Maintaining an all-terrain vehicle requires a thorough understanding of its components and systems. This guide is designed to equip enthusiasts and operators with the essential knowledge needed to keep their machines in optimal condition. From routine checks to intricate repairs, having the right information at hand can make all the difference in ensuring longevity and performance.

Whether you’re a seasoned mechanic or a novice user, familiarizing yourself with the intricacies of your vehicle will enhance your experience. This resource covers various aspects, including common issues, preventive measures, and detailed procedures for effective handling. With the right insights, you can tackle challenges confidently and improve your vehicle’s reliability.

In this section, you will find step-by-step instructions that emphasize safety and efficiency. Understanding the technical aspects will empower you to make informed decisions, ultimately saving time and money. Embrace the opportunity to deepen your skills and enhance your knowledge, ensuring that your vehicle remains a dependable companion on any adventure.

Understanding the Honda Rancher 350

This section aims to provide a comprehensive overview of a specific model in the world of all-terrain vehicles. Known for its durability and versatility, this vehicle is a favorite among outdoor enthusiasts and workers alike. With a focus on performance, it can tackle various terrains, making it an excellent choice for both recreational and utility purposes.

Key Features

The vehicle is designed with several notable characteristics that enhance its functionality. From a robust engine to an ergonomic design, each feature contributes to a superior riding experience. Here are some of the essential attributes:

| Feature | Description |

|---|---|

| Engine Capacity | Offers a powerful engine for optimal performance. |

| Suspension System | Equipped with a reliable suspension to handle rough terrain. |

| Fuel Efficiency | Designed for impressive fuel consumption, making it economical. |

| Storage Options | Includes ample storage for tools and personal items. |

Maintenance Considerations

| Task | Frequency |

|---|---|

| Oil Change | Every 100 hours of operation |

| Air Filter Cleaning | Every 50 hours of use |

| Tire Inspection | Monthly |

| Brake Check | Every 200 hours of operation |

Common Issues with the Rancher 350

This section highlights frequent challenges faced by owners of this popular all-terrain vehicle. Understanding these issues can help in maintaining optimal performance and longevity.

Engine Troubles

One of the most common concerns involves the engine, which may exhibit signs of poor performance. Issues such as difficulty starting, stalling, or unusual noises can arise from various factors. Regular checks of the fuel system and ignition components are crucial to prevent further complications.

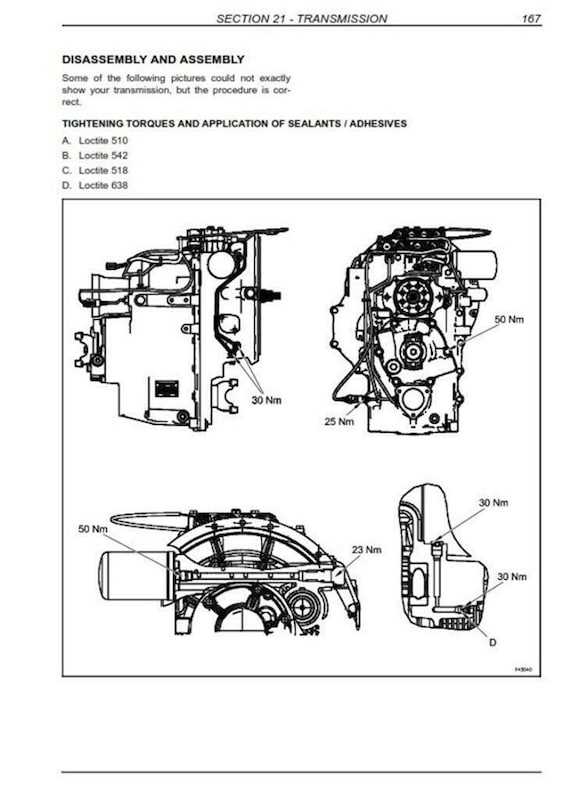

Transmission Problems

Another area where riders may encounter difficulties is the transmission. Slipping gears or unresponsive shifting can significantly affect riding experience. These issues often stem from wear and tear on the components or improper maintenance. Ensuring that the fluid levels are adequate and that the system is serviced regularly can mitigate these problems.

Essential Tools for Repairing ATVs

Maintaining and fixing all-terrain vehicles requires a specific set of instruments to ensure efficient and effective work. Understanding the importance of having the right equipment can significantly enhance the overall experience, whether you’re a novice or an experienced mechanic. This section will outline the vital tools needed for tackling common issues with off-road machines.

Socket Set: A comprehensive socket set is indispensable. It allows for easy removal and installation of various components. Ensure you have both metric and standard sizes to accommodate different fasteners.

Wrenches: A good collection of wrenches, including adjustable and torque wrenches, is crucial for precise adjustments and to prevent over-tightening. These tools help in working on tight spaces effectively.

Screwdrivers: A variety of screwdrivers, including flathead and Phillips, will enable you to handle numerous tasks, from minor fixes to major assembly tasks. Consider having both regular and precision screwdrivers for detailed work.

Pliers: Pliers, including needle-nose and slip-joint types, are essential for gripping, twisting, and cutting wires or small components. They provide versatility in handling different mechanical tasks.

Jack and Stands: Lifting equipment is necessary for working underneath the vehicle. A reliable jack and sturdy stands will ensure safety while you perform maintenance or repairs on the undercarriage.

Multimeter: This tool is vital for diagnosing electrical issues. A multimeter helps measure voltage, current, and resistance, allowing you to troubleshoot problems in the electrical system effectively.

Toolbox: Finally, having a sturdy toolbox to organize and store your tools will make your workspace more efficient. A well-organized toolbox not only saves time but also protects your instruments from damage.

Equipping yourself with these essential tools will ensure you are well-prepared for any challenges that arise when working on all-terrain vehicles. Proper maintenance and timely repairs can significantly extend the life of your machine and enhance its performance.

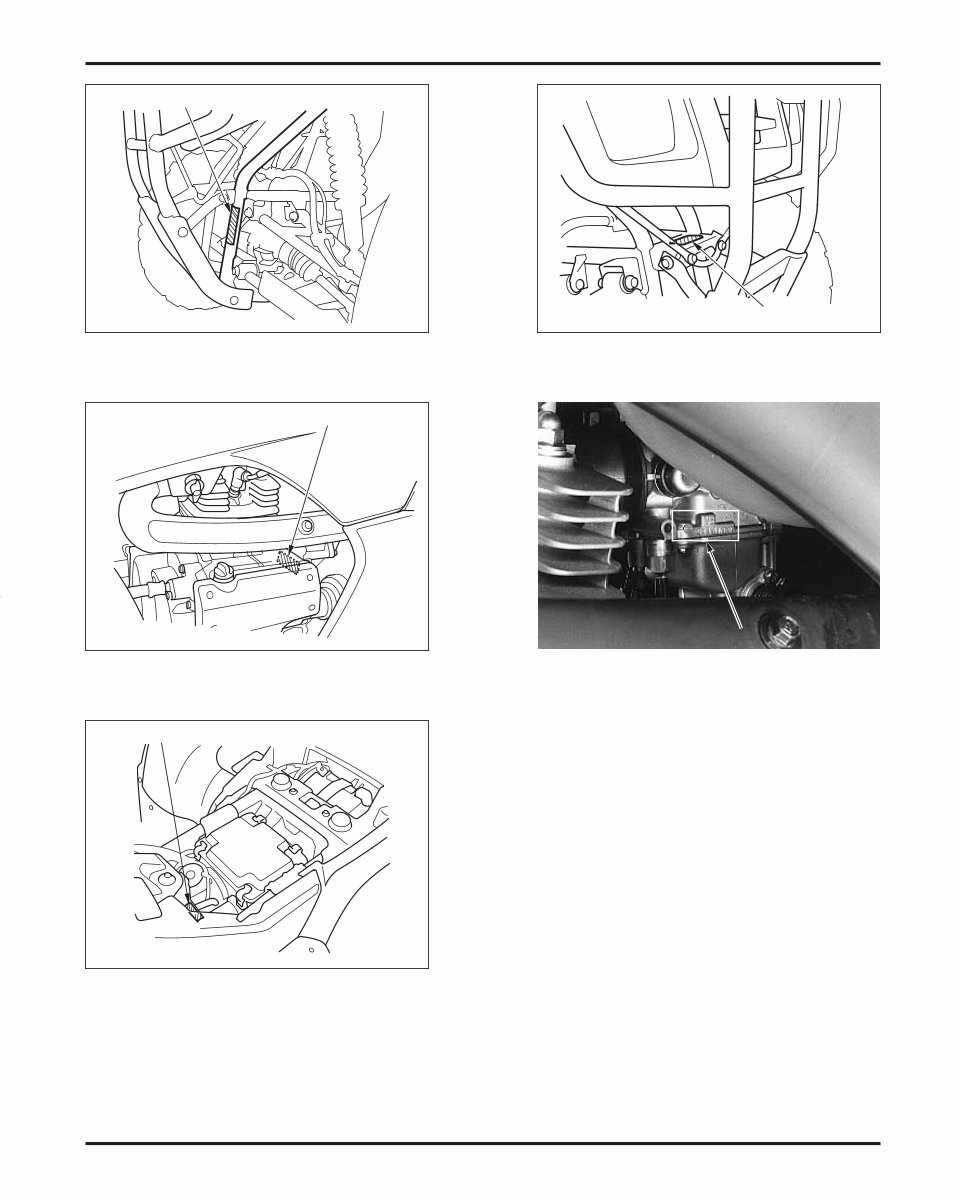

Step-by-Step Maintenance Guide

Proper upkeep of your vehicle is essential for ensuring longevity and optimal performance. This guide provides a comprehensive approach to routine care, allowing you to identify and address potential issues before they escalate. By following these systematic steps, you can enhance your riding experience and maintain the functionality of your machine.

1. Check the Oil Level: Regularly monitor the oil level to ensure it is within the recommended range. Insufficient lubrication can lead to engine damage. Always use the specified type of oil for your model.

2. Inspect the Air Filter: A clean air filter is crucial for maintaining proper airflow to the engine. Remove the filter and clean or replace it as needed to prevent performance issues.

3. Examine the Tires: Ensure that the tires are properly inflated and free from excessive wear. Inspect the tread depth and check for any visible damage that could affect handling.

4. Test the Battery: Check the battery terminals for corrosion and ensure they are securely connected. Test the battery’s charge and replace it if it shows signs of weakness.

5. Clean the Fuel System: Regularly inspect and clean the fuel lines and filter. This helps to maintain efficient fuel flow and prevent clogging, which can impact performance.

6. Review the Brakes: Inspect brake pads and discs for wear. Ensure that the braking system is functioning properly to guarantee safe operation.

7. Lubricate Moving Parts: Apply lubricant to all necessary components, including chains and joints, to reduce friction and prevent premature wear.

8. Check Lights and Indicators: Ensure all lights and indicators are operational. Replace any burnt-out bulbs to maintain visibility and safety on the road.

Following these steps diligently will not only enhance the performance of your vehicle but also contribute to a safer riding experience. Regular maintenance fosters reliability and allows you to enjoy your adventures without unexpected interruptions.

Engine Troubleshooting Techniques

Troubleshooting engine issues requires a systematic approach to identify and resolve potential problems. By understanding the common symptoms and utilizing effective diagnostic methods, one can efficiently isolate the cause of malfunctioning performance.

Start by observing any irregularities during operation, such as unusual noises, reduced power, or difficulty starting. These signs can guide you toward specific areas that may need attention. Utilize visual inspections to check for leaks, damaged components, or signs of wear that could impact functionality.

Next, employ diagnostic tools such as multimeters or compression gauges to gather data on electrical systems and engine pressure. This information can reveal inconsistencies that might not be apparent through visual inspection alone.

Additionally, consult the vehicle’s specifications to ensure that all components are functioning within their intended parameters. Comparing actual performance metrics against standard values can highlight discrepancies that require further investigation.

Finally, after narrowing down potential issues, test each system individually. This methodical approach not only helps pinpoint the exact problem but also aids in verifying that repairs are effective and restore optimal performance.

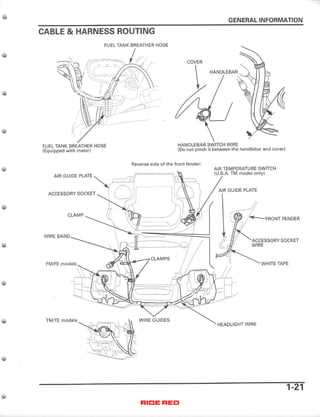

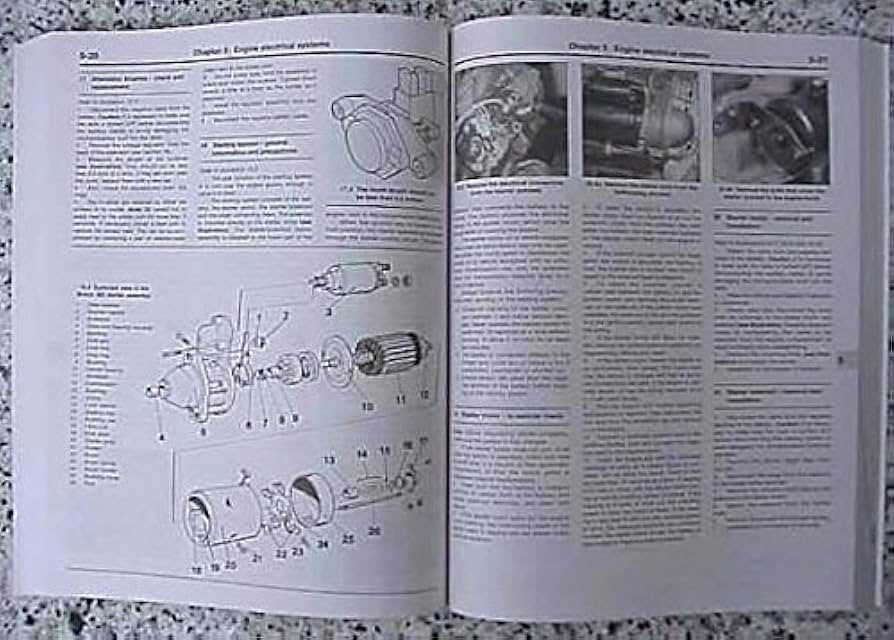

Electrical System Diagnostics Explained

The process of troubleshooting electrical systems in off-road vehicles is crucial for maintaining optimal performance and reliability. Understanding how to assess and diagnose electrical components can help identify issues before they escalate into more significant problems. Proper diagnostics not only enhances the longevity of the vehicle but also ensures safety during operation.

Effective diagnostics begin with a comprehensive understanding of the electrical architecture, including wiring harnesses, connectors, and various components such as batteries, switches, and sensors. Utilizing tools like multimeters and diagnostic scanners allows technicians to measure voltage, current, and resistance, providing vital information about the system’s health.

Common symptoms that may indicate electrical issues include difficulty starting, flickering lights, or malfunctioning accessories. By systematically evaluating these symptoms, one can isolate the problem area. For instance, if the battery shows a low charge, it may be necessary to check the alternator’s output or inspect the charging circuit for faults.

Additionally, visual inspections play a significant role in diagnostics. Damaged wires, corroded connectors, or loose terminals can often be identified through careful examination. Documenting findings during the troubleshooting process helps create a clear picture of the situation, which is invaluable for future reference or repairs.

Ultimately, mastering electrical diagnostics not only facilitates efficient problem-solving but also empowers vehicle owners to take proactive measures in vehicle maintenance, ensuring a smoother and more enjoyable riding experience.

Replacing the Brake System Components

Maintaining optimal performance of the braking system is essential for ensuring safety and reliability. Over time, various elements of the braking assembly may wear out or become damaged, necessitating their replacement. This section outlines the essential steps for effectively swapping out these critical components, ensuring your vehicle remains in peak condition.

Identifying the Components

Begin by familiarizing yourself with the key elements of the braking system. These typically include brake pads, rotors, calipers, and brake lines. Understanding each component’s function will aid in diagnosing issues and determining which parts require attention.

Gathering Necessary Tools

Before commencing the replacement process, ensure you have all required tools at hand. Commonly needed items include wrenches, screwdrivers, a jack, and a torque wrench. Having everything prepared will streamline the procedure and minimize downtime.

Step-by-Step Replacement

1. Safety First: Always begin by engaging the parking brake and securing the vehicle on a level surface. Use wheel chocks to prevent any movement.

2. Remove the Wheel: Use a jack to elevate the vehicle and remove the wheel, providing access to the braking components.

3. Inspect and Remove Old Parts: Carefully examine the brake pads and rotors for wear. Remove any components that show significant damage or are below the manufacturer’s specifications.

4. Install New Components: Place the new brake pads and rotors into position, ensuring they align correctly. Reattach any calipers and secure all connections.

5. Reassemble and Test: Once everything is in place, reattach the wheel, lower the vehicle, and pump the brake pedal to ensure proper engagement before taking it for a test drive.

Regular Maintenance

To prolong the life of the braking system, regular inspections and timely replacements are crucial. Monitoring the performance of these components will not only enhance safety but also improve overall driving experience.

Fluid Replacement and Management Tips

Effective maintenance of vital fluids is crucial for optimal performance and longevity of your vehicle. Regularly changing and managing these liquids can prevent costly damages and ensure smooth operation. Understanding the types of fluids involved and following a systematic approach to their upkeep can greatly enhance your riding experience.

Begin by consulting the specifications for the correct types and quantities of fluids required. Engine oil, transmission fluid, coolant, and brake fluid all play essential roles in maintaining functionality. Adhering to recommended replacement intervals is key; neglecting this can lead to premature wear and potential failure of critical components.

When replacing fluids, always use high-quality products that meet or exceed manufacturer standards. Ensure the vehicle is on level ground to obtain accurate readings and prevent spills. Use a funnel to minimize mess and dispose of old fluids in accordance with local regulations to protect the environment.

Additionally, periodically check fluid levels and conditions. Look for signs of contamination, such as discoloration or unusual odors, which can indicate the need for a change. Keeping an eye on fluid levels can help identify leaks early, allowing for timely repairs and preventing further damage.

Lastly, consider creating a maintenance schedule to keep track of fluid changes and inspections. This proactive approach will help ensure your vehicle remains in peak condition and ready for any adventure.

Upgrading Parts for Enhanced Performance

Improving your vehicle’s components can lead to significant gains in overall efficiency and capability. By focusing on specific upgrades, you can enhance speed, torque, and handling, creating a more enjoyable riding experience. Careful selection of aftermarket parts plays a crucial role in maximizing potential.

Engine enhancements often yield the most noticeable improvements. Upgrading air filters and exhaust systems can increase airflow, allowing for better combustion and power output. Additionally, tuning the engine’s performance software can optimize fuel delivery and ignition timing, leading to smoother operation.

Suspension upgrades can dramatically affect ride quality and handling. Investing in high-performance shocks and struts ensures better control over rough terrain, enhancing stability and comfort during rides. This not only improves safety but also boosts overall confidence on challenging trails.

Finally, tire selection can influence traction and performance. Choosing tires designed for specific conditions–whether mud, sand, or rocky surfaces–will ensure better grip and durability. This attention to detail can make a significant difference in how your vehicle performs under various circumstances.

Safety Precautions During Repairs

Ensuring personal safety is paramount when conducting maintenance or troubleshooting on vehicles. Adopting proper measures can prevent accidents and injuries, creating a safer working environment. Following established guidelines helps protect both the individual and the equipment involved.

Essential Safety Measures

- Wear appropriate protective gear, such as gloves, goggles, and sturdy footwear.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

- Ensure the vehicle is stable and secure before starting any work.

- Disconnect the battery to prevent electrical shocks or short circuits.

- Keep a fire extinguisher nearby, especially when working with flammable substances.

Tools and Equipment Safety

- Use tools that are in good condition and appropriate for the task.

- Avoid using makeshift tools that could lead to accidents.

- Follow the manufacturer’s instructions for any specialized equipment.

- Store tools properly to prevent tripping hazards.

By adhering to these precautions, individuals can significantly reduce the risk of injury and ensure a more efficient workflow during vehicle servicing.

Finding Reliable Parts and Resources

When maintaining and restoring off-road vehicles, sourcing dependable components is crucial for optimal performance and longevity. This process involves identifying trustworthy suppliers, understanding product specifications, and ensuring compatibility with your machine. With numerous options available, navigating through them can be challenging, but with the right approach, you can find quality parts that meet your needs.

Identifying Trusted Suppliers

Start by researching reputable dealers and online marketplaces that specialize in all-terrain vehicle components. Look for those with positive customer reviews and a solid track record. Forums and community groups dedicated to enthusiasts can also provide valuable insights and recommendations on where to purchase parts.

Evaluating Quality and Compatibility

Before making a purchase, assess the specifications of the parts you need. Check for compatibility with your specific model and consider OEM (original equipment manufacturer) options when possible. High-quality aftermarket alternatives can also be viable, but ensure they are from recognized brands. Comparing warranties and return policies can further safeguard your investment.