Understanding the intricacies of machinery designed for liquid conveyance is essential for optimal performance and longevity. This section delves into essential practices and guidelines to ensure these devices function efficiently. Regular upkeep and troubleshooting techniques are vital for addressing common challenges faced by users.

Familiarizing yourself with various components is crucial for effective management. Knowledge about assembly, disassembly, and operational principles empowers users to tackle issues independently. Emphasizing systematic examination techniques can significantly enhance the troubleshooting process.

Additionally, learning about specific maintenance routines tailored to these systems can prevent unnecessary downtime and costly repairs. By adopting proactive measures and understanding the nuances of operation, individuals can ensure the reliability of their equipment, thereby achieving consistent results in their applications.

Understanding Goulds Water Pumps

This section delves into the intricacies of these essential devices designed for fluid movement. Their fundamental purpose lies in efficiently transferring liquids from one location to another, ensuring a seamless flow for various applications. Knowledge of their components and functionality is crucial for optimal performance and longevity.

These mechanisms typically consist of a motor, impeller, and casing, each playing a vital role in the overall operation. The motor provides the necessary energy to initiate movement, while the impeller facilitates the fluid’s acceleration and direction. The casing encases these components, allowing for a controlled environment where fluid dynamics can occur effectively.

Regular assessment and maintenance of these systems can greatly enhance their efficiency and lifespan. Understanding the signs of potential issues, such as unusual noises or fluctuations in performance, enables users to take proactive measures, ensuring uninterrupted service. Additionally, familiarity with installation protocols and operational guidelines contributes to their reliable function, making them indispensable in many settings.

Common Issues in Water Pump Operation

When it comes to the functioning of fluid-moving devices, various challenges may arise that hinder optimal performance. Recognizing these common complications can lead to more effective troubleshooting and maintenance practices.

- Insufficient Flow Rate: A decrease in the expected flow can result from blockages, leaks, or improper installation.

- Noisy Operation: Unusual sounds may indicate mechanical wear or issues with the motor components.

- Overheating: Excessive heat often stems from lack of lubrication, insufficient cooling, or overloading the system.

- Vibration: This can be caused by misalignment, imbalance, or worn-out bearings.

- Frequent Cycling: This issue may occur when the device is unable to maintain pressure due to faulty sensors or leaks.

Identifying and addressing these common problems early can prolong the lifespan of the equipment and ensure reliable operation. Regular maintenance checks and timely interventions are essential to prevent significant malfunctions.

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing issues with your equipment. By following a systematic method, you can effectively diagnose and resolve problems, ensuring optimal performance and longevity.

Initial Assessment

Begin by evaluating the device to identify any visible signs of malfunction. This may include:

- Inspecting for leaks or unusual noises

- Checking connections and components for damage

- Ensuring power supply is functioning correctly

Disassembly and Inspection

Once initial issues are noted, proceed with disassembling the unit carefully. Follow these steps:

- Gather necessary tools for disassembly.

- Document the assembly process to aid in reassembly.

- Inspect each part for wear and tear, replacing any damaged components.

After thorough examination, reassemble the device carefully, ensuring all parts are secured properly. Conduct a final test to confirm the functionality has been restored.

Tools Needed for Effective Repairs

When undertaking maintenance tasks, having the right instruments at your disposal can significantly enhance the efficiency and effectiveness of your efforts. A well-equipped workspace not only streamlines the process but also minimizes the risk of damage to components. Below are essential implements that should be considered for optimal functionality.

Essential Hand Tools

- Screwdrivers: A set of various sizes, including flathead and Phillips, is crucial for loosening or tightening screws.

- Wrenches: Both adjustable and fixed types will help in gripping and turning nuts and bolts.

- Pliers: Needle-nose and standard pliers are useful for holding, twisting, or cutting wires.

Specialized Equipment

- Multimeter: This device measures voltage, current, and resistance, aiding in diagnosing electrical issues.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications, preventing over-tightening.

- Diagnostic Tools: Software or hardware that helps in troubleshooting performance problems.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular upkeep and attention. By following a systematic approach to maintenance, you can enhance performance and extend its operational life. This section provides essential practices that contribute to long-lasting functionality.

| Tip | Description |

|---|---|

| Regular Inspections | Conduct frequent checks to identify any signs of wear or potential issues. Early detection can prevent costly damage. |

| Proper Cleaning | Keep components free from debris and contaminants. Regular cleaning helps maintain optimal efficiency and prevents blockages. |

| Lubrication | Ensure moving parts are adequately lubricated. This reduces friction and wear, promoting smooth operation. |

| Temperature Control | Avoid exposing the equipment to extreme temperatures. Maintaining a stable environment supports proper functioning. |

| Follow Guidelines | Adhere to the manufacturer’s recommendations regarding operation and maintenance schedules to ensure reliability. |

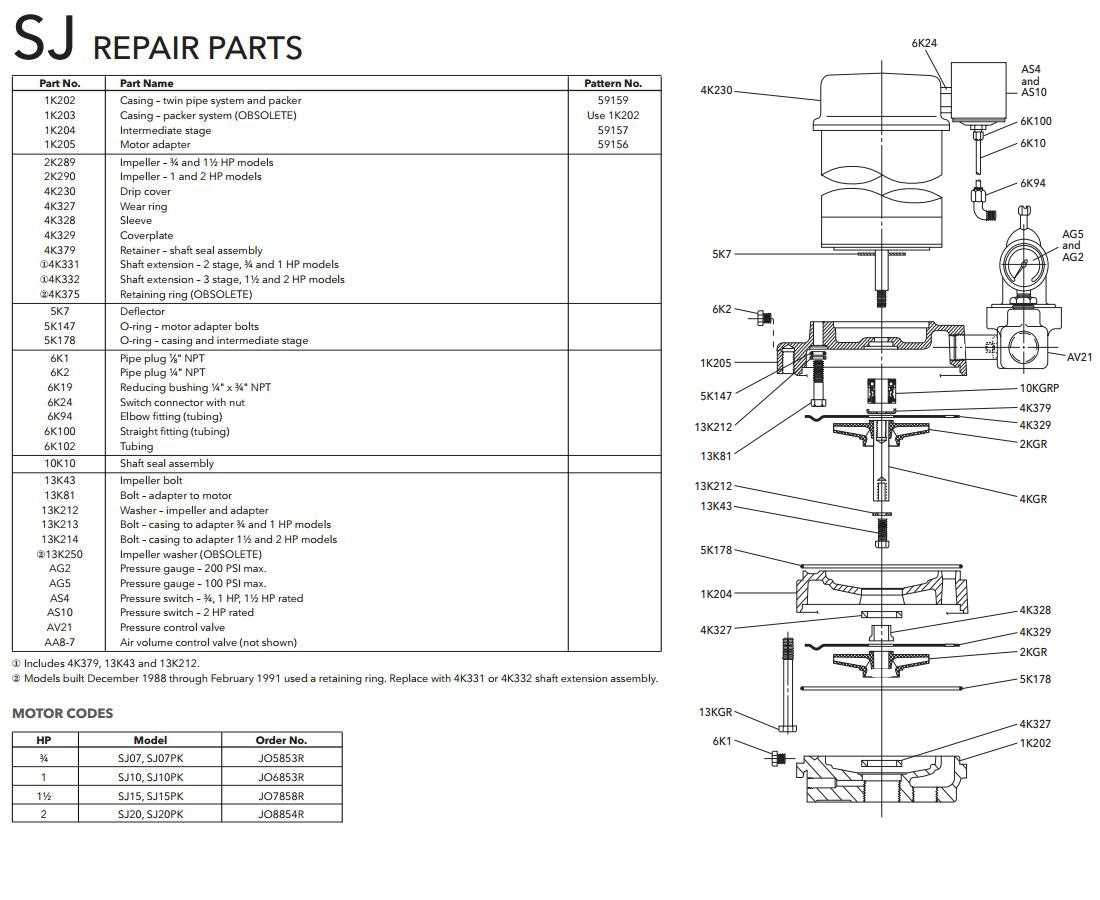

Identifying Pump Model Specifications

Understanding the unique characteristics of various models is essential for effective servicing and maintenance. Each design has specific features and performance metrics that influence its operation and longevity. Recognizing these details can significantly enhance troubleshooting efforts and ensure optimal functionality.

Key Characteristics to Consider

When examining a model, it is vital to focus on several attributes. These include the capacity, power requirements, and construction materials. Each of these elements plays a critical role in determining the suitability of a device for particular tasks. For instance, the capacity defines the volume it can handle, while the power specifications dictate energy consumption and efficiency.

Locating Model Information

Model specifications are typically found on identification tags affixed to the equipment. This information may include alphanumeric codes that signify various features and manufacturing details. Familiarizing yourself with how to interpret these codes is crucial for effective identification and subsequent service actions.

Troubleshooting Electrical Problems

When facing issues related to electrical systems, it is essential to systematically identify and address the underlying causes. This process involves checking various components and connections to ensure everything is functioning as intended. By following a methodical approach, users can effectively diagnose and rectify malfunctions.

Begin by inspecting all power sources. Ensure that the device is properly connected to an operational outlet, and verify that any switches are in the correct position. A tripped circuit breaker or blown fuse can also be common culprits behind electrical failures.

Next, examine wiring and connections. Look for any signs of damage, such as frayed wires or loose terminals. Ensuring that all connections are secure can often resolve connectivity issues. Additionally, checking for corrosion at terminals can prevent further complications.

Consider testing individual components. If specific parts can be isolated, using a multimeter to measure voltage and resistance can help determine if they are functioning correctly. This step is crucial for identifying faulty components that may require replacement.

Lastly, document your findings and any repairs made during the troubleshooting process. Keeping a record helps track recurring issues and can provide insights for future maintenance, ensuring long-lasting functionality.

Replacing Worn-Out Components

Over time, certain parts of a device may experience wear and tear, impacting its overall functionality. Addressing these issues promptly can enhance performance and extend the lifespan of the system. Understanding which components are susceptible to degradation is crucial for effective maintenance.

Common signs that indicate the need for component replacement include:

- Decreased efficiency or performance

- Unusual noises during operation

- Visible signs of damage or corrosion

When considering replacements, follow these steps:

- Identify the specific parts that require attention.

- Consult the specifications to ensure compatibility with your system.

- Carefully remove the old components using appropriate tools.

- Install the new parts, ensuring proper alignment and fit.

- Test the system to confirm improved operation.

Regularly monitoring and replacing aging parts can significantly improve reliability and efficiency, ultimately saving time and resources in the long run.

Sealing and Gasket Considerations

When it comes to maintaining the integrity of various mechanical systems, the importance of effective sealing cannot be overstated. Proper gaskets and seals play a crucial role in preventing leaks, ensuring optimal performance, and extending the lifespan of the components involved. Understanding the materials and techniques related to sealing can significantly impact functionality and reliability.

Material Selection

Choosing the right material for gaskets and seals is essential for effective operation. Various options are available, each with its unique properties:

- Rubber: Flexible and resilient, suitable for a range of applications.

- Metal: Provides durability and can withstand high temperatures and pressures.

- Composite: Combines different materials to enhance performance characteristics.

Installation Techniques

Proper installation is as critical as the materials used. Here are some best practices:

- Ensure surfaces are clean and free from debris before applying seals.

- Use appropriate torque specifications to avoid over-tightening.

- Inspect for any signs of wear or damage during installation.

By focusing on the right materials and installation methods, users can enhance the effectiveness of sealing solutions and contribute to the overall efficiency of their systems.

Flow Rate and Performance Adjustments

Understanding the dynamics of fluid movement is crucial for optimizing system efficiency. Adjustments to the flow rate can significantly impact overall performance, ensuring that the system operates within the desired parameters. By fine-tuning these aspects, users can enhance the functionality and longevity of their equipment.

Factors Influencing Flow Rate

Several elements play a pivotal role in determining fluid flow. These include the diameter of the conduit, the viscosity of the liquid, and the overall system pressure. Monitoring these factors allows for timely adjustments, which can lead to improved operational effectiveness.

Optimizing Performance

To achieve optimal performance, users should regularly assess the settings and make necessary modifications based on specific needs. Utilizing adjustable components and maintaining clean filters can help maintain consistent flow rates, leading to better performance and energy efficiency.

Safety Precautions During Repair

Ensuring a secure working environment is crucial when undertaking maintenance tasks. Adhering to proper guidelines not only protects the individual but also extends the lifespan of the equipment involved. Following a set of safety measures can significantly reduce risks associated with the job.

- Always wear appropriate personal protective equipment (PPE), such as gloves and safety goggles.

- Disconnect power sources before starting any maintenance work to prevent accidents.

- Ensure the workspace is clean and free of clutter to avoid tripping hazards.

- Use tools correctly and inspect them for damage before use.

- Follow manufacturer instructions for disassembly and reassembly to avoid injury.

- Keep flammable materials away from the work area to minimize fire risk.

By prioritizing safety and remaining vigilant, individuals can effectively mitigate hazards during maintenance activities.

Resources for Further Assistance

When facing challenges with your equipment, having access to reliable resources can significantly enhance your understanding and problem-solving capabilities. Numerous platforms offer valuable insights, guidelines, and community support to aid in troubleshooting and maintenance.

Online Forums and Communities

Engaging with fellow users can provide practical solutions and shared experiences. Consider the following platforms:

- Dedicated Discussion Boards: Explore specialized forums where enthusiasts and experts exchange knowledge.

- Social Media Groups: Join relevant groups on platforms like Facebook or Reddit to connect with a broader audience.

- Video Tutorials: Platforms like YouTube feature step-by-step guides and demonstrations from skilled individuals.

Official Support Channels

For professional guidance, utilizing official resources is advisable. Here are some options:

- Manufacturer’s Website: Access comprehensive documentation, FAQs, and contact information for customer support.

- User Manuals: Download specific documents that outline features, troubleshooting steps, and operational guidelines.

- Customer Service: Reach out to support representatives for personalized assistance and expert advice.