Effective maintenance of cleaning devices is crucial for ensuring optimal performance and longevity. Various models and types of these machines serve different purposes, making it essential for users to familiarize themselves with their specific operational characteristics. This section aims to provide comprehensive guidance on troubleshooting and servicing these valuable tools.

Many individuals encounter challenges while using their equipment, whether it’s due to minor malfunctions or the need for regular upkeep. By following systematic procedures, users can often address these issues independently, saving both time and money. Detailed instructions will enhance your understanding of essential functions and components, promoting a more satisfying ownership experience.

Regular care and informed handling can significantly reduce the frequency of breakdowns, ensuring that your cleaning apparatus remains efficient. This guide will delve into various aspects of maintaining your device, empowering you to tackle common problems confidently and effectively.

tags: Overview of the Cleaning Device

This section aims to provide a comprehensive understanding of a versatile cleaning machine, highlighting its features, functionality, and essential components. Knowing the intricacies of this device is crucial for effective troubleshooting and maintenance.

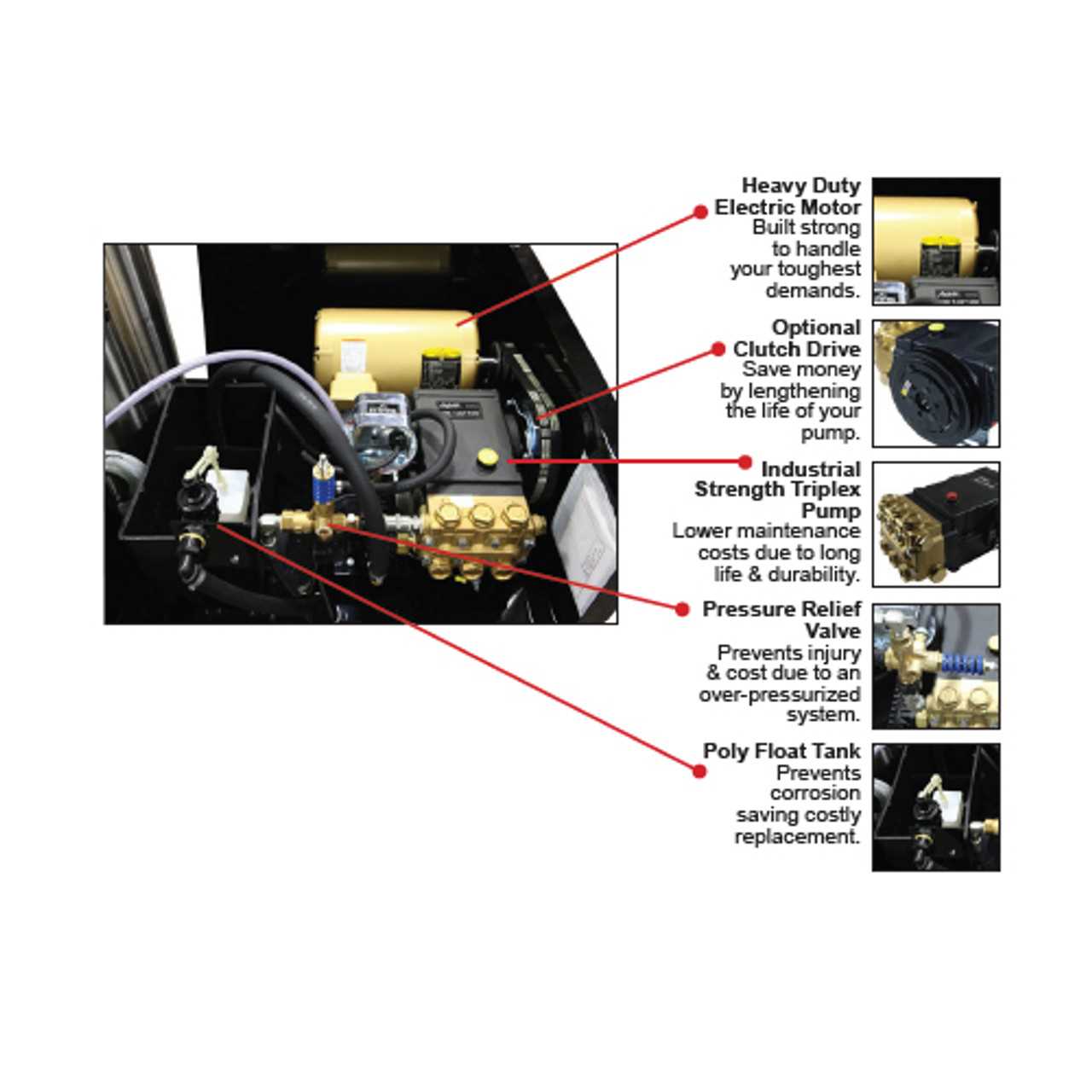

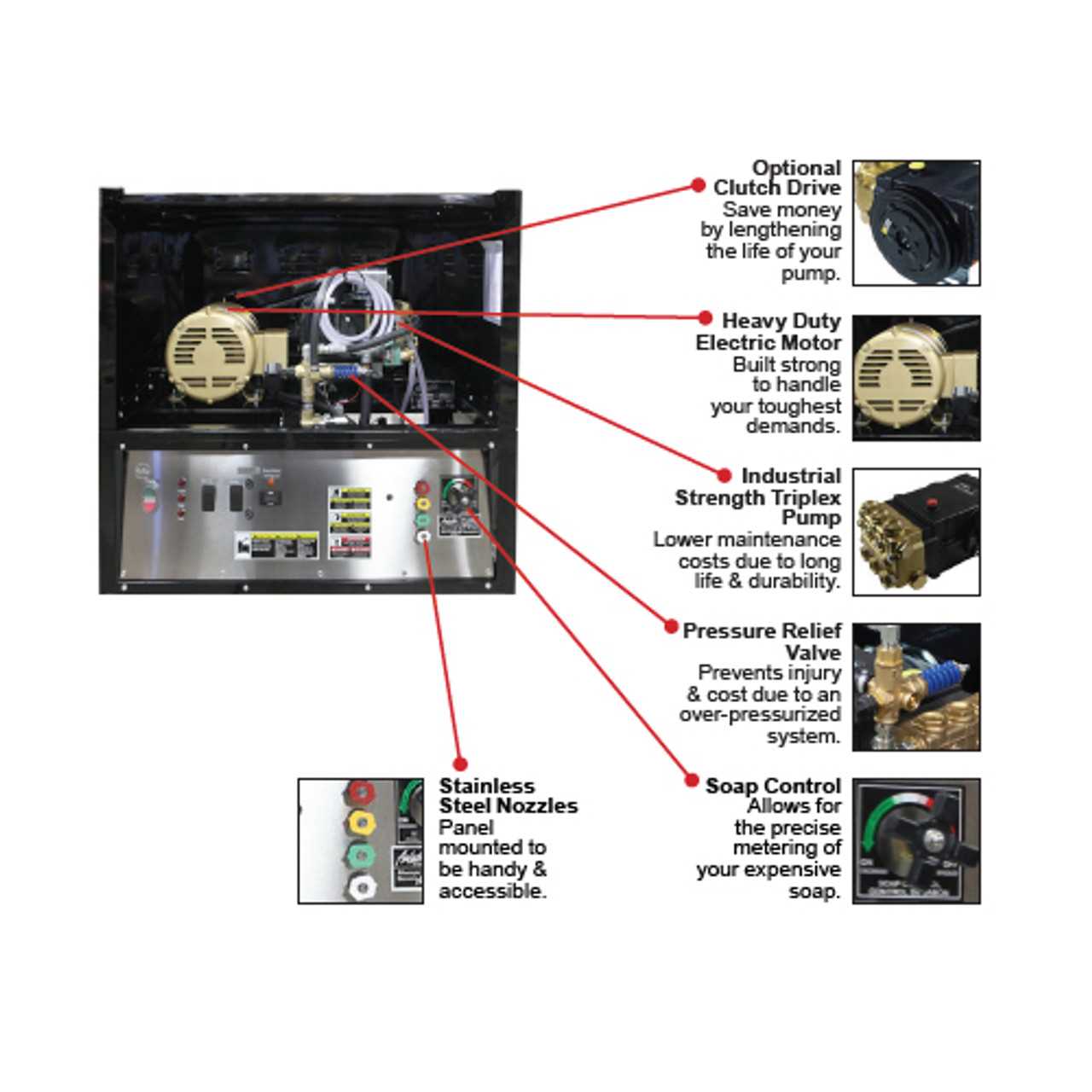

- Design and Construction: Explore the materials and engineering that contribute to its durability and performance.

- Functionality: Understand how the device operates to deliver high-pressure water for various cleaning tasks.

- Components: Familiarize yourself with key parts, including the motor, pump, and nozzle systems, which work in tandem for optimal results.

By grasping the fundamental aspects of this equipment, users can ensure its longevity and efficiency, paving the way for successful interventions when issues arise.

Common Issues with Pressure Washers

Many users encounter typical challenges when operating high-performance cleaning equipment. Understanding these common problems can enhance efficiency and extend the lifespan of the device.

Frequent Problems

- Inconsistent water flow

- Unit failing to start

- Loss of pressure

- Unusual noises during operation

Troubleshooting Steps

- Check for clogs in the intake and hoses.

- Inspect electrical connections and power sources.

- Verify the correct setup and settings for the task.

- Examine seals and fittings for leaks.

Tools Needed for Repairs

When tackling maintenance tasks for your cleaning device, having the right equipment is essential for efficient and effective work. The appropriate tools not only facilitate the process but also help in achieving better outcomes while minimizing potential damage.

First, you’ll require a set of basic hand tools, including screwdrivers of various sizes, pliers, and wrenches. These items will assist in disassembling components and securing them back in place. Additionally, a socket set can be invaluable for dealing with nuts and bolts that may be difficult to reach with standard tools.

For more intricate adjustments, specialized tools such as a multimeter for electrical diagnostics and a pressure gauge for performance checks are recommended. A quality set of replacement parts, such as seals and hoses, is also crucial to ensure the longevity of your device. Finally, ensure you have a clean workspace and appropriate safety gear, such as gloves and goggles, to protect yourself while you work.

Step-by-Step Troubleshooting Guide

This guide provides a systematic approach to diagnosing common issues encountered with cleaning equipment. By following these steps, users can identify problems effectively and find suitable solutions to restore functionality.

Identifying Common Issues

Begin by observing the unit for any visible signs of malfunction. Check for leaks, unusual noises, or loss of power. Understanding these symptoms can help narrow down potential causes.

Testing Components

Once issues are identified, proceed to test individual components. Ensure all connections are secure, inspect hoses and fittings for damage, and verify the functionality of switches and valves. Systematic testing will aid in pinpointing the exact problem.

Replacing the Pressure Hose

Over time, the flexible tubing used for fluid conveyance can wear out or become damaged, affecting performance. Replacing this component is essential to restore efficiency and functionality. This section outlines the steps needed to successfully replace the hose, ensuring optimal operation of your equipment.

Tools and Materials Needed

Before beginning the replacement process, gather the following items: a new length of flexible tubing, appropriate connectors, wrenches, and a safety knife. Having these tools on hand will streamline the procedure and minimize downtime.

Step-by-Step Replacement Process

Start by disconnecting the existing tubing from both the inlet and outlet ports. Use a wrench to loosen any fittings carefully, ensuring not to damage the surrounding components. Once detached, measure the length of the old tubing to cut the new piece accordingly. Securely attach the new hose by threading it into the fittings and tightening them with a wrench. Check for leaks by running the system briefly and inspect all connections for any signs of fluid escape.

Cleaning the Spray Nozzle

Maintaining optimal performance of your cleaning equipment often hinges on the condition of its dispensing components. One crucial aspect is ensuring the spray nozzle remains clear and free from debris, as blockages can significantly reduce efficiency and effectiveness.

To begin the cleaning process, disconnect the device from its power source and water supply. This step is essential for safety. Next, examine the nozzle for any visible buildup or clogs. If necessary, soak it in warm, soapy water for several minutes to help dissolve any stubborn residues.

Once soaked, use a soft brush or cloth to gently scrub the nozzle, paying particular attention to the small openings where water exits. This action helps dislodge any trapped particles. After cleaning, rinse the nozzle thoroughly under running water to remove any remaining soap or debris.

Finally, ensure the nozzle is completely dry before reattaching it to the device. Regular cleaning of this component not only prolongs the lifespan of your equipment but also enhances its overall performance, making your cleaning tasks more efficient.

Maintenance Tips for Longevity

To ensure the durability and efficient operation of your cleaning equipment, it is essential to follow a set of maintenance practices. Regular care not only enhances performance but also extends the lifespan of the machine, saving you time and money on replacements and repairs.

Regular Inspection

Conduct frequent checks of all components to identify wear or damage early. This proactive approach helps in maintaining optimal functionality and prevents unexpected breakdowns.

Cleaning and Storage

After each use, make it a habit to clean the unit thoroughly. Proper storage is also crucial; keep the equipment in a dry and sheltered location to protect it from environmental factors that could cause deterioration.

| Task | Frequency | Description |

|---|---|---|

| Component Inspection | Monthly | Check hoses, nozzles, and other parts for any signs of wear. |

| Cleaning | After Each Use | Remove debris and residue to maintain efficiency. |

| Oil Changes | Every 50 Hours | Replace oil to ensure smooth operation of internal components. |

Identifying Electrical Problems

Electrical issues can significantly impact the functionality of various devices, leading to operational failures or inefficiencies. Recognizing these problems early can help in diagnosing and resolving them effectively.

When troubleshooting electrical concerns, consider the following steps:

- Visual Inspection: Start by examining all visible wiring and connections for signs of wear, damage, or loose connections.

- Power Source Check: Ensure that the device is properly plugged in and that the outlet is functioning. Use a multimeter to test for voltage.

- Component Testing: Isolate and test individual components, such as switches, relays, and fuses, to determine if they are operational.

- Continuity Testing: Utilize a multimeter to check for continuity in wires and components, ensuring there are no breaks in the circuit.

- Consult Schematics: Refer to circuit diagrams to understand the electrical layout and identify potential problem areas.

By systematically evaluating these aspects, you can effectively identify and address electrical challenges, ensuring optimal performance of the equipment.

Understanding Pump Functionality

Pumps play a crucial role in various cleaning systems, converting mechanical energy into fluid motion. Their efficient operation is essential for achieving optimal performance in tasks that require water application under pressure.

The primary function of a pump is to intake fluid and generate pressure to propel it through a delivery system. This process involves several components working in harmony, including the motor, impeller, and housing. Each element must function correctly to ensure the system operates smoothly and effectively.

Common issues that may arise include blockages, leaks, and worn-out seals, which can hinder performance. Regular maintenance and understanding the underlying mechanics can significantly prolong the life of the pump and enhance overall efficiency.

By comprehending the operational principles of pumps, users can troubleshoot problems more effectively and maintain optimal performance in their cleaning systems.

Winterizing Your Pressure Washer

Preparing your cleaning equipment for the colder months is essential to ensure its longevity and performance. Properly protecting it from freezing temperatures can prevent damage and ensure that it’s ready for use when the weather warms up. This process involves several key steps to safeguard various components from the harsh conditions.

Start by draining all fluids from the unit. This includes removing water from the tank and hoses to prevent freezing. Make sure to operate the machine briefly to allow any remaining liquid to exit completely. Using a pump saver solution can further protect the internal components by providing a lubricating layer against moisture and corrosion.

Next, store the equipment in a dry, sheltered area. Keeping it indoors or in a garage helps to shield it from extreme temperatures and potential moisture buildup. Additionally, covering the unit with a breathable tarp can protect it from dust and debris while allowing airflow to prevent mildew.

Lastly, check and maintain other components like hoses and nozzles. Ensure they are free from kinks or cracks, as these can worsen with cold exposure. By following these steps, you can effectively prepare your equipment for the winter season, ensuring it remains in optimal condition for your next cleaning tasks.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring personal safety and preventing accidents is paramount. Following certain guidelines can significantly reduce risks and promote a secure environment for all involved.

Essential Safety Measures

- Always wear appropriate personal protective equipment, such as gloves and goggles.

- Ensure the workspace is clean and free from clutter to prevent tripping hazards.

- Disconnect power sources before starting any work to avoid electrical shocks.

- Use tools correctly and inspect them for any damage before use.

Emergency Preparedness

- Keep a first aid kit readily available and know how to use it.

- Familiarize yourself with emergency procedures and exits in the area.

- Have a fire extinguisher accessible in case of an unexpected fire.

Where to Find Replacement Parts

Locating the right components for your cleaning device can be crucial for maintaining its efficiency and performance. Several avenues are available to ensure you obtain the necessary items without hassle.

Online Retailers

Many online platforms specialize in providing parts for various machinery. Consider the following options:

- Dedicated e-commerce websites for equipment parts

- General online marketplaces

- Manufacturer’s official website

Local Supply Stores

Your local hardware or specialty stores may have the items you need. Check the following:

- Home improvement centers

- Specialty tool shops

- Automotive parts suppliers

Ensuring compatibility with your specific model is essential when sourcing components. Always verify that the parts meet the required specifications for optimal functionality.