening techniques, it’s important to familiarize oneself with the components of the chain. The cutting teeth, depth gauges, and tie straps each play a vital role in the chain’s functionality. Recognizing how these parts interact allows for more effective sharpening, leading to a balanced and efficient cutting experience.

Sharpening Techniques

There are several methods to sharpen a chainsaw chain, including manual sharpening with files or using electric sharpeners. Manual sharpening involves using a round file to grind the cutting teeth at the correct angle, typically between 25 to 35 degrees. This technique requires practice to master the angle and pressure applied. Electric sharpeners, on the other hand, provide a quicker and more uniform result, making them ideal for users who sharpen chains frequently.

Regardless of the chosen method, it is crucial to maintain the same angle and depth for each tooth to ensure even cutting performance. Regularly checking the tension and condition of the chain during the sharpening process can also prolong its lifespan and enhance cutting efficiency.

Fuel System Troubleshooting

The fuel system is a crucial component that ensures optimal performance in small engines. Issues within this system can lead to poor operation, starting difficulties, or even complete failure. Understanding common problems and their solutions can save time and enhance the longevity of your equipment.

Common Issues

- Fuel Contamination: Dirty or old fuel can lead to clogs and poor engine performance.

- Clogged Fuel Filter: A blocked filter restricts fuel flow, causing the engine to stall.

- Faulty Fuel Lines: Damaged or cracked lines can result in leaks and loss of pressure.

- Carburetor Problems: Incorrect adjustments or dirt in the carburetor can affect fuel mixing.

Troubleshooting Steps

- Inspect Fuel Quality: Check for signs of contamination or age in the fuel. If necessary, replace it with fresh fuel.

- Examine Fuel Filter: Remove and inspect the filter for blockages. Clean or replace as needed.

- Check Fuel Lines: Look for cracks or leaks in the lines. Replace any damaged sections.

- Adjust the Carburetor: Ensure that the carburetor is correctly adjusted according to specifications.

- Test the Fuel Pump: If applicable, verify that the fuel pump is functioning correctly and delivering fuel to the engine.

By following these troubleshooting steps, you can effectively identify and resolve issues within the fuel system, ensuring your engine operates smoothly and efficiently.

Electrical System Diagnostics

The electrical system is crucial for the proper functioning of any machinery. Diagnosing issues within this system requires a systematic approach to identify faults and ensure all components are operational. Understanding the various parts of the electrical system and their interconnections is essential for effective troubleshooting.

To conduct an effective diagnosis, follow these steps:

- Visual Inspection:

- Check for loose connections and damaged wires.

- Inspect connectors for corrosion or wear.

- Look for signs of overheating around electrical components.

- Testing Voltage:

- Use a multimeter to measure voltage at various points in the system.

- Ensure the voltage matches the specifications required for optimal performance.

- Continuity Testing:

- Perform continuity tests on wires and connections to confirm there are no breaks.

- Check the integrity of circuit paths to ensure proper flow of electricity.

- Component Testing:

- Test individual components such as switches, relays, and fuses.

- Replace any faulty parts to restore functionality.

By following these diagnostic steps, one can identify and resolve electrical issues effectively, ensuring reliable operation of the equipment.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when performing maintenance tasks on machinery. Proper precautions help prevent accidents and injuries, allowing for a smoother and more effective process. Adopting a proactive approach to safety not only protects the individual but also extends the lifespan of the equipment being serviced.

Personal Protective Equipment

Wearing appropriate personal protective gear is essential during maintenance activities. This includes gloves to protect hands from sharp objects and chemicals, safety goggles to shield the eyes from debris, and sturdy footwear to safeguard against heavy tools. Additionally, consider using ear protection when operating loud machinery to prevent hearing damage.

Work Area Organization

Keeping the workspace tidy is vital for maintaining safety. Ensure that tools are organized and readily accessible to minimize the risk of accidents. Clear away any clutter or obstacles that could cause tripping hazards. Adequate lighting is also important, as it allows for better visibility of components and reduces the chance of mistakes during service.

Where to Find Spare Parts

Finding replacement components for your outdoor equipment can enhance its longevity and efficiency. Various sources offer high-quality parts that can be easily accessed, ensuring your tools remain in optimal working condition.

Online Retailers

Numerous online platforms specialize in providing spare parts for various models. These websites typically offer a vast inventory, allowing users to search for specific components based on their equipment’s make and model. Popular online retailers often include customer reviews, making it easier to select reliable parts.

Local Dealers

Visiting local dealerships can be an effective way to acquire necessary components. These establishments often have knowledgeable staff who can assist in identifying the right parts and may provide installation services. Additionally, supporting local businesses can foster community ties and ensure you receive quality products.

| Source Type | Benefits |

|---|---|

| Online Retailers | Wide selection, customer reviews, convenience |

| Local Dealers | Expert advice, immediate availability, installation services |

| Second-Hand Markets | Cost savings, rare finds, sustainability |

| Manufacturer Websites | Authenticity, warranty options, direct support |