The importance of proper upkeep for specialized machinery cannot be overstated. This guide aims to provide comprehensive insights into the best practices for maintaining and troubleshooting various models of performance-driven tools. By following the outlined procedures, users can ensure their equipment operates at peak efficiency.

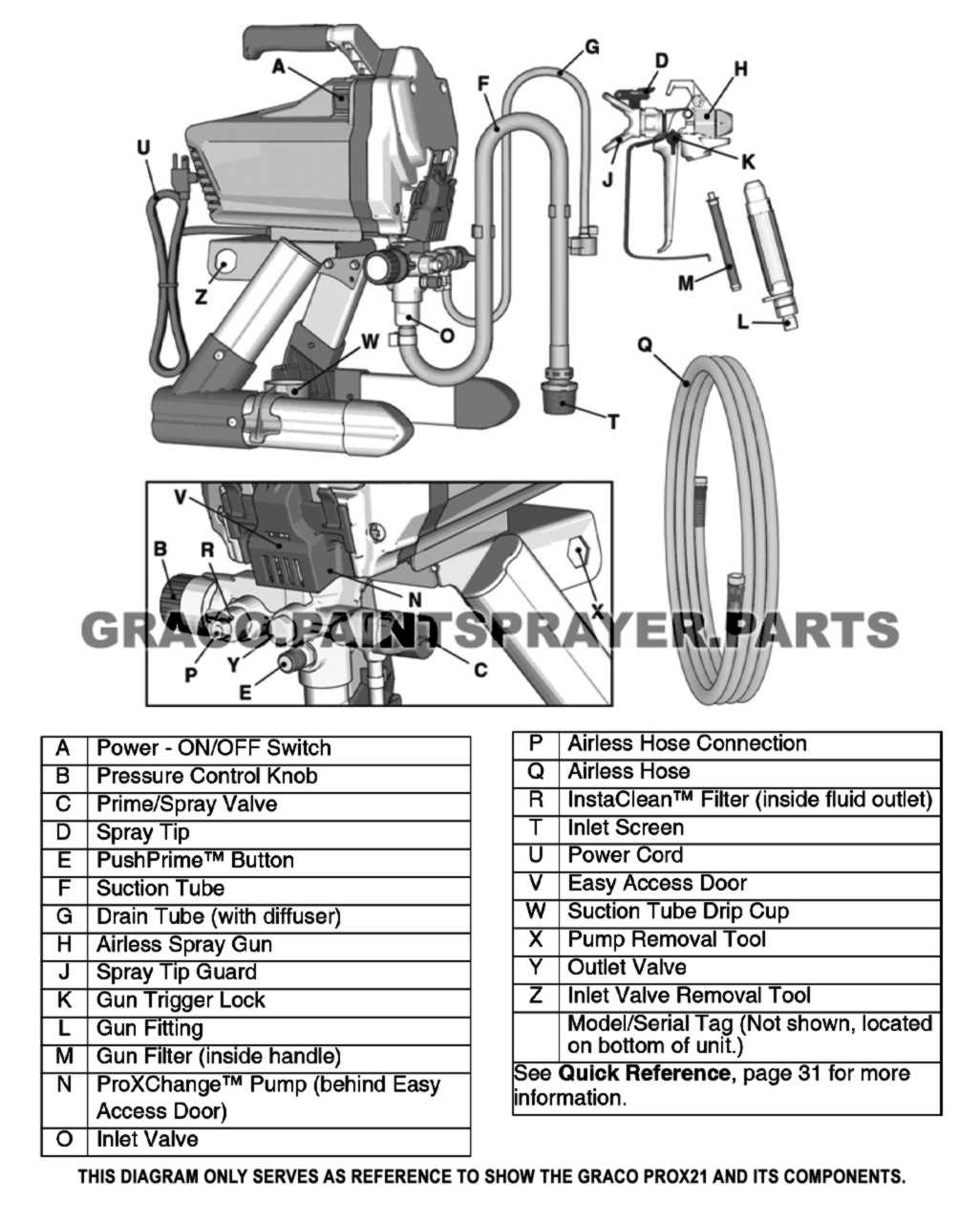

Understanding the key components and their functions is crucial for effective maintenance. This section will delve into essential techniques and strategies to prolong the lifespan of your tools. Proper handling and timely intervention can prevent minor issues from escalating into significant problems, ultimately saving both time and resources.

Additionally, this guide will explore common challenges faced by operators and offer practical solutions. Whether dealing with routine inspections or more complex adjustments, users will find valuable information tailored to enhance their experience. With a focus on clarity and precision, this resource aims to empower users in their maintenance endeavors.

Overview and Features

This section provides a comprehensive understanding of a highly efficient and versatile product designed for various applications. It highlights essential characteristics that make this equipment stand out in its category.

Key attributes include:

- Innovative design that ensures user-friendly operation

- Robust construction for enhanced durability

- Adjustable settings to accommodate different tasks

- Energy-efficient performance that reduces operational costs

Moreover, this device is equipped with advanced technology that improves functionality and reliability. The integration of modern features enhances productivity, making it an ideal choice for both professionals and DIY enthusiasts.

In summary, this exceptional apparatus combines practicality with superior performance, making it a valuable addition to any toolkit.

Common Issues with Graco e-30

When utilizing this specific model, users often encounter a variety of challenges that can affect its overall performance. Understanding these typical problems is crucial for ensuring proper functionality and longevity of the device. Common complaints range from mechanical malfunctions to operational inefficiencies, all of which can hinder the user experience.

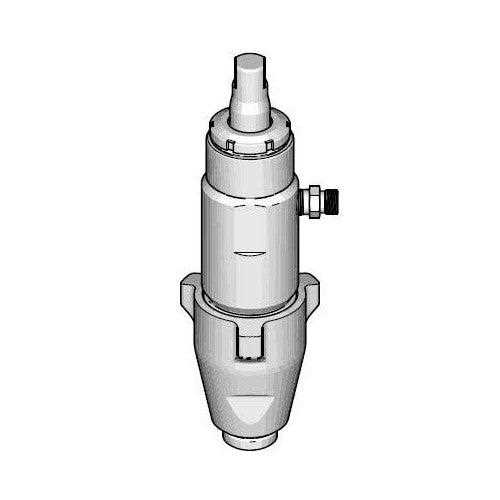

Mechanical Failures

One prevalent issue involves mechanical failures that may arise during usage. Users frequently report problems related to component wear and tear, leading to reduced effectiveness. Regular maintenance can help mitigate these issues, but neglecting routine checks can exacerbate the situation, resulting in more severe breakdowns.

Operational Inefficiencies

Another concern pertains to operational inefficiencies that manifest during the application process. Many individuals experience inconsistent performance, which can be attributed to various factors such as improper calibration or environmental conditions. Addressing these inefficiencies often requires a thorough understanding of the device’s settings and adjustments to achieve optimal results.

Step-by-Step Repair Instructions

This section provides a comprehensive guide for addressing common issues that may arise with your device. Following these organized steps will assist you in identifying problems and implementing effective solutions. It is essential to have the right tools and a clear understanding of the process to ensure success.

Initial Assessment

Begin by thoroughly inspecting the equipment for visible signs of damage or wear. Check for loose components, leaks, or unusual noises. Document your findings as they will guide you in the troubleshooting process. Make sure to disconnect the device from any power source before proceeding.

Replacement of Parts

Once you have identified the faulty components, proceed to replace them as needed. Utilize suitable replacement parts that match the specifications of the original items. Ensure that each component is installed correctly, paying attention to any instructions provided by the manufacturer. After replacing the necessary parts, reassemble the device and perform a final check to confirm that everything is secure.

Essential Tools for Repairs

Having the right instruments is crucial for any maintenance task. Properly selected tools not only streamline the process but also enhance the quality of the work performed. Understanding which items are fundamental can make a significant difference in efficiency and outcomes.

Below is a list of key instruments that are recommended for effective servicing:

| Tool | Description |

|---|---|

| Screwdriver Set | A variety of screwdrivers for different types of screws, essential for disassembling and assembling components. |

| Wrench Set | Adjustable and fixed wrenches help in tightening or loosening nuts and bolts with ease. |

| Socket Set | A collection of sockets and a ratchet to tackle various fasteners, providing more torque than traditional wrenches. |

| Pliers | Used for gripping, twisting, and cutting wires or other small items, pliers are versatile and indispensable. |

| Utility Knife | Perfect for making precise cuts in various materials, a utility knife is a handy addition to any toolkit. |

Maintenance Tips for Longevity

Ensuring the prolonged functionality of your equipment requires consistent care and attention. By adopting proper maintenance practices, you can enhance performance, minimize the likelihood of failures, and extend the lifespan of your machinery.

Here are several effective strategies to consider:

- Regularly inspect components for wear and tear to identify potential issues before they escalate.

- Keep the machinery clean and free from dust and debris, as buildup can lead to overheating and inefficiency.

- Utilize high-quality lubricants and fluids to ensure smooth operation and reduce friction among moving parts.

- Follow the manufacturer’s guidelines for recommended maintenance schedules, including filter changes and part replacements.

- Store the equipment in a controlled environment to protect it from extreme temperatures and moisture.

- Train personnel on proper handling and usage to prevent misuse and accidents.

By implementing these practices, you can significantly enhance the durability and reliability of your equipment, ensuring it serves you well for many years.

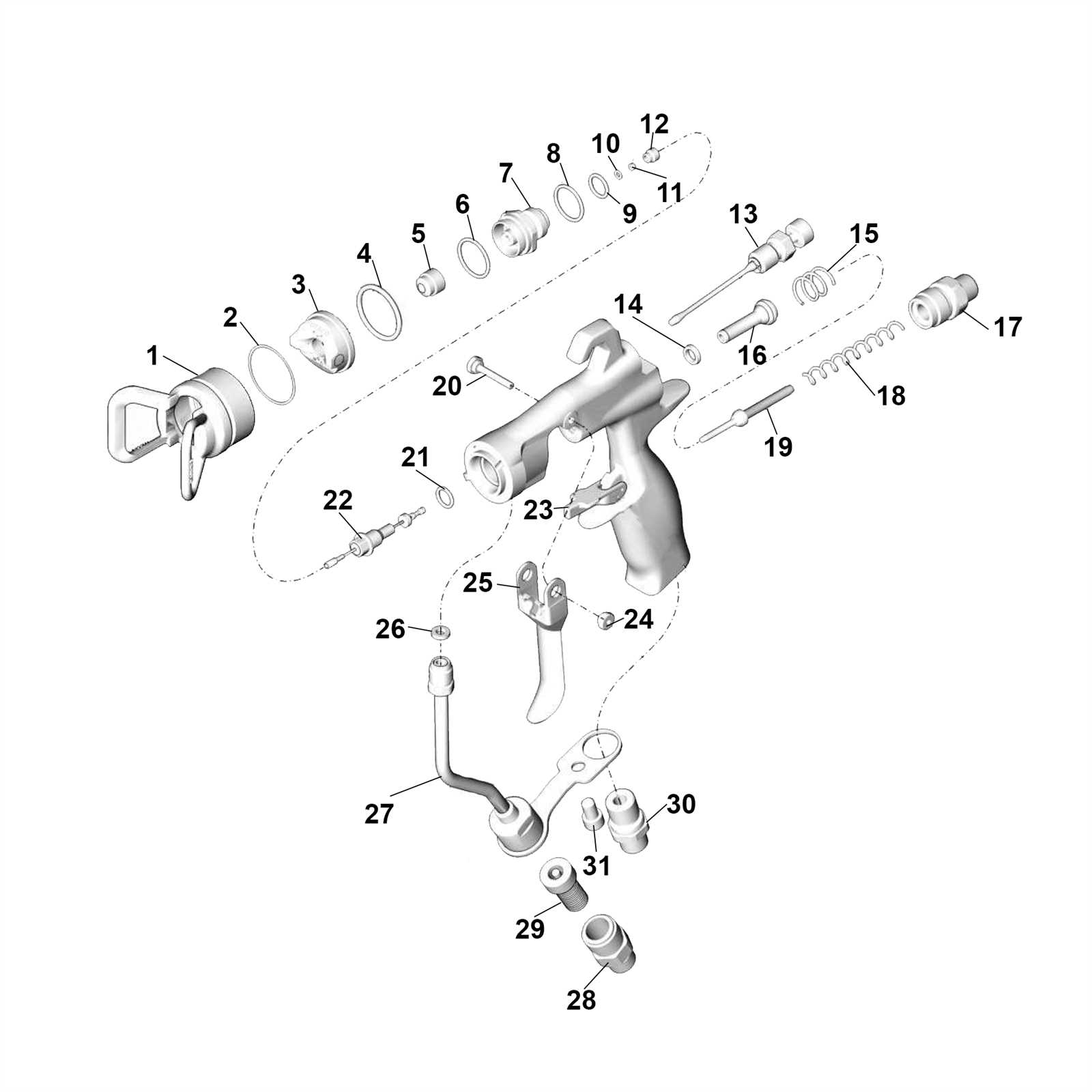

Parts Replacement Guide

This section provides essential information on how to effectively substitute various components of the equipment. Ensuring that parts are replaced correctly is vital for optimal functionality and longevity. This guide outlines the necessary steps and considerations for part exchanges to maintain peak performance.

When replacing components, follow these key points:

- Identify the specific part that requires substitution.

- Ensure you have the correct replacement component, compatible with your device.

- Gather the necessary tools for the replacement process.

- Follow safety precautions to prevent any injury or damage during the exchange.

To facilitate a smooth replacement process, adhere to the following steps:

- Turn off and disconnect the device from any power source.

- Carefully remove the faulty part, taking note of its installation method.

- Install the new component, ensuring it fits securely.

- Reconnect the device and perform a test to verify proper operation.

Regular maintenance and timely replacement of parts will enhance the overall efficiency and reliability of your equipment. Always refer to the manufacturer’s guidelines for specific instructions regarding parts compatibility and maintenance schedules.

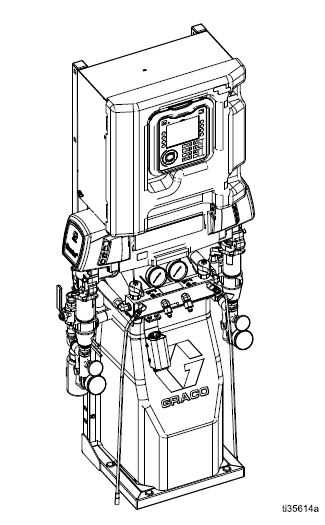

Understanding the Electrical System

The electrical framework of a device plays a crucial role in its functionality and performance. A clear comprehension of the various components involved is essential for troubleshooting and ensuring optimal operation. This section delves into the intricate details of the electrical setup, including its architecture, vital elements, and maintenance practices.

| Component | Description |

|---|---|

| Power Supply | Supplies electrical energy necessary for operation. |

| Control Panel | Interface for user commands and system feedback. |

| Sensors | Monitor various operational parameters and conditions. |

| Wiring | Connects different components, facilitating the flow of electricity. |

| Fuses | Protect circuits by breaking the connection during overload. |

Regular inspections and preventative measures are vital to maintaining the integrity of the electrical system. Understanding the specific functions of each component aids in identifying potential issues and ensuring a reliable and efficient performance.

Cleaning and Care Procedures

Maintaining the optimal performance of your equipment is essential for ensuring longevity and efficiency. Regular cleaning and proper care procedures are crucial in preventing buildup of residues that can impair functionality. By following straightforward guidelines, you can keep your device in excellent condition.

Initial Cleaning involves removing any external dirt or debris. Use a soft cloth or sponge moistened with a gentle detergent solution to wipe down surfaces. Avoid abrasive materials that may scratch or damage the finish. Thoroughly rinse the area with clean water to eliminate any soap residue.

Internal Maintenance should be performed periodically. Disassemble any accessible components as per the manufacturer’s guidelines. Clean these parts using a suitable cleaner, ensuring that no residue remains. Reassemble carefully, ensuring all components are securely fitted.

Storage Recommendations play a vital role in care. Store the equipment in a dry, cool place away from direct sunlight and extreme temperatures. If applicable, cover the device to prevent dust accumulation.

By implementing these practices, you can significantly enhance the lifespan of your machinery and ensure it operates at peak efficiency. Regular attention to cleaning and care will yield long-term benefits and reliability.

Troubleshooting Frequently Asked Questions

In this section, common operational issues are addressed to help users identify and resolve typical challenges that may arise. By understanding these frequently encountered issues, users can maintain optimal functionality and minimize downtime. The following table provides quick insights into the most common inquiries and their solutions.

Common Issues and Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| System fails to start | Power supply disruption or connection issue | Check all connections and ensure the power source is stable |

| Inconsistent flow rate | Blockage in the lines or nozzle | Inspect and clear any obstructions in the system components |

| Unexpected pressure drops | Leakage or worn parts | Identify and seal leaks; replace any worn components as needed |

Tips for Effective Troubleshooting

For best resu

Safety Precautions During Repairs

When performing maintenance, prioritizing safety is essential to prevent accidents and ensure a secure work environment. Understanding and applying basic safety measures can greatly reduce the risk of injury or equipment damage. These precautions are designed to protect individuals working on complex systems, especially in high-pressure or hazardous situations.

| Precaution | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate gear, including gloves, eye protection, and hearing protection to shield against potential hazards. |

| Power Disconnection | Before any work begins, disconnect the power supply to avoid accidental starts or electrical shocks. |

| Ventilation | Ensure proper airflow in the workspace, especially when dealing with chemicals or substances that could release harmful fumes. |

| Tool Inspection | Regularly inspect tools and equipment for wear or damage. Using compromised tools can lead to accidents or ineffective repairs. |

| Clear Work Area | Keep the workspace free from clutter and obstacles to enhance mobility and prevent tripping hazards. |

Adhering to these precautions helps maintain a safe and productive environment. Being mindful of safety protocols not only safeguards personnel but also contributes to the longevity of equipment and the quality of maintenance outcomes.

Where to Find Replacement Parts

Locating the right components for equipment maintenance ensures continued efficiency and longevity. It’s essential to source parts from reliable suppliers to guarantee compatibility and high performance, especially for specialized machinery. By securing quality replacements, you can prevent disruptions in usage and extend the lifespan of your equipment.

Authorized Distributors and Online Retailers

One of the most dependable sources for acquiring compatible parts is through authorized distributors. These vendors typically stock genuine parts and have access to a wide inventory. Additionally, online marketplaces provide a variety of options, allowing users to compare prices and find components that meet specific needs. Many reputable retailers also offer customer support to help select the correct parts.

Salvage and Equipment Shops

In cases where new components may be costly, exploring salvage and equipment shops can be a practical alternative. These shops often carry second-hand parts in good condition, offering a budget-friendly option for replacing key elements. However, it’s important to inspect each part for quality and durability to ensure it meets the operational standards of your equipment.