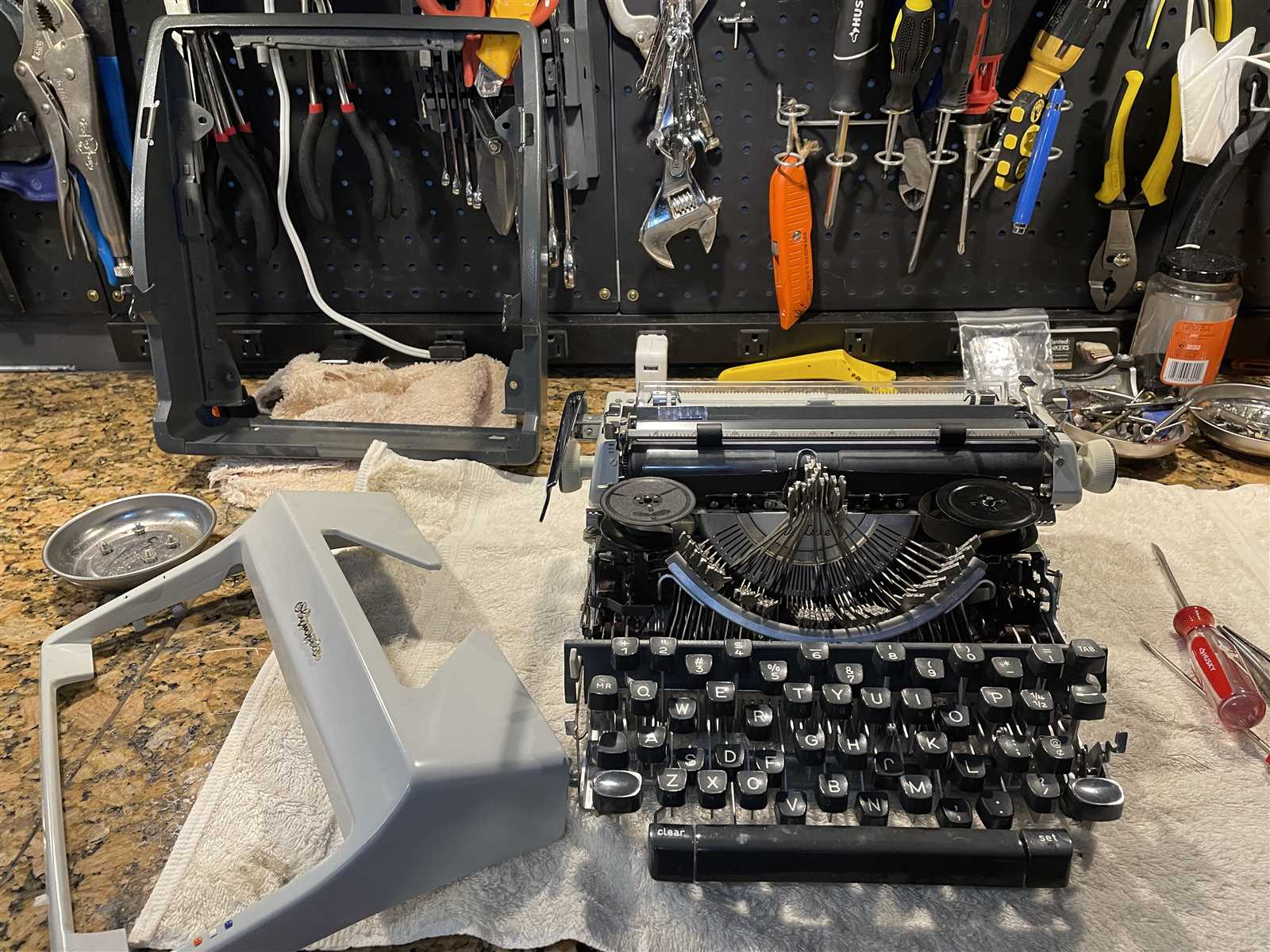

In a world increasingly dominated by digital technology, a unique charm lies in mechanical devices that once defined the art of written communication. These intricate machines, with their precise mechanics and tactile feedback, hold a special place in the hearts of many enthusiasts. This section explores the nuances of restoring and maintaining these classic instruments, ensuring their continued functionality and relevance.

Understanding the inner workings of these historical devices is essential for anyone looking to preserve their legacy. Knowledge of components and common issues will empower users to tackle challenges that arise with age and wear. This exploration will illuminate the journey from problem identification to effective solutions, offering insights into techniques that enhance longevity.

Whether you are a seasoned collector or a curious novice, engaging with these timeless tools fosters a deeper appreciation for craftsmanship. Embracing the art of maintenance not only revives the joy of writing but also connects individuals to the rich history of communication. Each restored piece tells a story, bridging the past with the present.

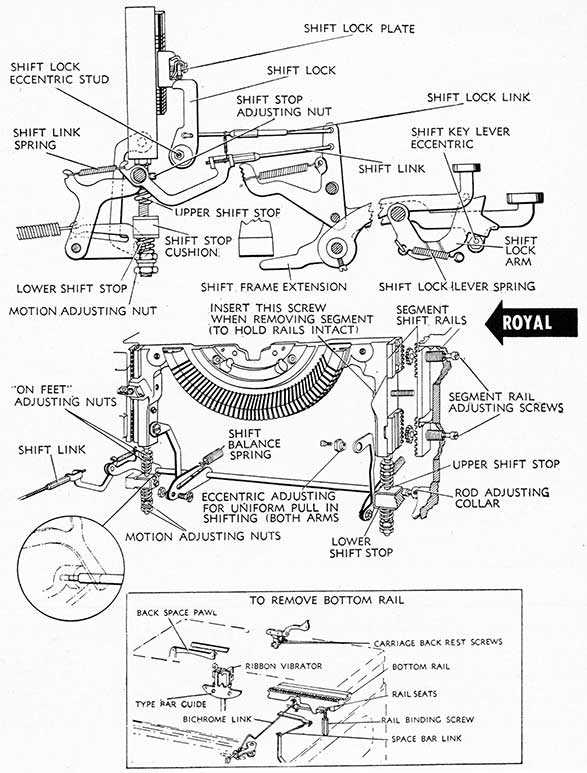

Understanding Typewriter Mechanics

Exploring the inner workings of this classic writing device reveals a fascinating blend of mechanical ingenuity and design. Each component plays a crucial role in producing clear, legible text on paper. By examining these elements, users can appreciate the complexity and artistry behind each keystroke.

At the heart of this system lies a series of interconnected parts that work together seamlessly. Understanding how these elements function not only enhances user experience but also enables effective troubleshooting and maintenance.

| Component | Function |

|---|---|

| Keyboard | Initiates the typing action by sending signals to other mechanisms. |

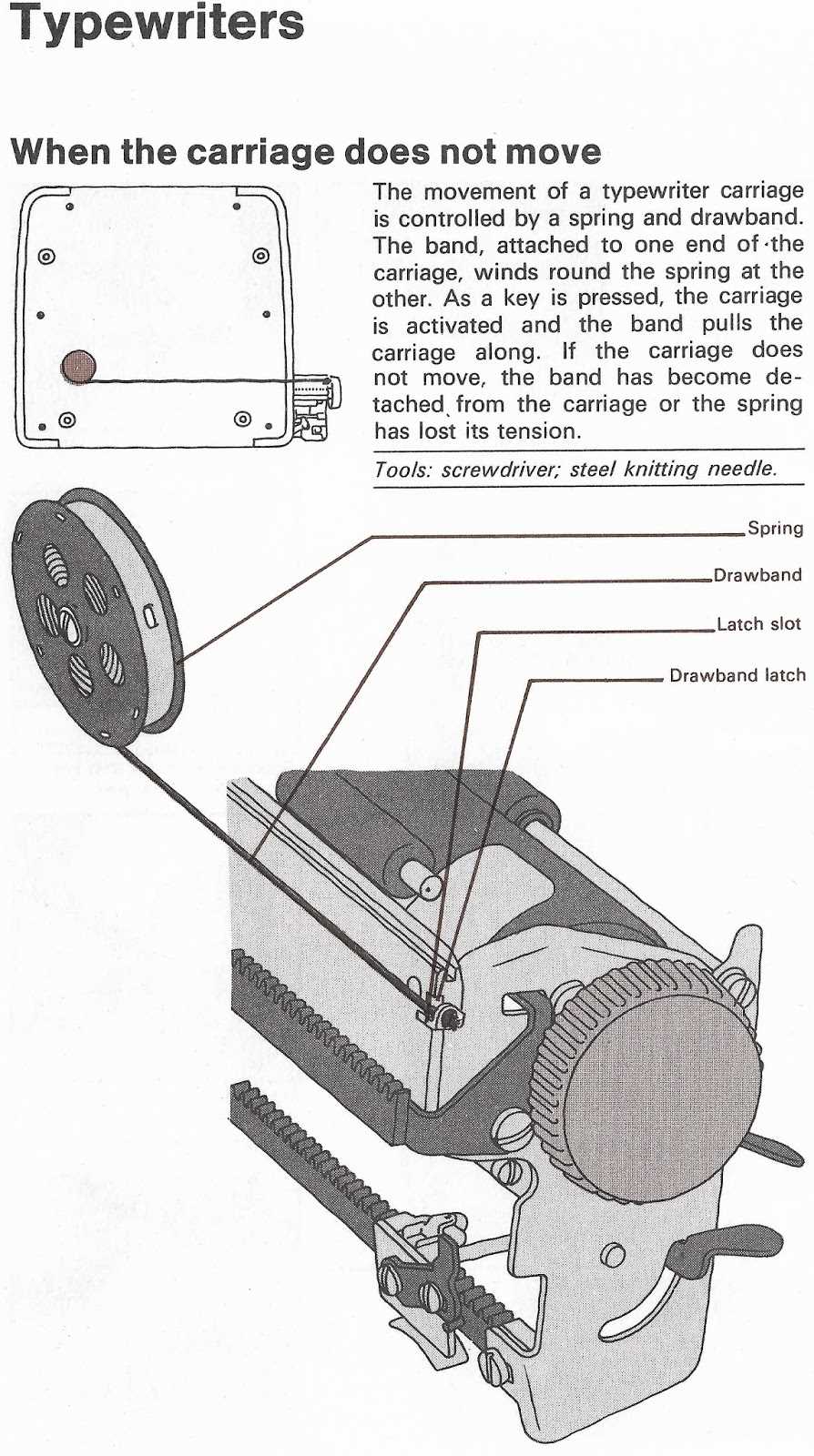

| Carriage | Holds the paper and moves it incrementally for each line typed. |

| Ribbon | Transfers ink onto paper with each key press, creating the text. |

| Typebars | Strike the ribbon and paper to imprint characters, controlled by key presses. |

| Platen | Supports the paper and provides a surface for typebars to hit against. |

A deep dive into these components highlights not only their individual functions but also how they interact to create the writing experience. Mastery of this knowledge transforms usage from a simple task to an art form, enabling enthusiasts to appreciate each letter crafted on the page.

Common Typewriter Issues Explained

Encountering difficulties with classic writing machines can be frustrating for enthusiasts and users alike. Understanding these common problems is essential for maintaining functionality and ensuring a smooth writing experience. This section will cover prevalent challenges faced by these mechanical devices and provide insight into their causes and potential solutions.

Sticking Keys: One frequent issue involves keys that become unresponsive or stick when pressed. This can often be attributed to dirt accumulation or mechanical misalignment. Regular cleaning and careful inspection can usually resolve this problem.

Uneven Print Quality: Another common concern is inconsistent impressions on the paper. This may occur due to worn-out ribbons or improperly set alignment. Replacing ribbons and adjusting the platen can help achieve clearer results.

Jammed Mechanism: A jammed mechanism can lead to frustration during use. This typically happens when multiple keys are pressed simultaneously or when foreign objects obstruct the moving parts. Clearing any blockages and ensuring proper key operation is key to preventing jams.

Ribbon Issues: Ribbons may wear out or become tangled, causing interruptions in typing. Regularly checking ribbon condition and ensuring correct threading can mitigate these issues. A well-maintained ribbon is crucial for optimal performance.

By familiarizing oneself with these typical challenges, users can enhance their experience and prolong the life of their beloved writing machines.

Essential Tools for Repairs

A comprehensive toolkit is crucial for maintaining and restoring mechanical devices. Having the right equipment on hand not only simplifies tasks but also enhances efficiency and precision. This section outlines key items that every enthusiast should consider for successful interventions.

Basic Toolkit Components

Every toolkit should start with fundamental instruments that allow for various adjustments and fixes. These essentials form the backbone of effective maintenance practices.

| Tool | Purpose |

|---|---|

| Screwdrivers | Used for fastening and loosening screws of different sizes. |

| Pliers | Essential for gripping, bending, and cutting wires or components. |

| Wrenches | Ideal for tightening or loosening nuts and bolts. |

| Brushes | Helpful for cleaning debris and dust from delicate areas. |

| Lubricants | Used to ensure smooth operation of moving parts. |

Advanced Equipment

For more intricate tasks, specialized tools can make a significant difference. These items allow for greater control and accuracy when addressing complex issues.

| Tool | Purpose |

|---|---|

| Calipers | Measures internal and external dimensions accurately. |

| Magnifying Glass | Assists in examining small components closely. |

| Multimeter | Used for testing electrical properties like voltage and resistance. |

| Soldering Iron | Necessary for connecting electronic components securely. |

| Heat Gun | Useful for removing adhesive or shrinking materials. |

Step-by-Step Troubleshooting Guide

This section provides a systematic approach for diagnosing and resolving common issues encountered with mechanical writing devices. Following these guidelines will help users effectively identify problems and apply solutions to restore functionality.

Common Issues and Solutions

Below are some typical challenges and their corresponding fixes. Each problem includes a brief description and actionable steps for resolution.

| Issue | Symptoms | Solution |

|---|---|---|

| Sticking Keys | Keys do not return to original position | Clean and lubricate the key mechanisms. |

| Inconsistent Impressions | Uneven or faint letters | Check ribbon tension and replace if worn. |

| Paper Jams | Paper gets stuck during typing | Remove and reinsert paper correctly; inspect feed rollers. |

| Incorrect Alignment | Text appears off-center | Adjust the carriage alignment using the adjustment knob. |

Additional Tips

For effective troubleshooting, always refer to specific components that might require attention. Regular maintenance practices can prevent many issues from arising. Consider keeping a log of any problems encountered and solutions applied for future reference.

Maintaining Your Typewriter’s Performance

Ensuring optimal functionality of your writing device requires regular attention and care. Simple maintenance practices can significantly enhance longevity and efficiency, allowing for a smoother writing experience. This section outlines essential steps for preserving your instrument’s performance and preventing common issues.

Key aspects to consider include cleaning, lubrication, and adjustments. Each of these components plays a crucial role in maintaining overall functionality and preventing wear and tear over time.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Cleaning | Weekly | Remove dust and debris from keys and mechanisms to prevent sticking and malfunction. |

| Lubrication | Monthly | Apply appropriate oil to moving parts to ensure smooth operation and reduce friction. |

| Adjustment | As Needed | Check alignment and tension of keys and ribbons to maintain consistent performance. |

| Ribbon Replacement | As Needed | Replace ink ribbons regularly to ensure clear and legible typing results. |

By adhering to these guidelines, one can effectively preserve the functionality of the writing device and ensure a pleasant typing experience for years to come.

Cleaning Techniques for Longevity

Maintaining the optimal condition of vintage writing machines requires regular attention to cleanliness. Proper techniques not only enhance functionality but also prolong the life of these mechanical marvels. Establishing a routine cleaning schedule will ensure that every component remains in peak performance, safeguarding your investment for years to come.

Essential Tools and Materials

Gathering the right supplies is crucial for effective maintenance. Soft brushes and lint-free cloths are essential for removing dust and debris without causing scratches. Additionally, using a mild solvent for stubborn spots can be beneficial. Always opt for non-abrasive materials to prevent damage to delicate surfaces.

Step-by-Step Cleaning Process

Start by gently brushing away loose particles from external surfaces. Pay special attention to crevices where dirt tends to accumulate. Next, use a damp cloth with a mild cleaning solution to wipe down the exterior, ensuring no moisture seeps into internal mechanisms. For internal components, carefully disassemble as needed, and clean with soft tools, taking care to avoid excessive force. Regularly checking and clearing the ribbon and paper feed areas will enhance overall performance.

Replacing Worn-Out Parts

Maintaining optimal functionality often requires attention to components that have deteriorated over time. Identifying and substituting these elements can significantly enhance performance and extend lifespan.

Key indicators that a component may need replacement include:

- Unusual noises during operation

- Decreased efficiency or sluggish response

- Visible signs of wear or damage

When preparing for a replacement, follow these steps:

- Identify the specific part that requires attention.

- Gather necessary tools and replacement components.

- Carefully disassemble the unit, taking note of the original configuration.

- Install the new part, ensuring proper alignment and fit.

- Reassemble the unit and perform a test to confirm functionality.

Regular checks and timely substitutions can lead to a more reliable and enjoyable experience. Investing effort in this process pays off in the long run, ensuring smooth operation and minimizing future issues.

Finding Quality Replacement Components

Locating high-grade components for vintage writing machines can significantly enhance functionality and longevity. It’s essential to consider sources that provide durability and reliability while ensuring compatibility with specific models. A well-informed approach to sourcing parts will yield better results and preserve the integrity of cherished equipment.

Where to Look

When seeking quality components, explore various avenues. Trusted suppliers often have an extensive inventory of both new and refurbished parts. Online marketplaces can also be useful, but due diligence is necessary to avoid subpar offerings. Local repair shops may offer valuable insights and recommendations as well.

Evaluating Quality

Assessing the quality of potential replacements involves a few key considerations. Look for reputable brands and read reviews from previous customers. Additionally, inspecting components for signs of wear and ensuring proper functionality can prevent future issues.

| Source | Advantages | Considerations |

|---|---|---|

| Specialized Retailers | Expertise, Authentic Parts | Higher Prices |

| Online Marketplaces | Wide Selection, Competitive Pricing | Variable Quality |

| Local Shops | Personalized Service, Local Support | Limited Inventory |

Adjusting Typewriter Alignment

Proper alignment is crucial for achieving crisp, clear impressions on paper. When letters fail to line up correctly, it can detract from the overall appearance and readability of your work. This section focuses on the methods and techniques to ensure that characters are positioned accurately, enhancing both functionality and aesthetics.

Step-by-step procedure: Start by checking the current alignment of the characters. This can be done by typing a few lines and examining the results. If inconsistencies are noticed, adjustments are necessary. It may involve tweaking the position of the carriage or the individual keys.

Tools required: A basic toolkit, including a screwdriver and a ruler, can facilitate the process. Additionally, a reference guide may help in understanding the specific mechanics involved in your model.

Common adjustments: Most alignments can be corrected by repositioning the alignment lever or adjusting the spacing between the platen and the hammers. Ensure that all parts move freely without obstruction, which could lead to further misalignment.

Regular maintenance and alignment checks can prevent future issues, ensuring your device remains in optimal working condition and continues to produce professional results.

Innovative Repair Tips from Experts

Insights from seasoned professionals can significantly enhance your approach to restoring vintage writing machines. By applying unique methods and creative solutions, enthusiasts can achieve remarkable results, even when facing challenging issues.

Utilize Common Household Items: Many problems can be addressed with everyday supplies. For instance, using vinegar can effectively clean rust, while baking soda serves as a gentle abrasive for stubborn grime. These alternatives not only save money but also provide eco-friendly solutions.

Prioritize Regular Maintenance: Preventive measures are essential. Establishing a routine that includes dusting and lubrication can prolong functionality. Set reminders for periodic check-ups to catch potential issues before they escalate.

Document Your Process: Keeping detailed records of each undertaking can be invaluable. Note the steps taken, challenges faced, and successful techniques employed. This log will serve as a reference for future projects and help refine skills over time.

Network with Other Enthusiasts: Joining communities focused on restoration can provide a wealth of knowledge. Sharing experiences and tips can lead to discovering innovative techniques that may not be widely known.