When it comes to maintaining robust powertrains, having a comprehensive guide is essential. Such a resource offers insights into the intricacies of engine systems, ensuring optimal performance and longevity. Whether you are a seasoned technician or an enthusiastic DIYer, mastering these concepts can lead to enhanced vehicle reliability.

Exploring the inner workings of these advanced mechanical systems reveals not just how to fix issues, but also how to prevent them. This knowledge empowers individuals to tackle challenges confidently, saving time and resources in the process. A detailed reference can illuminate the best practices for upkeep and troubleshooting, transforming the way we approach heavy machinery care.

Furthermore, understanding specific components and their functions can significantly streamline maintenance efforts. With clear instructions and thorough explanations, enthusiasts can engage deeply with their engines, cultivating a hands-on relationship that fosters both skill development and appreciation for engineering excellence. This guide serves as a valuable tool for anyone looking to delve into the world of heavy-duty vehicle maintenance.

Overview of Duramax Diesel Engines

This section provides a comprehensive examination of a specific line of high-performance engines known for their exceptional efficiency and power. These engines have been engineered to meet the demands of both heavy-duty applications and everyday driving, showcasing advanced technology and design innovations.

Engine Design and Features

The design of these powertrains emphasizes durability and reliability. They incorporate a robust architecture that supports high torque output, making them ideal for towing and hauling. Enhanced fuel injection systems and turbocharging technology contribute to their remarkable performance and fuel economy.

Applications

These engines are widely used in a range of vehicles, from commercial trucks to SUVs. Their versatility allows them to excel in various conditions, whether on the highway or off-road. Owners appreciate their ability to deliver consistent power, regardless of load or terrain.

Maintenance Considerations

Common Issues with Duramax Diesel

Owners of high-performance engines often encounter specific challenges that can affect both functionality and longevity. Understanding these common problems is crucial for maintaining optimal performance and preventing costly repairs.

One prevalent concern involves fuel system complications. Issues such as clogged filters or failing injectors can lead to reduced power and efficiency. Regular inspection and maintenance of the fuel components are essential to avoid these setbacks.

Another frequent problem is related to overheating. This can stem from a malfunctioning cooling system or a damaged thermostat, causing significant strain on the engine. Monitoring coolant levels and ensuring proper airflow can mitigate these risks.

Additionally, electrical failures may occur, impacting the vehicle’s overall performance. Faulty sensors or wiring issues can trigger warning lights or affect engine responsiveness. Keeping the electrical system in check is vital for reliable operation.

Finally, exhaust system issues, such as leaks or blockages, can significantly hinder performance and emissions. Regular checks and timely replacements can help maintain compliance with environmental standards and improve efficiency.

Awareness of these challenges allows owners to take proactive measures, ensuring their vehicles operate smoothly and efficiently for years to come.

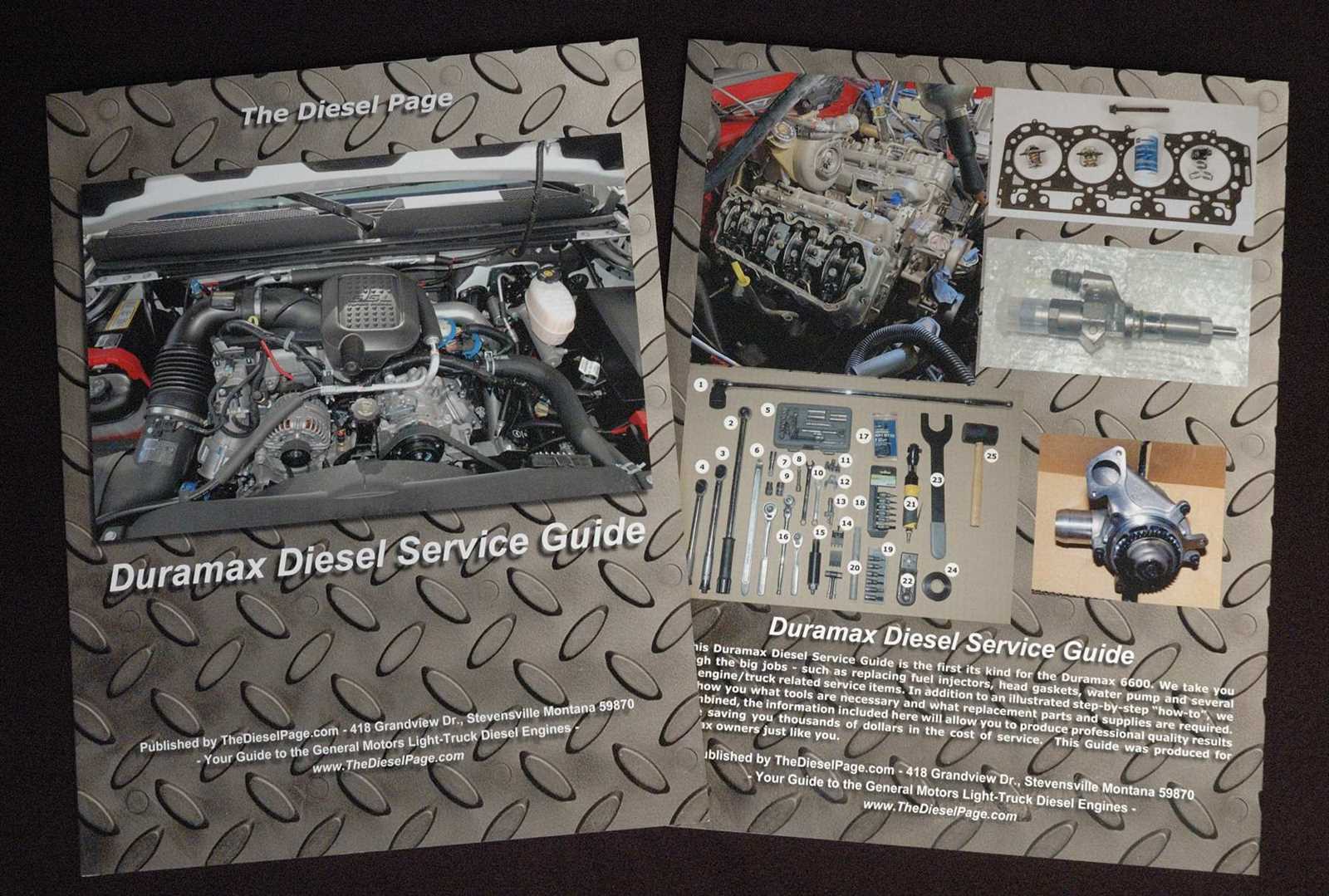

Essential Tools for Duramax Repairs

Having the right instruments at your disposal is crucial for effective maintenance and troubleshooting of high-performance engines. This section outlines key items that every enthusiast or technician should consider when working on these robust powertrains. Whether you’re tackling minor adjustments or significant overhauls, equipping yourself with essential tools will streamline the process and enhance efficiency.

Basic Hand Tools

Starting with the fundamentals, a comprehensive set of hand tools is vital. Wrenches, sockets, and ratchets in various sizes are necessary for loosening and tightening components. An adjustable wrench can be particularly useful for those hard-to-reach areas. Don’t forget about pliers, screwdrivers, and a sturdy hammer to assist with various tasks.

Specialized Equipment

In addition to basic tools, having specialized equipment can make a significant difference. A torque wrench is essential for ensuring that fasteners are tightened to the manufacturer’s specifications. A compression tester can help evaluate the health of the engine’s cylinders. Lastly, a reliable OBD-II scanner provides crucial diagnostic information, enabling you to quickly identify and address issues.

Step-by-Step Maintenance Procedures

Regular upkeep of your vehicle is essential to ensure optimal performance and longevity. Following a systematic approach to maintenance tasks not only enhances efficiency but also minimizes the risk of unexpected issues. This section outlines crucial procedures that should be routinely performed to maintain peak operational condition.

Fluid Checks and Replacements

One of the most vital aspects of vehicle maintenance is monitoring and replacing fluids. Start with engine oil, which should be checked frequently and replaced as needed. Additionally, inspect coolant levels, transmission fluid, and brake fluid. Each fluid has a specific service interval; adhere to the manufacturer’s guidelines for replacements to ensure proper function.

Filter Maintenance

Filters play a critical role in maintaining the integrity of various systems within your vehicle. Regularly check and replace air, fuel, and oil filters. Clean filters can improve performance and efficiency, while clogged ones can lead to unnecessary strain on the engine. Establish a routine schedule for filter inspections to keep systems operating smoothly.

Understanding Duramax Engine Components

The complexity of modern powertrains is astonishing, with various elements working in unison to deliver optimal performance and efficiency. A thorough comprehension of each part is essential for anyone involved in maintenance or enhancement tasks. This section will delve into the crucial components that play a vital role in engine operation, emphasizing their functions and interrelations.

Engine Block: At the core of the system lies the engine block, which houses essential elements such as cylinders and pistons. This robust structure provides the foundation for other components and withstands the extreme conditions present during operation.

Pistons: These cylindrical parts move up and down within the cylinders, converting fuel energy into mechanical energy. Their design is critical for maintaining compression and efficiency, impacting overall performance significantly.

Cylinder Head: The cylinder head caps the engine block and contains vital features like intake and exhaust ports. It plays a crucial role in regulating airflow and combustion, which are pivotal for power generation.

Fuel System: This intricate network delivers fuel to the combustion chambers. Comprising injectors, pumps, and filters, its efficiency directly influences engine performance and emissions.

Turbocharger: Enhancing power output, this component compresses incoming air, allowing for a more substantial fuel-air mixture in the combustion process. This results in improved efficiency and performance.

Cooling System: Maintaining optimal operating temperatures is essential for longevity and efficiency. The cooling system circulates coolant to absorb heat from the engine, preventing overheating and ensuring consistent performance.

Understanding these components not only aids in effective troubleshooting but also enhances the ability to optimize performance and prolong the lifespan of the powertrain. A solid grasp of each element’s role and functionality is vital for anyone engaged in engine upkeep or modifications.

Performance Enhancements for Duramax

Improving the output and efficiency of heavy-duty engines is a common pursuit among enthusiasts and professionals alike. With various modifications available, individuals can achieve significant gains in power, torque, and overall driving experience. This section explores several effective strategies to enhance performance while maintaining reliability and durability.

Upgraded Air Intake Systems

One of the most effective methods for boosting engine performance is through the installation of an upgraded air intake system. These systems allow for increased airflow, which can lead to better combustion and improved power output. By replacing factory components with high-performance alternatives, users can experience a notable increase in throttle response and acceleration.

Performance Tuners and Chips

Another key enhancement involves the use of performance tuners and chips. These devices modify the engine’s electronic control unit (ECU) to optimize fuel mapping and timing. This adjustment not only maximizes horsepower and torque but also improves fuel efficiency. Properly tuning the engine can lead to a balanced enhancement of both performance and economy.

Repair Techniques for Common Failures

Addressing frequent issues in high-performance engines requires a blend of diagnostic skills and effective strategies. Understanding the typical problems and their resolutions can significantly enhance reliability and longevity. Below are some prevalent failures along with suggested approaches to mitigate them.

| Common Issue | Symptoms | Recommended Solution |

|---|---|---|

| Overheating | Temperature gauge reading high, steam from engine | Check coolant levels, inspect radiator for blockages, replace thermostat |

| Loss of Power | Reduced acceleration, engine stuttering | Examine fuel filters, clean injectors, assess turbocharger functionality |

| Starting Issues | Engine cranking but not starting, unusual noises | Test battery voltage, inspect starter motor, check fuel delivery system |

| Excessive Smoke | Black or blue smoke from exhaust | Analyze air intake system, replace worn piston rings, check for injector leaks |

| Fluid Leaks | Puddles under the vehicle, low fluid levels | Identify the source of the leak, replace gaskets or seals, tighten connections |

By following these guidelines and conducting regular inspections, engine performance can be optimized while minimizing the likelihood of serious issues arising in the future.

Duramax Diesel Service Intervals

Regular maintenance is crucial for optimal performance and longevity of your engine. Adhering to scheduled service intervals helps prevent potential issues and ensures your vehicle operates smoothly. This section outlines recommended timelines for various maintenance tasks to keep your engine in peak condition.

Regular Maintenance Tasks

To maintain efficiency, it’s essential to conduct routine checks and replacements. This includes changing the oil and filter, inspecting the air intake system, and assessing the fuel system. Generally, oil changes should occur every 7,500 miles, while air filters may need replacement around 15,000 miles, depending on driving conditions.

Inspection and Additional Services

In addition to routine tasks, certain components require more detailed inspection at specified intervals. For example, the coolant and transmission fluid should be checked every 30,000 miles, with changes recommended every 60,000 miles. Timing belt replacement is critical and should be done approximately every 100,000 miles to avoid severe engine damage.

By following these service intervals diligently, vehicle owners can significantly enhance their engine’s performance and reliability over time.

Upgrades for Duramax Diesel Longevity

Enhancing the durability and performance of high-torque engines requires strategic modifications and improvements. These upgrades not only extend the lifespan of the vehicle but also ensure optimal functionality under various conditions. Below are some effective enhancements to consider for increased longevity.

Performance Enhancements

- Cold Air Intake Systems: Improving airflow can lead to better combustion efficiency.

- High-Performance Exhaust Systems: These systems help in reducing back pressure and enhancing engine breathing.

- ECU Remapping: Tuning the engine control unit can optimize fuel efficiency and power output.

Preventive Maintenance Upgrades

- Upgraded Filtration: Installing high-quality oil and fuel filters can significantly reduce contaminants.

- Enhanced Cooling Systems: A more efficient cooling system helps prevent overheating, especially during heavy loads.

- Regular Fluid Changes: Using premium lubricants and changing them at recommended intervals can extend engine life.

Safety Precautions During Repairs

Ensuring a secure working environment is paramount when performing maintenance tasks. Proper precautions not only protect the individual but also contribute to the longevity of the equipment involved.

Personal Protective Equipment

Always wear appropriate personal protective gear, including gloves, goggles, and steel-toed boots. This equipment serves as a barrier against potential hazards, reducing the risk of injury during the process.

Workspace Organization

Maintain a clean and organized workspace to minimize accidents. Keep tools and parts neatly arranged, and ensure that the area is well-lit to enhance visibility and focus during complex tasks.

Resources for Duramax Enthusiasts

For those passionate about heavy-duty engines and seeking to enhance their knowledge and skills, numerous valuable resources are available. From forums to specialized literature, enthusiasts can access a wealth of information to support their journey in maintaining and upgrading their vehicles.

Here are some key resources that can help deepen your understanding and improve your hands-on experience:

| Resource Type | Description | Website/Link |

|---|---|---|

| Online Forums | Community-driven platforms for discussions, advice, and troubleshooting. | Diesel Place |

| Technical Guides | Comprehensive literature covering various aspects of engine performance and modifications. | Amazon |

| Video Tutorials | Step-by-step visual guides on maintenance and upgrades. | YouTube |

| Social Media Groups | Active communities sharing tips, photos, and experiences. | Facebook Groups |

| Workshops and Events | Hands-on sessions and gatherings for enthusiasts to learn and network. | Eventbrite |

Engaging with these resources will not only enhance your technical knowledge but also connect you with fellow enthusiasts who share your passion for performance and innovation.