In the realm of automotive care, having access to detailed guidelines can significantly enhance the longevity and performance of any vehicle. This resource serves as a thorough reference, offering essential insights into various aspects of upkeep, from routine checks to more complex issues that may arise over time.

Understanding the intricacies of a vehicle’s operation is crucial for both novice and experienced enthusiasts. This guide encompasses a wide array of topics, including engine performance, transmission functions, and overall mechanical systems. With practical tips and step-by-step instructions, readers will be empowered to tackle challenges effectively.

Furthermore, familiarity with specific components and their functions can lead to more informed decision-making when it comes to maintenance and repairs. Whether it’s diagnosing unusual noises or addressing performance declines, this resource aims to equip users with the knowledge needed to ensure optimal functionality and safety.

Understanding the 1997 Ford F350 Diesel

This section delves into the features and characteristics of a specific heavy-duty vehicle renowned for its robust performance and reliability. Designed for both work and leisure, this model stands out in the automotive landscape for its durability and capability.

Key Features

- Powerful engine options for superior torque and towing capacity.

- Sturdy chassis designed to withstand heavy loads.

- Spacious interior offering comfort during long journeys.

- Advanced technology for its time, enhancing driving experience.

Maintenance Considerations

- Regular oil changes to ensure engine longevity.

- Routine checks on the braking system for safety.

- Inspection of the electrical system to prevent issues.

- Monitoring tire condition and alignment for optimal performance.

Understanding these aspects will help in appreciating the engineering and design that make this vehicle a trusted choice for many drivers.

Common Issues and Troubleshooting Tips

Vehicles may experience various challenges over time, and understanding these can greatly enhance maintenance efforts. Addressing common problems proactively can save both time and resources, ensuring reliable performance. This section highlights frequent complications encountered by owners and offers effective strategies for resolution.

Engine Performance Problems

One of the most prevalent issues is reduced engine efficiency, often manifested as sluggish acceleration or stalling. Common causes include fuel system blockages, air intake obstructions, or faulty sensors. To troubleshoot, check for clogged fuel filters and ensure that air passages are clear. Additionally, utilizing diagnostic tools can help identify sensor malfunctions that may require recalibration or replacement.

Electrical System Failures

Electrical anomalies can lead to a variety of symptoms, such as difficulty starting or malfunctioning lights. These issues might stem from worn-out batteries, corroded connections, or blown fuses. To resolve these, begin by inspecting the battery terminals for corrosion and testing the battery voltage. Replacing any damaged wiring or fuses can also restore normal functionality.

Essential Tools for DIY Repairs

Engaging in hands-on maintenance and enhancement of your vehicle requires a fundamental set of instruments. These tools not only simplify the tasks at hand but also ensure that the work is carried out efficiently and safely. Below is a compilation of must-have items for any enthusiast looking to undertake vehicle projects.

Basic Hand Tools

- Wrenches: A variety of sizes is essential for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips types will cover most needs.

- Pliers: Useful for gripping, twisting, and cutting wires or components.

- Socket Set: Allows for easy access to fasteners in tight spaces.

Specialized Equipment

- Jack and Stands: Necessary for lifting the vehicle safely for undercarriage work.

- Diagnostic Scanner: Helps in identifying issues through error codes.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Multimeter: Essential for electrical troubleshooting and testing circuits.

Equipping yourself with these essential tools will facilitate a smoother process in addressing your vehicle’s needs. Regular maintenance and improvements become more manageable when you have the right instruments at your disposal.

Maintenance Practices for Longevity

Implementing consistent upkeep routines is essential for ensuring the extended lifespan of any vehicle. By adopting sound practices, owners can enhance performance, reliability, and overall efficiency. Prioritizing maintenance not only preserves the integrity of components but also reduces the likelihood of costly repairs in the future.

Regular Inspections

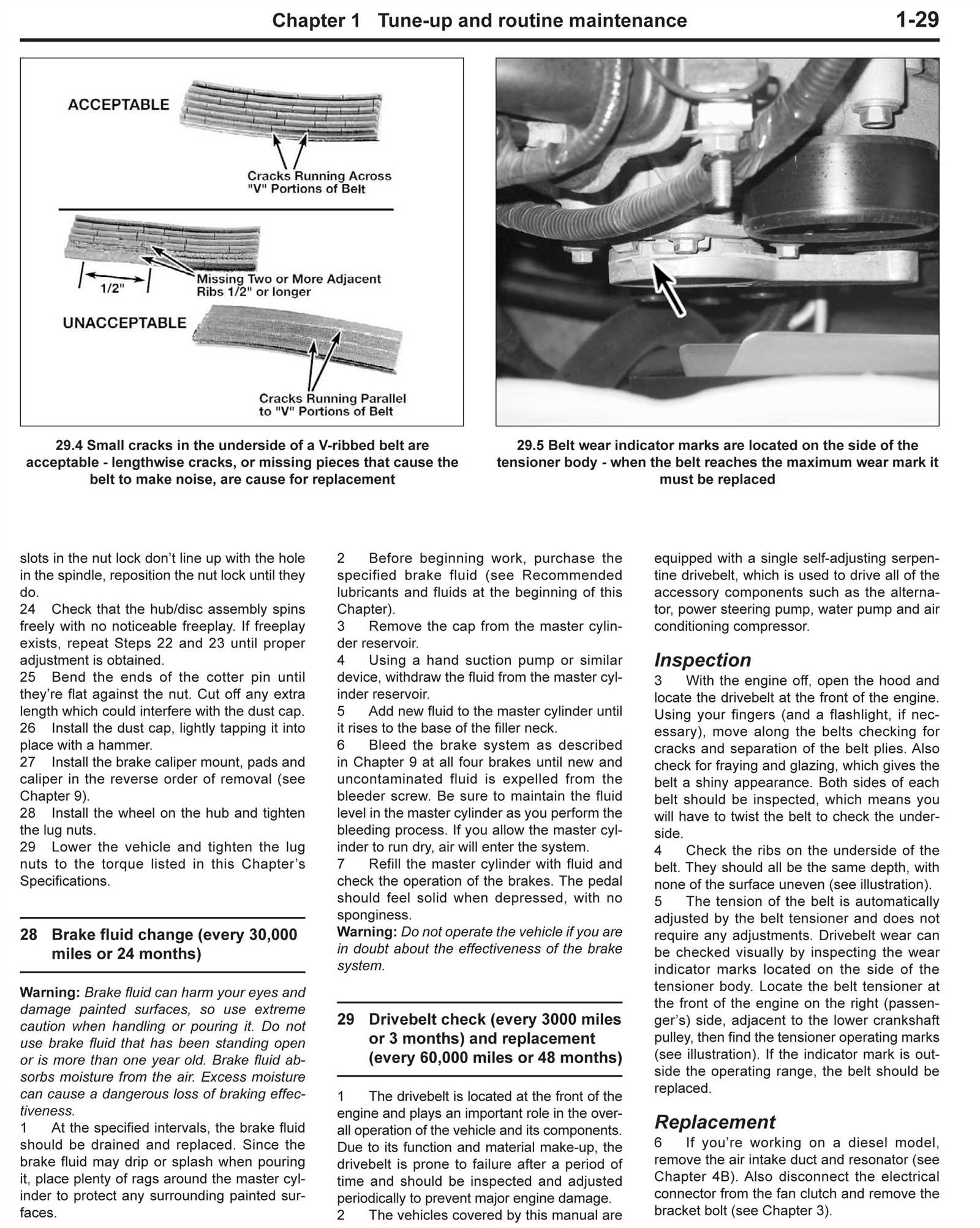

Conducting frequent evaluations of critical systems is vital. Check fluid levels, filters, and belts regularly to identify any signs of wear or damage. This proactive approach can prevent unexpected breakdowns and keep the vehicle operating smoothly.

Fluid Changes and Filter Replacements

Routine fluid changes and replacing filters are key aspects of maintenance. Engine oil, transmission fluid, and coolant should be changed at manufacturer-recommended intervals. Clean filters contribute to optimal performance, allowing systems to function efficiently and reducing strain on components.

Engine Overhaul Procedures Explained

Overhauling an engine involves a comprehensive set of procedures designed to restore performance and extend its lifespan. This process typically includes disassembly, inspection, cleaning, and reassembly of various components. Each step requires careful attention to detail to ensure optimal functionality once the engine is put back into service.

Key stages in the overhaul process include:

- Disassembly: Carefully removing components while keeping track of their arrangement.

- Inspection: Thoroughly examining parts for wear, damage, and any signs of failure.

- Cleaning: Removing old oil, carbon deposits, and debris to prepare parts for reconditioning.

- Reconditioning: Repairing or replacing worn-out components to restore them to acceptable standards.

- Reassembly: Putting the engine back together with a focus on proper torque specifications and alignment.

Attention to detail during each phase is crucial. Properly executed procedures can lead to enhanced performance, improved efficiency, and a reduction in future issues. Regular maintenance following an overhaul can further extend the life of the engine and ensure reliable operation.

Transmission Repair: A Step-by-Step Guide

Maintaining the functionality of your vehicle’s shifting mechanism is crucial for optimal performance. This section provides a comprehensive approach to addressing common issues associated with the transmission system, ensuring a smoother operation and longevity.

Essential Tools and Materials

Before beginning the process, gather the necessary tools and components. Having everything on hand will streamline the procedure and minimize downtime.

| Tool/Material | Purpose |

|---|---|

| Wrench Set | To loosen and tighten bolts |

| Screwdrivers | To remove panels and screws |

| Fluid Pump | For adding or replacing fluids |

| Transmission Fluid | Essential for proper lubrication |

Step-by-Step Procedure

Follow these steps to effectively address transmission concerns:

1. Start by securely lifting the vehicle using appropriate jack stands.

2. Locate the access panels and remove them using your tools.

3. Drain the existing fluid completely to prevent contamination.

4. Inspect the components for any visible damage or wear.

5. Replace any faulty parts and ensure all connections are tight.

6. Refill the system with new fluid, following manufacturer specifications.

7. Test the system by running the engine and checking for leaks.

By adhering to this guide, you can maintain the efficiency and reliability of your vehicle’s transmission system.

Electrical System Diagnostics Techniques

This section provides an overview of effective methods for analyzing and troubleshooting electrical systems in vehicles. Understanding these techniques is crucial for identifying issues that may arise in various components, ensuring optimal performance and safety.

One of the fundamental approaches involves visual inspections, where technicians examine wiring, connectors, and components for signs of damage or corrosion. Additionally, employing multimeters for measuring voltage, current, and resistance can reveal inconsistencies within the system. This quantitative data aids in pinpointing faulty elements.

Another technique is utilizing diagnostic tools such as scan tools or oscilloscopes, which facilitate communication with onboard computers. These devices can retrieve error codes and monitor real-time data, providing valuable insights into system performance. Analyzing this information helps in formulating an effective repair strategy.

Moreover, conducting functional tests is essential. This involves operating various electrical components while monitoring their behavior. Such tests can highlight problems that may not be evident during static inspections, allowing for a more comprehensive evaluation of the system’s health.

Incorporating these diagnostic techniques enhances the ability to effectively troubleshoot and resolve electrical issues, leading to improved vehicle reliability and performance.

Cooling System Maintenance and Repair

The effective operation of a vehicle’s cooling mechanism is crucial for maintaining optimal engine performance and longevity. Regular upkeep and timely interventions can prevent overheating, reduce wear, and enhance overall efficiency. Understanding the components and their functions is essential for proper management and resolution of potential issues.

Routine Inspections

Consistent examinations of the cooling apparatus can identify leaks, corrosion, or blockages. Checking fluid levels and inspecting hoses for cracks or wear are fundamental practices. Ensure that the radiator is free from debris and that the coolant is in good condition, as this directly impacts heat dissipation.

Fluid Replacement

Changing the coolant at recommended intervals is vital to avoid the buildup of harmful deposits. Using the appropriate type of coolant helps maintain system efficiency and prevents corrosion within the components. Be sure to follow guidelines for flushing the system to remove old fluid and contaminants.

By implementing these maintenance strategies, you can ensure the cooling system operates smoothly and effectively, supporting the overall health of your vehicle.

Exhaust System Upgrades and Issues

The exhaust system plays a crucial role in vehicle performance, influencing both efficiency and emissions. Upgrading this system can lead to significant improvements, including enhanced airflow, reduced back pressure, and a more aggressive sound. However, certain complications can arise, necessitating careful consideration during any modifications.

Common Upgrades: Many enthusiasts seek to enhance their exhaust systems through the installation of high-performance components. Options such as larger diameter pipes, performance mufflers, and catalytic converters are popular choices. These enhancements can boost horsepower and torque while providing a distinctive auditory experience.

Potential Issues: Despite the benefits, upgrading the exhaust system can lead to various challenges. For instance, improper installation may result in leaks, which can decrease efficiency and lead to undesirable noises. Additionally, modifications that exceed legal emissions standards can cause regulatory issues and may require further adjustments to maintain compliance.

In conclusion, while upgrading the exhaust system can yield performance benefits, it is essential to address potential pitfalls to ensure a balanced enhancement of your vehicle’s capabilities.

Suspension and Steering Adjustments

Proper alignment and adjustment of the vehicle’s suspension and steering systems are crucial for optimal performance and safety. These components work in harmony to ensure a smooth ride, enhance handling, and improve tire longevity. Regular maintenance and timely adjustments can prevent uneven tire wear and handling issues, leading to a more enjoyable driving experience.

To begin, it’s essential to check the alignment settings, which dictate the relationship between the wheels and the road. Misalignment can occur due to various factors, including road conditions and wear on suspension parts. Adjusting these settings involves measuring angles such as camber, caster, and toe, followed by making necessary corrections to bring them within manufacturer specifications.

Additionally, inspecting and adjusting the suspension components, such as shocks and struts, can significantly impact ride quality and vehicle stability. Worn-out parts should be replaced promptly to maintain the effectiveness of the system. Regularly checking for proper tension in springs and ensuring that the bushings are in good condition also contribute to improved handling and comfort.

Lastly, steering mechanisms should be examined for any play or wear. Adjustments can be made to the steering gear to enhance responsiveness and reduce slack. Ensuring that the linkage and tie rods are correctly adjusted will also help in achieving precise control over the vehicle’s direction.

Brake System Inspection and Repair

Ensuring the proper functioning of the stopping mechanism is vital for safety and performance. Regular examination of the braking components helps to identify potential issues before they escalate into serious problems. This section outlines essential practices for assessing and maintaining these crucial systems.

Inspection Procedures

The first step involves a thorough evaluation of the entire braking assembly. Check for any signs of wear on pads and discs, ensuring they are free from cracks or excessive thinning. Inspect hydraulic lines for leaks or corrosion, and verify that the fluid levels are adequate. Emphasizing the importance of checking for unusual noises during operation can also signal underlying issues.

Repair Techniques

If any components are found to be deficient, immediate action should be taken. Replacing worn pads and discs is crucial, as is addressing any leaks in the hydraulic system. Utilizing quality replacement parts ensures optimal functionality and longevity. Regular maintenance, including bleeding the braking system, enhances performance and ensures reliable stopping power.

Fuel System Troubleshooting and Fixes

The fuel system is a critical component of any vehicle, ensuring that the engine receives the proper mixture of fuel for optimal performance. When issues arise, it is essential to diagnose and address them promptly to maintain efficiency and prevent further damage. This section outlines common problems, their symptoms, and effective solutions to restore functionality.

Common Issues and Symptoms

Recognizing the signs of fuel system malfunctions can save time and effort in diagnosing the problem. Below are typical issues along with their corresponding symptoms:

| Issue | Symptoms |

|---|---|

| Clogged Fuel Filter | Poor acceleration, engine stalling |

| Fuel Pump Failure | Engine won’t start, whining noise from the tank |

| Leaking Fuel Lines | Strong fuel odor, visible fuel spots |

| Faulty Injectors | Misfiring, poor fuel economy |

Solutions and Recommendations

Once the issue is identified, implementing the appropriate fixes is crucial. Here are some recommended actions:

For a clogged filter, replacing it is the most effective solution. Ensure to use a quality replacement part to prevent future blockages. If the fuel pump is not functioning, testing it with a multimeter can help determine if replacement is necessary. For leaks, inspect the lines thoroughly and use fuel line tape or clamps as a temporary fix; however, replacement is advised for long-term solutions. Finally, for malfunctioning injectors, cleaning them or replacing faulty units will help restore proper engine function.

Bodywork and Paint Maintenance Tips

Maintaining the exterior of a vehicle is crucial for preserving its aesthetic appeal and ensuring long-term durability. Regular care can prevent damage from environmental factors and keep the surface looking pristine. Here are some essential practices to follow for effective upkeep.

Regular Cleaning

Frequent washing is vital to remove dirt, grime, and contaminants that can lead to corrosion. Use gentle products and soft cloths to avoid scratching the surface. Pay special attention to the undercarriage and wheel wells where debris tends to accumulate.

Protective Measures

Applying a quality wax or sealant creates a barrier against the elements. This step not only enhances shine but also helps in repelling moisture and preventing rust formation. Consider using a ceramic coating for added protection and longevity.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Washing | Every 2 weeks | Use pH-balanced soap |

| Waxing | Every 3 months | Choose high-quality wax |

| Inspection for Scratches | Monthly | Address chips promptly |

| Detailing | Twice a year | Consider professional services |