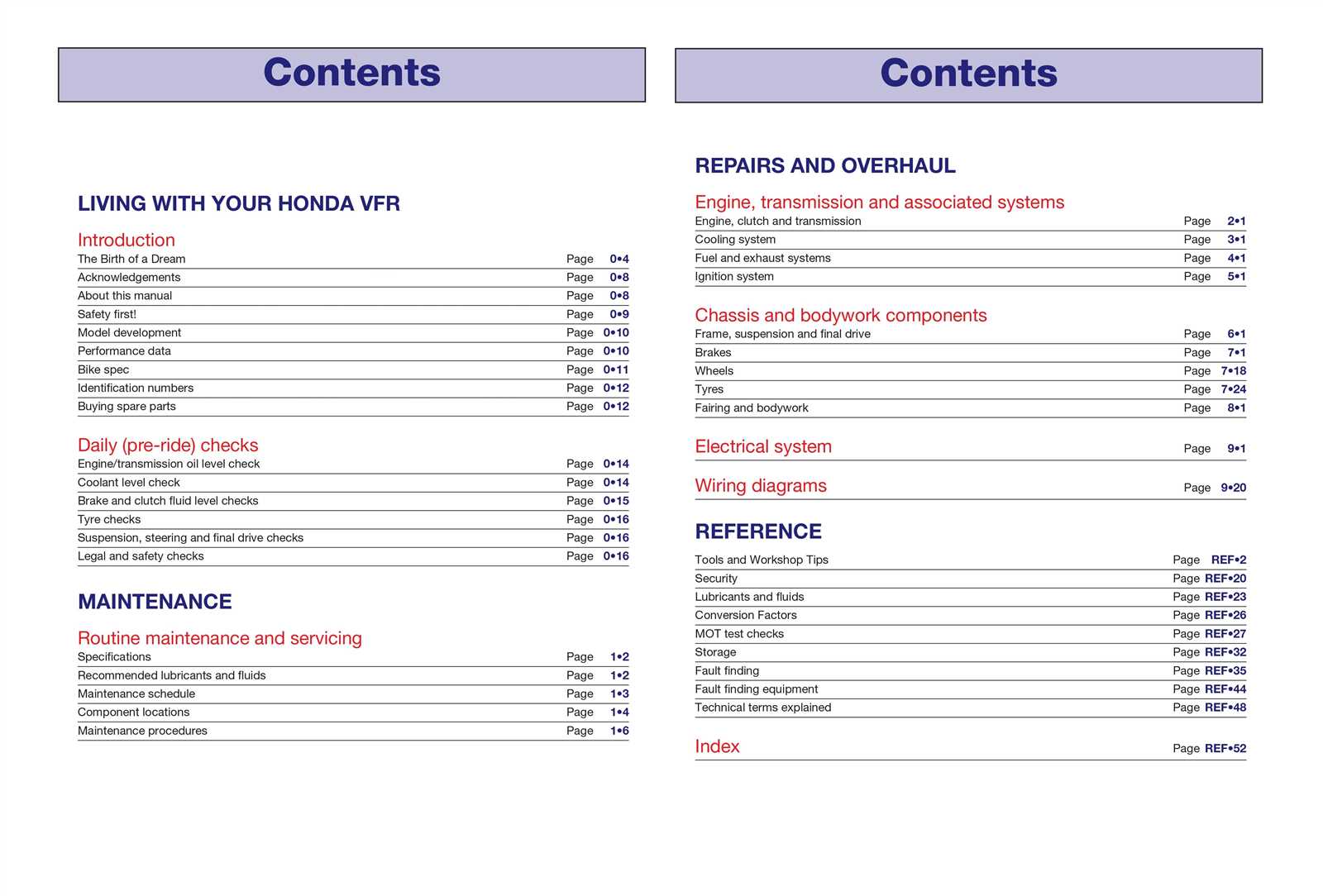

Owning a personal vehicle on two wheels offers freedom, speed, and efficiency, but ensuring consistent performance requires attention to detail and routine care. This guide provides a thorough overview of essential upkeep practices, helping enthusiasts and owners alike maintain peak functionality over time.

From checking vital components to diagnosing and resolving common issues, understanding how various systems work together is crucial for optimal longevity. Even minor adjustments can make a significant difference in ensuring smooth rides and preventing future malfunctions.

This resource delves into the technical aspects of troubleshooting mechanical challenges, offering clear explanations and actionable advice. Whether you’re performing routine checks or tackling more complex problems, staying informed will empower you to make the right choices for your machine’s upkeep and safety.

Honda Maintenance Guidelines

Regular upkeep ensures that any two-wheeled machine performs reliably and remains safe throughout its lifecycle. Following a structured schedule minimizes unexpected issues and extends the functionality of all essential components.

- Fluid Levels: Routinely monitor oil, coolant, and brake fluid to maintain peak performance and prevent mechanical failures.

- Tire Care: Inspect air pressure and tread depth to ensure optimal traction and safety during all road conditions.

- Brake System: Examine brake pads and discs for signs of wear to maintain effective stopping power.

- Chain and Drive System: Lubricate and adjust tension regularly to prevent premature wear and ensure smooth operation.

- Electrical Checks: Confirm battery health and ensure all lights and indicators function properly.

By adhering to these guidelines, riders can prevent avoidable breakdowns and enjoy smoother journeys for longer. Regular inspections make it easier to identify potential problems early, promoting safety and efficiency on every ride.

Essential Tools for Smooth Repairs

Efficient maintenance requires the right equipment to ensure every step is performed with precision. Having a well-organized set of instruments not only streamlines the process but also helps prevent complications during adjustments or replacements.

- Socket Set: A complete collection of sockets ensures compatibility with various fasteners and eliminates the need for improvisation.

- Torque Wrench: This tool guarantees precise force application, preventing over-tightening or loosening of essential components.

- Multimeter: Useful for diagnosing electrical circuits, ensuring smooth functioning of wiring and sensors.

- Allen Keys: Ideal for handling bolts in hard-to-reach areas, providing versatility for multiple tasks.

- Needle-Nose Pliers: Essential for gripping, bending, and maneuvering small parts in confined spaces.

- Lubricants and Cleaners: Ensure smooth operation by reducing friction and preventing corrosion over time.

A complete toolkit not only improves the efficiency of every operation but also enhances safety by minimizing the risk of damage to sensitive parts.

Troubleshooting Common Engine Issues

Identifying and resolving frequent performance problems can extend the longevity of an engine. This section outlines practical methods to diagnose malfunctions and prevent minor issues from becoming major breakdowns.

Signs of Potential Performance Problems

- Unusual noises during startup or while idling

- Reduced power output when accelerating

- Difficulty starting in cold or humid conditions

- Sudden increases in fuel consumption

Systematic Approach to Diagnostics

- Check the fuel supply: Ensure there are no blockages in lines and that filters are clean.

- Inspect air intake: A clogged filter can limit airflow, leading to poor combustion.

- Examine the ignition system: Test spark plugs for wear or improper gapping.

- Evaluate fluid levels: Low oil or coolant levels can cause overheating or stalling.

- Monitor sensor readings: Ensure temperature and pressure sensors are functioning correctly.

By following these steps, minor disruptions can often be quickly isolated and repaired, minimizing downtime and ensuring optimal engine performance.

Electrical System Diagnosis Tips

Identifying faults in the electrical components of a two-wheeled vehicle requires a structured approach. The goal is to trace potential issues systematically, ensuring the entire power flow operates as intended. A clear understanding of current paths and common weak points helps in resolving malfunctions efficiently.

Common Symptoms of Electrical Issues

Some of the frequent signs of electrical problems include dim lighting, non-responsive switches, and sudden power loss. These signs often indicate disruptions in voltage distribution or a breakdown in one of the connectors. Detecting the source early can prevent further damage and ensure stable operation.

Tools and Techniques for Testing

Using diagnostic tools like multimeters and continuity testers allows precise checks of wires and connectors. Regular inspection of wiring harnesses helps identify loose or corroded connections, which can lead to unstable performance. Following a step-by-step testing plan ensures no component is overlooked.

| Component | Issue | Recommended Action |

|---|---|---|

| Battery | Low voltage | Recharge or replace |

| Wiring | Frayed insulation | Repair or replace |

| Fuses | Blown fuse | Replace with

Brake Adjustment and Safety Checks

Ensuring proper responsiveness of the stopping system is essential for secure and smooth operation. Regular fine-tuning and inspections help maintain optimal performance, preventing unnecessary wear and enhancing control during use. This section provides guidance on essential steps to keep the braking mechanism functioning reliably. Step 1: Examine the Cables and Connections Step 2: Calibrate Pad Alignment Step 3: Test for Sufficient Lever Pressure Final Safety Tip: After every adjustment, roll the vehicle forward slowly and engage the brakes to confirm they activate properly without delay or noise. Consistent checks ensure safe performance and extend the life of the braking system. Chain Care and Replacement Advice

Proper maintenance of the driving mechanism is essential for optimal performance and longevity. Regular inspection and timely intervention can prevent more significant issues and ensure a smooth operation. Cleaning is a crucial step in preserving the integrity of the mechanism. Use a specialized cleaning agent to remove dirt and grime that accumulate over time. A soft brush can help access hard-to-reach areas, ensuring thorough cleansing. Afterward, apply a suitable lubricant to minimize friction and wear. Additionally, it is vital to monitor tension. A well-adjusted tension prevents slippage and excessive wear. Refer to the manufacturer’s specifications for the ideal tension range and make adjustments accordingly. Checking tension regularly will help maintain optimal performance. When the time comes for replacement, choose a high-quality component that meets the required specifications. Signs of wear include elongated links, rust, or excessive stiffness. Replacing the mechanism promptly can prevent damage to other parts and enhance overall efficiency. By following these guidelines, enthusiasts can ensure the longevity and reliability of their driving systems, leading to a more enjoyable experience on the road. Proper Tire Inspection Techniques

Ensuring optimal performance and safety of any two-wheeled vehicle requires regular assessment of the wheel components. Conducting a thorough examination can prevent potential hazards and enhance overall riding experience. The following methods can assist in effectively evaluating tire condition and integrity.

Regularly implementing these inspection techniques contributes significantly to the longevity of the wheels and overall vehicle safety. Always refer to professional guidelines for specific requirements and recommendations. Fuel System Maintenance Practices

Regular upkeep of the fuel delivery system is crucial for ensuring optimal performance and longevity of any two-wheeled vehicle. Proper maintenance not only enhances fuel efficiency but also reduces the likelihood of operational issues caused by fuel contaminants or system blockages. One of the key aspects of maintaining the fuel system involves routinely inspecting and replacing the fuel filter. This component plays a vital role in trapping impurities before they enter the engine. Neglecting this part can lead to decreased engine efficiency and potential damage. In addition, it is essential to monitor fuel lines and connections for any signs of wear or leaks. Any deterioration in these components can adversely affect fuel flow and engine performance. Regularly checking for cracks or loose fittings will help maintain system integrity. Another important practice is to ensure that the fuel tank is kept clean. Sediments can accumulate over time, potentially clogging the fuel system. Utilizing a fuel stabilizer during periods of inactivity can help prevent the buildup of harmful deposits. Lastly, periodic inspection of the fuel injectors is recommended. These components should be cleaned or replaced as necessary to ensure efficient fuel atomization and delivery. Addressing injector issues promptly can significantly improve engine response and efficiency. Cooling System Upkeep Strategies

Maintaining the efficiency of the cooling system is crucial for optimal performance and longevity of your two-wheeled vehicle. Proper care ensures that the engine remains at an ideal temperature, preventing overheating and enhancing overall functionality. Here are some effective strategies to keep the cooling system in top condition:

Implementing these strategies will help in preserving the efficiency of the cooling system, ensuring that the engine operates smoothly under various conditions. Transmission Tuning and Improvements

Enhancing the performance of a vehicle’s gear system can lead to significant gains in efficiency and responsiveness. This section explores various methods to fine-tune and upgrade the mechanism that transfers power from the engine to the wheels, ensuring smoother operation and improved acceleration. Understanding the intricacies of gear ratios, shifting patterns, and component upgrades is crucial for achieving optimal results. Adjusting Gear Ratios

One of the primary ways to enhance the performance of the transmission system is by adjusting the gear ratios. By altering these ratios, riders can achieve a better balance between speed and torque, tailoring the power delivery to suit specific riding conditions. This modification allows for quicker acceleration without sacrificing top-end speed, creating a more engaging riding experience. Upgrading Internal Components

Investing in high-quality internal components can significantly improve the overall performance of the gear system. Upgraded clutches, synchronizers, and shift forks are designed to handle increased power and provide smoother engagement. Additionally, utilizing lightweight materials can reduce rotational mass, enhancing responsiveness and efficiency during gear changes. Winter Storage Preparation Guide

As colder months approach, it becomes essential to ensure your two-wheeled vehicle is properly prepared for hibernation. Taking the right steps can prevent damage and maintain the machine’s performance for the upcoming season. This guide outlines key procedures to follow for optimal preservation during winter storage. Begin by thoroughly cleaning the exterior to remove dirt and grime, which can lead to corrosion. Pay special attention to the undercarriage and hard-to-reach areas. Next, consider changing the oil and replacing the filter to eliminate contaminants that could affect engine longevity. To protect the fuel system, add a fuel stabilizer to prevent the gasoline from deteriorating. Run the engine for a few minutes to ensure the additive circulates throughout the system. Afterward, it’s advisable to either drain the tank completely or fill it up to reduce the amount of air in the tank. Check and inflate the tires to the recommended pressure, as underinflated tires can develop flat spots. Additionally, placing the vehicle on a stand can help alleviate weight on the tires during storage. Finally, cover the machine with a breathable cover to protect it from dust while allowing moisture to escape. |