Keeping your outdoor machinery in top condition is essential for achieving a beautiful and healthy garden. Regular maintenance not only enhances performance but also prolongs the lifespan of your tools. This guide aims to provide valuable insights into how to effectively troubleshoot and maintain your gardening devices.

Understanding the intricacies of your equipment can save you both time and money. By learning the basic components and functions, you empower yourself to handle common issues with confidence. This comprehensive approach will enable you to perform necessary checks and interventions when problems arise.

In this guide, you will find step-by-step instructions, useful tips, and essential advice for maintaining your garden tools. Whether you are dealing with minor adjustments or more significant challenges, our information is designed to assist you in ensuring your equipment operates smoothly and efficiently.

Understanding Your Craftsman Lawn Mower

Maintaining a well-functioning outdoor equipment is essential for achieving a neat and tidy landscape. Familiarity with your device’s components and operation can enhance its efficiency and longevity. This section will guide you through the essential aspects of your machine, ensuring that you maximize its performance while minimizing potential issues.

Key Components and Their Functions

Your device consists of various parts, each playing a crucial role in its operation. The engine serves as the powerhouse, providing the necessary energy. The cutting mechanism is responsible for the precision of your trimming tasks, while the wheels and chassis allow for maneuverability across different terrains. Understanding how these components work together can help you troubleshoot issues more effectively.

Routine Maintenance Practices

Regular upkeep is vital for preventing wear and tear. Start by checking the fuel and oil levels, ensuring they are at optimal levels for efficient functioning. Cleaning the cutting blades and air filters can significantly improve performance and prevent clogs. Additionally, inspect the tires for proper inflation, as this affects mobility and stability. By adopting these practices, you can prolong the lifespan of your equipment and maintain its reliability throughout the seasons.

Common Issues with Lawn Mowers

Maintaining outdoor equipment can often reveal a range of typical challenges that users face. Understanding these common problems can help in diagnosing issues and ensuring optimal performance. This section explores various malfunctions that may arise, providing insights into their causes and potential solutions.

One prevalent issue is difficulty in starting the engine. This can stem from a depleted fuel supply, stale gasoline, or faulty spark plugs. Regular maintenance of these components can prevent such complications.

Another frequent concern is poor cutting performance, which may result from dull blades or improper height settings. Ensuring blades are sharp and adjusted correctly can significantly enhance the efficiency of the equipment.

Overheating is also a common problem, often caused by inadequate lubrication or debris blocking airflow. Regular cleaning and oil changes can mitigate this risk and extend the lifespan of the machine.

Finally, uneven operation can be linked to tire pressure discrepancies or issues with the drive system. Regularly checking tire inflation and inspecting the drivetrain can help maintain even functionality.

Tools Required for Repairs

Undertaking maintenance tasks necessitates a variety of instruments to ensure efficiency and effectiveness. Having the right tools on hand not only simplifies the process but also enhances safety and precision during the procedure. Below is a comprehensive list of essential equipment that will aid in addressing common issues encountered.

Essential Tools

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening nuts and bolts. |

| Screwdriver Set | To remove or secure screws of various sizes. |

| Pliers | To grip, twist, or cut wire and other materials. |

| Socket Set | For working with fasteners in tight spaces. |

| Fuel Stabilizer | To preserve fuel quality during storage. |

Additional Supplies

In addition to the primary tools, consider having a few supplementary items that can facilitate the process:

| Supply | Function |

|---|---|

| Shop Towels | For cleaning surfaces and hands during tasks. |

| Protective Gloves | To safeguard hands while handling sharp or hot components. |

| Multimeter | To test electrical components and diagnose issues. |

| Oil and Grease | For lubrication of moving parts to ensure smooth operation. |

Step-by-Step Maintenance Guide

Proper upkeep of your gardening equipment is essential for optimal performance and longevity. This guide outlines a systematic approach to ensure your machine runs smoothly and efficiently throughout the seasons.

-

Clean the Equipment

- Remove any debris and grass clippings from the exterior.

- Use a brush or compressed air to clear the underside.

- Wipe down all surfaces with a damp cloth to prevent rust.

-

Check the Fuel System

- Inspect the fuel tank for any signs of contamination.

- Replace old fuel with fresh gasoline, if necessary.

- Examine fuel lines for cracks or leaks.

-

Inspect the Blades

- Remove the blades for thorough examination.

- Sharpen any dull edges using a file or sharpening tool.

- Check for signs of wear or damage; replace if needed.

-

Change the Oil

- Warm up the engine slightly to thin the oil.

- Drain the old oil into a suitable container.

- Replace it with the recommended type of oil.

-

Inspect the Air Filter

- Remove the air filter and check for dirt and debris.

- Clean or replace the filter as required.

- Ensure proper sealing to maintain engine efficiency.

Regular attention to these tasks will help maintain the reliability and efficiency of your equipment, ensuring it remains in top condition for all your gardening needs.

How to Change the Oil

Maintaining the performance of your equipment is crucial, and one essential aspect of this upkeep is the routine oil change. Proper lubrication not only enhances efficiency but also extends the lifespan of your machine. This guide will walk you through the steps to effectively replace the oil, ensuring optimal operation.

Tools and Materials Needed

Before starting, gather the following items:

- New oil (refer to the specifications for the correct type)

- Oil filter (if applicable)

- Wrench or socket set

- Oil drain pan

- Funnel

- Clean cloths

Step-by-Step Process

1. Prepare the Machine: Ensure the equipment is on a level surface and turned off. Allow it to cool down if it was recently in use.

2. Drain the Old Oil: Locate the drain plug, place the oil pan underneath, and remove the plug to let the used oil flow out completely. Replace the plug once drained.

3. Replace the Oil Filter: If your model includes a filter, remove the old one and install the new filter, ensuring a secure fit.

4. Add New Oil: Using the funnel, pour the new oil into the designated fill tube, taking care not to overfill. Check the dipstick to confirm the correct level.

5. Clean Up: Wipe any spills and dispose of the old oil and filter properly, adhering to local regulations.

Following these steps will help ensure your equipment runs smoothly and efficiently, keeping it in peak condition for all your tasks.

Replacing Spark Plugs Effectively

Changing out ignition components is a vital maintenance task that ensures optimal engine performance. By following proper techniques, you can enhance the longevity and efficiency of your machinery.

Here’s a step-by-step guide to help you accomplish this task:

- Gather necessary tools: socket wrench, spark plug socket, torque wrench, and a gap gauge.

- Ensure the engine is cool to prevent burns.

- Locate the spark plug: consult your device’s guide for exact positioning.

- Remove the old plug carefully, avoiding damage to surrounding parts.

- Check the gap on the new plug and adjust if necessary.

- Install the new spark plug by hand first, then tighten with the wrench to the manufacturer’s specifications.

- Reconnect any wires or components that were removed.

Regularly replacing these components can significantly improve your engine’s efficiency and reliability.

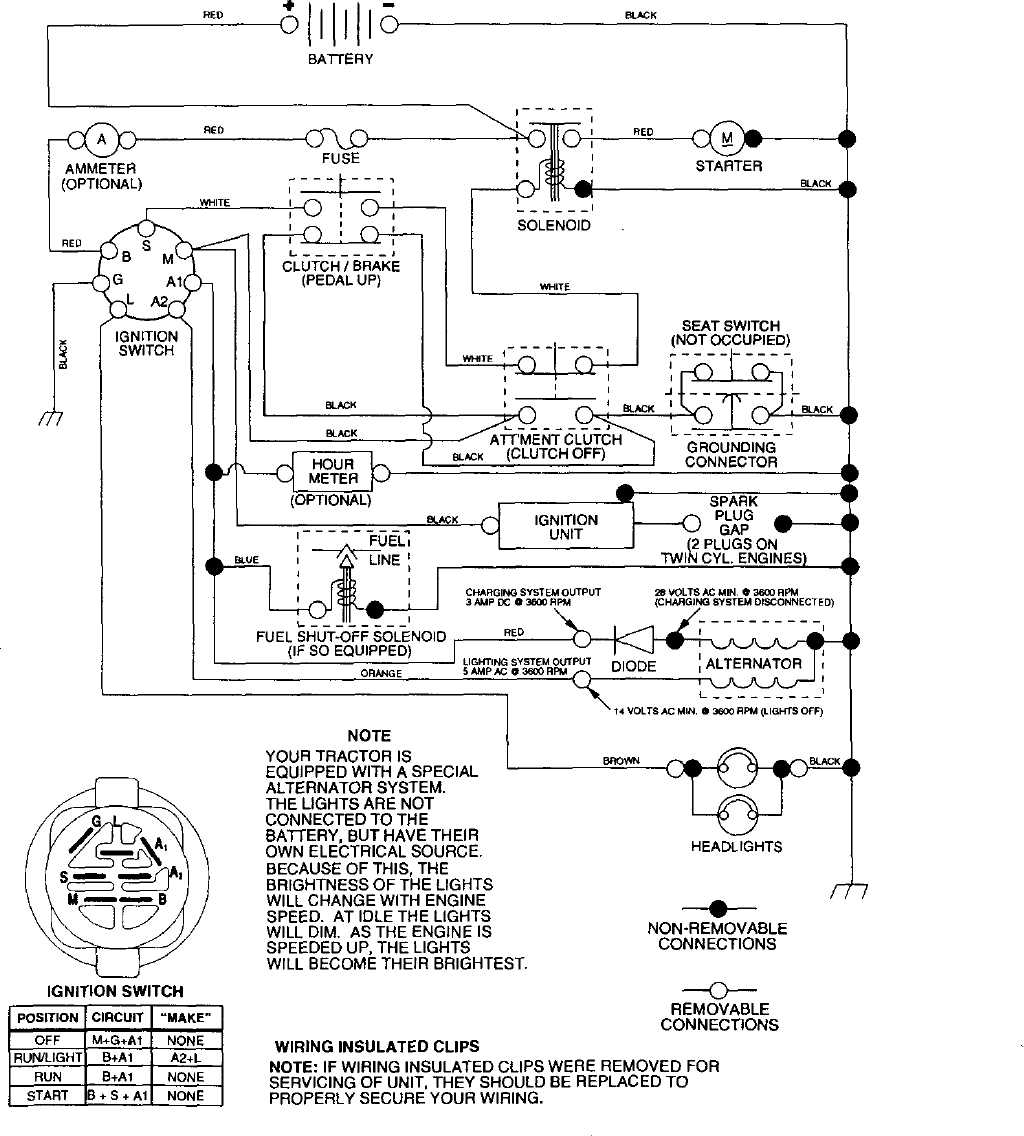

Troubleshooting Electrical Problems

Identifying and resolving electrical issues can be a challenging task, yet it is essential for ensuring the optimal performance of your equipment. By following a systematic approach, you can pinpoint malfunctions and restore functionality. This guide provides a clear outline for diagnosing common electrical difficulties.

Here are some typical symptoms that may indicate electrical problems:

- Device fails to start

- Intermittent operation

- Strange noises during operation

- Burning smell or visible damage

To effectively address these issues, consider the following troubleshooting steps:

- Check the Power Source:

- Ensure the power cord is securely connected.

- Inspect for any visible damage on the cord.

- Test the outlet with another device to confirm functionality.

- Examine Fuses and Circuit Breakers:

- Locate the fuse box and check for blown fuses.

- Reset any tripped circuit breakers.

- Inspect Switches and Controls:

- Test the power switch for functionality.

- Look for loose or corroded connections in the control panel.

- Assess Internal Components:

- Check for damaged wiring inside the device.

- Inspect motors and relays for wear and tear.

If problems persist after these checks, consider seeking assistance from a qualified technician to avoid further damage. Regular maintenance can also help prevent future electrical issues.

Blade Sharpening Techniques

Properly maintaining cutting edges is essential for achieving optimal performance and longevity in your outdoor equipment. Sharpening techniques can vary, but the goal remains the same: to ensure that your tools cut efficiently and smoothly. This section will explore effective methods to keep those blades in prime condition, enhancing their effectiveness and prolonging their lifespan.

Manual Sharpening Methods

One of the most traditional approaches to honing cutting edges involves using a hand file or sharpening stone. Begin by securing the blade in a stable position to prevent any movement. Using a coarse file, apply consistent pressure while moving the tool along the edge at a slight angle. This process should be followed by finer stones to achieve a sharper finish. Regularly check the edge’s progress to avoid over-sharpening.

Power Sharpening Options

If you’re seeking a faster and more efficient method, power sharpeners can be a great alternative. These electric devices use a rotating grinding wheel to quickly restore the edge. When utilizing this method, it’s important to keep the blade cool to prevent overheating, which can alter the temper of the metal. Periodically dip the blade in water to maintain a safe temperature while sharpening.

Safety Tips: Always wear protective gear when sharpening to safeguard against flying debris. Ensure your workspace is clean and well-lit to enhance visibility and control.

By employing these techniques regularly, you can ensure your cutting implements remain efficient and effective, ready for any task at hand.

Cleaning the Air Filter

Maintaining optimal performance of your equipment is essential for longevity and efficiency. One key component that often requires attention is the filtration system, which plays a critical role in ensuring clean air intake. Regular cleaning of this part helps prevent engine wear and improves overall functionality.

Why Clean the Filter?

Over time, debris and dust can accumulate in the filtration element, restricting airflow and reducing power. A clogged filter can lead to overheating and decreased efficiency, causing unnecessary strain on the engine. By keeping this component clean, you ensure better performance and extend the lifespan of your machine.

How to Clean the Air Filter

Begin by disconnecting the power source for safety. Remove the filter from its housing, taking care to avoid damage. Use compressed air or a soft brush to gently remove dirt and debris. If the filter is excessively dirty, consider washing it with warm, soapy water, then allowing it to dry completely before reinstallation. Ensure that it is fitted snugly in place to maintain optimal performance.

Regular maintenance of the filtration system is a simple yet effective way to keep your equipment running smoothly. Checking and cleaning this part periodically can prevent larger issues and ensure reliable operation.

Adjusting Wheel Heights Properly

Setting the appropriate heights for the wheels of your equipment is crucial for optimal performance and cutting efficiency. Proper adjustments not only enhance the quality of your work but also extend the lifespan of the machine. Here’s a guide to help you achieve the best results.

Before you begin, gather the necessary tools, which typically include:

- Wrench or socket set

- Measuring tape

- Level surface

Follow these steps to adjust the wheel heights effectively:

- Prepare the Area: Ensure the machine is on a flat, stable surface. This prevents inaccurate measurements and adjustments.

- Measure Current Heights: Use a measuring tape to determine the existing heights of all wheels. Note any discrepancies.

- Adjust Each Wheel:

- Loosen the adjustment bolts or screws on the desired wheel.

- Raise or lower the wheel to the required height based on your previous measurements.

- Securely tighten the bolts once the desired position is reached.

- Repeat for All Wheels: Ensure consistency across all wheels for even performance.

- Final Check: Once adjustments are made, do a final measurement to confirm all wheels are set to the same height.

Regularly checking and adjusting the wheel heights will ensure your equipment operates efficiently and delivers excellent results every time.

Identifying Fuel System Failures

Understanding the signs of fuel system malfunctions is essential for maintaining optimal engine performance. Several indicators can point to issues within this critical component, affecting the overall functionality of the machinery. Recognizing these symptoms early can help prevent further damage and ensure efficient operation.

Common Symptoms of Fuel System Issues

- Difficulty starting the engine

- Unusual engine noises or sputtering

- Decreased power or acceleration

- Frequent stalling during operation

- Unpleasant odors or visible fuel leaks

Steps for Diagnosis

- Check the fuel level and quality.

- Inspect fuel lines for cracks or blockages.

- Examine the fuel filter for clogs.

- Test the fuel pump for proper operation.

- Evaluate the carburetor or injection system for faults.

By systematically addressing these areas, you can identify and resolve fuel system failures effectively, restoring the performance of your equipment.

When to Seek Professional Help

Understanding when to call in an expert can save time and prevent further issues. While many minor issues can be resolved with basic knowledge and tools, certain situations require specialized skills and equipment. Recognizing the signs that indicate a need for professional assistance is crucial for effective maintenance and longevity of your equipment.

Signs That Indicate a Need for Expertise

Several warning signs suggest that you should consider hiring a professional. Ignoring these indicators may lead to more significant damage or costly repairs down the line.

| Warning Sign | Explanation |

|---|---|

| Strange Noises | Unusual sounds can indicate mechanical issues that require diagnosis and repair by a technician. |

| Smoke or Burning Smell | This often signals overheating or electrical problems, which should be addressed by a qualified individual. |

| Frequent Stalling | Regular interruptions in operation may point to fuel or ignition issues that an expert should investigate. |

| Visible Damage | Cracks, leaks, or broken components typically need replacement parts and professional installation. |

Benefits of Professional Assistance

Hiring a qualified technician not only ensures that problems are resolved correctly but also often comes with a warranty for the work performed. Professionals bring experience, tools, and expertise that can lead to more effective and safer solutions than attempting to fix issues independently.