In the world of automotive technology, understanding the intricacies of a specific power unit is essential for ensuring optimal performance and longevity. This segment delves into crucial aspects of maintaining a particular diesel unit, emphasizing the importance of routine checks and troubleshooting techniques. By familiarizing yourself with its components and functionalities, you can enhance both efficiency and reliability.

Thorough knowledge of mechanical systems allows for better diagnostic capabilities, empowering users to address issues before they escalate. This guide serves as a resource for enthusiasts and professionals alike, detailing methods for maintaining and restoring functionality. Each section provides insights that can help avoid common pitfalls associated with neglect.

Moreover, having a well-structured approach to care not only extends the lifespan of the unit but also optimizes its performance under various conditions. This resource will walk you through step-by-step processes and offer tips that are essential for anyone looking to ensure their diesel powerhouse operates at peak levels.

Understanding the 2KD FTV Engine

This section explores the intricacies of a highly regarded power unit known for its efficiency and reliability. It has been widely used in various applications, combining robust performance with fuel economy. Understanding its components and functionality is essential for anyone interested in optimizing its capabilities or addressing potential issues that may arise during its operation.

Key Features and Specifications

The unit is characterized by its compact design, which allows it to deliver impressive torque while maintaining a lightweight profile. Its configuration includes advanced features that enhance performance, including a turbocharger and intercooler system, which significantly boosts power output without compromising fuel consumption. Moreover, its engineering incorporates modern technologies that ensure durability and longevity.

Common Issues and Maintenance Tips

Like any mechanical system, this power unit may encounter certain challenges over time. Common concerns include overheating, oil leaks, and injector malfunctions. Regular maintenance, such as timely oil changes, filter replacements, and thorough inspections, can help prevent these problems. Understanding the typical symptoms and addressing them early can significantly extend the lifespan of the unit and improve overall efficiency.

Common Issues with the 2KD FTV

This section highlights prevalent problems associated with a specific diesel unit commonly found in various vehicles. Understanding these issues can help owners identify symptoms early and seek appropriate solutions to maintain optimal performance.

- Oil Leaks: Many users report frequent leaks, often due to worn seals or gaskets.

- Turbocharger Failures: Over time, the turbocharger may experience performance degradation, resulting in reduced power and efficiency.

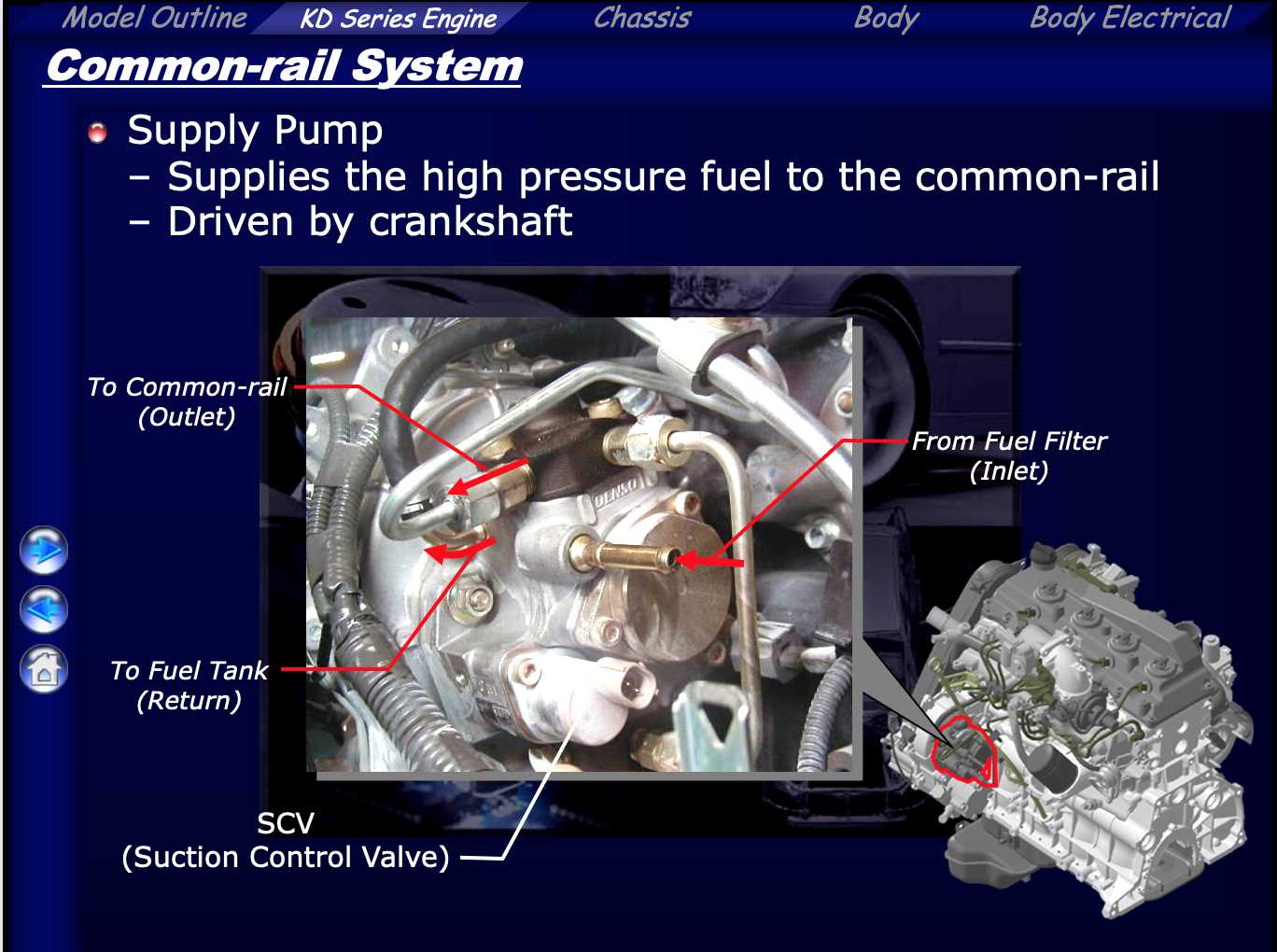

- Fuel System Problems: Clogged injectors or faulty pumps can lead to starting issues and irregular engine behavior.

- Cooling System Failures: Issues such as radiator leaks or thermostat malfunctions can cause overheating.

- Exhaust Smoke: Excessive smoke may indicate incomplete combustion or oil burning, requiring attention to the combustion process.

Awareness of these common concerns can aid in early detection and prolong the lifespan of the unit. Regular maintenance checks are crucial for ensuring smooth operation and addressing potential issues before they escalate.

Essential Tools for Engine Repair

Having the right equipment is crucial for anyone looking to maintain or fix their vehicle’s performance. A well-equipped workspace can significantly enhance the efficiency and accuracy of any task. From basic hand tools to specialized instruments, each item plays a vital role in ensuring that every component functions smoothly.

Basic hand tools such as wrenches, screwdrivers, and pliers form the foundation of any toolkit. These versatile implements are indispensable for loosening or tightening fasteners, making them essential for a variety of tasks. Additionally, a good set of sockets allows for easy access to hard-to-reach areas, ensuring that every bolt is handled with care.

For more intricate work, precision instruments such as torque wrenches and calipers are invaluable. They provide the accuracy needed for proper assembly and adjustment, preventing damage and ensuring optimal performance. A reliable diagnostic tool can also be a game changer, enabling quick identification of issues and streamlining the troubleshooting process.

Lastly, safety equipment should never be overlooked. Items like gloves, goggles, and masks protect the individual from potential hazards, making the working environment safer and more efficient. By equipping oneself with these essential tools, the process of maintaining and enhancing vehicle performance becomes not only manageable but also rewarding.

Step-by-Step Repair Process

This section outlines a systematic approach to restoring the functionality of your power unit. By following these detailed stages, you can ensure thoroughness and precision throughout the task.

1. Preparation: Begin by gathering all necessary tools and components. Ensure you have a clean workspace and appropriate safety gear. Familiarize yourself with the specifications and parts involved in your unit.

2. Disassembly: Carefully take apart the relevant sections. Document each step with notes or photos to aid in reassembly. Use the right tools to avoid damaging any components.

3. Inspection: Thoroughly examine each piece for wear and tear. Look for signs of damage such as cracks, corrosion, or excessive wear. Make a list of parts that need replacement.

4. Cleaning: Clean all components using suitable solvents and brushes. Remove any accumulated grime or debris to ensure optimal performance. Rinse and dry thoroughly before proceeding.

5. Replacement: Install new parts where necessary. Follow the manufacturer’s guidelines for each component to ensure compatibility and longevity. Be cautious to avoid misalignment during installation.

6. Reassembly: Begin reassembling the unit, referring back to your notes or photos for guidance. Ensure all connections are secure and that components are placed in their correct positions.

7. Testing: Once reassembled, conduct a series of tests to confirm functionality. Monitor for any irregularities or issues during operation. Make adjustments if needed to achieve optimal performance.

8. Final Checks: Conduct a thorough inspection to ensure everything is properly secured and functioning as intended. Review your work and make any final adjustments before considering the task complete.

Maintenance Tips for Longevity

Ensuring the durability of your vehicle requires consistent care and attention. By following a few essential practices, you can significantly extend its lifespan and maintain optimal performance. This section outlines key strategies that can help keep your transportation in prime condition.

Regular Fluid Checks: Monitoring and replacing vital fluids is crucial. Regularly inspect oil, coolant, and transmission fluids to ensure they are at appropriate levels and free from contaminants. This simple step can prevent severe internal damage.

Scheduled Inspections: Adhering to a routine inspection schedule can help identify potential issues before they escalate. Look for wear and tear on belts, hoses, and other components, and replace them as necessary to avoid costly repairs down the line.

Tire Maintenance: Keeping tires properly inflated and rotated can enhance fuel efficiency and improve handling. Regular alignment checks also contribute to even tire wear, promoting a smoother ride and longer tire life.

Air Filter Replacement: A clean air filter ensures optimal airflow to the system. Replacing the air filter at recommended intervals can enhance performance and fuel efficiency, as well as prolong the life of various components.

Driving Habits: Adopting gentle driving practices can make a significant difference. Avoiding sudden acceleration and hard braking not only conserves fuel but also reduces stress on mechanical parts.

Implementing these practices can lead to a more reliable and efficient vehicle, ultimately saving time and money while enhancing your driving experience.

Diagnosing Engine Problems Accurately

Accurate diagnosis of mechanical issues is crucial for effective maintenance and longevity of any vehicle. Understanding the symptoms and identifying underlying causes can save both time and resources. A systematic approach is essential for pinpointing faults and ensuring that repairs address the root of the problem rather than just the symptoms.

To begin with, it is vital to listen to the sounds emitted during operation. Unusual noises, such as knocking or grinding, can indicate specific malfunctions. Observing the behavior of the vehicle during acceleration and deceleration can also provide significant clues. Changes in performance may point to issues with various components, including fuel delivery systems or ignition mechanisms.

Next, visual inspection plays a key role in troubleshooting. Checking for leaks, worn belts, and damaged hoses can reveal potential problems before they escalate. Using diagnostic tools such as OBD-II scanners can enhance accuracy, allowing for the retrieval of trouble codes that guide the investigation process.

Finally, conducting test drives under different conditions is essential for gathering further insights. Monitoring parameters such as temperature, pressure, and emissions during these tests will help in confirming suspicions and ensuring a comprehensive understanding of the situation. By meticulously following these steps, one can achieve a reliable diagnosis that sets the stage for effective interventions.

Replacement Parts and Specifications

This section focuses on the essential components and their specifications necessary for maintaining optimal performance of the vehicle’s power system. Understanding these parts and their attributes is crucial for ensuring longevity and efficiency.

Key Components

- Fuel Pump: Ensures adequate fuel delivery to the combustion chamber.

- Injectors: Responsible for precise fuel atomization for efficient combustion.

- Turbocharger: Enhances engine performance by increasing air intake.

- Cooling System: Maintains optimal operating temperatures to prevent overheating.

- Timing Belt: Synchronizes the rotation of various components for proper function.

Specifications

- Fuel Pump Pressure: Typically ranges from 40 to 60 PSI, depending on the design.

- Injector Flow Rate: Usually measured in cc/min, commonly between 200 and 400 cc/min.

- Turbocharger Boost Pressure: Standard boost levels are around 10 to 15 PSI.

- Cooling System Capacity: Often varies between 8 to 12 liters, based on the vehicle model.

- Timing Belt Replacement Interval: Recommended every 60,000 to 100,000 kilometers.

Identifying and sourcing the right parts based on these specifications is essential for effective maintenance and ensuring the overall performance of the vehicle. Regular checks and timely replacements contribute significantly to reliability and safety on the road.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring a secure environment is paramount. Adhering to specific guidelines can significantly reduce risks and enhance the overall efficiency of the process. Being aware of potential hazards and implementing safety measures is essential for a successful outcome.

Personal Protective Equipment (PPE) is crucial. Always wear appropriate gear, such as gloves, goggles, and masks, to safeguard against harmful substances and physical injuries. This equipment acts as a first line of defense against unforeseen incidents.

Furthermore, maintaining a tidy workspace is vital. A clutter-free area minimizes the chances of accidents, allowing for easier navigation and access to tools. Regularly inspect your surroundings for any hazards, such as spills or sharp objects, and address them promptly.

It’s also important to have a reliable support system in place. Inform others about your activities, and if possible, work alongside a partner. This can provide assistance in case of emergencies and ensures that someone is aware of your whereabouts.

Lastly, familiarize yourself with the tools and materials you’ll be using. Understanding their functions and potential dangers can prevent accidents. Always read instructions and follow guidelines meticulously to maintain a safe and effective workflow.

Engine Performance Optimization Techniques

Enhancing the output and efficiency of a power unit involves a variety of methods that can lead to noticeable improvements in overall performance. These strategies can help achieve better acceleration, increased fuel economy, and improved reliability. By focusing on specific areas of enhancement, enthusiasts can maximize the potential of their vehicles.

Key Strategies for Enhancement

- Regular Maintenance: Consistent upkeep, including oil changes and air filter replacements, ensures that all components operate at peak efficiency.

- Tuning Adjustments: Fine-tuning the ignition timing and fuel mixture can significantly boost responsiveness and power output.

- Upgraded Components: Installing high-performance parts, such as aftermarket exhaust systems and intake manifolds, can facilitate better airflow and reduce restrictions.

- Weight Reduction: Minimizing unnecessary weight through the removal of non-essential items or using lightweight materials contributes to improved speed and handling.

Advanced Techniques

- ECU Remapping: Reprogramming the control unit can optimize fuel delivery and ignition timing, enhancing performance tailored to specific driving conditions.

- Turbocharging or Supercharging: Adding forced induction systems increases the amount of air entering the combustion chamber, resulting in higher power levels.

- Performance Tires: Upgrading to high-grip tires improves traction, allowing for better acceleration and cornering capabilities.

- Cooling Enhancements: Installing upgraded radiators and intercoolers helps maintain optimal operating temperatures, which is vital for performance.

Implementing these techniques can lead to a significant transformation in the vehicle’s dynamics, offering a more exhilarating driving experience while ensuring longevity and efficiency.

Cost-Effective Repair Strategies

Implementing budget-friendly approaches to maintaining and restoring mechanical systems can significantly reduce expenses while ensuring optimal performance. By leveraging smart techniques and preventive measures, you can prolong the lifespan of your machinery without compromising quality.

- Regular Maintenance: Conduct routine checks to identify issues before they escalate. Simple tasks such as oil changes and filter replacements can save substantial costs in the long run.

- DIY Repairs: Educate yourself on basic troubleshooting and fix minor problems independently. Utilizing online resources and community forums can provide valuable insights and guidance.

- Quality Parts: Invest in high-quality components. Although they may have a higher upfront cost, they often lead to enhanced durability and reduced frequency of replacements.

- Bulk Purchasing: Buy consumables and spare parts in larger quantities. This approach often results in discounts and minimizes the need for urgent orders.

- Local Workshops: Collaborate with local technicians who may offer competitive rates compared to larger service centers. Building a relationship with a trusted mechanic can lead to favorable deals.

By adopting these strategies, you can effectively manage costs while maintaining the functionality and reliability of your machinery.