Every automobile requires regular attention to maintain its performance and longevity. Understanding the essential aspects of upkeep and troubleshooting can significantly enhance your driving experience. This section delves into the various techniques and guidelines necessary for ensuring that your vehicle operates smoothly and efficiently.

Proper maintenance not only helps in preventing unexpected breakdowns but also extends the lifespan of the components. Familiarizing yourself with the key processes involved in vehicle care is crucial for both novice and seasoned drivers alike. Here, you will find valuable insights into common practices that can safeguard your automobile against wear and tear.

Moreover, being equipped with the right information enables you to tackle minor issues independently. This resource serves as a valuable reference, providing step-by-step instructions and tips to navigate the complexities of vehicle service. By empowering yourself with knowledge, you can confidently address various challenges that may arise over time.

This section provides a comprehensive overview of the essential characteristics that define this remarkable vehicle. It delves into the key attributes that contribute to its performance, comfort, and utility, making it a popular choice among drivers seeking reliability and capability.

| Feature | Description |

|---|---|

| Engine Options | A variety of powerful engine choices that deliver strong performance and efficiency. |

| Towing Capacity | Designed to handle heavy loads with ease, making it ideal for hauling trailers and equipment. |

| Interior Comfort | Spacious cabin with high-quality materials and advanced technology for a pleasant driving experience. |

| Safety Features | Equipped with various safety technologies to enhance driver and passenger protection. |

| Off-Road Capability | Built to navigate rugged terrains, offering exceptional traction and stability. |

Common Issues and Troubleshooting Tips

Vehicles, regardless of make or model, can experience a range of problems over time. Understanding these common issues and knowing how to address them can enhance vehicle longevity and performance. Below are typical challenges faced by drivers and practical solutions for effective resolution.

| Issue | Description | Troubleshooting Tips |

|---|---|---|

| Engine Noise | Unusual sounds from the engine can indicate various underlying problems. | Check for loose components and ensure proper oil levels. |

| Brake Problems | Squeaking or grinding noises when braking may signal worn brake pads. | Inspect the brake pads and rotors; replace if necessary. |

| Transmission Issues | Slipping gears or difficulty shifting can disrupt driving. | Check transmission fluid levels and inspect for leaks. |

| Electrical Malfunctions | Failure of lights, radio, or dashboard indicators can stem from electrical faults. | Examine fuses and wiring connections for damage. |

| Overheating | Excessive engine heat can lead to severe damage. | Monitor coolant levels and inspect the radiator for leaks. |

Maintenance Schedule for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your vehicle. Establishing a systematic maintenance routine not only enhances performance but also minimizes the risk of unexpected breakdowns. Following a well-structured schedule helps in identifying potential issues before they escalate, ensuring that your vehicle operates smoothly and reliably.

Key Maintenance Tasks

To maintain peak functionality, several critical tasks should be performed at specified intervals. These include checking fluid levels, inspecting tire condition, and replacing filters as necessary. Below is a recommended schedule outlining essential maintenance actions.

| Task | Frequency |

|---|---|

| Oil Change | Every 5,000 miles or 6 months |

| Brake Inspection | Every 10,000 miles |

| Air Filter Replacement | Every 15,000 miles |

| Tire Rotation | Every 5,000 miles |

| Coolant Check | Every 30,000 miles |

Additional Considerations

In addition to routine tasks, keep an eye on warning lights and unusual sounds that may indicate underlying problems. Prompt attention to these signs can prevent costly repairs and enhance overall driving experience. Regular inspections and timely interventions are key to maximizing the reliability of your vehicle.

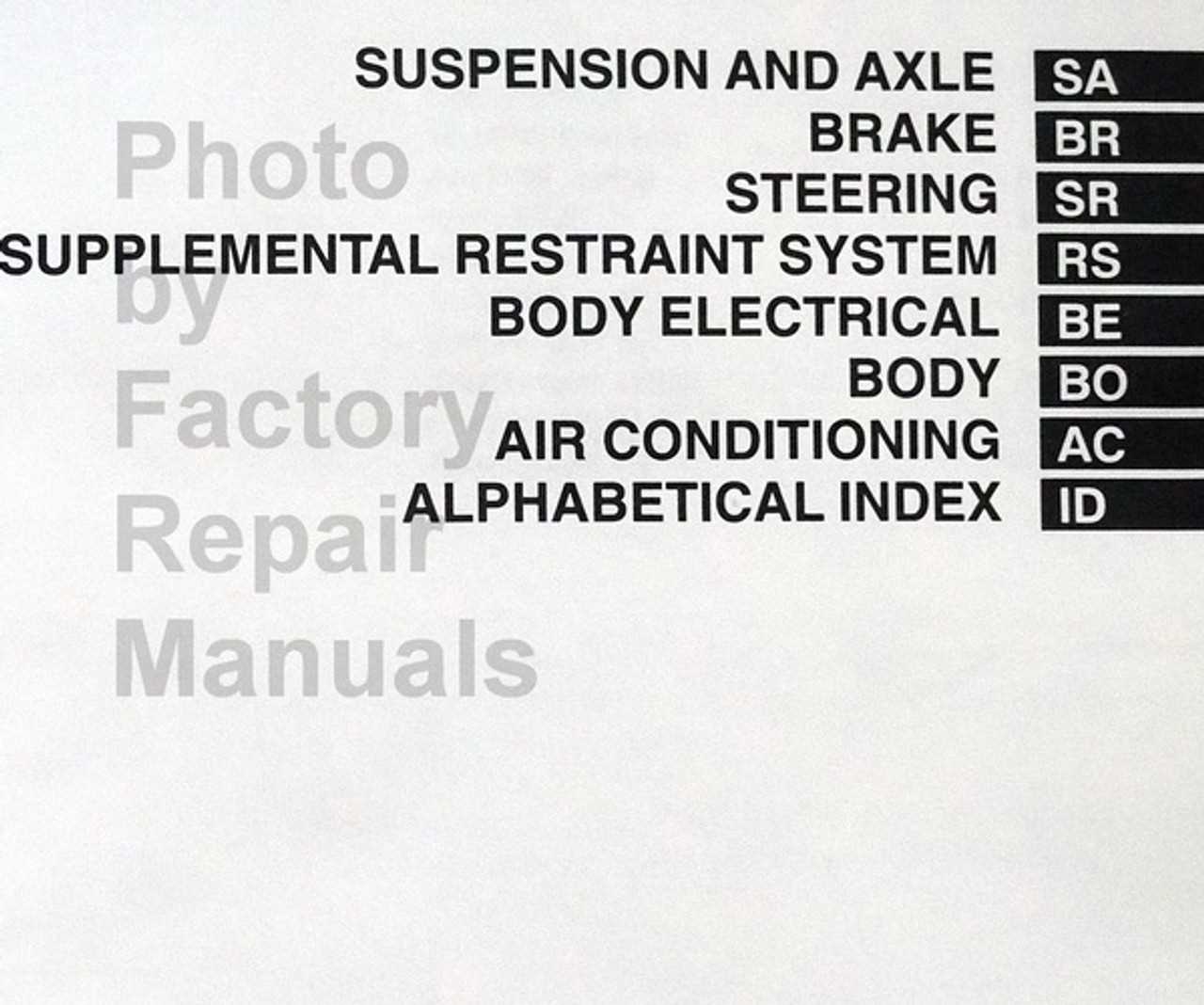

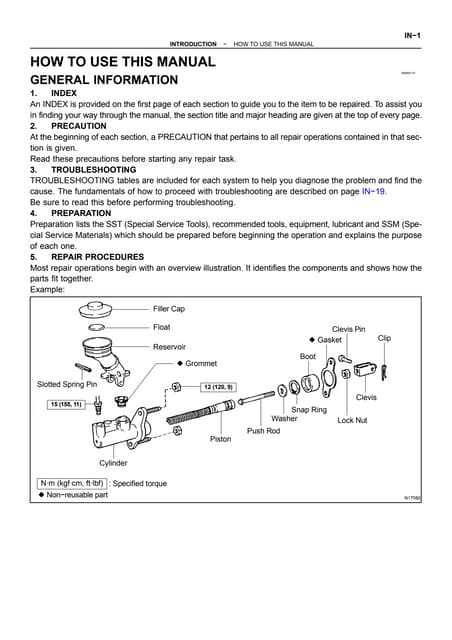

Step-by-Step Repair Procedures

This section outlines the detailed methods for addressing various issues encountered in your vehicle. Following a systematic approach not only ensures effective maintenance but also enhances safety and reliability.

Here are the essential steps to consider during the troubleshooting and repair process:

- Diagnosis:

- Identify symptoms of the problem.

- Utilize diagnostic tools to gather error codes.

- Consult the technical specifications for guidance.

- Preparation:

- Gather necessary tools and equipment.

- Ensure a clean and well-lit workspace.

- Review safety protocols to prevent accidents.

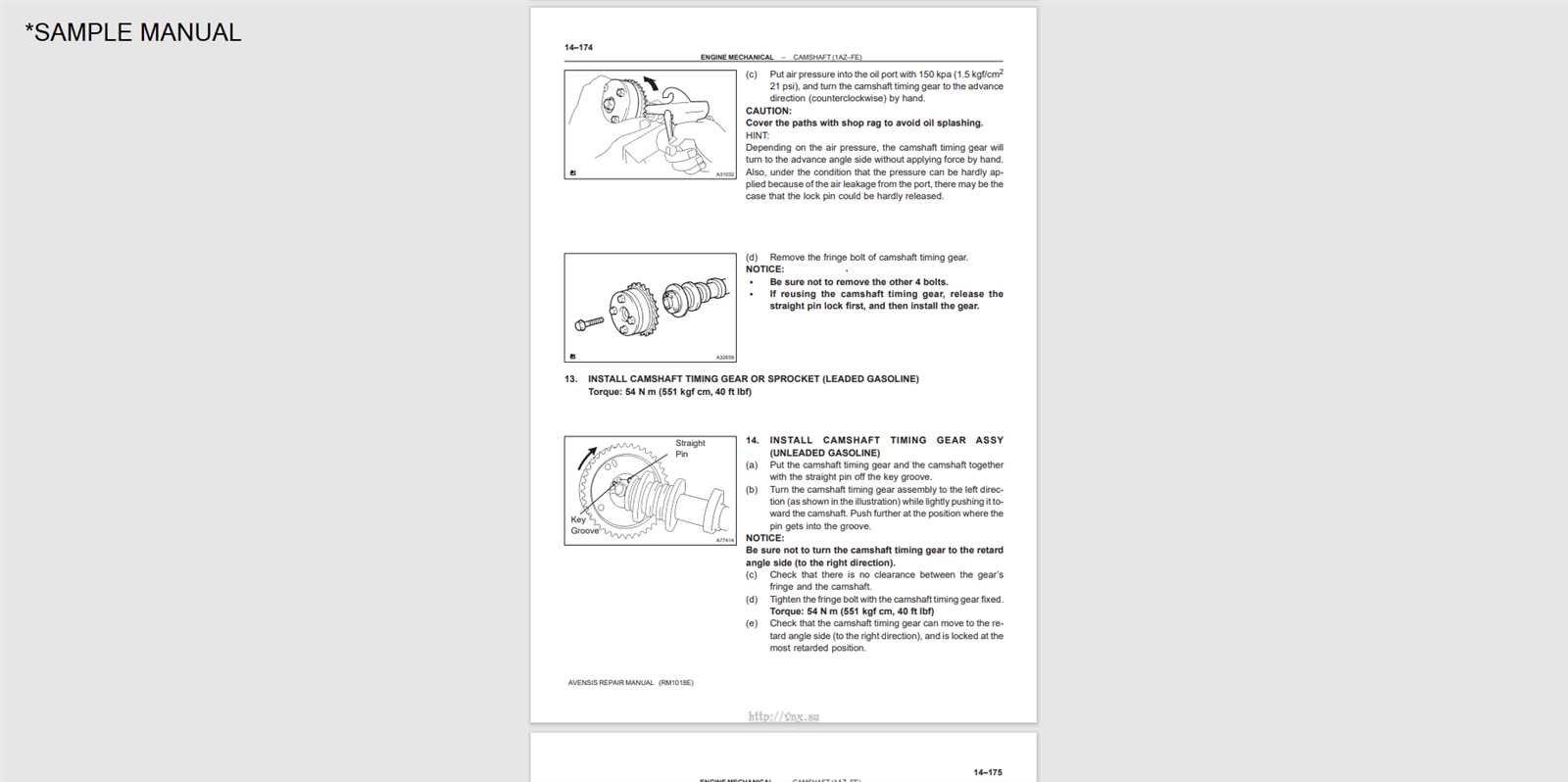

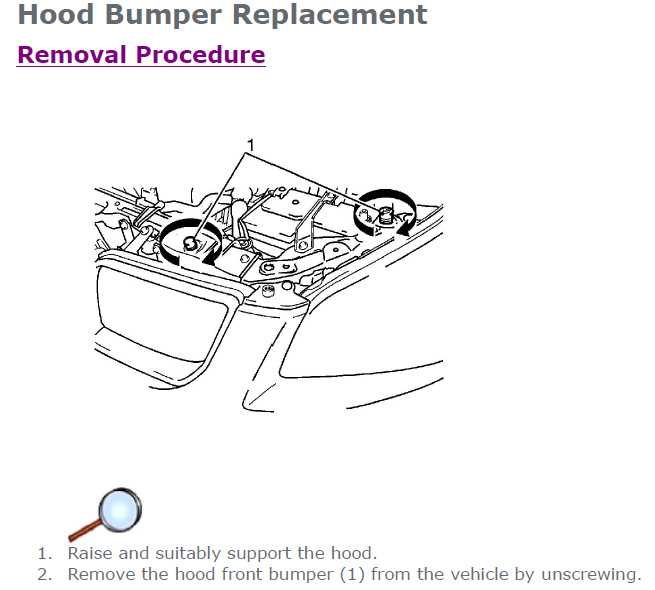

- Disassembly:

- Carefully remove components as needed.

- Organize parts for easy reassembly.

- Document the disassembly process for reference.

- Repair:

- Replace damaged or worn parts.

- Perform necessary adjustments to align components.

- Follow recommended torque specifications during reinstallation.

- Reassembly:

- Reattach all components in reverse order of disassembly.

- Ensure all fasteners are securely tightened.

- Double-check connections and placements.

- Testing:

- Start the vehicle and observe for any irregularities.

- Conduct road tests to confirm successful repairs.

- Use diagnostic tools again to check for error codes.

By adhering to these structured procedures, you can effectively address mechanical challenges while maintaining the integrity and performance of your vehicle.

Tools Required for Repairs

When undertaking maintenance or fixing issues on your vehicle, having the right set of instruments is essential. A well-equipped toolkit not only streamlines the process but also ensures that tasks are performed efficiently and safely. Different operations may require specific implements, ranging from basic hand tools to specialized devices.

Basic Hand Tools: Start with fundamental tools such as wrenches, sockets, and screwdrivers. These are crucial for loosening and tightening various components. Adjustable wrenches and ratchet sets provide flexibility for accessing tight spaces.

Electrical Tools: For tasks involving electrical systems, include a multimeter and wire strippers. These instruments assist in diagnosing and repairing wiring issues, ensuring optimal performance.

Specialized Equipment: Some jobs may necessitate unique tools like a torque wrench for precise tightening or a compression tester for evaluating engine health. Investing in these specialized items can significantly impact the quality of your work.

Safety Gear: Don’t forget personal protective equipment such as gloves and safety glasses. Keeping safe while working on your vehicle is paramount to prevent injuries and ensure a successful maintenance experience.

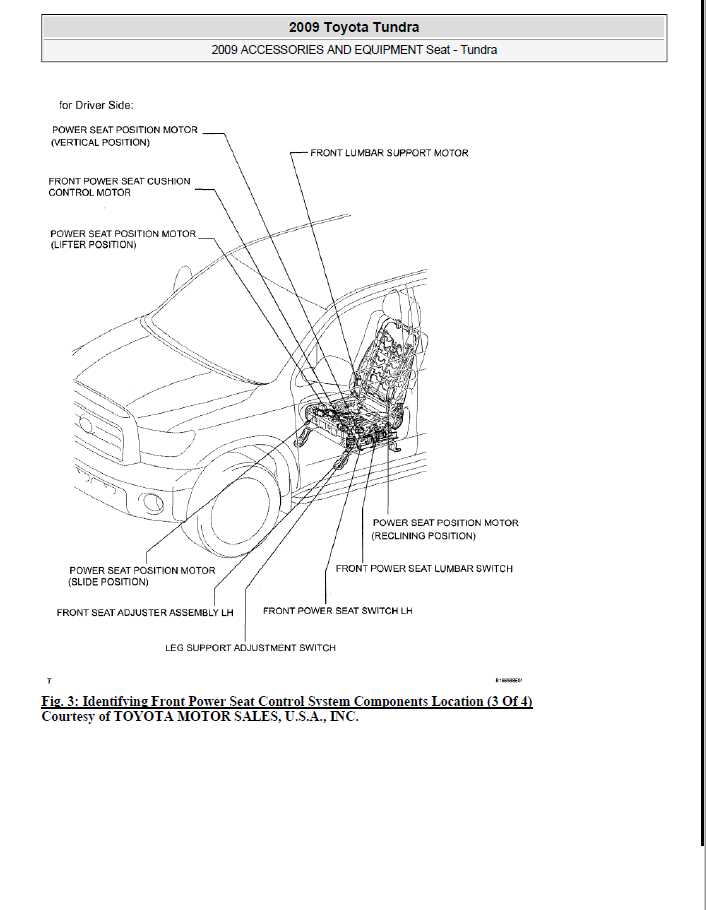

Electrical System Diagnostics

The evaluation of an automobile’s electrical framework is crucial for ensuring optimal performance and reliability. This process involves identifying faults and understanding the functionality of various components within the system. By employing systematic diagnostic techniques, one can efficiently pinpoint issues that may affect the vehicle’s overall operation.

Understanding the Components

To effectively assess the electrical system, it’s essential to familiarize oneself with its key elements, including the battery, alternator, and wiring harnesses. Each component plays a vital role in the distribution and management of electrical energy. Regular inspection of these parts can reveal signs of wear or malfunction that may lead to performance issues.

Diagnostic Tools and Techniques

Utilizing specialized tools, such as multimeters and oscilloscopes, allows for accurate measurements and analysis of electrical signals. Diagnostic scans can also be beneficial in detecting fault codes that provide insights into potential problems. Understanding how to interpret these readings is essential for successful troubleshooting and repair.

Understanding the Engine Specifications

When delving into the characteristics of a vehicle’s powertrain, it’s essential to comprehend the fundamental aspects that define its performance and efficiency. These specifications provide valuable insights into the engine’s capabilities, offering a clearer picture of what to expect in terms of power delivery, fuel consumption, and overall reliability.

Engine Type: The configuration of the engine significantly impacts its operation. Different setups, such as V6 or V8 arrangements, each bring unique advantages and performance traits that cater to various driving needs.

Displacement: The total volume of the engine’s cylinders plays a crucial role in determining its power output. Generally, a higher displacement can lead to increased horsepower and torque, enhancing the vehicle’s acceleration and towing capacity.

Fuel System: The method by which fuel is delivered to the engine is vital for its efficiency and performance. Options may include traditional carburetors or more modern fuel injection systems, each affecting the responsiveness and fuel economy of the vehicle.

Power Output: Understanding the horsepower and torque ratings allows owners to gauge the performance of their engine. These figures indicate how well the vehicle can perform under various conditions, whether for everyday driving or demanding tasks.

Compression Ratio: This specification reflects the efficiency of the engine. A higher compression ratio often leads to better fuel efficiency and power output, but it may also require high-octane fuel to prevent knocking.

By grasping these key specifications, vehicle owners can make informed decisions regarding maintenance, upgrades, and overall expectations for performance.

Brake System Maintenance Guidelines

Proper upkeep of the braking mechanism is crucial for ensuring vehicle safety and performance. Regular inspections and maintenance can help prevent unexpected failures, enhancing both longevity and reliability. This section outlines essential practices and recommendations for maintaining an effective braking system.

Inspection Frequency

It is recommended to conduct a thorough inspection of the braking components at regular intervals. The following table summarizes the suggested frequency for various inspection tasks:

| Inspection Task | Frequency |

|---|---|

| Brake Pads and Shoes | Every 10,000 miles |

| Brake Fluid Level | Monthly |

| Brake Lines and Hoses | Every 20,000 miles |

| Brake Rotors | Every 15,000 miles |

Fluid Replacement

Regularly replacing the brake fluid is essential to maintain optimal braking performance. Contaminated or old fluid can lead to diminished braking efficiency and potential system failures. It is advisable to replace the fluid every two years, or as recommended by the manufacturer, to ensure maximum effectiveness.

Bodywork and Exterior Care

The appearance of a vehicle significantly influences its overall value and aesthetic appeal. Proper maintenance of the outer shell and finish is essential for preserving the vehicle’s integrity and prolonging its lifespan. This section delves into various techniques and practices to keep the exterior in optimal condition, ensuring both functionality and style.

Regular Cleaning

Consistent washing is crucial to remove dirt, grime, and contaminants that can damage the paintwork. Consider the following steps for effective cleaning:

- Use a gentle automotive soap and a soft sponge or microfiber cloth.

- Rinse thoroughly to eliminate all soap residues.

- Dry with a clean towel to prevent water spots.

Protective Measures

Taking proactive steps to safeguard the exterior can prevent wear and tear. Consider implementing the following measures:

- Apply a high-quality wax or sealant to enhance shine and protect against environmental elements.

- Utilize paint protection films or ceramic coatings for additional durability.

- Regularly inspect for scratches and dents, addressing them promptly to avoid rust formation.

FAQs About Tundra Repairs

This section aims to address common inquiries related to maintenance and servicing of a popular full-size pickup. Understanding the typical issues and solutions can significantly enhance the ownership experience.

Common Questions

- What are the typical problems encountered with this model?

- How often should regular maintenance be performed?

- What signs indicate that professional assistance is needed?

- Are there specific parts known for wear and tear?

Service Tips

- Always consult a comprehensive guide for detailed instructions.

- Keep a log of all maintenance activities for future reference.

- Use quality components to ensure longevity and reliability.

- Seek professional help for complex issues to avoid further damage.