Ensuring the longevity and performance of a two-wheeled vehicle requires a thorough understanding of its inner workings. This section aims to provide insightful knowledge for enthusiasts and novice mechanics alike, focusing on common issues and effective solutions. Proper maintenance not only enhances reliability but also elevates the overall riding experience.

From the intricate systems that drive functionality to the essential components that ensure safety, familiarity with each part is crucial. Whether tackling routine checks or addressing specific malfunctions, a methodical approach empowers individuals to make informed decisions. Emphasizing hands-on experience, this guide serves as a valuable resource for anyone looking to deepen their comprehension of motorcycle upkeep.

As we delve into the specifics, attention will be given to the tools and techniques required for successful intervention. The subsequent sections will cover troubleshooting procedures, optimal practices, and tips for achieving peak performance. With dedication and the right information, even the most challenging tasks can be transformed into manageable projects.

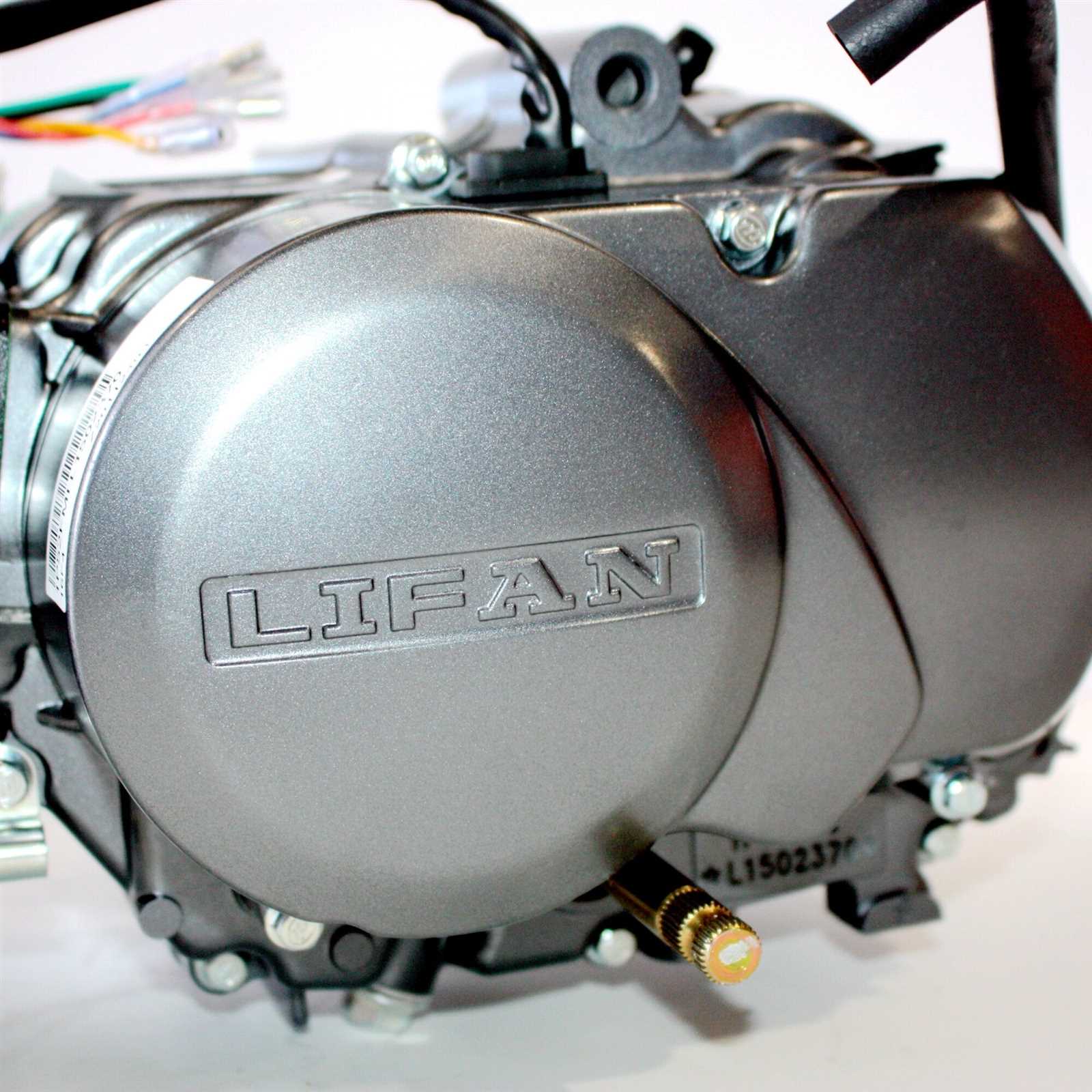

This section outlines a structured approach to understanding the complexities involved in maintaining and restoring a specific small displacement power unit. The following headings will guide readers through essential topics to ensure effective troubleshooting and servicing.

- Introduction to the Power Unit

- Common Issues Encountered

- Essential Tools and Equipment

- Disassembly Procedures

- Inspecting Key Components

- Reassembly Guidelines

- Lubrication and Maintenance Practices

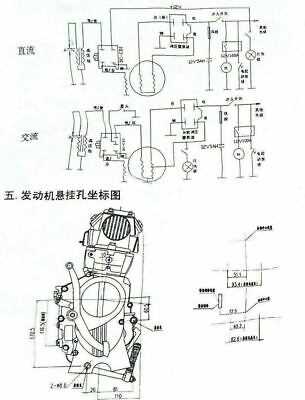

- Electrical System Diagnostics

- Fuel System Insights

- Performance Enhancements

- Safety Precautions to Follow

- Conclusion and Future Considerations

Essential Tools for Engine Maintenance

Proper upkeep of a motor requires a variety of essential instruments that facilitate effective tasks. These implements not only streamline the process but also ensure that every component functions optimally, enhancing overall performance and longevity. Familiarity with these tools is crucial for anyone looking to undertake maintenance work efficiently.

Basic Hand Tools

Starting with the basics, a reliable set of hand tools is vital. Wrenches, screwdrivers, and pliers are fundamental for loosening and tightening bolts and screws. A sturdy ratchet and socket set can significantly reduce the time spent on adjustments, allowing for a smoother workflow. Having these tools organized and easily accessible will make the maintenance process much more manageable.

Specialized Equipment

In addition to basic tools, specialized equipment can greatly enhance maintenance efforts. A torque wrench is essential for applying the correct force to fasteners, preventing damage from over-tightening. Additionally, a compression gauge can help diagnose performance issues by measuring the pressure within cylinders. Investing in high-quality instruments will yield better results and improve the reliability of the machinery.

Understanding the Engine Components

The functionality of a motor relies heavily on its various parts working in harmony. Each component plays a crucial role in ensuring optimal performance, efficiency, and longevity. By examining these elements, one can gain insight into the overall operation and maintenance of the power unit.

At the core of this system lies the combustion chamber, where fuel and air mix for ignition. Surrounding it are crucial elements such as the piston, which converts the energy generated into mechanical motion. Additionally, the crankshaft translates this linear movement into rotational force, powering the vehicle forward.

Another vital component is the camshaft, which regulates the timing of the intake and exhaust valves, facilitating the efficient flow of gases. The lubrication system is equally important, as it minimizes friction between moving parts, ensuring smooth operation and preventing wear and tear.

Understanding these components not only aids in diagnosing issues but also enhances the ability to perform maintenance effectively, ultimately contributing to a more reliable and efficient machine.

Common Issues and Troubleshooting

When maintaining a small displacement two-wheeler, it’s essential to be aware of frequent complications that can arise. Addressing these challenges promptly can ensure optimal performance and longevity. Below are some typical problems along with effective solutions to help keep your vehicle running smoothly.

Engine Performance Problems

A decrease in power output or irregular acceleration can often be traced back to issues within the combustion chamber or fuel system. Common culprits include:

- Fuel Blockages: Contaminated or old fuel can obstruct flow, leading to reduced efficiency. Regularly replace fuel and check filters.

- Ignition Failures: Worn-out spark plugs can cause misfires. Inspect and replace them as needed.

Cooling System Failures

Overheating is a prevalent issue that can lead to severe damage. To prevent this, consider:

- Cooling Fluid Levels: Ensure coolant is at the appropriate level and free of contaminants.

- Radiator Condition: Inspect for leaks or blockages that may hinder airflow.

Step-by-Step Disassembly Process

Understanding the disassembly of a small power unit is crucial for effective maintenance and troubleshooting. This process allows for thorough inspection and necessary repairs, ensuring optimal performance.

Follow these essential steps to carefully disassemble the power unit:

- Preparation:

- Gather all necessary tools, including wrenches, screwdrivers, and pliers.

- Ensure a clean workspace to avoid losing small components.

- Disconnect the power supply for safety.

- Removing External Components:

- Take off the outer casing and any covers.

- Detach the exhaust system if applicable.

- Remove any attached accessories or sensors.

- Accessing Internal Parts:

- Unscrew and remove the access panel to reach internal components.

- Take note of the arrangement of parts for easier reassembly.

- Component Disassembly:

- Carefully detach each part, starting from the top and moving downwards.

- Label and organize screws and small components to prevent confusion.

- Inspect each part for wear or damage as you remove it.

- Final Steps:

- Document the disassembly process with photos if needed.

- Clean all components before storage or repair.

- Review the next steps for maintenance or replacement of parts.

By following these steps meticulously, you can ensure a smooth disassembly process and set the stage for effective maintenance and repair.

Inspecting and Replacing Gaskets

Gaskets play a crucial role in ensuring proper sealing within various components of a mechanical system. Over time, these components may wear out or become damaged, leading to leaks and inefficiencies. Regular inspection and timely replacement are essential to maintain optimal performance and prevent potential failures.

Begin by carefully examining each gasket for signs of wear, such as cracks, tears, or deformation. Pay special attention to areas prone to high pressure or heat, as these conditions can accelerate deterioration. If any abnormalities are detected, it’s advisable to proceed with replacement to avoid further complications.

| Step | Description |

|---|---|

| 1 | Remove any components obstructing access to the gasket. |

| 2 | Carefully detach the old gasket, ensuring no debris remains on the surfaces. |

| 3 | Clean the surfaces thoroughly to promote a secure fit for the new gasket. |

| 4 | Install the new gasket, ensuring proper alignment with the corresponding parts. |

| 5 | Reassemble the components and check for leaks after the system is operational. |

By following these steps, you can ensure a proper seal and enhance the longevity of your mechanical system. Regular maintenance not only prevents issues but also improves overall efficiency.

Cleaning the Carburetor Effectively

Maintaining optimal performance of a small motorized unit often hinges on the condition of its fuel delivery system. Regular cleaning of the carburetor can prevent a multitude of issues, ensuring that the machine runs smoothly and efficiently. This section outlines the essential steps for effectively cleaning this critical component.

Before beginning the cleaning process, gather the necessary tools and materials:

- Cleaning solution or carburetor cleaner

- Soft brush or toothbrush

- Compressed air source

- Screwdriver set

- Cloth or rags

Follow these steps for a thorough cleaning:

- Disassemble the Component: Carefully remove the carburetor from the unit, taking note of the arrangement of parts for reassembly.

- Soak in Cleaner: Submerge the disassembled parts in the cleaning solution, allowing them to soak for a period recommended by the product instructions.

- Scrub Residues: Use a soft brush to gently scrub away any stubborn deposits, ensuring all passageways are clear.

- Blow Dry: Utilize compressed air to blow out any remaining cleaning solution and debris from the components.

- Reassemble and Test: Carefully reassemble the carburetor, ensuring all parts are correctly positioned before reinstalling it back onto the unit.

Following these steps will help maintain the efficiency of the fuel system and enhance the overall performance of the machinery.

Adjusting the Valves for Performance

Properly calibrating the valve mechanism is essential for optimizing the overall functionality of your two-wheeled vehicle. This procedure can enhance power output, improve fuel efficiency, and ensure smoother operation. Taking the time to adjust these components correctly will result in a more responsive ride and prolonged longevity of the motor.

Tools and Preparation

Before beginning the adjustment process, gather the necessary tools, including a feeler gauge, wrench set, and screwdrivers. Make sure to consult the specifications for your particular model to determine the correct clearance measurements. Additionally, ensure that the vehicle is on a stable surface and the ignition is off to maintain safety during the procedure.

Adjustment Process

Start by removing any covers to access the valve assembly. Rotate the crankshaft to set the piston at the top dead center of the compression stroke. Use the feeler gauge to check the clearance between the valve stem and rocker arm. If the clearance deviates from the specified range, carefully loosen the lock nut and adjust the screw until the correct measurement is achieved. Once satisfied, re-tighten the lock nut and recheck the clearance to confirm accuracy.

Regular maintenance of the valve mechanism is crucial for sustaining optimal performance. Make it a routine to inspect and adjust as needed to ensure your vehicle operates at its best.

Fuel System Checks and Repairs

The efficiency and performance of a small power unit heavily depend on its fuel delivery system. Regular inspections and timely interventions can prevent significant issues and ensure smooth operation. This section outlines essential steps for assessing and maintaining the fuel components.

Begin by examining the fuel tank for any signs of contamination or corrosion. It is vital to ensure that the tank is clean and free from debris. Follow these steps for thorough assessment:

- Inspect the tank’s interior using a flashlight.

- Look for rust, dirt, or foreign substances.

- Check the fuel level and ensure it is adequate.

Next, focus on the fuel lines and connections. Any leaks or blockages can disrupt flow and cause performance issues:

- Examine all hoses for cracks or wear.

- Ensure all connections are tight and secure.

- Replace any damaged hoses promptly.

Finally, assess the fuel filter and carburetor. These components are crucial for maintaining a clean fuel supply:

- Remove the fuel filter and inspect it for clogs.

- If necessary, replace the filter to ensure optimal flow.

- Disassemble the carburetor for cleaning, paying attention to jets and passages.

By performing these checks and addressing any identified issues, one can significantly enhance the longevity and functionality of the power unit.

Transmission Maintenance Tips

Proper upkeep of the transmission system is crucial for ensuring optimal performance and longevity of your vehicle. Regular attention to this component helps prevent costly repairs and enhances overall efficiency. Here are some essential practices to keep in mind.

Regular Fluid Checks

Maintaining the right fluid level is vital for the smooth operation of the transmission. Inspect the fluid regularly for signs of contamination or low levels. Change the fluid as recommended by the manufacturer to ensure effective lubrication and cooling.

Inspect and Replace Filters

The transmission filter plays a key role in keeping the system free from debris and contaminants. Check the filter periodically and replace it when necessary to maintain optimal flow and prevent damage. Clean filters contribute to better overall functionality and reliability.

Reassembly Techniques for Durability

Ensuring long-lasting performance during the reassembly of mechanical components requires careful attention to detail and strategic methods. Proper techniques not only enhance the durability of the assembly but also reduce the likelihood of future issues.

Essential Steps for a Successful Reassembly

- Clean all parts thoroughly to remove debris and old lubricants.

- Inspect components for wear and replace damaged parts as necessary.

- Utilize appropriate sealing agents to prevent leaks.

- Follow manufacturer specifications for torque settings.

Tools and Materials for Optimal Results

- High-quality lubricants to reduce friction.

- Specialized tools to ensure precise assembly.

- Protective equipment to safeguard against injuries.

- Storage containers to keep small parts organized.

By implementing these techniques and using the right materials, the longevity and reliability of the assembled unit can be significantly improved.

Conducting Routine Performance Tests

Regular assessments of machinery functionality are essential to ensure optimal operation and longevity. These evaluations help identify any underlying issues, enabling timely interventions that can prevent more significant complications in the future. Implementing a systematic approach to performance testing can enhance reliability and efficiency.

Key Evaluation Procedures

To effectively gauge performance, several critical procedures should be followed:

- Fluid Levels Check: Ensure that all necessary fluids are at appropriate levels to avoid overheating or inadequate lubrication.

- Visual Inspections: Conduct thorough inspections for signs of wear or damage on external components, including fasteners and mounts.

- Start-Up Assessment: Monitor the initial start-up to detect any unusual noises or vibrations that may indicate problems.

Final Thoughts on Testing

Consistent testing not only improves performance but also extends the life of the unit. Establishing a routine schedule for these evaluations ensures that any anomalies are promptly addressed, maintaining peak operational conditions.

Preventive Measures for Longevity

To ensure the sustained performance and durability of your machinery, implementing proactive strategies is essential. These methods not only extend the lifespan of components but also enhance efficiency and reliability during operation.

Regular maintenance is a cornerstone of longevity. This involves routine inspections and timely servicing, which help identify potential issues before they escalate into significant problems.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Check oil levels | Every 500 km | Reduces friction and wear |

| Inspect air filter | Every 1000 km | Improves airflow and performance |

| Clean spark plugs | Every 2000 km | Ensures efficient combustion |

| Check cooling system | Every 3000 km | Prevents overheating |

Additionally, utilizing high-quality fluids and components can significantly enhance performance. Investing in reputable products ensures that your machinery operates under optimal conditions, reducing the risk of unexpected failures.