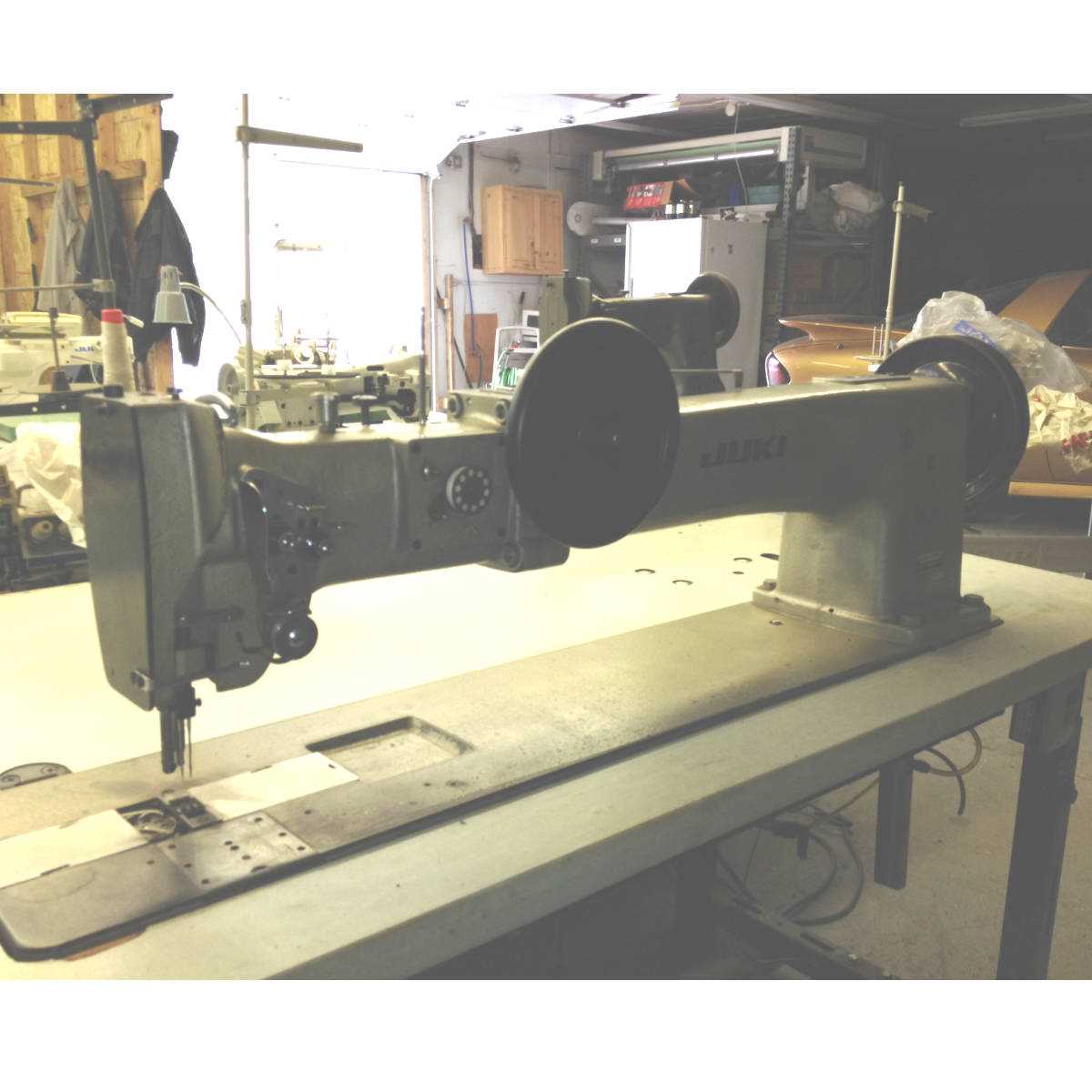

Understanding the intricacies of sewing equipment is essential for both enthusiasts and professionals alike. This section aims to provide valuable insights into the common issues that may arise with specific models of stitching devices, alongside effective solutions to enhance their longevity and performance. By delving into the nuances of these machines, users can foster a deeper connection with their tools and ensure seamless operation.

In this guide, readers will discover essential techniques for diagnosing faults, along with step-by-step procedures to resolve them. From addressing minor glitches to executing more complex adjustments, the information presented here is tailored to empower users in their journey toward mastering their sewing equipment. Emphasizing practicality and ease of use, this resource is designed to support individuals in maintaining their devices with confidence.

Equipping oneself with the right knowledge can transform the experience of working with sewing machines. Whether one is a novice seeking to understand the basics or an experienced user aiming to refine their skills, this section serves as a valuable companion, providing the tools necessary for effective maintenance and care.

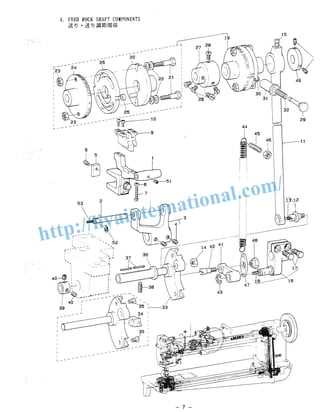

This section aims to provide an overview of the essential components and functionalities of a specific sewing apparatus. Understanding its design and features is crucial for anyone looking to maintain or troubleshoot the device effectively.

| Component | Description |

|---|---|

| Needle Mechanism | Responsible for the up-and-down motion to create stitches. |

| Feed Dogs | Assist in moving the fabric through the machine during operation. |

| Tension Control | Regulates the tightness of the thread for optimal stitching. |

| Bobbin Case | Holds the lower thread and ensures smooth feeding during sewing. |

| Foot Pedal | Controls the speed and activation of the machine. |

Familiarity with these elements not only aids in effective usage but also facilitates troubleshooting, ensuring the longevity of the apparatus.

Common Issues and Symptoms

In the realm of sewing devices, users often encounter a variety of challenges that can affect performance and efficiency. Recognizing these issues and their corresponding indicators is essential for effective troubleshooting and restoration of functionality.

| Issue | Symptoms |

|---|---|

| Thread Bunching | Loops of thread on the fabric surface, uneven stitching. |

| Needle Breakage | Frequent snapping of the needle, irregular sounds during operation. |

| Fabric Snagging | Material getting caught in the feed dogs, difficulty moving the fabric. |

| Inconsistent Stitch Length | Stitches appearing uneven, varying lengths in a single seam. |

| Machine Not Starting | No response when powered on, unusual electrical sounds. |

Tools Required for Repair

To successfully address issues in a sewing machine, having the right instruments on hand is essential. The following items will aid in diagnosing problems and performing necessary adjustments or replacements. Each tool plays a critical role in ensuring efficiency and precision throughout the process.

Essential Hand Tools

- Screwdrivers: Various sizes for loosening and tightening screws.

- Wrenches: Used for adjusting nuts and bolts securely.

- Pliers: Helpful for gripping and bending components.

- Scissors: Necessary for cutting threads and fabric accurately.

Specialized Instruments

- Needle Puller: Assists in removing and replacing needles safely.

- Cleaning Brushes: Used to remove lint and debris from internal parts.

- Oil Dropper: For applying lubricant to moving components.

- Threading Tool: Simplifies the process of threading the machine.

Step-by-Step Troubleshooting Guide

This section aims to provide a systematic approach to identifying and resolving common issues encountered with sewing machines. By following these steps, users can efficiently diagnose problems and implement effective solutions, ensuring optimal performance and longevity of their equipment.

Initial Checks

Before delving into complex troubleshooting, it is crucial to perform basic inspections to rule out simple issues. Here are the primary areas to examine:

| Area | Common Issues | Possible Solutions |

|---|---|---|

| Power Supply | Machine not turning on | Check power cord and outlet |

| Threading | Thread breaks frequently | Re-thread the machine correctly |

| Needle | Skipped stitches | Replace needle with the correct type |

Advanced Diagnostics

If initial checks do not resolve the issue, consider more advanced troubleshooting techniques. Look into the following:

- Inspecting the tension settings

- Examining the bobbin case for damage

- Cleaning the feed dogs and interior components

Maintaining Optimal Performance

To ensure long-lasting efficiency and reliability, it is essential to implement proper care and maintenance practices for your sewing device. Regular upkeep not only enhances functionality but also prolongs the lifespan of the equipment, minimizing the risk of unexpected breakdowns.

Begin by routinely cleaning the components to prevent dust and lint accumulation, which can impede operation. Utilize appropriate tools and solutions for cleaning, ensuring that each part is free from debris. Additionally, lubricating moving parts with high-quality oils can reduce friction and promote smooth operation.

Regular inspections are crucial. Examine threads, needles, and other consumables frequently to identify wear and replace them as needed. This practice will help maintain consistent stitching quality and prevent complications during use.

Finally, always refer to the manufacturer’s guidelines for specific maintenance schedules and recommendations. By adhering to these practices, you can enjoy optimal performance from your sewing device for years to come.

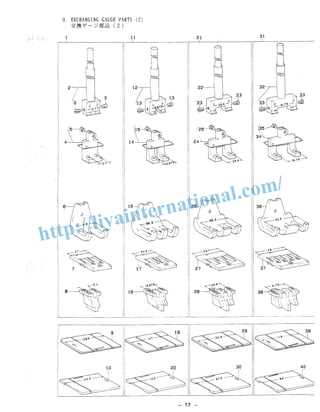

Replacing Worn Components

Regular maintenance of sewing machines is crucial for optimal performance. Over time, certain parts may wear out, affecting the overall functionality. Identifying and replacing these components can significantly extend the lifespan of your equipment and ensure smooth operation.

When considering component replacement, pay attention to the following areas:

- Needles: Dull or damaged needles can lead to fabric snags and uneven stitching.

- Bobbin Case: A worn bobbin case may cause thread tension issues, impacting stitch quality.

- Belt: A frayed or stretched belt can result in slippage, hindering the machine’s ability to function properly.

- Feed Dogs: Worn feed dogs can lead to inconsistent fabric movement, affecting stitching accuracy.

- Motor Brushes: Replacing worn motor brushes can restore power efficiency and improve speed control.

To ensure effective replacement, follow these steps:

- Identify the worn component through inspection.

- Gather the necessary tools and replacement parts.

- Carefully disassemble the machine as needed.

- Replace the worn component with a new one, ensuring proper alignment.

- Reassemble the machine and conduct a test run to verify functionality.

By promptly addressing worn components, you can maintain the quality of your sewing projects and enhance the longevity of your equipment.

Adjusting Tension Settings

Proper tension calibration is essential for achieving optimal stitching results. When the tension is too tight or too loose, it can lead to a variety of issues, such as uneven stitches or fabric puckering. Understanding how to fine-tune these settings can greatly enhance the quality of your projects.

Identifying the Right Tension

Begin by assessing the current tension levels. Use a sample piece of fabric similar to your project and sew a few test stitches. Observe the stitch formation: if the threads are visible on the fabric surface, the tension may be too tight. Conversely, if the threads are loose and create a loopy appearance, the tension may require tightening.

Making Adjustments

To modify the tension, locate the tension dial or mechanism on your device. Turn the dial in small increments, testing the results after each adjustment. Typically, a clockwise rotation increases tension, while a counterclockwise turn decreases it. Continue testing until you achieve balanced stitches that meet your expectations.

Remember: Regularly checking and adjusting tension settings will help maintain the performance of your sewing apparatus and improve your sewing outcomes.

Electrical System Diagnostics

Assessing the electrical framework of a sewing device is crucial for ensuring optimal functionality and performance. This process involves a systematic evaluation of various components to identify any discrepancies that may hinder operation. Understanding the intricacies of the electrical system helps in pinpointing potential issues and implementing effective solutions.

Key Components to Inspect

When diagnosing the electrical system, several essential elements require attention:

| Component | Function | Common Issues |

|---|---|---|

| Power Supply | Provides energy to the device | Voltage irregularities |

| Circuit Board | Controls electronic functions | Burnt traces or damaged components |

| Motors | Enables movement and operation | Overheating or stalling |

Diagnostic Steps

To effectively diagnose the electrical system, follow these essential steps:

- Visual inspection for physical damage

- Testing voltage levels at various points

- Checking connections for corrosion or looseness

- Utilizing diagnostic tools to assess functionality

Cleaning and Lubrication Techniques

Proper maintenance is essential for the longevity and performance of any sewing device. Regular cleaning and lubrication help to prevent wear, reduce friction, and ensure smooth operation. Implementing effective techniques can significantly enhance the functionality and lifespan of your equipment.

To achieve optimal results, follow these key steps:

| Step | Technique | Description |

|---|---|---|

| 1 | Dust Removal | Use a soft brush or a vacuum cleaner with a narrow attachment to eliminate dust and debris from the surface and internal components. |

| 2 | Thread Tension Adjustment | Regularly check and adjust the thread tension to prevent fabric bunching and ensure even stitching. |

| 3 | Lubrication | Apply appropriate lubricant to moving parts, such as gears and joints, to reduce friction and ensure smooth movement. |

| 4 | Oil Application | Utilize a few drops of high-quality sewing machine oil on critical points as recommended by the manufacturer. |

| 5 | Regular Inspection | Periodically inspect all components for wear and damage to address issues promptly. |

Implementing these techniques will help maintain the efficiency of your device, leading to better performance and fewer issues in the long run.

Upgrading Software and Firmware

Enhancing the performance of your device often involves updating its software and firmware. These updates can introduce new features, improve functionality, and resolve existing issues, ensuring optimal operation.

Before proceeding with upgrades, it is essential to follow these guidelines:

- Backup Data: Always create a backup of important data to prevent any loss during the upgrade process.

- Check Compatibility: Ensure that the new software version is compatible with your device model.

- Read Release Notes: Review the release notes for the latest updates to understand changes and enhancements.

To initiate the upgrade, follow these steps:

- Visit the official website or trusted source to download the latest version.

- Connect your device to a power source to prevent interruptions during the upgrade.

- Follow the provided instructions carefully to complete the installation.

- After installation, restart the device to apply the changes.

Regular updates not only improve performance but also enhance security, protecting your device from vulnerabilities. Stay informed about the latest versions to ensure your device operates smoothly.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and troubleshooting for sewing equipment. Here, you will find useful information that can assist in resolving typical issues and enhancing the performance of your machine.

General Inquiries

Many users often have similar questions regarding functionality and common problems. Below are answers to some frequently encountered issues:

| Question | Answer |

|---|---|

| What should I do if the machine is not stitching? | Check the needle and ensure it is properly installed and not damaged. Verify that the threading is correct and the tension settings are appropriate. |

| How can I prevent fabric jams? | Ensure that the fabric is fed evenly and that the presser foot is adjusted correctly for the material being used. |

| Why does the thread keep breaking? | This can occur due to incorrect threading, using the wrong type of thread, or a dull needle. Inspect these components and make necessary adjustments. |

Maintenance Tips

Regular upkeep can significantly extend the lifespan of your equipment. Consider the following suggestions:

- Clean the machine regularly to remove dust and lint.

- Oil the moving parts as per the guidelines to ensure smooth operation.

- Store the machine in a dry place to prevent moisture damage.