When it comes to maintaining small portable power units, ensuring long-term functionality and efficiency can make a significant difference in performance and lifespan. Understanding key maintenance practices helps keep these devices operating smoothly, minimizing unexpected disruptions in various scenarios, from outdoor adventures to backup power situations at home.

Routine upkeep of portable generators allows users to address common issues before they escalate. This approach involves regular inspection, component adjustments, and understanding basic troubleshooting techniques. Addressing minor concerns early helps in achieving consistent functionality, extending the life of essential components, and maintaining optimal output levels.

Through a well-rounded approach to service and periodic inspections, you can ensure that each element of the device continues to perform efficiently. With careful attention to detail, maintaining these units becomes straightforward, empowering you to handle various power needs with confidence.

Overview of Honda EU2000i Generator

Compact, efficient, and remarkably reliable, this portable power source stands out for its ability to deliver smooth, stable energy to a variety of devices. Designed with an emphasis on portability, it’s ideal for both outdoor activities and emergency situations. Its structure combines advanced technology and simplicity, making it easy to use while providing reliable operation under diverse conditions.

Key Features and Benefits

This versatile unit offers multiple features that cater to convenience and adaptability. Fuel efficiency allows for extended use, supported by an intelligent engine that automatically adjusts to power demands. Additionally, its lightweight design and quiet operation make it ideal for recreational use, ensuring minimal disturbance. This model’s attention to safety includes overload protection and low-oil shutoff, adding extra security during prolonged operation.

Common Applications

From camping trips to power outages, this power source suits various needs. Its compatibility with sensitive electronics allows users to safely connect devices without risk of damage. For those seeking a dependable energy supply in remote locations, this model provides a highly adaptable solution, consistently delivering power with minimal emissions and an eco-friendly profile.

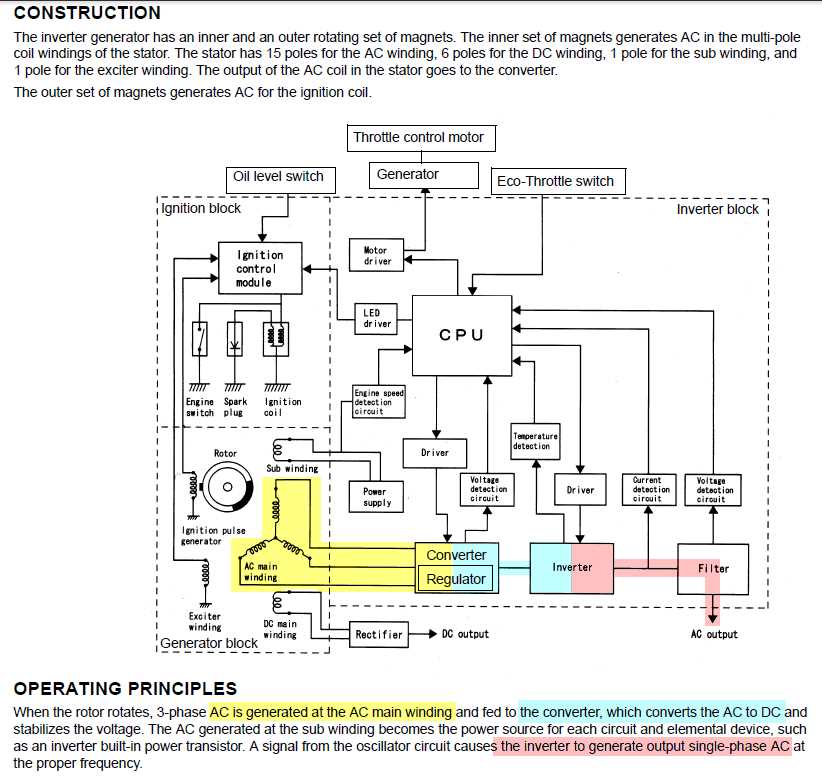

Key Components and Their Functions

Understanding the essential components and their roles is crucial to maintaining the performance and longevity of this equipment. Each part serves a distinct purpose, working together to deliver efficient energy production and operational reliability.

Engine

The engine is the primary power source, converting fuel into mechanical energy. Designed to run smoothly and efficiently, it initiates power generation, setting the foundation for the unit’s overall operation. A well-maintained engine ensures optimal fuel usage and consistent performance.

Power Control Unit

The power control unit regulates the generated electricity, stabilizing output and managing voltage. This component is vital for safe power distribution, protecting connected devices from unexpected surges. With precise management, the power control unit enhances efficiency and ensures a stable flow of energy.

These components, along with various support systems, create a dependable and balanced structure, each part complementing the others to achieve reliable operation.

Common Issues with Portable Generator Model

Many users encounter certain recurring issues while using this compact generator model. Recognizing and understanding these typical problems can aid in maintaining smooth functionality and prolonging device lifespan.

- Starting Problems: Sometimes, the generator can be hard to start or may not start at all. This issue can be linked to various factors, including fuel quality, ignition components, or air flow obstructions.

- Frequent Shutdowns: Unexpected shutdowns during operation are another common complaint. This can often be traced to overheating, oil levels, or fuel flow interruptions, all of which need regular monitoring.

- Power Output Fluctuations: Inconsistent power delivery can affect connected appliances. This may arise from issues with the voltage regulator, worn-out electrical connections, or engine-related factors.

- Overheating: Extended usage or lack of ventilation can lead to the unit overheating, which could potentially damage internal components if not addressed promptly.

- Unusual Noises: Users occasionally notice excessive noise during operation. This can result from loose parts, exhaust blockages, or engine component wear.

Addressing these challenges promptly and performing regular maintenance checks can significantly enhance performance and prevent major repairs.

Maintenance Tips for Optimal Performance

Regular attention to upkeep can extend the longevity and efficiency of any equipment. By following a few simple practices, you ensure that your machine operates smoothly and reliably, even under demanding conditions.

Routine Checks

Performing routine inspections helps detect potential issues early. Examine key components periodically, such as air filters and fuel levels, ensuring that they are free from blockages and filled to recommended levels. This practice prevents unnecessary wear and enhances operational readiness.

Fluid Management

Maintaining clean and sufficient fluid levels is essential for optimal operation. Regularly change oil and check coolant levels to avoid overheating or component damage. Make sure to use quality oils and fluids to maximize performance.

| Maintenance Task | Frequency | Notes | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Air Filter Inspection | Every 50 hours | Replace if clogged or damaged | ||||||||||||||||||||

| Oil Change | Every 100 hours | Step-by-Step Troubleshooting Guide

Effective troubleshooting requires a clear approach to diagnosing and addressing various operational issues. This section provides a systematic guide to identify potential causes and solutions in a logical sequence. By following each step, even those with limited experience can gain insights into handling common challenges and restoring functionality. 1. Check Power Connections Begin by inspecting all connections to ensure they are secure. Loose or corroded connectors can interrupt the flow and lead to functionality problems. Clean and tighten any affected areas as needed, and confirm that the system receives a stable source of energy. 2. Examine Fuel Levels and Quality Low or contaminated fuel often leads to start-up and performance difficulties. Verify that fuel levels are adequate and that it is fresh. If fuel seems stale, draining and replacing it may improve functionality significantly. 3. Inspect Air Filters A clogged air filter restricts airflow, affecting the performance. Check the filter’s condition, clean it if it appears dirty, or replace it if necessary. Regular maintenance of air filters promotes consistent efficiency and extends the system’s operational life. 4. Test Spark Plug Condition A faulty spark plug can prevent proper ignition. Remove the plug and examine it for wear or residue. Cleaning or Replacing the Fuel FilterMaintaining optimal performance in small engines often requires routine checks and part replacements. One critical component that may need attention is the fuel filter. This element ensures that impurities in the fuel do not enter the engine, thereby protecting its internal systems and enhancing efficiency. Signs of a Clogged FilterBefore proceeding with the replacement, it is essential to recognize the signs indicating that the filter may be blocked:

Replacement StepsFollow these steps to effectively replace the fuel filter:

Regularly checking and replacing the fuel filter can prolong the life of your equipment and ensure it runs smoothly. Keep an eye on the symptoms mentioned above to maintain top performance. Cleaning the Carburetor for Better EfficiencyRegular maintenance of the fuel delivery system is essential for optimal performance. One critical aspect is ensuring that the carburetor remains free from deposits and obstructions. A clean carburetor not only enhances fuel efficiency but also promotes smoother operation and reduces the likelihood of engine issues. Here are the steps to effectively clean the carburetor:

By following these steps, you can significantly improve the efficiency and longevity of the engine. Regular cleaning helps prevent fuel delivery problems and ensures consistent performance. How to Check Oil Levels CorrectlyEnsuring proper lubrication in your equipment is essential for its efficient operation and longevity. Regularly verifying the oil levels helps prevent potential damage and maintains optimal performance. Here’s a concise guide on how to accurately assess oil levels. Preparation Steps

Checking the Oil Level

By following these steps, you can ensure that your machinery remains well-lubricated, enhancing its efficiency and lifespan. Understanding the Ignition SystemThe ignition system is a crucial component responsible for starting and running small engines. Its primary function is to create a spark that ignites the air-fuel mixture within the combustion chamber. This process is vital for the engine’s overall performance, efficiency, and reliability. A thorough understanding of this system can aid in troubleshooting issues and maintaining optimal functionality. Components of the Ignition SystemVarious elements work together within the ignition system to ensure effective operation. Each component plays a specific role in generating and delivering the spark needed for ignition. Below is a table summarizing the main parts of the system and their functions:

Troubleshooting Common IssuesIdentifying problems within the ignition system can be straightforward if you know what to look for. Common symptoms of ignition system failure include difficulty starting, rough idling, and loss of power during operation. By understanding how each component functions, one can quickly diagnose and address issues, ensuring reliable engine performance. Inspecting and Replacing Spark PlugsRegular examination and replacement of ignition components are vital for optimal engine performance. These elements play a crucial role in initiating combustion and ensuring efficient operation. Over time, wear and carbon buildup can hinder functionality, making it essential to conduct routine checks and timely replacements. Steps for Inspection

Replacing the Spark Plug

Battery Care and Replacement GuideMaintaining the power source of your device is crucial for ensuring optimal performance and longevity. Proper care can prevent unexpected failures and enhance efficiency. Understanding how to manage your battery effectively will not only prolong its life but also improve the overall functionality of the equipment. Routine Maintenance PracticesRegular inspections and cleaning are essential for battery longevity. Keep the terminals free from corrosion by applying a mixture of baking soda and water. Ensure that connections are tight and free from dirt. Regularly check the charge level to avoid deep discharges, which can significantly shorten the battery’s lifespan. Replacement Considerations

When it becomes necessary to replace the power source, select a compatible option that meets or exceeds the original specifications. Carefully follow the manufacturer’s guidelines for installation to ensure proper functionality. Dispose of the old unit responsibly by utilizing recycling programs available in your area. Essential Safety PrecautionsPrioritizing safety is crucial when operating and maintaining portable power equipment. Adhering to specific guidelines helps prevent accidents and ensures efficient performance. This section outlines fundamental measures to consider for safe usage and upkeep. Always operate in well-ventilated areas to minimize the risk of carbon monoxide buildup, which can be hazardous. Avoid enclosed spaces, such as garages or basements, while the unit is in operation. Additionally, keep the equipment dry and away from wet surfaces. Moisture can lead to electrical hazards and malfunction. Ensure that the device is positioned on a stable surface to prevent tipping or falling. Wear appropriate personal protective equipment such as gloves and safety goggles to shield yourself from potential injuries during operation or maintenance tasks. This will enhance your safety and minimize exposure to any harmful substances. Finally, always follow the manufacturer’s guidelines regarding fuel storage and handling. Use the recommended type of fuel, and avoid overfilling the tank to prevent spills and potential fire hazards. Winterizing Your Generator ProperlyPreparing your generator for the cold months is essential to ensure its longevity and optimal performance. Proper winterization safeguards your equipment against the adverse effects of freezing temperatures and inactivity. This process involves several critical steps to maintain functionality and prevent damage. Steps for Effective WinterizationTo ensure your equipment remains in peak condition, follow these essential steps:

Final PreparationsOnce all maintenance steps are complete, cover your generator with a weather-resistant tarp or storage cover to protect it from the elements. By following these guidelines, you can ensure your equipment will be ready to go when the warmer months return, maintaining reliability and performance. |