Maintaining small machinery is crucial for ensuring optimal performance and longevity. This section delves into the fundamental aspects of caring for your power equipment, focusing on troubleshooting common issues and enhancing overall functionality.

Understanding the inner workings of these machines allows users to perform necessary interventions effectively. With a comprehensive approach, enthusiasts and professionals alike can navigate the challenges of upkeep and achieve seamless operation.

In the following segments, practical insights and detailed steps will be provided to empower individuals in their maintenance endeavors. By following these guidelines, you can ensure your machinery remains reliable and efficient throughout its lifecycle.

Ensuring safety while conducting maintenance tasks is essential for both personal well-being and successful outcomes. Adhering to specific guidelines helps prevent accidents and promotes a secure working environment.

Personal Protective Equipment

Utilizing appropriate personal protective gear is crucial during any maintenance activity. This includes items such as gloves, goggles, and sturdy footwear. Each of these components plays a significant role in safeguarding against potential hazards.

Work Area Organization

Maintaining a tidy and organized workspace minimizes risks associated with clutter and distractions. Ensuring that tools and materials are within reach reduces the likelihood of accidents and improves efficiency.

| Equipment | Purpose |

|---|---|

| Gloves | Protect hands from injuries and chemicals |

| Goggles | Shield eyes from debris and harmful substances |

| Sturdy Footwear | Provide support and protection from falling objects |

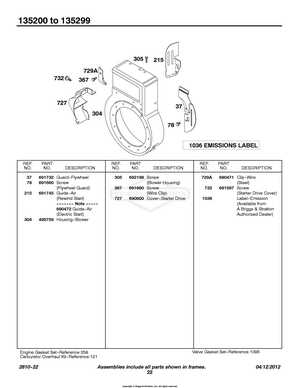

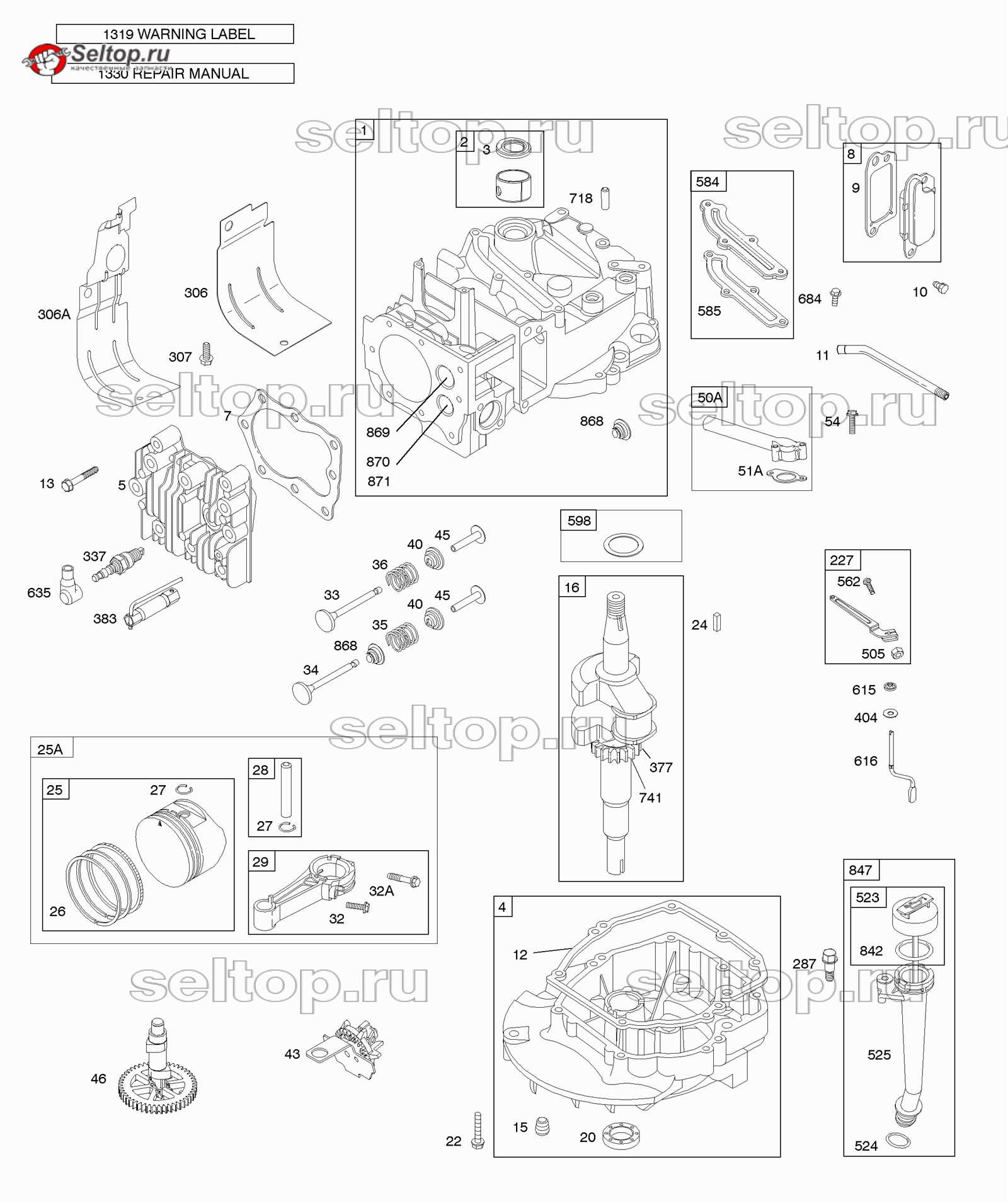

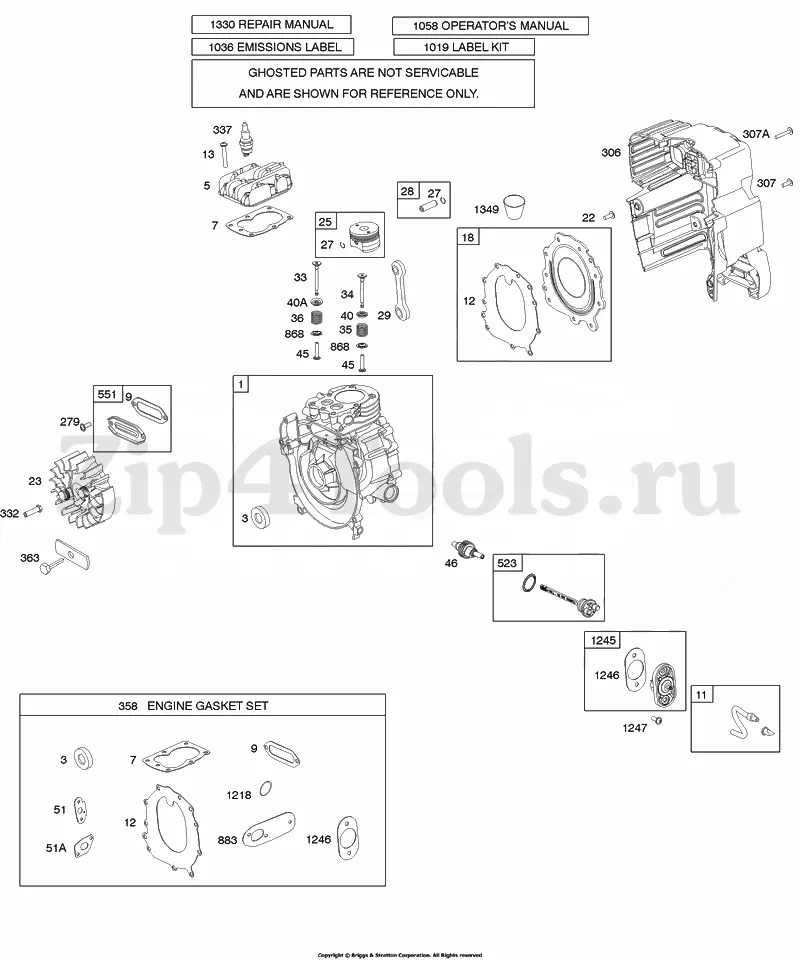

Replacing Engine Components Effectively

When it comes to maintaining optimal performance, the replacement of various parts is crucial. Understanding the process and ensuring proper installation can greatly enhance the longevity and efficiency of the machinery.

Identifying the Right Components: Before beginning the replacement process, it is essential to identify which components require attention. Regular inspections can help in detecting wear and tear early, allowing for timely interventions.

Preparation is Key: Gather all necessary tools and new parts before starting. A well-organized workspace will minimize disruptions and ensure that the process flows smoothly.

Step-by-Step Approach: Follow a systematic method for removing the old components. Take note of how parts are connected, as this will assist in reassembly. Documenting the process with photographs can also be beneficial.

Ensuring Proper Fit: Once new parts are ready for installation, ensure they are compatible. A proper fit is vital to avoid future complications. Refer to specifications provided by the manufacturer for guidance.

Testing After Replacement: After completing the installation, conduct thorough tests to ensure everything functions correctly. This step is crucial in confirming that the new components are working as intended.

By following these guidelines, you can effectively replace vital parts, contributing to the overall health and performance of your machinery.

Tuning Your Engine for Performance

Enhancing the functionality of your power unit can lead to remarkable improvements in efficiency and output. This process involves a series of adjustments aimed at optimizing fuel delivery, ignition timing, and overall balance. With the right modifications, you can unlock the true potential of your machine, ensuring it operates at peak performance.

Adjusting Fuel Mixture

The correct fuel-to-air ratio is crucial for achieving maximum power. A lean mixture can cause overheating, while a rich mixture may lead to excessive carbon buildup. Start by fine-tuning the carburetor settings to achieve the ideal blend, ensuring smooth acceleration and improved throttle response.

Ignition Timing Optimization

Timing plays a vital role in the performance of your apparatus. By adjusting the ignition timing, you can enhance the combustion process, resulting in better torque and horsepower. Consult the specifications for the optimal timing settings and make precise adjustments to achieve the best results.

Diagnosing Fuel System Problems

Understanding issues within the fuel delivery system is essential for optimal performance of your machinery. Identifying symptoms accurately can lead to effective solutions and prevent further complications. This section focuses on common indicators of fuel-related difficulties and their potential causes.

Starting Issues: One of the primary signs of fuel system trouble is difficulty starting the machinery. If the unit fails to start or requires multiple attempts, it may indicate inadequate fuel supply or blockages within the system.

Inefficient Performance: A noticeable decrease in power or performance while operating can signal issues such as clogged filters or faulty injectors. Monitoring performance closely can help in pinpointing specific problems.

Stalling: Sudden stalling during operation is another critical symptom. This can occur due to air leaks, fuel starvation, or other disruptions in the fuel flow. Addressing these factors promptly can prevent unexpected shutdowns.

Visual Inspection: Regularly inspecting fuel lines, filters, and connections for leaks or damage is vital. Any visible signs of wear or contamination should be addressed immediately to ensure proper functionality.

By recognizing these common signs and symptoms, you can take the necessary steps to diagnose and resolve fuel system problems effectively.

Electrical System Troubleshooting Techniques

Troubleshooting the electrical system of small machinery can be a challenging yet rewarding task. By understanding the components involved and employing systematic approaches, one can efficiently diagnose and resolve issues that may arise. This section will explore effective techniques for identifying common electrical problems, ensuring optimal performance.

Identifying Symptoms

The first step in troubleshooting is recognizing the symptoms of electrical faults. Common indicators include difficulty starting, erratic operation, or complete failure of the system. Observing these signs can help narrow down the potential causes.

Testing Components

Once symptoms are identified, testing individual components is crucial. This involves checking the integrity of wiring, switches, and connectors. Utilizing a multimeter can provide valuable insights into voltage and continuity, facilitating accurate diagnosis.

| Component | Testing Method | Expected Reading |

|---|---|---|

| Battery | Measure voltage | 12.6V or higher |

| Wiring | Check for continuity | Zero resistance |

| Switches | Test for open/closed states | Should operate smoothly |

Lubrication and Cooling Systems Explained

The efficiency of any motorized device relies heavily on its lubrication and cooling mechanisms. These systems play a crucial role in maintaining optimal performance and extending the lifespan of components by reducing friction and managing heat. Understanding their functions and maintenance requirements is essential for ensuring reliable operation.

Importance of Proper Lubrication

Lubrication minimizes wear and tear by creating a protective layer between moving parts. Here are the key benefits:

- Reduces friction, enhancing efficiency.

- Prevents overheating by dissipating heat.

- Extends the life of components through reduced wear.

Cooling Mechanisms

Adequate cooling is vital to prevent overheating. The most common methods include:

- Air Cooling: Utilizes airflow to regulate temperature.

- Liquid Cooling: Circulates coolant through a closed system to absorb and dissipate heat.

Regular checks and maintenance of both lubrication and cooling systems are essential to ensure peak performance and avoid potential damage.

Storage Tips for Long-Term Use

Proper storage of machinery components is essential for maintaining their functionality over extended periods. Following these guidelines can help ensure that your equipment remains in optimal condition when it’s time to use it again.

| Tip | Description |

|---|---|

| Clean Thoroughly | Remove any dirt, debris, and residues from the surface to prevent corrosion and damage. |

| Drain Fluids | Empty fuel and oil tanks to avoid deterioration and potential leaks during storage. |

| Cover and Seal | Use protective covers to shield components from dust, moisture, and other environmental factors. |

| Store in a Dry Place | Choose a climate-controlled area to prevent humidity-related issues and rust formation. |

| Check Periodically | Inspect the stored items occasionally to address any issues before they become serious problems. |

Upgrading Parts for Enhanced Efficiency

Improving the performance of a small power unit can significantly enhance its overall functionality and lifespan. Upgrading specific components not only boosts efficiency but also ensures smoother operation, reduced fuel consumption, and increased power output. By focusing on key parts, users can optimize their machines for better performance in various applications.

Key Components to Consider

- Air Filter: A high-performance air filter improves airflow and filtration, leading to better combustion and power generation.

- Fuel System: Upgrading fuel injectors or carburetors can enhance fuel atomization, resulting in improved efficiency and response.

- Ignition System: A modern ignition module can provide a more reliable spark, improving starting and overall engine performance.

- Exhaust System: A high-flow exhaust reduces back pressure, allowing the unit to breathe better and operate more efficiently.

Benefits of Upgrading

- Increased Power: Enhanced components can lead to a noticeable boost in output.

- Improved Fuel Economy: Upgraded parts often lead to better fuel efficiency, saving costs in the long run.

- Longevity: Quality upgrades can extend the lifespan of the unit by reducing wear and tear.

- Smoother Operation: Better components contribute to a more stable and enjoyable user experience.

Finding Replacement Parts Easily

Locating suitable components for your machinery can be straightforward if you know where to look. Accessing the right sources and understanding your options is crucial for maintaining optimal performance.

- Online Retailers: Many websites specialize in selling machinery parts. They often provide detailed descriptions and compatibility information.

- Local Stores: Hardware and automotive supply shops may carry essential components. Visiting these stores can allow you to consult with knowledgeable staff.

- Manufacturer Websites: Checking the official site of your equipment’s brand can lead to accurate part specifications and ordering options.

- Community Forums: Engaging in discussions with other users online can help you identify trustworthy sources and recommendations.

By utilizing these resources, you can efficiently find the necessary components to ensure your machinery runs smoothly.