Understanding the intricacies of textile machinery is essential for anyone passionate about crafting. Proper upkeep not only enhances the longevity of these devices but also ensures optimal performance. A well-maintained machine can make all the difference in achieving flawless stitching and intricate designs.

In this section, we will explore the essential aspects of maintaining and troubleshooting various features of a popular model. We will provide valuable insights into common issues users might encounter and offer practical solutions that can be applied effectively. By following these guidelines, you can significantly improve the efficiency of your equipment and enjoy a smoother sewing experience.

Equipped with the right knowledge, crafters can confidently tackle minor challenges, keeping their tools in peak condition. From routine cleaning to adjustments, this guide aims to empower users with the skills necessary for effective maintenance. Embrace the art of sewing with confidence and precision!

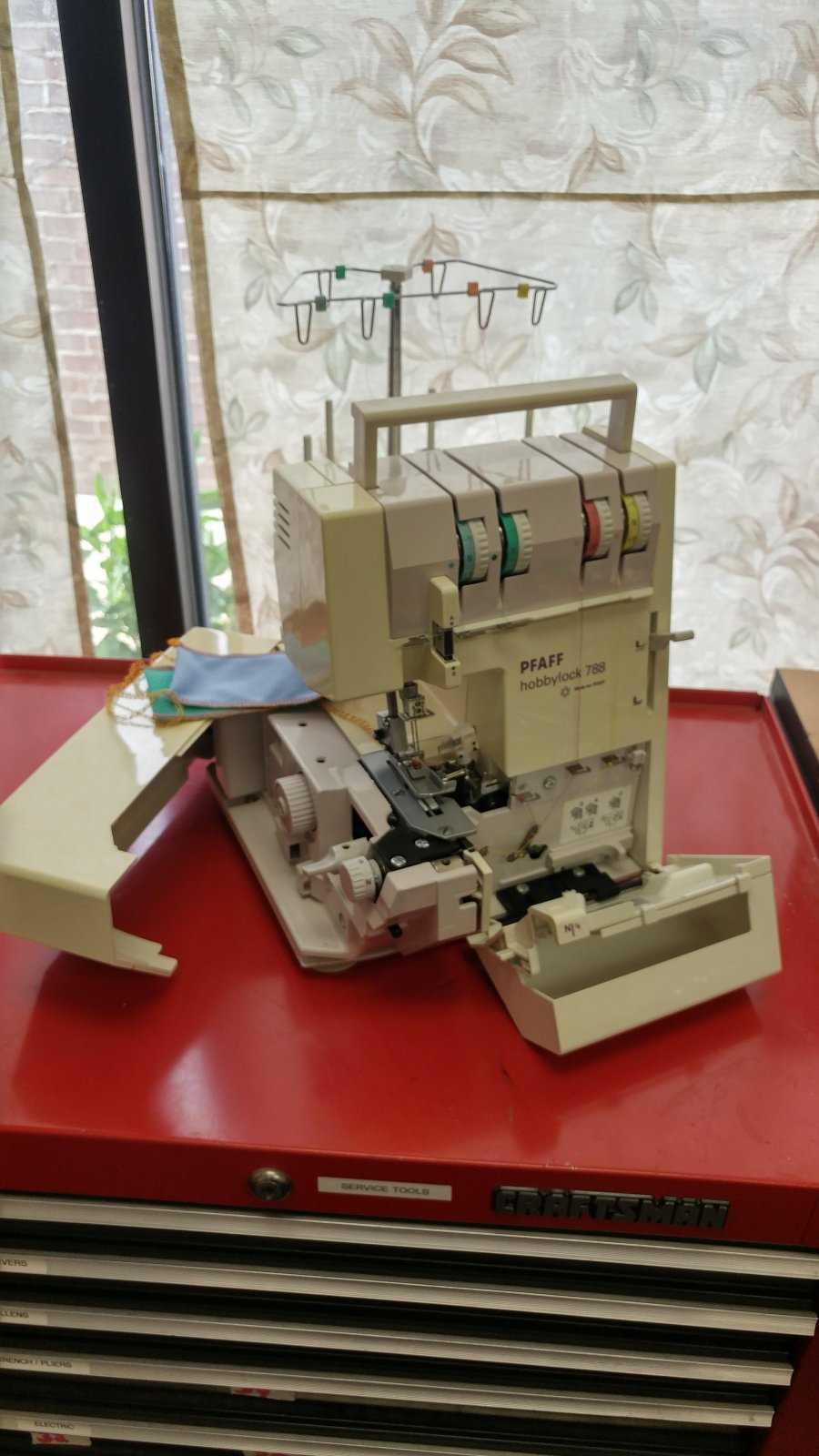

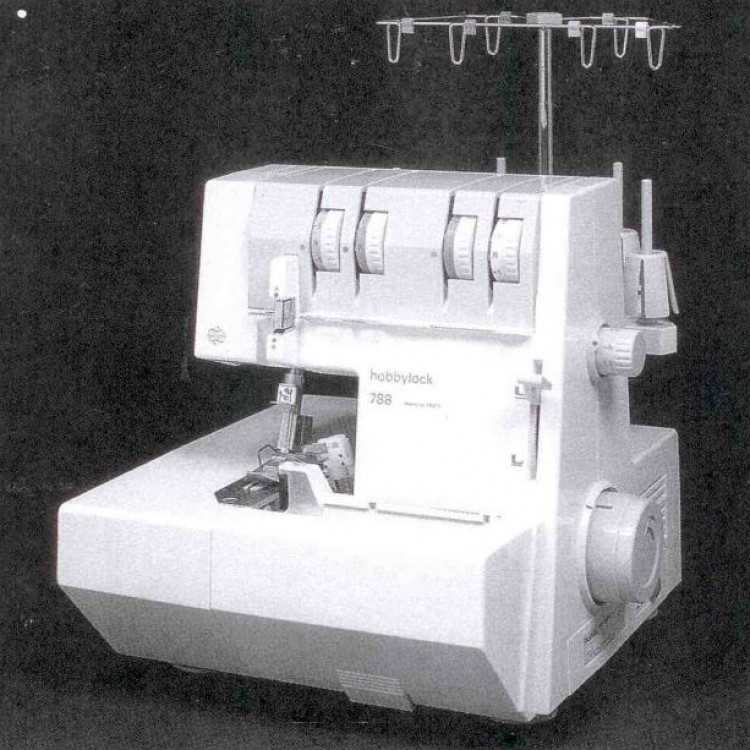

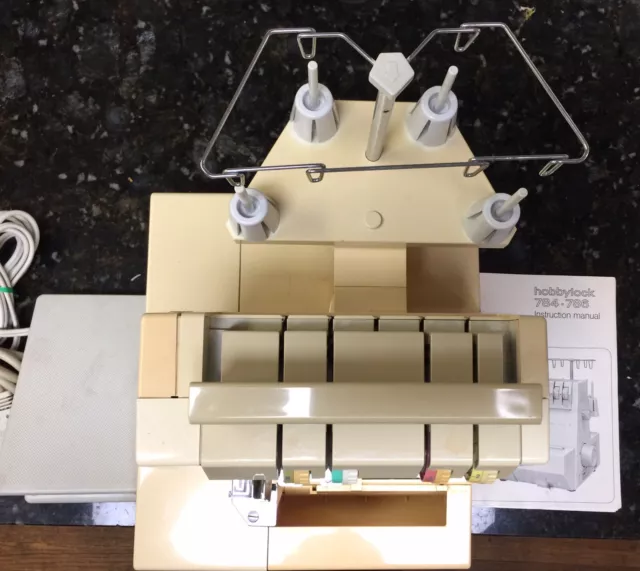

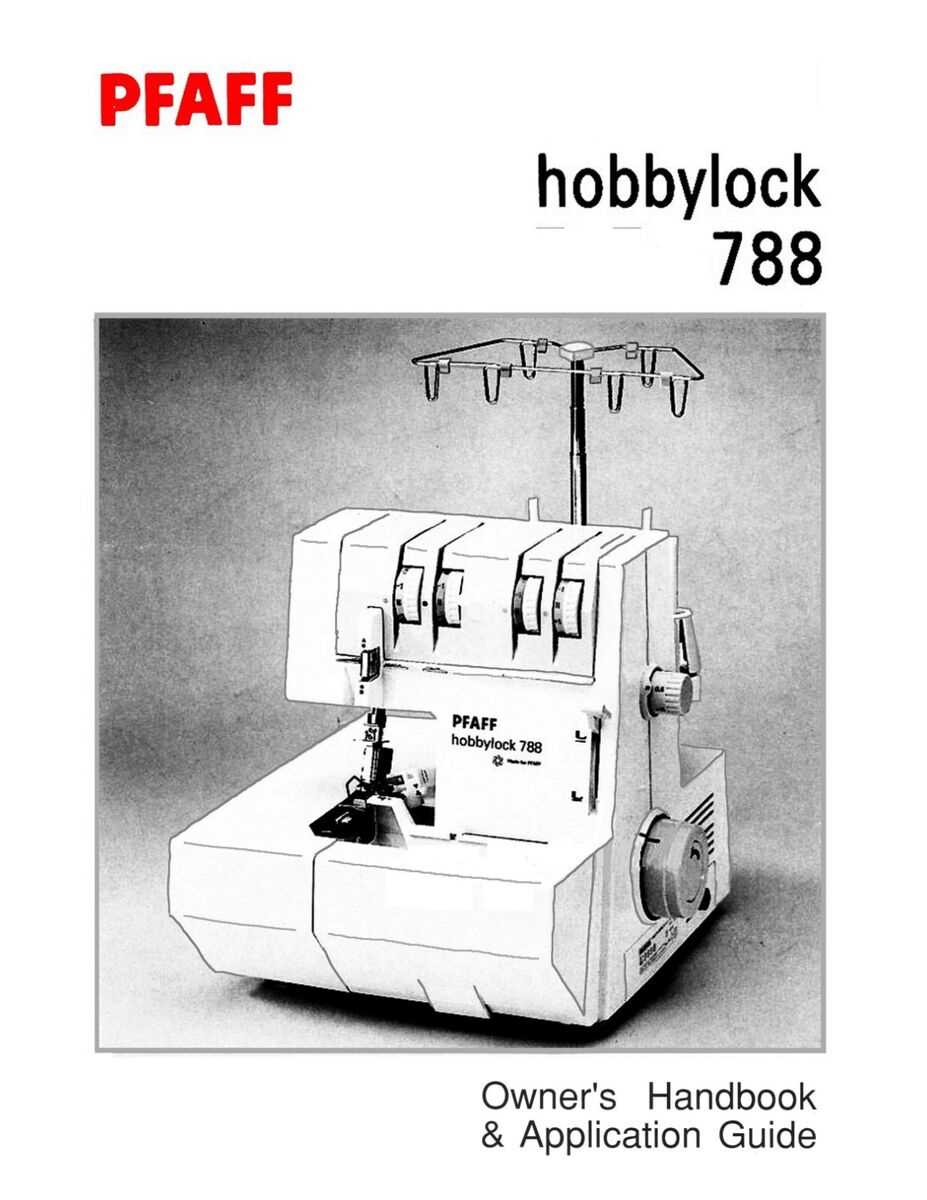

Understanding the Pfaff Hobbylock 788

This section provides insights into a versatile sewing machine designed for both amateur and professional users. With its range of features, it serves as an essential tool for creating intricate stitches and efficiently handling various fabric types.

Key Features

- Multiple threading options for different stitching styles

- Adjustable tension settings for precise control

- Compact design that enhances portability

- Built-in safety mechanisms to prevent accidents

Common Issues and Solutions

- Tension Problems: Check the threading path and adjust the tension dial as necessary.

- Skipped Stitches: Ensure the needle is correctly installed and not damaged.

- Fabric Jamming: Clean the machine and check for any obstructions in the feed mechanism.

Understanding these aspects can significantly enhance the user experience and prolong the lifespan of the device.

Common Issues with the Machine

Every sewing device can encounter certain challenges over time. Understanding these common problems can help users troubleshoot effectively and maintain optimal performance.

- Thread Jamming: This is a frequent issue that can occur due to incorrect threading or the presence of lint and debris in the mechanism.

- Tension Problems: Incorrect tension settings can lead to uneven stitching, causing frustration during the sewing process.

- Needle Breakage: A broken needle can stem from using the wrong type or size for the fabric being worked on, or from improper installation.

- Fabric Feeding Issues: If the material does not feed smoothly, it may be due to worn feed dogs or incorrect presser foot settings.

- Noise During Operation: Unusual sounds might indicate mechanical wear or the need for lubrication in specific parts of the machine.

Addressing these challenges promptly can enhance the lifespan of the device and improve the overall sewing experience.

Essential Tools for Repair

When tackling maintenance tasks on stitching machines, having the right instruments is crucial for achieving optimal results. A well-equipped toolkit not only simplifies the process but also enhances the overall efficiency of adjustments and modifications. Below is an overview of vital implements that should be included in every enthusiast’s collection.

Basic Toolkit

A fundamental set of tools lays the groundwork for successful handling. This assortment typically includes:

| Tool | Purpose |

|---|---|

| Screwdrivers | Used for tightening or loosening screws. |

| Wrenches | Essential for adjusting various nuts and bolts. |

| Scissors | Needed for trimming threads and fabric. |

| Needles | Various types are necessary for different tasks. |

| Thread | Replacement threads in multiple colors and weights. |

Advanced Instruments

For those seeking to delve deeper into the intricacies of machine functionality, additional tools may prove beneficial. These include:

| Tool | Purpose |

|---|---|

| Multimeter | For diagnosing electrical issues. |

| Oil Can | To ensure smooth operation through lubrication. |

| Magnifying Glass | Helps in examining small parts closely. |

| Cleaning Brush | Essential for removing lint and debris. |

| Replacement Parts | Stocking spare components for quick fixes. |

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to identifying and resolving common issues that may arise during the operation of a stitching machine. Following a structured troubleshooting process can help users effectively diagnose problems and implement solutions, ensuring optimal performance.

1. Identify the Issue: Begin by observing the machine’s behavior. Take note of any unusual sounds, stitching irregularities, or error messages. Understanding the specific symptoms will guide the troubleshooting process.

2. Check Threading: Ensure that the threading is correct. Improper threading is a common cause of many issues. Consult the user guide for the proper threading path and confirm that the thread is seated correctly in all tension discs.

3. Inspect Needles: Examine the needles for damage or wear. A bent or dull needle can lead to poor stitching quality. Replace any compromised needles with appropriate replacements.

4. Clean the Machine: Regular maintenance is essential. Dust, lint, and debris can accumulate and interfere with performance. Use a brush or vacuum to clean the machine, especially around the feed dogs and bobbin area.

5. Adjust Tensions: If the stitching is uneven, check the tension settings. Adjust both the upper and lower tensions according to the fabric type and thickness. Test on a scrap piece to ensure the correct balance.

6. Test with Different Fabrics: Sometimes, the issue may arise due to the type of fabric being used. Test the machine with various fabrics to determine if the problem persists across all materials.

7. Seek Professional Assistance: If issues remain unresolved after following these steps, consider consulting a professional technician. Expert evaluation may be necessary for complex problems that require specialized knowledge.

Replacing the Needle and Threading

Replacing the needle and properly threading your sewing machine are essential tasks for maintaining optimal performance and ensuring high-quality stitching. These processes not only enhance the functionality of your device but also contribute to the longevity of your materials and projects.

To begin with, always ensure the machine is powered off before attempting any changes. Start by removing the old needle by loosening the needle clamp screw. Carefully slide out the old needle and replace it with a new one, ensuring it is inserted correctly, typically with the flat side facing the back.

Next, threading the machine can vary slightly depending on the model, but generally involves guiding the thread through various guides and tension discs. Follow the threading path as indicated in the device’s guidelines. Make sure the thread passes through the needle from front to back, securing it firmly.

After replacing the needle and threading, it’s advisable to test the machine on a scrap piece of fabric. This step allows you to check the tension and make any necessary adjustments before starting your actual project.

Adjusting Tension Settings Effectively

Achieving the ideal thread tension is crucial for obtaining professional results in fabric work. Properly calibrated tension settings ensure that stitches are secure, evenly distributed, and visually appealing. Understanding how to adjust these settings can greatly enhance the quality of your projects and prevent common issues such as puckering or thread breakage.

Understanding Thread Tension

Thread tension refers to the amount of pull exerted on the threads during the stitching process. Each type of fabric and thread combination may require different tension levels. Therefore, it is essential to experiment with various settings to find the perfect balance for your specific materials. A well-adjusted tension allows the upper and lower threads to interlock smoothly, creating strong and consistent stitches.

Steps to Adjust Tension

To effectively modify the tension settings, begin by testing on a scrap piece of the same fabric you will be using for your project. Start with the manufacturer’s recommended settings and gradually make small adjustments. Observe the stitch quality, focusing on whether the threads lie flat and if there are any visible loops or puckering. Continue to tweak the tension until the desired outcome is achieved, ensuring a flawless finish in your work.

Cleaning and Maintenance Tips

Proper upkeep of your sewing equipment is essential for ensuring optimal performance and longevity. Regular cleaning and maintenance not only enhance functionality but also prevent potential issues that may arise from neglect. Adopting a few simple practices can keep your machine in excellent condition, allowing for smooth operation and consistent results.

Routine Cleaning Steps

Begin by disconnecting the power source to ensure safety. Remove any fabric remnants and lint from the feed dogs and the surrounding areas using a soft brush or a lint roller. Pay special attention to the bobbin area, as debris can accumulate here and hinder performance. A damp cloth can be used to wipe down the exterior surfaces, keeping them free from dust and grime.

Lubrication and Inspection

Regular lubrication of moving parts is vital for seamless operation. Refer to the equipment’s guidelines for recommended lubricant types and application points. Additionally, periodically check for any signs of wear or damage on components such as belts and needles. Addressing minor issues promptly can prevent more significant problems in the future.

In summary, consistent cleaning and careful maintenance practices will ensure your sewing device operates at its best, providing you with reliable performance and durability for years to come.

Repairing the Cutting Mechanism

Ensuring the proper function of the cutting apparatus is essential for achieving clean and accurate fabric edges. This section focuses on troubleshooting and addressing common issues associated with this critical component. A well-maintained cutting system not only enhances the performance of the machine but also prolongs its lifespan.

Common Issues and Solutions

Identifying typical problems can facilitate a smoother resolution process. Here are some frequent concerns along with their corresponding remedies:

| Issue | Possible Cause | Solution |

|---|---|---|

| Uneven cutting | Worn blades or misalignment | Replace the blades and realign the cutting mechanism |

| Clogged cutting area | Fabric debris buildup | Clean the area thoroughly and ensure proper threading |

| Excessive noise | Loose components | Tighten screws and inspect for wear |

Maintenance Tips

Regular upkeep of the cutting system is vital for optimal functionality. Here are some practical suggestions:

- Lubricate moving parts regularly to reduce friction.

- Check blade sharpness frequently and replace when necessary.

- Keep the cutting area clean to prevent material buildup.

Common Error Codes Explained

Understanding the various indicators that a sewing machine may display can significantly aid in troubleshooting and ensuring smooth operation. This section delves into some frequent codes that users may encounter, offering insights into their meanings and suggested resolutions.

- Error Code 1: This code typically signals a threading issue. Check that the threads are correctly threaded through all necessary guides and tension discs.

- Error Code 2: Often related to fabric tension, this error indicates that the material may be too thick or incorrectly positioned. Adjust the fabric or change the needle type as needed.

- Error Code 3: This code usually points to a malfunction in the needle. Replace the needle if it is bent or dull, ensuring it is the correct type for the project.

- Error Code 4: This error is indicative of a stitch formation problem. Review the machine settings and refer to the manual for correct adjustments to stitch length and width.

- Error Code 5: Often related to the cutting mechanism, this indicates a blockage. Inspect the area for any thread remnants or fabric caught in the blades and clear it out carefully.

By familiarizing yourself with these common codes, you can enhance your troubleshooting skills and maintain the efficiency of your device. Always refer to the device documentation for specific guidance related to your model.

Upgrading Parts for Better Performance

Enhancing the components of your sewing machine can significantly improve its functionality and overall efficiency. By selecting higher-quality materials and modernized parts, you can achieve smoother operation, reduce wear and tear, and increase the longevity of the equipment. This section focuses on key upgrades that can transform your machine into a more reliable and efficient tool for your sewing projects.

| Component | Upgrade Options | Benefits |

|---|---|---|

| Needles | Specialty needles (e.g., stretch, denim) | Improved stitch quality and reduced thread breakage |

| Presser Foot | Walking foot, adjustable foot | Better fabric feed and control over various materials |

| Motor | High-speed motor | Increased speed and power for heavy fabrics |

| Thread Tension System | Upgraded tension discs | More consistent stitching across different fabric types |

| Foot Pedal | Electronic foot control | Smoother speed control and improved responsiveness |

Investing in these enhancements not only boosts the performance of your machine but also makes the sewing experience more enjoyable and efficient.

Where to Find Replacement Parts

Finding suitable components for your sewing machine can be a straightforward process if you know where to look. Numerous resources are available, ranging from online stores to local suppliers, ensuring that you can maintain or enhance your device with the right items.

Online Resources

- Manufacturer’s Website: Check the official site for authorized parts and accessories specifically designed for your model.

- Specialty Retailers: Websites that focus on sewing and crafting supplies often carry a variety of components.

- Marketplaces: Platforms such as eBay or Amazon may list new and used items, often at competitive prices.

Local Options

- Sewing Machine Shops: Local stores that specialize in sewing machines often have parts in stock or can order them for you.

- Craft Stores: Some larger craft retailers carry a selection of sewing supplies, including components for various models.

- Repair Services: Contact local repair shops; they may have spare parts or be able to direct you to where you can find them.