Maintaining the longevity and performance of your watercraft is essential for any enthusiast. This section delves into the intricate processes involved in the upkeep and rejuvenation of composite vessels. Through careful attention to details, one can ensure that their aquatic companion remains in top-notch condition for years to come.

From addressing minor surface blemishes to tackling significant structural challenges, this guide offers insights into effective techniques and materials that facilitate effective interventions. Each method outlined aims to enhance both the aesthetic appeal and functional integrity of your craft, providing a pathway to seamless enjoyment on the water.

Understanding the principles behind preservation not only empowers owners but also fosters a deeper connection with their vessels. With the right knowledge and tools, navigating the complexities of upkeep becomes a rewarding endeavor, ultimately enriching the overall experience of maritime adventures.

Understanding West System Fiberglass

This section explores the fundamental aspects of a popular composite material widely used in the marine industry, focusing on its properties, applications, and the best practices for ensuring longevity and durability. Grasping the intricacies of this material is essential for achieving optimal performance in various aquatic vessels.

Comprehending the characteristics of this composite helps in making informed decisions about its use and upkeep. Below is a comparison of essential features that contribute to its effectiveness.

| Feature | Description |

|---|---|

| Strength | Offers excellent tensile and compressive strength, ensuring structural integrity. |

| Weight | Lightweight nature aids in enhancing speed and maneuverability on the water. |

| Durability | Resistant to corrosion, moisture, and UV damage, extending the lifespan of marine crafts. |

| Versatility | Suitable for a variety of applications, from recreational vessels to commercial platforms. |

Delving into these attributes enables users to better appreciate the potential and ultimate benefits of utilizing this material in aquatic applications.

Essential Tools for Boat Repair

Having the right equipment is crucial for effective maintenance and restoration tasks. A well-stocked toolkit can significantly enhance efficiency and ensure that each project is completed with precision. Below is a list of indispensable instruments that every enthusiast should consider for various tasks.

Basic Hand Tools

Every toolkit should include a variety of fundamental hand tools. These instruments are essential for performing a range of tasks, from minor adjustments to more extensive modifications.

| Tool | Purpose |

|---|---|

| Screwdrivers | For tightening or loosening screws in various materials. |

| Wrenches | To fasten or loosen nuts and bolts. |

| Pliers | Useful for gripping, twisting, and cutting wire. |

| Utility Knife | For cutting materials with precision. |

Power Tools

In addition to hand tools, power tools can greatly improve efficiency and reduce physical strain. They are particularly valuable for larger tasks that require more strength and speed.

| Tool | Purpose |

|---|---|

| Drill | For creating holes and driving screws quickly. |

| Sander | To smooth surfaces and prepare them for finishing. |

| Router | For shaping edges and creating decorative patterns. |

| Grinder | For sharpening tools and cutting materials. |

Common Fiberglass Damage Types

Understanding the various forms of damage that can occur to composite structures is essential for effective upkeep and restoration. These types of harm can arise from environmental factors, impacts, or wear over time, and recognizing them early can help in taking appropriate corrective actions.

| Damage Type | Description |

|---|---|

| Cracks | Visible fissures that may penetrate the surface, potentially compromising structural integrity. |

| Delamination | Separation of layers that can lead to weakening and increased vulnerability to further damage. |

| Blistering | Formation of bubbles beneath the surface, often caused by moisture trapped within the layers. |

| Impact Damage | Crushed or dented areas resulting from collisions with hard objects, affecting both appearance and strength. |

| UV Degradation | Fading and weakening due to prolonged exposure to sunlight, affecting color and surface texture. |

Step-by-Step Repair Techniques

This section provides a comprehensive guide to effectively address damage and enhance the longevity of your vessel. Following systematic methods not only ensures successful outcomes but also fosters confidence in handling various challenges that may arise during the upkeep process.

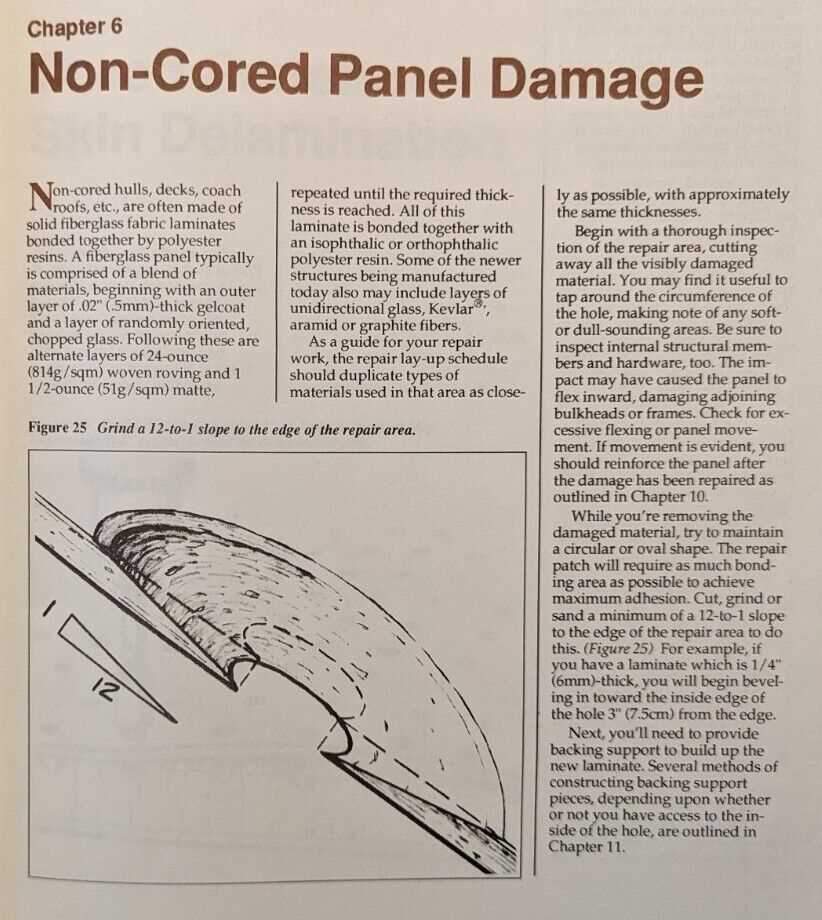

Assessment and Preparation

Begin by thoroughly inspecting the affected area. Identify any cracks, blisters, or structural issues that need attention. Clean the surface with appropriate solvents to remove dirt, grease, and old coatings. Ensure the environment is suitable for work–adequate ventilation and controlled temperature can significantly affect the materials used.

Application of Repair Materials

Once the surface is prepared, select suitable compounds that align with the project requirements. Mix the chosen materials according to the manufacturer’s instructions, ensuring the consistency is optimal for application. Apply the mixture evenly across the damaged area, using tools like brushes or rollers for a smooth finish. Allow sufficient curing time before proceeding with any additional layers or finishing touches.

Surface Preparation Tips

Proper groundwork is essential for achieving a durable finish and ensuring long-lasting performance. Adequate surface treatment enhances adhesion and promotes a smooth application process. Follow these steps to prepare surfaces effectively before any coating or sealing work.

1. Clean the Surface: Begin by removing any dirt, grease, or old coatings. Utilize a suitable cleaner and a soft scrubber to eliminate contaminants. Rinse thoroughly with fresh water and allow it to dry completely.

2. Sanding: Lightly sand the area to create a rough texture, which aids in adhesion. Use fine-grit sandpaper for optimal results. Be cautious not to over-sand, as this can damage the underlying material.

3. Dust Removal: After sanding, ensure all dust and debris are removed. A vacuum or a damp cloth can effectively eliminate particles that may interfere with the bonding process.

4. Inspect for Damage: Check the surface for any cracks or weaknesses. Address these issues before proceeding to ensure a solid foundation for any additional work.

5. Temperature Considerations: Ensure the working environment is within the recommended temperature range for optimal adhesion. Avoid applying materials in extreme conditions, as this can affect performance.

By following these guidelines, you will create a well-prepared surface that supports a successful application and enhances overall durability.

Choosing the Right Epoxy Resin

When it comes to enhancing the durability and longevity of your projects, selecting the appropriate adhesive is crucial. The right formulation can significantly impact the performance, strength, and overall quality of your work. Understanding the various types available will guide you in making an informed decision.

Here are some key factors to consider:

- Type of Application: Different formulations are tailored for specific uses. Determine if you need a resin for bonding, coating, or laminating.

- Working Time: Evaluate the pot life of the resin. Some projects require quick curing, while others may benefit from extended working times.

- Viscosity: The thickness of the resin affects application methods. Choose a consistency that aligns with your technique, whether it’s brushing, pouring, or injection.

- Flexibility and Strength: Consider the mechanical properties required for your application. Some resins offer enhanced flexibility, while others provide superior rigidity.

- Environmental Resistance: If your project will face moisture, UV exposure, or chemicals, select a formulation that provides the necessary protection.

- Color and Clarity: Depending on aesthetic preferences, you may want a clear finish or a specific tint to complement your design.

By carefully assessing these elements, you can confidently choose a resin that meets your project needs, ensuring optimal results and durability.

Maintenance Routines for Longevity

Ensuring the durability and performance of your watercraft requires regular attention and systematic practices. By implementing a series of routine tasks, you can extend the lifespan of your vessel and enhance its overall efficiency. Below are essential procedures to consider for optimal upkeep.

- Regular Cleaning:

Remove salt, dirt, and grime to prevent degradation of surfaces. Use appropriate cleaning agents and tools.

- Inspection of Components:

Conduct frequent assessments of key elements such as hull integrity, hardware, and fastenings. Look for signs of wear or damage.

- Lubrication:

Apply lubricants to moving parts to minimize friction and reduce wear. Focus on hinges, locks, and any mechanical components.

- Storage Practices:

When not in use, store the vessel in a sheltered environment to protect it from harsh weather conditions. Utilize covers to shield from UV rays.

- System Checks:

Regularly test all systems, including electrical and plumbing, to ensure they function properly. Address any issues immediately.

By incorporating these practices into your routine, you can significantly enhance the resilience of your watercraft, ensuring many enjoyable voyages ahead.

Inspection Checklist for Owners

This section provides a comprehensive guide for proprietors to evaluate their vessels regularly. Conducting periodic inspections can help identify potential issues before they escalate, ensuring optimal performance and longevity. The following checklist outlines key areas to assess for the overall well-being of your craft.

Exterior Examination

- Inspect the hull for cracks, blisters, or discoloration.

- Check the condition of the deck surface for any wear or damage.

- Examine the transom for signs of deterioration.

- Look at the fittings and hardware for corrosion or loosening.

- Ensure that all seals and joints are intact and watertight.

Interior Assessment

- Evaluate the integrity of the interior structure for any soft spots.

- Inspect storage compartments for moisture or mold.

- Check all electrical systems for functionality and any frayed wiring.

- Test the plumbing system for leaks and proper operation.

- Assess safety equipment for compliance and accessibility.

By adhering to this checklist, owners can maintain their vessels in peak condition, promoting safety and enhancing the overall experience on the water.

Seasonal Care for Your Boat

Proper seasonal care is essential for ensuring the longevity and performance of your watercraft. Different times of the year present unique challenges and opportunities for maintaining its condition. By following a few straightforward steps, you can protect your investment and enjoy many days on the water.

Spring Preparation

As the warmer months approach, it’s time to prepare your vessel for action. Focus on these key tasks:

- Inspect the hull for any damage or wear.

- Check all mechanical systems, including the engine and electrical components.

- Clean and polish the exterior surfaces.

- Ensure that safety equipment is in good condition and readily accessible.

- Test the navigation systems and any onboard electronics.

Winterization Tips

When the boating season comes to an end, proper winterization is crucial to prevent damage during colder months. Consider the following steps:

- Drain all water systems to avoid freezing and cracking.

- Apply a protective cover to shield from snow and ice.

- Store in a dry, well-ventilated area to reduce moisture buildup.

- Perform routine checks on any stored equipment and supplies.

- Review and replenish safety gear as necessary.

By dedicating time to seasonal care, you ensure that your vessel remains in optimal condition, ready for your next adventure.

Resources for Further Learning

Expanding your knowledge in the realm of composite material care and enhancement can significantly benefit your projects. A variety of resources are available to help you deepen your understanding and refine your skills, ranging from online platforms to printed literature. Whether you are a novice or an experienced enthusiast, tapping into these materials can provide valuable insights and techniques.

Online Courses and Tutorials

Numerous websites offer comprehensive courses that cover various aspects of composite handling and techniques. Platforms like Udemy and Coursera feature tutorials led by industry experts, allowing you to learn at your own pace. Additionally, YouTube hosts a plethora of video guides, providing visual demonstrations that can enhance your practical understanding.

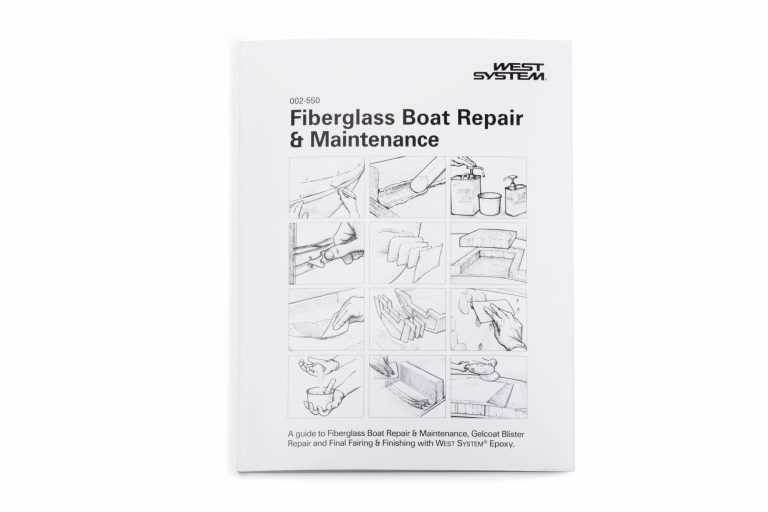

Books and Publications

Investing in specialized books can serve as an excellent reference for both fundamental concepts and advanced methodologies. Look for titles that delve into topics such as composite fabrication, surface finishing, and repair strategies. Magazines and journals focusing on maritime topics also frequently publish articles that discuss new technologies and innovative practices in the field.