Ensuring optimal performance of your snow-clearing equipment is essential for efficient winter operations. Proper understanding of the various components and their functions can greatly enhance longevity and reliability. This section aims to provide valuable insights into common challenges faced by operators and effective solutions to address them.

From routine checks to intricate adjustments, mastering the intricacies of your system will empower you to tackle issues proactively. Whether you are dealing with mechanical failures or performance inefficiencies, having a structured approach to addressing these concerns is crucial. Here, we will delve into essential practices and techniques to keep your equipment in peak condition.

Additionally, understanding the underlying mechanics can facilitate quicker diagnostics and repairs, ultimately saving time and resources. By equipping yourself with the right knowledge and strategies, you can ensure that your equipment remains a reliable ally during the harshest weather conditions.

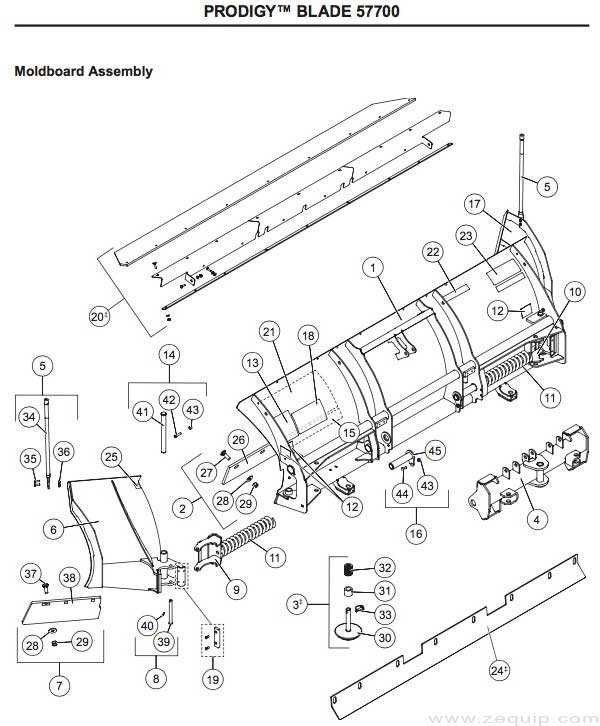

Understanding Western Plow Components

This section delves into the essential elements that constitute a snow-clearing apparatus. Gaining a comprehensive understanding of these components is crucial for effective operation and maintenance. Each part plays a vital role in ensuring optimal performance and durability during harsh winter conditions.

| Component | Description | Function |

|---|---|---|

| Blade | The primary surface that makes contact with snow. | Clears snow from the surface. |

| Mounting Frame | The structure that connects the apparatus to the vehicle. | Provides stability and support. |

| Hydraulic System | Mechanism that allows for lifting and angling. | Enables maneuverability and adjustment. |

| Controller | The interface used to operate the system. | Facilitates user input for various functions. |

| Wear Shoes | Replaceable components at the blade’s edge. | Protect the blade and enhance longevity. |

Understanding these components not only aids in efficient usage but also helps in troubleshooting and addressing potential issues, ultimately extending the lifespan of the equipment.

Common Issues with Western Plows

Maintaining snow removal equipment is crucial for optimal performance during winter months. Various problems can arise, impacting efficiency and effectiveness. Understanding these common challenges can help operators address them swiftly and minimize downtime.

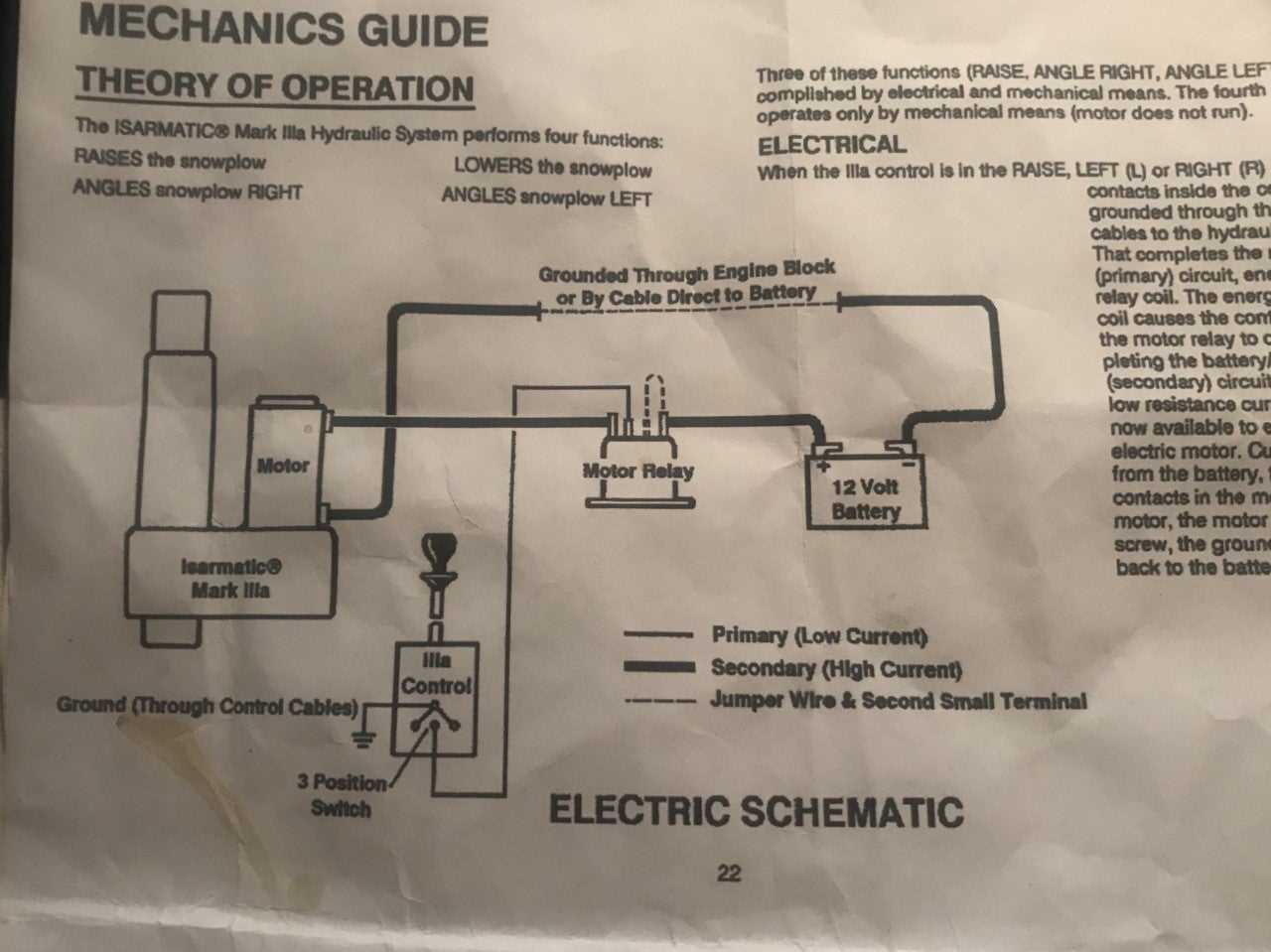

1. Hydraulic System Failures

One prevalent issue is the malfunction of hydraulic components. This can manifest as sluggish or unresponsive movements, often due to leaks or air in the system. Regular inspection of hoses and fittings is essential to prevent these setbacks.

2. Blade Wear and Damage

Wear and tear on cutting edges are inevitable. Dull blades can hinder performance, making it difficult to clear surfaces effectively. Frequent sharpening or replacement is recommended to maintain optimal cutting ability.

3. Electrical Issues

Electrical malfunctions can lead to operational failures. Problems with wiring, switches, or fuses may disrupt functionality. It is important to regularly check electrical connections to ensure everything is in working order.

4. Corrosion and Rust

Exposure to harsh winter elements can cause corrosion. This affects the durability of various components and can lead to more significant repairs down the line. Applying protective coatings can help mitigate these effects.

5. Mounting Problems

Improper mounting can lead to instability during operation. Ensuring that all brackets and fasteners are secure is vital for safe and effective usage. Regular checks and adjustments can help maintain stability.

Step-by-Step Repair Procedures

This section outlines a systematic approach to addressing common issues encountered with your equipment. By following these detailed steps, you can effectively troubleshoot and restore functionality to ensure optimal performance.

| Step | Description |

|---|---|

| 1 | Assess the situation by inspecting the unit for visible damage or wear. Take note of any unusual sounds or performance issues. |

| 2 | Gather necessary tools and replacement parts based on your initial evaluation. Ensure all items are compatible with your specific model. |

| 3 | Disconnect the power source to prevent any accidents during the servicing process. Safety should be your top priority. |

| 4 | Begin disassembling the relevant components carefully. Keep track of all screws and small parts to avoid misplacement. |

| 5 | Inspect internal mechanisms and parts for any signs of damage or malfunction. Clean components as necessary. |

| 6 | Replace any damaged parts with the new components you gathered earlier. Ensure all connections are secure. |

| 7 | Reassemble the unit, paying close attention to the order of parts and any specific assembly instructions. |

| 8 | Reconnect the power source and test the equipment to confirm that it is functioning properly. Monitor for any irregularities. |

| 9 | If issues persist, revisit your steps to identify any missed details or consult additional resources for guidance. |

Tools Needed for Effective Repairs

When it comes to maintaining and restoring equipment, having the right instruments at your disposal is crucial. Proper tools not only enhance efficiency but also ensure safety and precision during the maintenance process. Understanding which implements to use can significantly impact the outcome of your tasks.

Essential Instruments

Start with the basics: a sturdy set of hand tools including wrenches, screwdrivers, and pliers. These items are fundamental for most adjustments and modifications. Additionally, a reliable socket set can make tasks easier by providing better access to hard-to-reach bolts and screws.

Specialized Equipment

For more complex jobs, consider investing in specialized machinery such as hydraulic jacks and alignment tools. These devices allow for more accurate work, particularly when dealing with larger components. Furthermore, having safety gear like gloves and goggles is vital to protect yourself while performing any maintenance activities.

Ultimately, the right collection of tools not only facilitates effective work but also promotes a safe and organized environment for all your tasks.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment involves regular attention and care. By following a few essential practices, you can enhance performance and reduce the likelihood of costly failures.

1. Regular Inspections: Schedule routine checks to identify wear and tear. This proactive approach allows for timely adjustments and replacements, preventing more significant issues down the line.

2. Lubrication: Keep moving parts well-lubricated to minimize friction. Use the appropriate lubricants as recommended, ensuring smooth operation and preventing rust.

3. Cleaning: After each use, remove dirt and debris from components. This simple step helps maintain functionality and prevents corrosion.

4. Storage: Store your equipment in a dry, sheltered location to protect it from the elements. Covering it during periods of inactivity can further safeguard against damage.

5. Follow Manufacturer Guidelines: Adhere to the specific instructions provided by the manufacturer. This ensures you’re performing maintenance correctly and efficiently.

By implementing these strategies, you can effectively prolong the life of your machinery and ensure optimal performance for years to come.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is paramount. Implementing proper protocols minimizes the risk of accidents and injuries, safeguarding both the individual and the equipment. Adhering to safety guidelines not only promotes a secure working environment but also enhances the overall efficiency of the operation.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Ensure the work area is well-lit and free from clutter to prevent tripping hazards.

- Utilize tools correctly and ensure they are in good working condition before use.

- Disconnect power sources when working on electrical components to avoid shock hazards.

- Keep fire extinguishers readily available and ensure they are easily accessible.

Emergency Preparedness

- Familiarize yourself with emergency procedures and the location of first aid kits.

- Have a communication plan in place in case of an accident or emergency.

- Regularly conduct safety drills to reinforce protocols and ensure readiness.

Upgrading Your Plow System

Enhancing your snow removal equipment can significantly improve performance and efficiency during the winter months. By focusing on specific components and incorporating the latest technologies, you can ensure your setup is not only effective but also reliable.

Consider the following areas for enhancement:

- Hydraulic Systems: Upgrading to higher-capacity hydraulic pumps can provide faster operation and better control.

- Control Mechanisms: Investing in modern electronic controls allows for precise adjustments and improved user experience.

- Material Composition: Switching to lightweight yet durable materials for your equipment can increase maneuverability and longevity.

Additionally, implementing features such as:

- LED Lighting: Improved visibility during nighttime operations can enhance safety.

- Wear Resistant Coatings: Protecting surfaces from wear can extend the lifespan of your gear.

- Smart Technology: Integrating sensors for real-time feedback on performance can optimize operations.

By focusing on these enhancements, you can maximize the efficiency and effectiveness of your snow management setup, ensuring you are well-prepared for any winter challenge.

Cost-Effective Repair Solutions

When it comes to maintaining essential equipment, finding economical methods can significantly reduce expenses while ensuring optimal performance. Exploring innovative and budget-friendly strategies is crucial for extending the lifespan of your machinery.

1. Routine Maintenance: Regular checks and upkeep can prevent major issues before they arise. Simple tasks like cleaning components and lubricating moving parts can lead to substantial savings over time.

2. DIY Approaches: Leveraging your skills to tackle minor fixes can cut down on labor costs. There are numerous online resources, including videos and forums, that provide guidance for self-servicing your gear.

3. Quality Parts: Investing in high-quality components may seem more expensive initially, but they often outlast cheaper alternatives, reducing the need for frequent replacements.

4. Local Workshops: Collaborating with nearby repair shops can sometimes yield cost advantages. Local experts may offer competitive pricing or discounts for regular customers.

5. Group Purchasing: Joining forces with other users to buy parts in bulk can lower costs significantly. Collective buying power often leads to discounts from suppliers.

By implementing these strategies, you can enhance the efficiency of your equipment without breaking the bank, ensuring reliable operation for years to come.

Finding Replacement Parts Easily

Locating suitable components for your equipment can often feel daunting, yet with the right strategies, it becomes a manageable task. Understanding where to search and how to assess quality is crucial for ensuring seamless operation and longevity of your machinery.

Utilizing Online Resources

The internet offers a wealth of information and resources for sourcing components. Various specialized websites provide detailed catalogs, allowing users to filter by model, part type, or even compatibility. Joining forums and communities dedicated to equipment maintenance can also yield recommendations for reliable suppliers and alternatives.

Local Dealers and Salvage Yards

In addition to online options, visiting local dealers and salvage yards can be an effective way to find needed parts. Dealers often have access to new components and can order specific items if they are not in stock. Salvage yards may have used parts at a fraction of the cost, offering a budget-friendly solution without sacrificing quality.

Expert Recommendations for DIY Repairs

When tackling maintenance tasks on your equipment, having a structured approach can greatly enhance your efficiency and effectiveness. This section offers valuable insights to help you confidently address common issues and perform necessary adjustments, ensuring your machinery operates optimally.

1. Gather the Right Tools

Before commencing any task, ensure you have all the necessary tools at hand. A well-stocked toolkit can save you time and frustration. Essential items include wrenches, screwdrivers, and safety gear. Always check the specific requirements for your machinery to avoid missing any crucial instruments.

2. Follow Safety Protocols

Safety should be your top priority. Always disconnect power sources and wear appropriate protective equipment. Familiarize yourself with safety guidelines related to your equipment to minimize the risk of accidents during maintenance.

3. Consult Reliable Resources

Utilize credible sources for guidance. Online forums, instructional videos, and manufacturer documentation can provide detailed instructions and troubleshooting tips. Engaging with communities of enthusiasts can also yield practical advice and support.

4. Document Your Work

Keep a record of your maintenance activities. Documenting repairs and adjustments can help you track issues over time and identify recurring problems. This practice will facilitate future maintenance and ensure a more efficient workflow.

5. Test Thoroughly After Repairs

After completing any adjustments, conduct thorough testing to ensure everything functions as intended. Take the time to observe your equipment in action, checking for any unusual noises or behaviors that may indicate further issues. Early detection can prevent larger problems down the line.

By adhering to these expert recommendations, you can enhance your confidence and competence in handling maintenance tasks, ultimately leading to better performance and longevity of your equipment.