Ensuring the longevity and optimal performance of your vehicle requires a comprehensive understanding of its essential components and systems. This section aims to provide valuable insights into the upkeep of the KX model, emphasizing key procedures and best practices that enhance reliability.

In this guide, you will discover various strategies and techniques tailored to facilitate effective maintenance. From routine checks to troubleshooting common issues, the information presented will equip you with the knowledge needed to keep your vehicle in prime condition. By following these recommendations, you can contribute to the overall efficiency and safety of your ride.

Whether you are a seasoned enthusiast or a new owner, this resource serves as a practical companion in navigating the complexities of vehicle care. Understanding these fundamental aspects will empower you to make informed decisions and tackle maintenance tasks with confidence.

This section provides a comprehensive look at the essential features and characteristics of the KX model. Understanding these specifications is crucial for effective maintenance and optimal performance.

Key Features

- Engine Type: Explore the specifics of the power unit, including displacement and cooling system.

- Transmission: Examine the gearbox configuration and gear ratios that enhance driving dynamics.

- Chassis Design: Review the frame material and geometry that contribute to stability and handling.

Performance Metrics

- Power Output: Assess the horsepower rating and torque characteristics for acceleration and speed.

- Weight: Discuss the overall weight and its impact on maneuverability and control.

- Suspension System: Analyze the front and rear suspension setups for ride comfort and terrain adaptability.

Common Issues and Troubleshooting Tips

This section addresses frequent problems that users may encounter with their vehicles and provides helpful strategies for resolution. Understanding these common challenges can enhance your overall experience and ensure optimal performance.

-

Engine Won’t Start:

If the engine fails to ignite, check the battery connections, fuel supply, and ignition system. Ensure that there are no obstructions preventing airflow to the engine.

-

Overheating:

Overheating can result from low coolant levels or a malfunctioning thermostat. Regularly inspect coolant levels and ensure the radiator is functioning properly.

-

Strange Noises:

Unusual sounds may indicate mechanical issues. Inspect components such as the chain, brakes, and bearings for wear or damage.

-

Loss of Power:

A noticeable decrease in power can stem from fuel delivery problems or clogged air filters. Regular maintenance of these parts is essential.

-

Electrical Issues:

If lights or instruments are malfunctioning, inspect the wiring harness and fuses. Corrosion can often be a culprit, so cleaning connections may help.

By addressing these issues promptly, you can maintain the functionality and longevity of your vehicle.

Essential Tools for Repairing KX 250

To maintain and enhance the performance of your motorcycle, having the right equipment is crucial. A well-equipped toolkit not only facilitates efficient work but also ensures that every task is completed to a high standard.

Below is a list of indispensable items that should be included in your toolkit:

- Wrenches: A set of various sizes is essential for loosening and tightening bolts.

- Sockets and Ratchets: These tools allow for greater leverage and easier access to hard-to-reach fasteners.

- Torque Wrench: This ensures that all components are secured to the correct specifications.

- Screwdrivers: Both flathead and Phillips varieties are necessary for different types of screws.

- Pliers: Useful for gripping, twisting, and cutting wires or cables.

- Oil Filter Wrench: A specialized tool for easy removal of oil filters.

- Cleaning Supplies: Rags, brushes, and solvents help keep the machine clean during maintenance.

Having these tools readily available will streamline your workflow and ensure that you can effectively tackle any task that arises.

Step-by-Step Maintenance Procedures

This section outlines essential practices to ensure optimal performance and longevity of your vehicle. Following these procedures regularly will help maintain its functionality and enhance safety on the road.

Regular Inspection

Start with frequent checks of critical components. This will allow you to identify potential issues before they escalate.

- Check the oil level and quality.

- Inspect the brakes for wear and responsiveness.

- Examine the tires for proper inflation and tread depth.

- Look over the lights and signals to ensure they are operational.

Scheduled Servicing

Adhering to a maintenance schedule is vital for your vehicle’s upkeep. Refer to the manufacturer’s recommendations for guidance.

- Change the oil and replace the oil filter every few thousand miles.

- Replace air filters to improve engine efficiency.

- Flush and refill coolant to prevent overheating.

- Inspect and replace spark plugs as necessary.

Engine Disassembly and Reassembly Guide

This section provides a comprehensive overview of the steps involved in dismantling and reassembling the power unit of your vehicle. Proper execution of these procedures is essential to ensure optimal performance and longevity of the engine.

Before you begin, gather the necessary tools and equipment:

- Socket set

- Torque wrench

- Screwdrivers (flat and Phillips)

- Pliers

- Container for small parts

- Service manual for torque specifications

Follow these steps for disassembly:

- Ensure the engine is cool and the vehicle is on a stable surface.

- Disconnect the battery to prevent any electrical accidents.

- Remove any external components, such as the air filter and exhaust system.

- Carefully detach the fuel lines and electrical connectors.

- Unbolt the engine from its mounts and lift it out of the frame.

- Proceed to disassemble the engine components systematically, noting the order for reassembly.

For reassembly, adhere to the following guidelines:

- Inspect all parts for wear or damage before reinstallation.

- Use new gaskets and seals to ensure a proper fit.

- Follow the reverse order of disassembly, ensuring each component is secured to the manufacturer’s specifications.

- Double-check torque settings with a wrench to avoid over-tightening.

- Reconnect all external components and ensure the engine is properly mounted back into the vehicle.

Finally, perform a thorough inspection before starting the engine to confirm that everything is in place and secure. Following these steps will help maintain the efficiency and reliability of your power unit.

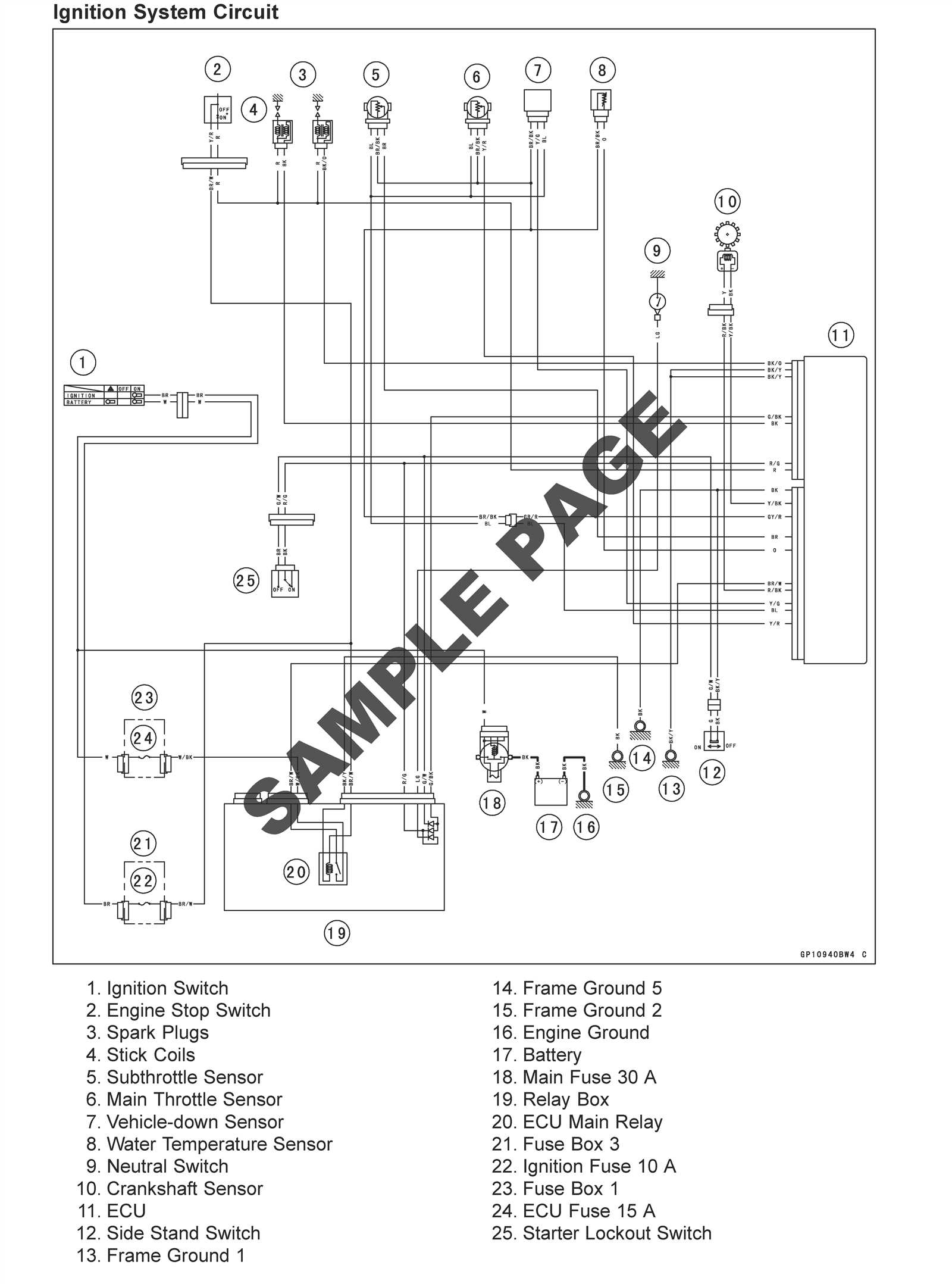

Electrical System Diagnostics and Repair

The electrical system of any vehicle is crucial for its overall functionality and performance. Diagnosing issues within this system requires a systematic approach to identify and address faults effectively. This section provides insights into common problems, diagnostic techniques, and solutions that ensure optimal electrical performance.

Initially, it is essential to check the battery condition and connections, as these are often the root cause of electrical failures. Corrosion or loose terminals can lead to insufficient power supply, affecting various components. Using a multimeter can help assess voltage levels and ensure the battery operates within the required parameters.

Next, inspecting wiring harnesses and connectors is vital. Damaged wires or poor connections can cause intermittent failures. It is advisable to look for frayed insulation or signs of wear. Proper grounding is also critical, as poor ground connections can lead to erratic behavior in electrical components.

Moreover, testing individual components, such as relays, switches, and fuses, can help isolate specific malfunctions. Each component should be evaluated based on its specifications, ensuring it functions correctly within the electrical circuit. If a component fails, replacing it with a high-quality equivalent is recommended.

Finally, documenting all findings and actions taken during the diagnostic process is essential. This record helps track recurring issues and informs future maintenance strategies. A thorough understanding of the electrical system enhances reliability and performance, ensuring the vehicle operates efficiently.

Replacing Worn Parts: Best Practices

Maintaining optimal performance requires periodic attention to components that may show signs of fatigue. Recognizing when to substitute these elements is essential for preserving functionality and safety. This section outlines effective strategies for identifying and replacing aged parts to ensure longevity and reliability.

Assessment of Component Condition

Before proceeding with any substitutions, it is crucial to evaluate the state of the parts meticulously. Look for signs of wear such as cracks, discoloration, or irregularities in function. Regular inspections will help in detecting issues early, allowing for timely intervention.

Choosing the Right Replacements

When selecting new components, prioritize quality and compatibility. Utilizing genuine replacements or reputable alternatives can greatly enhance performance. Additionally, always consult the specifications to ensure that the chosen parts meet the necessary standards for your specific model.

Upgrades and Performance Enhancements

Enhancing the capabilities and efficiency of your machine involves various modifications that can significantly improve its performance. By focusing on key areas such as power output, handling, and overall responsiveness, you can transform your vehicle into a more competitive and enjoyable ride.

| Modification | Description | Benefits |

|---|---|---|

| Exhaust System Upgrade | Replacing the stock exhaust with a high-performance system to improve airflow. | Increased horsepower and torque, reduced weight. |

| Suspension Tuning | Adjusting or replacing suspension components for better handling. | Enhanced stability and cornering performance. |

| Fuel Management System | Installing an aftermarket fuel controller for precise tuning. | Optimized fuel-air mixture for improved efficiency and power. |

| Tyre Upgrade | Switching to high-performance tyres suitable for various terrains. | Better grip and traction for improved acceleration and braking. |

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring a safe environment is paramount. This involves not only protecting oneself but also safeguarding the equipment and workspace. Adhering to specific safety measures can prevent accidents and enhance the overall effectiveness of the process.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear.

- Ensure that the workspace is well-lit and organized to minimize hazards.

- Disconnect any power sources or fuel lines before starting any work.

- Keep a first aid kit readily available in case of emergencies.

Tool Handling and Usage

- Use tools that are specifically designed for the task to avoid injuries.

- Inspect tools for damage before use; replace or repair any defective items.

- Store tools properly after use to prevent tripping hazards.

- Follow the manufacturer’s instructions for all equipment to ensure safe operation.

Regular Maintenance Schedule Recommendations

To ensure optimal performance and longevity of your vehicle, it is crucial to adhere to a structured maintenance routine. This routine helps in identifying potential issues before they escalate and ensures that all components function efficiently. A well-planned schedule not only enhances reliability but also contributes to a safer riding experience.

Weekly Inspections

Conducting weekly checks is essential for maintaining peak operational condition. Focus on examining tire pressure, brake functionality, and fluid levels. Ensure that lights and signals are in working order. Regular inspections can prevent minor problems from becoming significant repairs.

Monthly and Seasonal Maintenance

In addition to weekly assessments, monthly and seasonal upkeep should include detailed inspections of the chain, air filter, and battery. Replace worn components as necessary and clean any debris from critical areas. Performing these tasks routinely enhances performance and extends the lifespan of your machine.

Resources for Additional Support

When encountering challenges or seeking further information regarding your vehicle, a variety of resources can provide valuable assistance. These tools and platforms are designed to enhance your understanding and help you resolve any issues effectively.

Online Forums and Communities

Engaging with online forums and communities allows you to connect with fellow enthusiasts and experts. These platforms often feature discussions on common problems, solutions, and experiences, making them a great place to gather insights and tips from those who share similar interests.

Instructional Videos and Tutorials

Video tutorials offer a visual and step-by-step approach to understanding complex processes. Many channels dedicated to automotive maintenance provide comprehensive guides that can help you navigate various tasks with confidence, making the learning experience more accessible.

Frequently Asked Questions About Repairs

This section aims to address common inquiries related to the maintenance and restoration of your vehicle. Here, you will find valuable insights and guidance to help you navigate the most pressing concerns that arise during the upkeep process.

One of the most frequently posed questions involves the best practices for ensuring longevity and optimal performance. Regular check-ups and timely interventions are essential in preventing minor issues from escalating into significant problems.

Another common inquiry pertains to the appropriate tools and techniques required for effective servicing. Utilizing the right equipment can make a considerable difference in the efficiency and quality of the work performed.

Many individuals also wonder about the signs indicating the need for professional assistance. Recognizing these indicators early can save both time and resources, ensuring that your vehicle remains in top condition.

Finally, it is essential to consider how to document and track the history of maintenance. Keeping detailed records not only aids in future servicing but also enhances the resale value of your vehicle.