Maintaining the functionality of a vehicle’s power unit is essential for ensuring optimal performance and longevity. A thorough understanding of the intricacies involved in the upkeep and restoration processes can significantly enhance your driving experience. This section aims to provide valuable insights and practical guidance for enthusiasts and professionals alike.

From troubleshooting common issues to executing complex rejuvenation tasks, possessing a solid knowledge base empowers individuals to tackle challenges confidently. Whether you’re an amateur mechanic or a seasoned expert, this guide offers step-by-step instructions and valuable tips that are crucial for achieving desired outcomes.

Additionally, understanding the various components and their interrelations is vital for effective interventions. This comprehensive overview will equip you with the necessary skills to navigate through repair procedures, ensuring that every aspect is addressed meticulously for the best results.

Mazda FE Engine Overview

This section delves into a specific power unit renowned for its reliability and performance. It highlights the characteristics and design features that contribute to its popularity among enthusiasts and mechanics alike. The unit is celebrated for its efficiency and smooth operation, making it a preferred choice for various vehicle models.

Developed with a focus on durability and maintenance ease, this power unit showcases a blend of innovation and traditional engineering practices. Its construction allows for optimal performance across different driving conditions, ensuring a balance between power and fuel efficiency.

| Specification | Details |

|---|---|

| Configuration | Inline-4 |

| Displacement | 2.0 L |

| Power Output | 135 hp |

| Torque | 130 lb-ft |

| Fuel System | Multi-point Fuel Injection |

The thoughtful engineering behind this power unit includes a well-structured design that promotes longevity. Regular maintenance practices can enhance its lifespan, ensuring optimal performance over time. Understanding the components and their interactions is crucial for anyone looking to optimize its functionality.

Common Issues with the FE Engine

This section explores frequently encountered problems associated with a specific power unit, highlighting the importance of regular maintenance and timely intervention. Understanding these common challenges can help ensure longevity and optimal performance.

- Overheating: Excessive heat can lead to various malfunctions, including warped components and diminished efficiency.

- Oil Leaks: Leaking lubricants can arise from worn seals or gaskets, potentially causing significant damage if not addressed promptly.

- Fuel Inefficiency: Deteriorating fuel delivery systems can result in increased consumption and diminished performance.

- Rough Idling: Irregular running at idle may indicate issues with ignition timing or air-fuel mixture imbalance.

- Noisy Operation: Unusual sounds during operation can be symptomatic of internal wear or insufficient lubrication.

Regular diagnostics and maintenance checks can mitigate these issues, ensuring reliable performance and extending the lifespan of the unit.

Essential Tools for Engine Repair

When it comes to maintaining and restoring automotive power units, having the right equipment is crucial. Proper tools not only enhance efficiency but also ensure safety and precision during the task. Understanding which implements are indispensable can significantly impact the success of the work.

Wrenches and Sockets: A variety of wrenches and socket sets are fundamental for loosening and tightening fasteners. Look for both standard and metric sizes to accommodate different components.

Screwdrivers: A set of quality screwdrivers, including flat-head and Phillips types, is essential for accessing various parts. Ensure you have different sizes for versatility.

Torque Wrench: This specialized tool allows for precise tightening of bolts to manufacturer specifications, preventing over-tightening and potential damage.

Pliers: A selection of pliers, including needle-nose and locking types, can be invaluable for gripping, twisting, and cutting wires and small components.

Diagnostic Tools: An OBD-II scanner or multimeter is vital for identifying issues within the system. These tools provide insights into performance and help diagnose problems effectively.

Lift or Jack: Elevating the vehicle safely is paramount. A sturdy lift or hydraulic jack allows for easy access to the lower sections of the unit, making it simpler to perform necessary tasks.

Having these essential tools at your disposal will significantly enhance your ability to conduct thorough maintenance and ensure optimal performance of the vehicle.

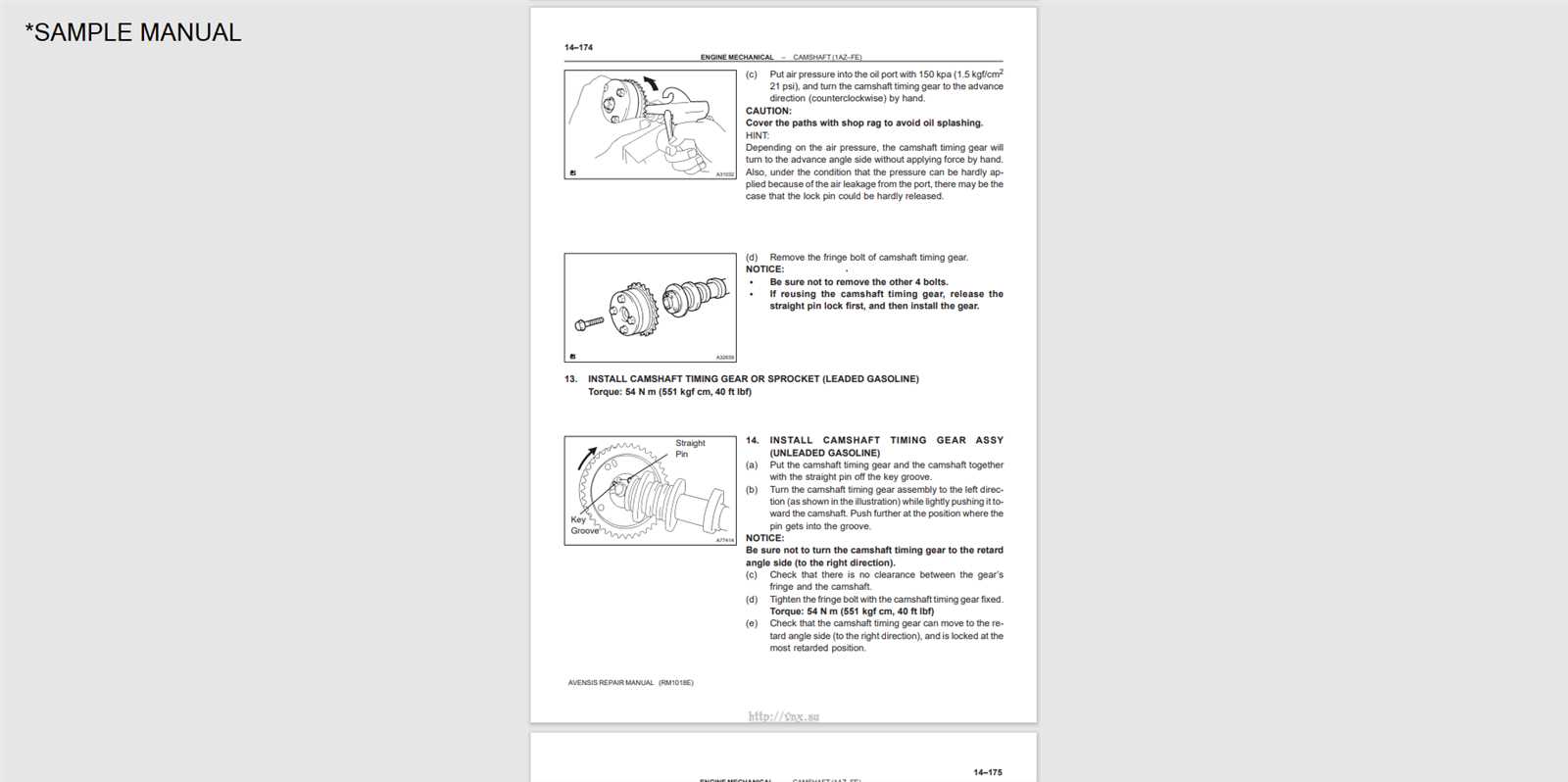

Step-by-Step Repair Procedures

This section outlines a comprehensive approach to addressing various issues that may arise in the automotive unit. By following a systematic procedure, enthusiasts and technicians can effectively diagnose and resolve concerns, ensuring optimal performance and longevity of the vehicle’s components.

Preparation and Safety Measures

Before commencing any tasks, it is crucial to gather all necessary tools and materials. Ensure the workspace is clean and well-lit. Always prioritize safety by wearing protective gear, such as gloves and goggles, to prevent injuries. Disconnect the battery to avoid any electrical hazards during the process.

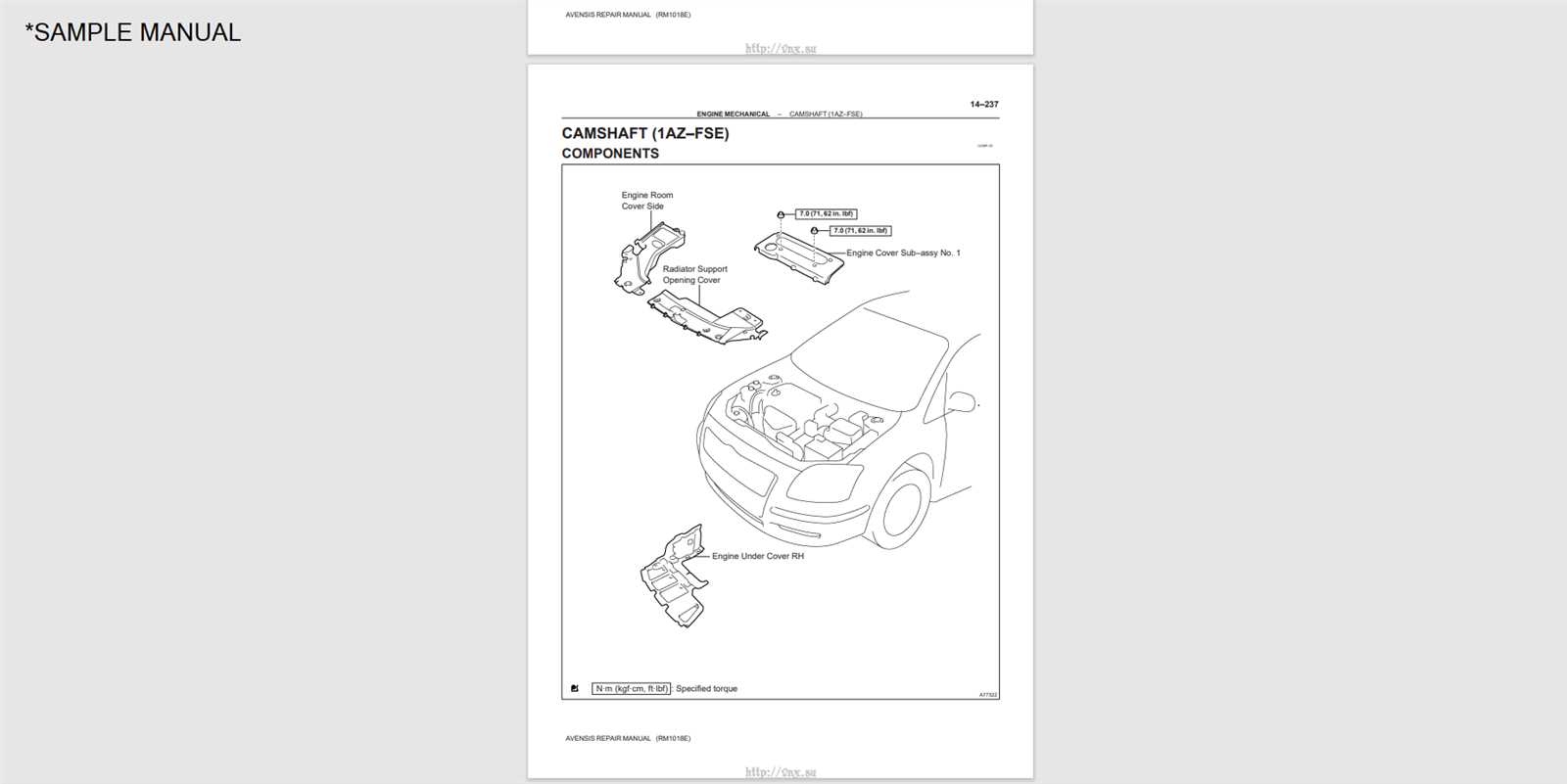

Disassembly and Inspection

Begin by carefully removing the outer covers and components. Keep track of all fasteners and parts to facilitate reassembly. Inspect each item for signs of wear, damage, or contamination. Document any findings, as this information will assist in determining the required replacements or adjustments. After thorough inspection, proceed with the necessary corrective actions based on your observations.

Parts Replacement Guidelines

Ensuring optimal performance and longevity of your vehicle requires attention to component updates. Timely substitution of worn or damaged parts is crucial for maintaining functionality and safety. This section outlines essential considerations and practices for effective replacement, aiming to enhance the reliability of your automobile.

Identifying Components for Replacement

Begin by assessing the condition of various elements within the system. Regular inspections can reveal signs of wear, such as leaks, unusual noises, or decreased performance. Utilize diagnostic tools to pinpoint specific components that may require attention, ensuring a systematic approach to maintenance.

Choosing Quality Parts

Opt for high-quality replacements that meet or exceed manufacturer specifications. Investing in reliable components can significantly affect the overall performance and durability of your vehicle. Always verify compatibility and consider both original equipment and aftermarket options that provide suitable warranties and customer support.

Maintaining Your Mazda FE Engine

Proper upkeep of your vehicle’s power unit is essential for optimal performance and longevity. Regular attention to various components can significantly enhance the driving experience while minimizing the risk of unexpected breakdowns. This section covers key practices to ensure your system operates smoothly.

Essential Maintenance Practices

- Regularly check and replace fluids, including oil, coolant, and transmission fluid, to keep everything running efficiently.

- Inspect filters, such as air and fuel, and replace them as needed to maintain optimal airflow and fuel delivery.

- Monitor the condition of belts and hoses for wear or cracks, replacing them before they fail to avoid complications.

- Conduct routine checks on the battery and electrical system to ensure reliability during operation.

Performance Enhancements

- Consider upgrading to high-performance spark plugs for improved ignition and fuel efficiency.

- Maintain proper tire pressure and alignment for better handling and fuel economy.

- Utilize quality fuel to help maintain cleanliness and performance of the combustion chamber.

- Keep the exhaust system free of blockages to ensure efficient expulsion of gases and optimal operation.

Diagnosing Engine Performance Problems

Identifying issues that affect the functionality of a vehicle’s powertrain is crucial for maintaining optimal performance. Various factors can contribute to irregularities, and understanding these can lead to effective troubleshooting. By following a systematic approach, one can isolate and resolve concerns efficiently.

The following table summarizes common performance-related symptoms and their potential causes:

| Symptom | Possible Cause |

|---|---|

| Loss of power | Clogged air filter, fuel supply issues, exhaust restrictions |

| Rough idle | Vacuum leaks, misfiring cylinders, faulty sensors |

| Poor fuel economy | Incorrect tire pressure, malfunctioning fuel injectors, engine timing issues |

| Excessive exhaust smoke | Oil consumption, coolant leaks, fuel mixture problems |

| Unusual noises | Worn components, loose belts, failing accessories |

Utilizing this information, one can systematically evaluate and address each symptom. Early detection and resolution of these issues can greatly enhance the longevity and efficiency of the system.

Torque Specifications for the FE Engine

Understanding the appropriate tightening levels is crucial for optimal performance and longevity of your vehicle’s power unit. Ensuring that all components are securely fastened prevents issues such as leaks, vibrations, and premature wear. This section provides essential data regarding the required torque values for various parts of the power unit.

Key Torque Values

- Cylinder head bolts: 75-80 ft-lbs

- Connecting rod bolts: 40-45 ft-lbs

- Main bearing cap bolts: 55-60 ft-lbs

- Oil pan bolts: 10-15 ft-lbs

- Exhaust manifold bolts: 20-25 ft-lbs

Tightening Sequence

Following the correct tightening order is essential to ensure an even distribution of pressure. The recommended sequence typically involves:

- Start with the center bolts and work outward.

- Gradually increase the torque in multiple passes.

- Recheck all values after a short operating period to ensure consistency.

Adhering to these specifications will greatly enhance the reliability and efficiency of the power unit in your vehicle.

Fuel System Troubleshooting

When facing challenges with the fuel delivery mechanism of your vehicle, it is essential to methodically assess the various components involved. Issues may arise from the supply lines, filters, injectors, or the fuel pump itself, each affecting performance and efficiency in distinct ways. Identifying the root cause of these problems is crucial for restoring optimal operation.

Common Symptoms: Drivers may notice several indicators suggesting fuel system issues. These can include irregular idling, poor acceleration, or even stalling during operation. Additionally, unusual sounds from the fuel pump or visible leaks around the system components can also signal the need for further inspection.

Troubleshooting Steps: Start by examining the fuel level in the tank. Low fuel can often lead to inadequate pressure in the delivery system. Next, check for any blockages in the fuel lines or a clogged filter that could impede flow. It is also advisable to listen for any abnormal noises coming from the pump, as these could indicate a malfunction. If necessary, testing the pressure output can help determine if the pump is functioning within the required specifications.

Regular maintenance of the fuel system is vital for preventing future complications. Keeping components clean and ensuring connections are secure can greatly enhance the longevity and reliability of the system, ultimately leading to improved performance.

Electrical System Insights

The performance and reliability of any vehicle heavily depend on its electrical components. This section delves into the intricacies of the power distribution and control systems, highlighting the essential elements that ensure smooth functionality. Understanding these components is crucial for troubleshooting and maintenance, enabling enthusiasts and technicians to keep their vehicles operating optimally.

Key Components of the Power Network

The primary aspects of the electrical framework include the battery, alternator, and wiring harness. The battery serves as the energy reservoir, supplying the necessary voltage for ignition and accessories. Meanwhile, the alternator plays a vital role in replenishing the battery’s charge while the vehicle is in motion. A well-maintained wiring harness ensures that the electrical current flows seamlessly to various systems, preventing potential failures.

Troubleshooting Common Issues

Diagnosing faults within the electrical setup requires a systematic approach. Begin by examining the battery connections for corrosion or loose terminals, as these can lead to power interruptions. Additionally, assessing the alternator output voltage with a multimeter can help identify charging issues. Understanding the significance of each component allows for effective resolution of common electrical dilemmas, ensuring prolonged service life.

Upgrading Your Mazda FE Engine

Enhancing the performance of your vehicle’s power unit can significantly improve driving experience and overall efficiency. Various modifications can be applied to boost power output, improve responsiveness, and increase fuel economy. This section explores essential upgrades that can transform your ride into a high-performance machine.

One of the most effective enhancements involves optimizing airflow. Upgrading the intake system allows for a greater volume of air to enter the combustion chamber, leading to improved combustion and increased power. A high-flow air filter or a performance intake manifold can make a noticeable difference in the vehicle’s responsiveness.

Additionally, tuning the fuel delivery system is crucial. Installing larger injectors or a performance fuel pump can ensure that the right amount of fuel is delivered for optimal performance. Pairing these components with a custom ECU tune can maximize gains, ensuring that your vehicle runs smoothly with the new upgrades.

Finally, improving exhaust flow is vital for releasing the gases efficiently. A performance exhaust system can reduce back pressure, enhancing engine efficiency and adding a sportier sound. These enhancements not only improve power but also contribute to a more enjoyable driving experience.

Preventive Maintenance Tips

Regular upkeep is essential for ensuring optimal performance and longevity of your vehicle. Implementing a systematic approach to care can prevent unexpected issues and enhance the overall driving experience. Here are some valuable strategies to maintain your automobile effectively.

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 5,000 miles | Regularly changing the lubricant helps to keep the internal components running smoothly. |

| Tire Rotation | Every 6,000 miles | Rotating tires promotes even wear and extends their lifespan. |

| Fluid Checks | Monthly | Inspecting coolant, brake fluid, and transmission fluid levels ensures optimal operation. |

| Air Filter Replacement | Every 15,000 miles | Changing the air filter improves air quality and fuel efficiency. |

| Battery Inspection | Every 6 months | Regularly checking battery connections can prevent starting issues. |