Ensuring the longevity and safety of flying vehicles is paramount in the aviation industry. This section delves into the comprehensive processes and best practices aimed at preserving the essential framework of these machines. It highlights critical techniques that support maintaining operational efficacy and adhering to safety regulations.

Understanding the underlying principles involved in the upkeep of aviation structures is essential for professionals in the field. Knowledge of various methods and tools allows technicians to address issues that may compromise performance and safety. The guidance provided here is designed to enhance the skills required for effective intervention and enhance overall durability.

Adhering to industry standards is crucial when undertaking any form of maintenance. This segment outlines key procedures and considerations that facilitate a thorough examination and restoration of integral components. By following these established practices, experts can ensure that their interventions contribute positively to the lifespan and reliability of these vital machines.

Understanding Structural Repairs in Aviation

In the realm of aviation, maintaining the integrity of flying machines is paramount. This section delves into the essential practices involved in addressing damages and ensuring safety in the skies. It highlights the methodologies and considerations necessary for restoring functionality and reliability.

Key aspects to consider include:

- Assessment of Damage: Identifying the extent and nature of the issues present.

- Materials Used: Selecting appropriate substances for reinforcements and fixes.

- Techniques and Tools: Employing various methods and equipment tailored for effective interventions.

- Regulatory Compliance: Adhering to industry standards and guidelines to ensure safety.

Through a systematic approach, professionals can effectively tackle challenges and extend the operational lifespan of their machines.

Furthermore, continuous education and training are crucial in keeping personnel updated on the latest advancements and best practices. As technology evolves, so do the strategies for enhancing the resilience of flying vehicles.

- Regular inspections to identify potential vulnerabilities.

- Documentation of procedures and outcomes for future reference.

- Collaboration among teams to share knowledge and experiences.

Ultimately, the aim is to cultivate an environment of safety and reliability, ensuring that every flight is as secure as possible.

Importance of Aircraft Structural Integrity

The soundness of an aircraft’s framework is crucial for ensuring safety and efficiency during flight operations. It serves as the backbone that supports various components, allowing for the reliable performance of the vehicle under varying conditions. Without maintaining this integrity, the risks associated with operation significantly increase, potentially endangering both passengers and crew.

Safety Considerations

Ensuring the robustness of the framework directly influences the overall safety of the flight. Regular assessments and maintenance help to identify and address potential weaknesses before they escalate into critical failures. In this context, a comprehensive approach to monitoring and upkeep is essential to prevent accidents and enhance the longevity of the vehicle.

Operational Efficiency

In addition to safety, the durability of the framework affects the operational efficiency of the vehicle. A well-maintained structure allows for optimal aerodynamics, fuel efficiency, and performance under various flight conditions. Therefore, prioritizing the integrity of the framework not only safeguards lives but also contributes to the economic viability of aviation operations.

Types of Structural Damage

Understanding the various forms of damage that can occur in aviation vehicles is crucial for ensuring safety and longevity. Different categories of impairments can arise due to external forces, material fatigue, or manufacturing defects, each requiring careful assessment and intervention.

One common type of impairment is deformation, which can occur from impact or excessive loads. This may lead to misalignment of components, affecting overall performance. Another significant category includes corrosion, often resulting from environmental exposure, which can weaken materials over time and compromise integrity.

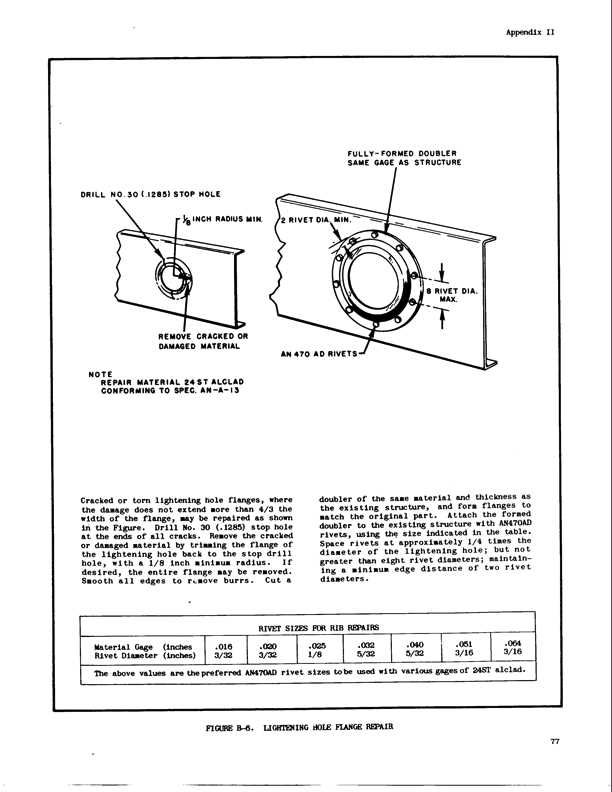

Fatigue cracks are also prevalent, particularly in areas subjected to repeated stress cycles. These fractures can propagate silently, posing serious risks if not detected early. Additionally, there can be issues related to bonding failures, where adhesive joints weaken, leading to separations that affect structural cohesion.

Finally, delamination is a concern, especially in composite materials, where layers may separate, reducing strength and stability. Each of these damage types necessitates specific evaluation methods and solutions to restore functionality and safety.

Materials Used in Aircraft Repair

In the realm of aviation maintenance, the selection of appropriate components is crucial for ensuring the longevity and safety of flying vehicles. Various substances are employed, each offering unique properties that cater to specific requirements. Understanding these materials allows technicians to make informed choices that enhance performance and reliability.

Commonly Used Materials

A variety of materials are utilized in the maintenance of flying vehicles. These range from metals to composites, each chosen based on their mechanical characteristics and compatibility with the overall structure. Below is a summary of some of the most frequently used substances.

| Material Type | Properties | Applications |

|---|---|---|

| Aluminum Alloys | Lightweight, corrosion-resistant, high strength-to-weight ratio | Fuselage, wings, control surfaces |

| Titanium | High strength, low density, excellent corrosion resistance | Engine components, fasteners, critical structural parts |

| Carbon Fiber Composites | Very lightweight, high stiffness, resistant to fatigue | Wings, fuselage skins, internal structures |

| Steel Alloys | High tensile strength, good toughness, relatively heavy | Landing gear, engine mounts, heavy structural components |

| Epoxy Resins | Strong adhesion, excellent chemical resistance, versatile | Bonding composites, repairing damaged surfaces |

Considerations in Material Selection

Choosing the right substances involves evaluating factors such as weight, strength, fatigue resistance, and environmental exposure. Each component must not only fulfill its intended purpose but also comply with industry standards to ensure the safety of operations. Continuous advancements in material science contribute to the development of innovative solutions that further enhance the capabilities of aviation technologies.

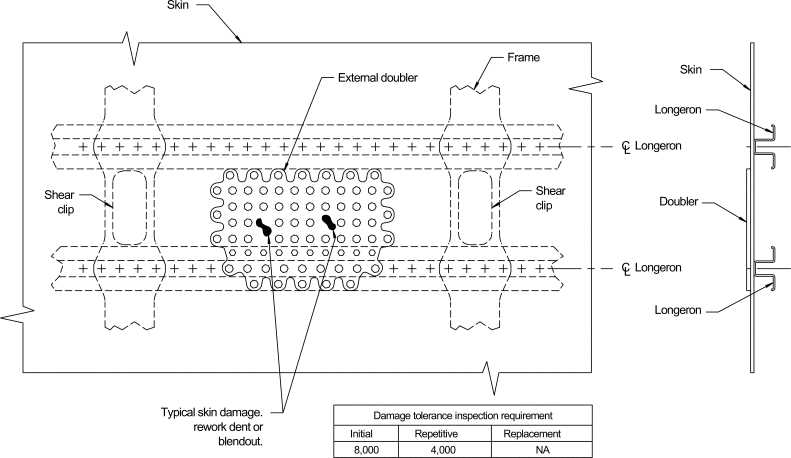

Inspection Techniques for Structural Issues

Identifying and addressing underlying issues within a vehicle’s framework is crucial for ensuring safety and performance. Employing various examination methods allows technicians to detect potential problems early, thereby preventing more significant failures. This section outlines key techniques utilized in the evaluation of framework integrity.

- Visual Inspection: The most fundamental technique, involving a thorough examination of the surface for any visible signs of damage, corrosion, or wear. Key aspects to look for include:

- Cracks

- Dents

- Surface discoloration

- Ultrasonic Testing: This non-destructive method uses high-frequency sound waves to detect internal flaws. Benefits include:

- Ability to assess thickness

- Detection of hidden cracks

- Magnetic Particle Inspection: Ideal for ferromagnetic materials, this technique identifies surface and near-surface discontinuities by applying a magnetic field and introducing iron particles. It is effective for:

- Detecting surface-breaking defects

- Assessing weld integrity

- Dye Penetrant Inspection: This method involves applying a visible or fluorescent dye to reveal surface-breaking flaws. The process includes:

- Cleaning the surface

- Applying the penetrant

- Inspecting after development

lessCopy code

Regular implementation of these techniques not only enhances safety but also extends the lifespan of critical components. Proper training and adherence to protocols ensure accurate assessments and effective management of issues as they arise.

Common Repair Methods Explained

In the field of aviation maintenance, various techniques are employed to address damages and ensure safety. Understanding these methods is crucial for technicians and engineers who strive to uphold the highest standards of performance and reliability. This section delves into widely used approaches that facilitate effective restoration, each suited to different types of issues encountered during inspections.

Bonding is a prevalent technique that involves the use of adhesives to join materials together. This method is particularly effective for lightweight components, allowing for a seamless integration without adding significant weight. The strength of the bond depends on the preparation of surfaces and the type of adhesive used.

Replacement is another common strategy, where damaged sections are removed and substituted with new or refurbished parts. This approach is often chosen when the integrity of the original material is compromised, ensuring that the overall structure remains robust and secure.

Reinforcement involves adding additional material to enhance the strength of a specific area. This can be achieved through various means, such as applying composite patches or inserting support plates. This method is particularly useful in zones subjected to high stress or where previous repairs may have failed.

Welding, though less frequently used in modern designs, remains a vital technique for metallic components. This process fuses materials by applying heat, creating a strong joint. Proper technique and material compatibility are essential to prevent further damage or weakening of the structure.

Each of these methods serves a distinct purpose and is chosen based on the nature of the damage and the materials involved. Mastery of these techniques is essential for professionals in the field, ensuring both safety and efficiency in maintenance practices.

Regulatory Standards for Repairs

Ensuring the integrity and safety of flying vehicles involves adhering to a set of established guidelines. These standards provide a framework that governs the procedures and practices necessary for restoring components to their original functionality. Compliance with these regulations is crucial for maintaining operational efficiency and safeguarding passengers.

International and National Guidelines

Various organizations, both on a global and national scale, have established protocols that dictate how maintenance tasks should be carried out. These include the International Civil Aviation Organization (ICAO) and local aviation authorities, which outline requirements for personnel qualifications, materials used, and testing methods. Adherence to these guidelines helps ensure uniformity and high standards across the industry.

Documentation and Record Keeping

Maintaining accurate records is essential for demonstrating compliance with the established regulations. Every intervention must be documented, detailing the procedures followed, materials utilized, and outcomes achieved. This documentation not only provides accountability but also serves as a reference for future inspections and evaluations, thereby enhancing overall safety and reliability.

Tools Required for Structural Repairs

Ensuring the integrity of various components in aviation requires a range of essential instruments. The right tools not only facilitate the execution of tasks but also enhance safety and precision throughout the process.

Below is a list of critical items that are typically needed for effective interventions:

- Hand Tools

- Wrenches

- Screwdrivers

- Pliers

- Hammers

- Power Tools

- Drills

- Saws

- Grinders

- Sanders

- Measuring Instruments

- Calipers

- Tape measures

- Levels

- Micrometers

- Specialized Equipment

- Rivet guns

- Torque wrenches

- Ultrasonic testers

- Non-destructive testing tools

Using appropriate instruments enhances the efficiency of the work and ensures adherence to safety protocols, ultimately leading to successful outcomes.

Safety Protocols During Repairs

Ensuring the well-being of personnel and the integrity of the environment is paramount when undertaking maintenance tasks. Following established safety protocols mitigates risks and fosters a culture of vigilance among workers. Adherence to these guidelines not only protects individuals but also enhances the overall efficiency of operations.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and helmets.

- Conduct thorough inspections of tools and equipment before use to identify any defects.

- Implement proper lifting techniques to avoid injuries when handling heavy components.

- Maintain a clean and organized workspace to reduce hazards and facilitate quick access to tools.

- Ensure proper ventilation in enclosed areas to prevent inhalation of harmful substances.

Emergency Preparedness

- Familiarize all personnel with emergency exit routes and evacuation procedures.

- Keep first aid kits readily accessible and regularly stocked.

- Conduct regular safety drills to ensure readiness for various emergency scenarios.

- Designate safety officers to oversee compliance and address any potential hazards.

Documentation and Reporting Requirements

This section outlines the essential guidelines for maintaining comprehensive records and effective communication throughout the assessment and correction processes. Proper documentation is crucial for ensuring accountability, traceability, and adherence to established protocols, thereby enhancing safety and reliability.

Detailed Records: Every intervention should be meticulously documented, including the specifics of inspections, findings, and the actions taken. These records serve as a vital resource for future evaluations and audits, allowing for informed decision-making and continuous improvement.

Reporting Protocols: Adhering to standardized reporting formats is necessary to ensure consistency and clarity. Reports should include a summary of activities, any discrepancies identified, and recommendations for further actions. Timely submission of these documents is critical for maintaining compliance with regulatory standards.

Review and Approval Processes: All documentation must undergo a rigorous review and approval process before being finalized. This step guarantees that all information is accurate, complete, and meets the required guidelines. Stakeholders should be involved in this process to foster transparency and collaboration.

Training and Awareness: Regular training sessions for personnel involved in documentation and reporting are essential. This ensures that all team members are familiar with the protocols and understand the importance of accurate record-keeping and reporting in enhancing operational integrity.

In summary, the systematic approach to documentation and reporting is vital for achieving operational excellence and ensuring safety standards are upheld throughout the lifecycle of the equipment.

Challenges in Structural Maintenance

The process of maintaining the integrity of a flying machine involves various hurdles that professionals must navigate. Ensuring that the frame and components remain safe and functional requires meticulous attention to detail and adherence to strict protocols. Factors such as environmental conditions, material fatigue, and the complexity of designs contribute to the difficulties faced in this field.

One significant challenge is the assessment of wear and tear over time. Identifying subtle signs of deterioration can be tricky, as many issues may not be visible to the naked eye. This necessitates the use of advanced diagnostic tools and techniques, which can be costly and time-consuming.

Another obstacle is compliance with evolving regulations and standards. As technology advances, so do the guidelines governing maintenance practices. Keeping up with these changes requires continuous education and training for personnel, which can strain resources and budgets.

Furthermore, the availability of replacement parts poses a challenge. Depending on the age and model of the vehicle, sourcing the necessary components can be difficult, leading to potential delays in service and increased operational costs.

Finally, effective communication among maintenance teams is crucial. Misunderstandings or lack of coordination can lead to errors that jeopardize safety. Establishing clear protocols and fostering a collaborative environment is essential to overcoming these challenges.

Future Trends in Aircraft Repair

The landscape of aviation maintenance is evolving rapidly, driven by technological advancements and a growing emphasis on efficiency and safety. As the industry looks toward the future, new methodologies and innovations promise to enhance the way professionals address the needs of their fleets. This section explores the emerging trends that are shaping the maintenance sector, highlighting the potential benefits and challenges that lie ahead.

Technological Innovations

One of the most significant shifts in the maintenance domain is the integration of cutting-edge technologies. The use of data analytics, artificial intelligence, and predictive maintenance is transforming traditional practices. These tools enable technicians to anticipate issues before they escalate, reducing downtime and increasing operational reliability.

Materials and Processes

The future also points towards advancements in materials and manufacturing processes. Lightweight composites and advanced alloys are gaining traction, offering greater durability and performance. Additionally, 3D printing is emerging as a viable option for producing spare parts, allowing for quicker turnaround times and reduced inventory costs.

| Trend | Description | Benefits |

|---|---|---|

| Data Analytics | Utilizing big data to monitor performance and predict maintenance needs. | Increased efficiency and reduced operational costs. |

| 3D Printing | On-demand production of components and parts. | Faster repairs and lower inventory management costs. |

| Lightweight Materials | Use of advanced composites to enhance performance. | Improved fuel efficiency and extended service life. |

Training for Aircraft Repair Technicians

The foundation for proficient technicians in the aviation sector lies in comprehensive training programs. These initiatives equip individuals with the essential skills and knowledge required to ensure safety and efficiency in the field. A structured educational approach not only fosters technical expertise but also instills a deep understanding of industry standards and practices.

Key Components of Training Programs

- Theoretical Knowledge

- Hands-On Experience

- Safety Regulations

- Tools and Equipment Proficiency

- Problem-Solving Techniques

Certification and Continuous Learning

Obtaining certification is a crucial step for professionals aiming to validate their expertise. Furthermore, ongoing education is vital to stay updated with the latest technological advancements and regulatory changes. Participation in workshops and seminars enhances practical skills and fosters networking opportunities within the industry.

- Initial Training

- Certification Process

- Continuing Education