When it comes to ensuring optimal performance and longevity of your trusted cutting tool, understanding its components and functionality is essential. This section delves into the intricacies of care and troubleshooting for one of the most widely used models in its category.

Effective upkeep not only enhances efficiency but also significantly reduces the risk of malfunctions. By familiarizing yourself with common issues and their solutions, you can maintain a seamless operation and extend the life of your equipment.

In this guide, you will find detailed insights into various aspects of maintaining your chainsaw, from basic adjustments to more complex repairs. Empower yourself with the knowledge needed to tackle challenges and keep your tool in peak condition.

Stihl MS 170 Overview

This section provides a comprehensive examination of a popular power tool designed for cutting and trimming tasks. Its lightweight structure and efficient engine make it suitable for both beginners and experienced users, offering a perfect balance of power and usability.

Key Features

Equipped with several notable characteristics, this tool is engineered to enhance performance and ease of use. Users can expect efficient fuel consumption, user-friendly controls, and reliable safety features.

| Feature | Description |

|---|---|

| Engine Type | High-performance two-stroke engine |

| Weight | Lightweight design for easy handling |

| Fuel Efficiency | Optimized for reduced fuel consumption |

| Safety Features | Integrated safety mechanisms to protect users |

Applications

This tool is ideal for various applications, ranging from light landscaping to more demanding cutting jobs. Its versatility allows it to be a valuable asset for homeowners and professionals alike.

Common Issues and Solutions

This section addresses frequent problems encountered with the equipment and provides practical solutions to enhance performance and reliability. Understanding these challenges can help users troubleshoot effectively.

One common issue is difficulty starting the device. This may result from stale fuel or a clogged air filter. Ensuring fresh fuel and checking the filter can often resolve this problem.

Another frequent concern involves the chain not moving properly. This can be due to insufficient lubrication or tension. Regularly inspecting the oil reservoir and adjusting the chain tension are vital steps in maintaining functionality.

Users might also experience overheating during operation. This issue may stem from excessive workload or a blocked cooling system. Allowing the equipment to rest and cleaning the cooling fins can help mitigate overheating.

Lastly, if the tool produces an unusual noise, it could indicate wear in the components. Regular maintenance checks and timely replacement of worn parts can prevent further damage and ensure smooth operation.

Maintenance Tips for Longevity

Ensuring the longevity of your equipment requires regular care and attention. Implementing proper maintenance practices can significantly extend its lifespan and enhance performance. Below are essential tips to help you keep your device in top shape.

Regular Cleaning

After each use, clean the exterior and components to remove debris and buildup. This prevents damage and maintains optimal function.

Periodic Inspections

Regularly check all parts for signs of wear or damage. Early detection can save you from more extensive repairs down the line.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Clean air filter | After every 5 uses | Ensure airflow is unobstructed. |

| Inspect spark plug | Monthly | Replace if worn or dirty. |

| Check fuel quality | Before each use | Use fresh fuel to avoid starting issues. |

Essential Tools for Repair

Having the right equipment is crucial for maintaining and restoring machinery effectively. Each tool serves a specific purpose, ensuring tasks are completed efficiently and safely. Understanding which instruments to utilize can significantly enhance the overall repair process.

First and foremost, a quality set of screwdrivers is indispensable. Both flathead and Phillips options are necessary for loosening and tightening various screws. Additionally, a comprehensive socket set will aid in dealing with nuts and bolts of different sizes, providing versatility for various projects.

Another vital component is a reliable wrench, particularly adjustable types, allowing for flexibility in handling fasteners. A pair of pliers can also prove useful for gripping and twisting components that require additional force.

Safety equipment should not be overlooked. Protective eyewear and gloves are essential to safeguard against potential hazards during maintenance tasks. Furthermore, having a workbench or sturdy surface will facilitate a more organized and secure working environment.

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to identifying and resolving common issues encountered with the equipment. By following these steps, users can effectively diagnose problems and implement solutions to ensure optimal performance.

Identifying Common Issues

- Check for power supply issues.

- Inspect for fuel blockages.

- Examine the chain for damage or dullness.

- Look for signs of wear on the air filter.

Troubleshooting Steps

- Ensure the device is turned off and disconnected from the power source.

- Inspect the fuel level and replenish if necessary.

- Clean or replace the air filter as needed.

- Examine the spark plug for wear and replace if damaged.

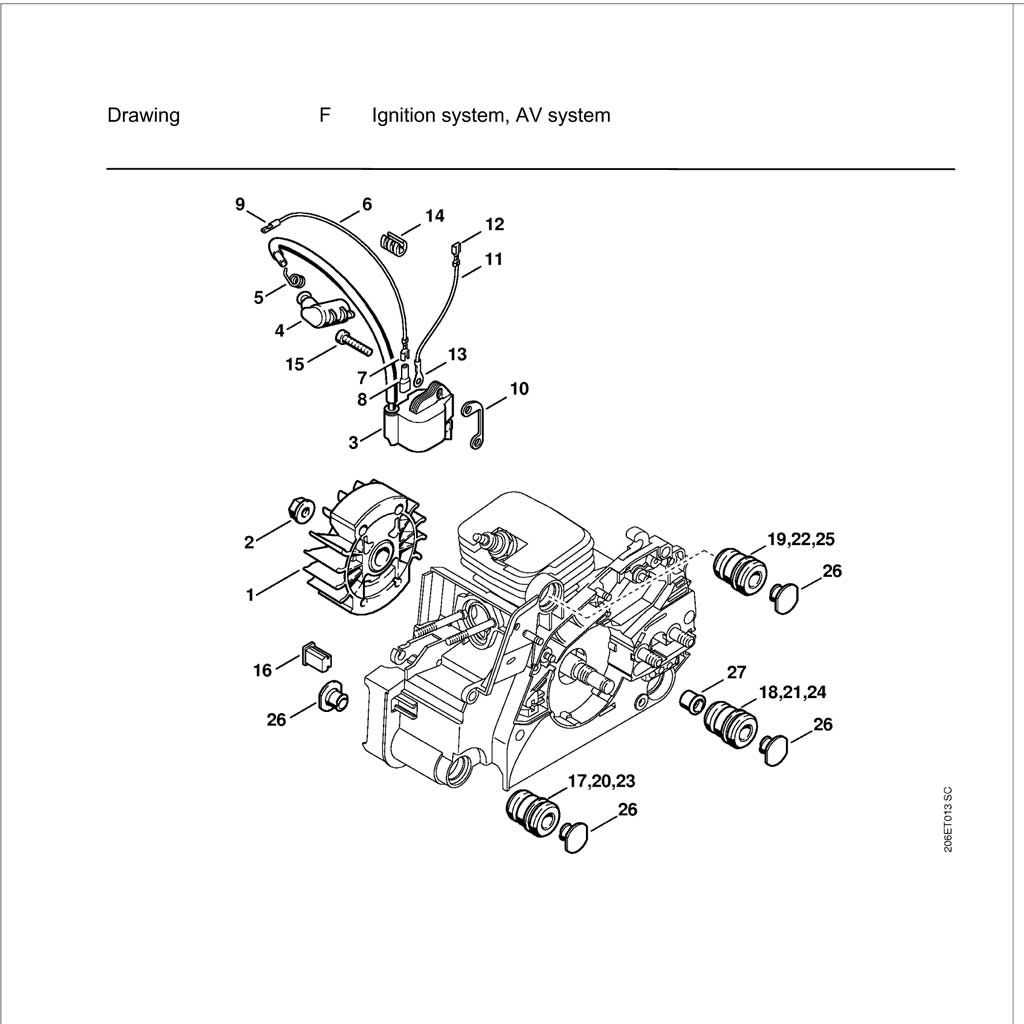

- Test the ignition system for faults.

- Perform a final inspection to ensure all components are secure.

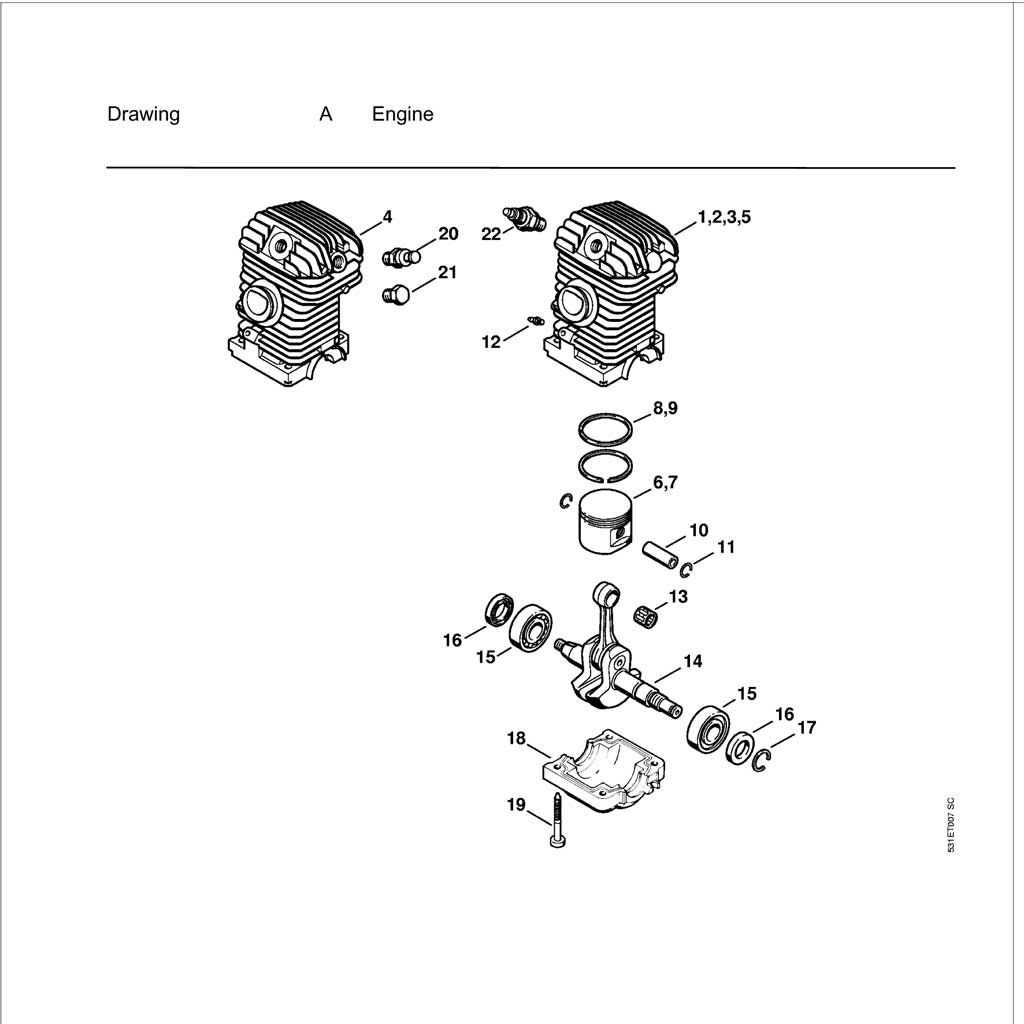

Understanding Engine Components

Grasping the fundamental parts of a motor is essential for effective maintenance and troubleshooting. Each component plays a vital role in the overall functionality, contributing to the engine’s performance and longevity.

Main Parts of the Engine

- Crankshaft: Converts linear motion into rotational motion.

- Piston: Moves up and down within the cylinder, facilitating combustion.

- Cylinder: Houses the piston and is crucial for compression.

- Fuel System: Delivers the appropriate mixture of fuel and air for combustion.

- Ignition System: Initiates the combustion process by producing a spark.

Importance of Each Component

Understanding how these elements interact is key to diagnosing issues and ensuring optimal operation. Regular inspections and timely replacements of worn parts can significantly enhance performance and reliability.

Replacing Chainsaw Chains

Changing the cutting element of a power saw is an essential maintenance task that ensures optimal performance and safety. Properly replacing the chain not only enhances the efficiency of the tool but also prolongs its lifespan. Understanding the steps involved can make the process straightforward and effective.

Steps to Remove the Old Chain

Begin by ensuring the tool is powered off and disconnected from any power source. Locate the chain tensioning mechanism, typically found on the side of the guide bar. Loosen the tension to allow for easier removal of the chain. Carefully detach the chain from the sprocket and remove it from the guide bar, taking note of the arrangement for reinstallation.

Installing the New Chain

When installing the new cutting element, position it on the guide bar with the sharp edges facing forward. Ensure the chain fits snugly around the sprocket. Adjust the tensioning mechanism to secure the chain properly, allowing minimal play while ensuring smooth movement. Finally, check the alignment and tension before reconnecting the power source, ensuring everything is secure for safe operation.

Fuel System Diagnostics

Effective assessment of the fuel system is crucial for ensuring optimal performance and reliability of the equipment. Identifying issues early can prevent costly repairs and extend the lifespan of the machine. This section outlines key aspects of diagnosing potential problems within the fuel delivery mechanism.

Common Symptoms of Fuel System Issues

Operators may notice a range of symptoms indicating fuel system malfunctions. These can include difficulty starting the engine, inconsistent power delivery, or excessive smoke during operation. Understanding these signs can lead to quicker identification of underlying issues.

Diagnostic Steps to Follow

To accurately diagnose fuel system problems, start by examining the fuel supply lines for leaks or blockages. Check the filter for clogs that may restrict flow, and inspect the carburetor for proper function. Additionally, testing fuel quality is essential, as contaminated fuel can lead to various performance issues.

Adjusting Carburetor Settings

Proper calibration of the fuel delivery system is essential for optimal performance of your equipment. Ensuring that the mixture of air and fuel is correctly balanced can lead to improved efficiency and reduced emissions. This section will guide you through the process of fine-tuning these settings.

Follow these steps for effective adjustment:

- Preparation:

- Ensure the machine is on a flat, stable surface.

- Gather necessary tools: a screwdriver and a tachometer if available.

- Initial Setup:

- Locate the adjustment screws, typically marked as H (high speed) and L (low speed).

- Start the machine and let it warm up for a few minutes.

- Adjusting Low Speed:

- Turn the L screw clockwise to increase fuel flow or counterclockwise to decrease.

- Listen for a steady idle; aim for a smooth sound without stalling.

- Adjusting High Speed:

- Accelerate the engine and adjust the H screw similarly, focusing on performance under load.

- Watch for excessive smoking, which indicates a rich mixture.

- Final Check:

- Once adjustments are made, test the machine under various loads.

- Make minor tweaks as necessary to ensure consistent operation.

Regular maintenance and adjustment of the fuel delivery system can significantly extend the life of your equipment while ensuring efficient operation. Always refer to your equipment’s guidelines for specific settings and recommendations.

Electrical System Check

Ensuring the functionality of the electrical components is vital for optimal performance. A thorough assessment of the system helps identify potential issues that could hinder operation.

Start with the following steps:

- Examine the battery for any signs of corrosion or damage.

- Check the connections to ensure they are secure and free from debris.

- Inspect the wiring for any frays or breaks that could disrupt the flow of electricity.

Once the initial inspection is complete, proceed with testing the components:

- Ignition System: Verify the spark plug for wear and clean it if necessary.

- Starter: Test the starter motor for proper operation and listen for unusual sounds.

- Switches: Ensure that all switches are functioning correctly by testing their responsiveness.

Regular checks of the electrical system are crucial for maintaining efficiency and preventing future complications.

Cleaning and Maintenance Procedures

Proper upkeep and sanitation are essential for optimal performance and longevity of your equipment. Regular attention to these areas can prevent issues and enhance efficiency.

Here are key procedures to follow:

- Cleaning the Exterior: Remove debris and dirt from the outer surfaces. Use a soft cloth and mild detergent.

- Air Filter Maintenance: Inspect and clean the air filter regularly. A clogged filter can hinder performance.

- Chain and Bar Care: Clean the cutting chain and bar after each use. Ensure they are free from sap and residue.

- Fuel System Check: Inspect the fuel system for leaks. Clean fuel lines to prevent clogging.

- Regular Lubrication: Apply appropriate lubricants to moving parts to reduce wear and tear.

Following these steps consistently will ensure your equipment remains in top condition, ready for any task.

Safety Precautions During Repairs

Ensuring safety is paramount when undertaking maintenance on power tools. Proper precautions not only protect the user but also contribute to effective troubleshooting and servicing. Understanding potential hazards and implementing safety measures can significantly reduce the risk of accidents.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) when working on machinery. This includes safety goggles to protect your eyes from debris, gloves to prevent cuts and abrasions, and sturdy footwear to shield your feet from heavy objects. Additionally, consider using ear protection if the noise level is high during maintenance tasks.

Work Environment

Maintain a clean and organized workspace to minimize hazards. Ensure that tools and parts are stored properly to avoid tripping or slipping. Adequate lighting is essential to see clearly while working, reducing the likelihood of mistakes. Furthermore, ensure that the area is well-ventilated to prevent the buildup of harmful fumes from fuels or lubricants.

Parts Replacement and Upgrades

Maintaining and enhancing the functionality of your equipment involves understanding when to replace components and consider upgrades. Regular assessments can lead to improved performance, longevity, and efficiency of the machine.

When replacing parts, it is essential to choose high-quality alternatives that match the original specifications. Upgrading specific components can also yield better results, allowing users to adapt their tools to various tasks more effectively.

| Component | Replacement Option | Benefits |

|---|---|---|

| Chain | High-performance chain | Increased cutting efficiency |

| Filter | Premium air filter | Enhanced engine protection |

| Sprocket | Upgraded sprocket | Improved power transfer |

| Bar | Longer guide bar | Greater reach and versatility |