In the realm of outdoor maintenance, understanding the intricacies of your equipment is essential for optimal performance. Proper upkeep not only enhances efficiency but also extends the lifespan of your tools, ensuring they remain reliable for years to come. Whether you are a seasoned professional or an enthusiastic hobbyist, having access to detailed guides is invaluable for navigating the complexities of your machines.

These resources serve as comprehensive references, providing insights into troubleshooting, component identification, and essential servicing techniques. By familiarizing yourself with the specificities of your devices, you can effectively address common issues and perform necessary adjustments. This knowledge empowers you to tackle challenges head-on, transforming potential setbacks into manageable tasks.

Embracing these instructional documents fosters a deeper connection with your equipment, allowing you to appreciate its mechanics while enhancing your overall maintenance skills. As you delve into the world of turf care apparatus, you’ll find that a proactive approach not only leads to better results but also instills a sense of confidence in your capabilities.

Understanding Craftsman Lawn Mower Types

Different types of gardening machines cater to various needs and preferences, making it essential to recognize their distinct features and functionalities. This knowledge empowers users to choose the most suitable equipment for their tasks, enhancing efficiency and satisfaction in yard maintenance.

Common Categories

Various models can be classified based on their design and operation. Below are some prevalent categories that enthusiasts and professionals may encounter:

| Type | Description |

|---|---|

| Push | Manually operated, offering a workout while maintaining small to medium-sized areas. |

| Self-Propelled | Equipped with a drive system, allowing users to navigate larger spaces with ease. |

| Riding | Designed for extensive properties, providing comfort and efficiency for significant tasks. |

Choosing the Right Type

Selecting the ideal machine depends on several factors, including the size of the area, the type of terrain, and the user’s physical capability. Understanding these categories will ultimately lead to more informed decisions and improved gardening experiences.

Essential Tools for Lawn Mower Repair

Maintaining and restoring outdoor equipment requires a specific set of instruments that ensure efficiency and precision. Having the right tools at hand can make a significant difference in the outcome of your tasks. This section outlines the key items needed to effectively address common issues and perform general maintenance.

Basic Hand Tools

- Screwdrivers: A set of both flathead and Phillips screwdrivers is crucial for loosening and tightening various fasteners.

- Wrenches: Adjustable and socket wrenches allow for easy access to nuts and bolts in tight spaces.

- Pliers: Needle-nose and regular pliers are useful for gripping and manipulating small components.

- Hammers: A rubber mallet can help in tapping components into place without causing damage.

Specialized Equipment

- Spark Plug Wrench: This tool is specifically designed for removing and installing spark plugs.

- Feeler Gauge: Essential for measuring gap widths, ensuring optimal performance of ignition components.

- Fuel Line Clamp: Useful for preventing fuel spillage during maintenance.

- Oil Filter Wrench: A must-have for easy removal and installation of oil filters.

Common Issues with Craftsman Mowers

Every outdoor maintenance tool can encounter problems over time, impacting performance and efficiency. Understanding typical challenges can help users troubleshoot and maintain their equipment effectively. Below are some frequently observed issues that may arise with these machines, along with potential causes and solutions.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Engine Won’t Start | Fuel issues, faulty spark plug, or air filter blockage. | Check fuel level and quality, replace spark plug, and clean or replace the air filter. |

| Uneven Cutting | Dull blades, incorrect cutting height, or uneven terrain. | Sharpen blades, adjust cutting height, and level the terrain if possible. |

| Excessive Vibration | Loose components or damaged blades. | Tighten all screws and bolts, and inspect blades for damage or imbalance. |

| Fuel Leaks | Worn fuel lines or loose fittings. | Inspect fuel lines for cracks and replace if necessary; ensure all connections are tight. |

| Stalling | Clogged fuel filter, old fuel, or ignition issues. | Replace the fuel filter, use fresh fuel, and check the ignition system. |

Step-by-Step Troubleshooting Guide

This guide provides a systematic approach to diagnosing common issues with outdoor equipment. By following these steps, users can identify problems effectively and implement solutions to restore functionality.

Identifying Symptoms

Begin by observing the symptoms exhibited by the device. Common issues may include difficulty starting, unusual noises, or lack of power. Take note of any specific indicators, such as smoke or unusual vibrations, as these can help narrow down the potential causes.

Basic Checks

Before delving deeper, perform a few essential checks:

- Fuel Quality: Ensure that the fuel is fresh and free of contaminants.

- Battery Condition: Inspect the battery for corrosion or damage.

- Air Filter: Check if the air filter is clean and unobstructed.

By completing these preliminary steps, you can often resolve minor issues quickly. If problems persist, further investigation may be necessary.

How to Access Your Manual Online

Finding the right guide for your equipment can significantly enhance your experience and help you maintain it effectively. Online resources are invaluable for accessing essential documentation that can assist you in understanding your device’s features and troubleshooting any issues that may arise.

To locate your specific guide online, follow these simple steps:

| Step | Description |

|---|---|

| 1 | Visit the official website of the manufacturer. |

| 2 | Navigate to the support or resources section. |

| 3 | Enter the model number of your equipment in the search bar. |

| 4 | Browse the results to find the relevant documentation. |

| 5 | Download the guide in your preferred format. |

By following these steps, you can easily access the information needed to operate and maintain your equipment with confidence.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your equipment. By following a consistent maintenance routine, you can ensure optimal performance and reduce the likelihood of breakdowns. This section provides valuable insights into practices that promote durability and efficiency.

Regular Cleaning

Keeping your machinery clean prevents the buildup of dirt and debris, which can lead to rust and other issues. Make it a habit to wipe down surfaces and remove any clippings or residues after each use.

Scheduled Inspections

Conducting routine checks allows you to identify potential problems before they escalate. Pay close attention to key components and replace worn-out parts as needed to maintain functionality.

| Task | Frequency |

|---|---|

| Clean Air Filter | Every 25 hours |

| Change Oil | Every 50 hours |

| Sharpen Blades | At least once per season |

| Check Spark Plug | Every 100 hours |

Adhering to these guidelines will enhance the reliability of your machinery and help you achieve better results over time. Prioritize maintenance to enjoy years of efficient operation.

Replacing Mower Blades: A Guide

Keeping your grass-cutting tool in optimal condition is essential for achieving a clean and even cut. One of the key maintenance tasks is the replacement of the cutting edges, which can become dull or damaged over time. This guide will walk you through the steps to ensure a smooth replacement process.

Tools Required

Before you start, gather the necessary tools to make the task easier:

| Tool | Purpose |

|---|---|

| Socket Wrench | To remove bolts securing the blades |

| Safety Gloves | To protect your hands during handling |

| Blade Removal Tool | For safe and easy blade handling |

| New Blades | To replace the old, worn-out cutting edges |

Step-by-Step Replacement Process

Follow these steps to effectively replace the cutting edges:

- Ensure the machine is turned off and disconnected from the power source.

- Lift the device using a jack or a sturdy surface for easy access to the underside.

- Use the socket wrench to loosen and remove the bolts holding the old blades in place.

- Carefully take off the old cutting edges and inspect the mounting area for debris.

- Position the new blades, ensuring they are oriented correctly, and secure them with the bolts.

- Tighten the bolts securely, making sure the new edges are firmly in place.

- Lower the device back to the ground and reconnect the power source.

Regularly replacing the cutting edges not only enhances performance but also extends the life of your equipment. Always refer to specific guidelines for your model to ensure proper installation and safety.

Cleaning the Carburetor Effectively

Maintaining optimal performance of your equipment requires regular attention to various components, with the fuel delivery system being particularly crucial. A clean carburetor ensures efficient operation and prolongs the lifespan of the machine. In this section, we will explore effective techniques for cleaning this essential part, helping you achieve a smooth-running engine.

Tools and Materials Needed

Before you begin, gather the following tools and materials to ensure a thorough cleaning process:

| Tool/Material | Purpose |

|---|---|

| Screwdriver | For disassembling the carburetor |

| Cleaning solution | To remove built-up deposits |

| Brush | For scrubbing hard-to-reach areas |

| Compressed air | To clear out debris |

| Rags | For wiping surfaces |

Step-by-Step Cleaning Process

Follow these steps to effectively clean the carburetor:

- Turn off the fuel supply and disconnect the spark plug to ensure safety.

- Carefully remove the carburetor from the engine using a screwdriver.

- Disassemble the carburetor components, taking note of the arrangement.

- Soak the parts in a suitable cleaning solution for several minutes.

- Use a brush to scrub away any stubborn deposits.

- Rinse the components with clean water and allow them to dry completely.

- Use compressed air to blow out any remaining debris.

- Reassemble the carburetor and reinstall it on the engine.

Regular cleaning of the fuel delivery system will help maintain efficiency and ensure reliable operation of your equipment.

Safety Precautions During Repairs

When engaging in maintenance or fixing equipment, ensuring safety is paramount. Understanding and adhering to specific precautions can significantly reduce the risk of accidents and injuries. This section outlines essential safety measures to follow during such activities.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Ensure the work area is clean and well-lit to avoid tripping hazards and enhance visibility.

- Disconnect the power source before beginning any work to prevent accidental activation.

- Familiarize yourself with the equipment and its components to minimize mistakes during the process.

By taking these steps, you can create a safer environment that allows for effective and efficient work. Prioritizing safety not only protects you but also enhances the overall quality of the task at hand.

- Keep all tools organized and within reach to avoid unnecessary movements.

- Follow the manufacturer’s guidelines to ensure that you are using the correct techniques and practices.

- Never rush through a task; take your time to ensure each step is completed properly.

Remember, safety should always be your top priority, allowing for a smooth and successful maintenance experience.

Ordering Replacement Parts Made Easy

Finding the right components for your equipment can often feel overwhelming. However, simplifying the process is crucial for maintaining efficiency and ensuring that everything runs smoothly. This guide aims to provide you with straightforward steps to streamline your ordering experience, allowing you to focus on getting back to work without unnecessary delays.

Identifying the Correct Components

Before placing an order, it is essential to identify the specific parts you need. Start by checking the model number of your device, as this will help narrow down your options. Utilizing online resources or catalogs can aid in pinpointing the exact components required. Visual aids, such as diagrams or pictures, can further enhance your understanding, ensuring you select the right items.

Choosing a Reliable Supplier

Once you know which parts you need, the next step is selecting a trustworthy supplier. Look for vendors that specialize in equipment components and have positive customer reviews. Many online retailers offer comprehensive listings and descriptions, making it easy to compare prices and quality. Consider options that provide customer support for any inquiries you may have. Additionally, check if they offer a return policy to safeguard your purchase.

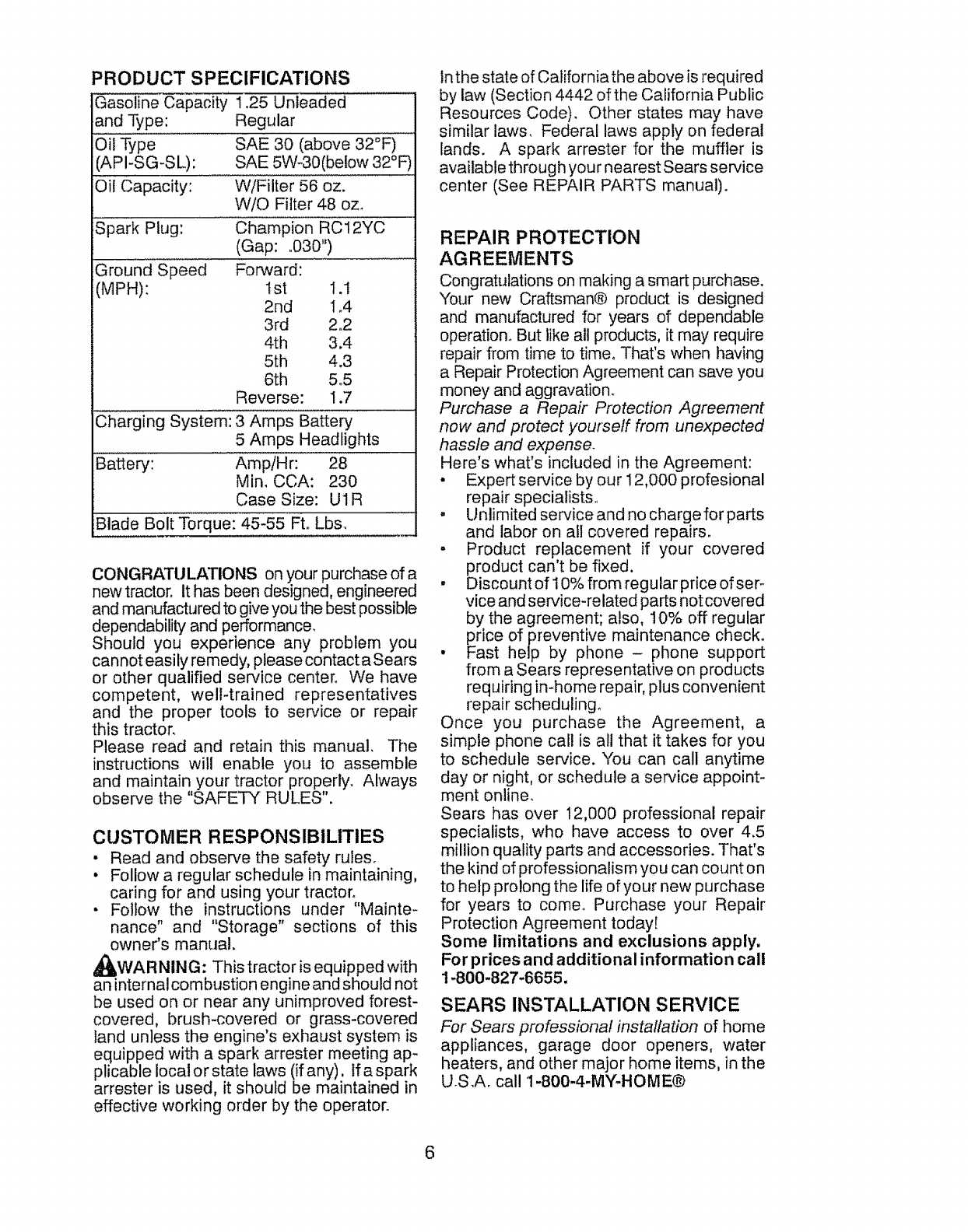

Understanding Engine Specifications

When it comes to the performance of outdoor power equipment, the characteristics of the engine play a crucial role. These specifications provide essential insights into how the machinery operates, its efficiency, and its suitability for various tasks. By familiarizing yourself with these details, you can make informed decisions regarding maintenance and upgrades.

Key attributes of an engine include displacement, power output, and torque. Displacement refers to the total volume of all the cylinders in the engine, influencing its ability to generate power. Power output indicates the engine’s strength and is typically measured in horsepower or kilowatts, essential for assessing performance capabilities. Lastly, torque affects the equipment’s ability to perform demanding tasks, particularly in challenging conditions.

Understanding these elements will enhance your ability to optimize performance and prolong the lifespan of your equipment. Regularly consulting the specifications can also aid in identifying potential issues before they escalate.

When to Seek Professional Help

Determining the right moment to call in an expert can significantly impact the longevity and performance of your equipment. While many issues can be resolved through basic troubleshooting and maintenance, certain signs indicate that professional assistance may be necessary to avoid further complications.

Signs of Serious Issues

If you notice unusual noises, persistent leaks, or significant drops in performance, these could be indicators of underlying problems that require specialized knowledge. Ignoring these symptoms might lead to more extensive damage, which could be costly to fix later on.

Lack of Experience

For those who lack familiarity with mechanical systems, attempting to resolve intricate issues without adequate expertise can be risky. If you find yourself unsure or overwhelmed by the complexity of the situation, seeking professional guidance is a prudent choice to ensure safety and effective resolution.