The intricacies of maintaining a complex machinery system require a thorough understanding of its components and functions. This guide aims to equip enthusiasts and professionals alike with the essential knowledge needed to restore performance and reliability in these mechanical wonders. By delving into systematic approaches, we can ensure longevity and efficiency, ultimately enhancing the driving experience.

In the following sections, we will explore the fundamental aspects of diagnostics and maintenance, emphasizing the importance of proper techniques and tools. Recognizing symptoms of wear and tear is crucial for preemptive measures, allowing for timely interventions. This resource is designed to serve as a valuable reference for anyone seeking to enhance their technical skills in automotive care.

Furthermore, we will cover common challenges faced during the disassembly and reassembly processes, offering practical solutions and tips. With detailed explanations and step-by-step guidance, readers will gain confidence in their ability to tackle even the most daunting tasks. Embrace the journey of understanding and restoring mechanical systems, ensuring they perform at their best for years to come.

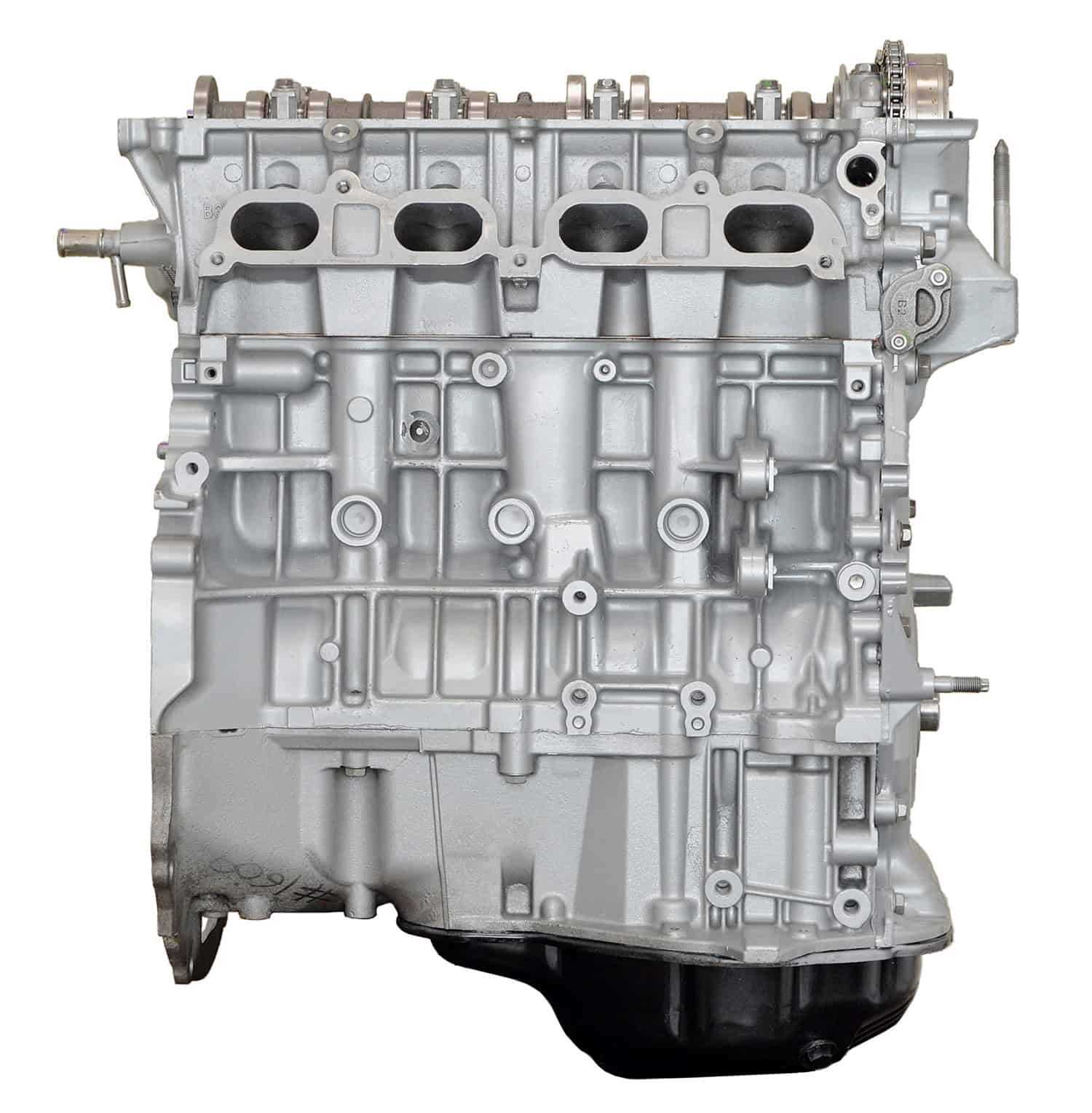

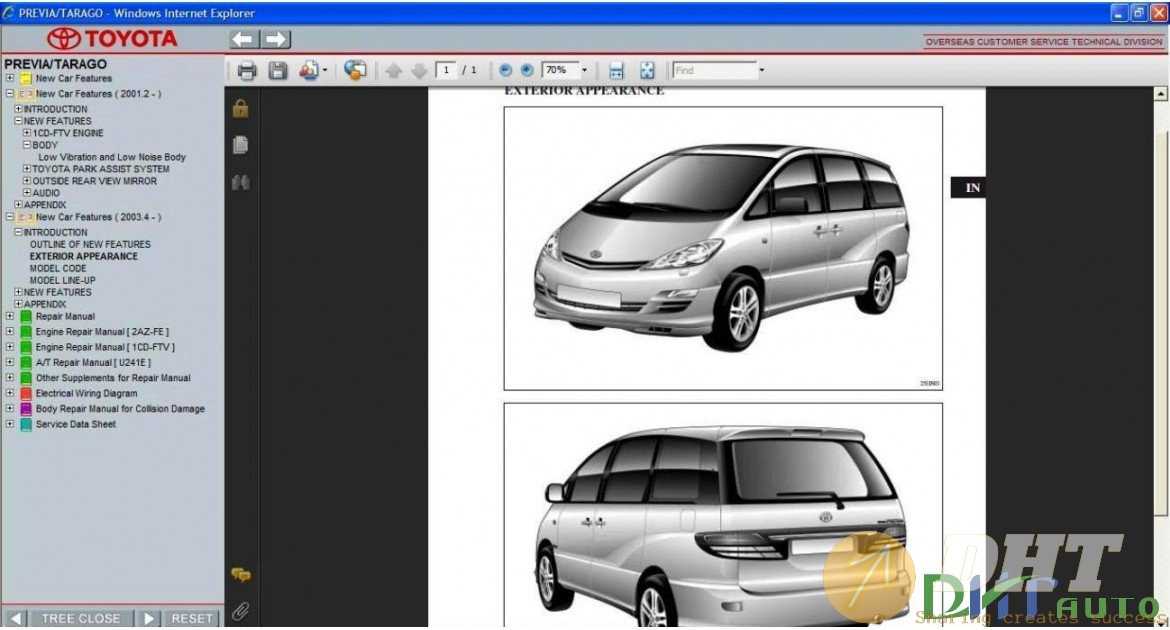

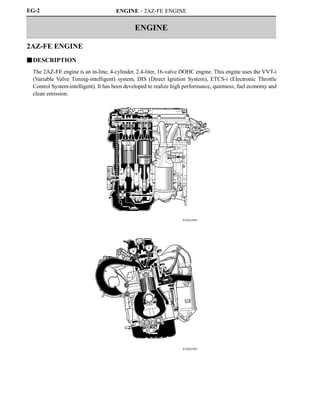

Overview of 2AZ-FE Engine

This section provides a comprehensive understanding of a specific automotive power unit known for its reliability and efficiency. Designed for various vehicles, this unit combines advanced engineering with practicality, making it a popular choice among manufacturers and drivers alike.

Design and Specifications

The assembly features a four-cylinder layout, ensuring a balance between performance and fuel economy. With a displacement of approximately 2.4 liters, it is engineered to deliver adequate power while maintaining low emissions. The innovative architecture incorporates dual overhead camshafts, enhancing airflow and overall efficiency.

Performance and Applications

This power unit is renowned for its smooth operation and durability, often found in a range of vehicles from sedans to SUVs. Its design allows for a harmonious blend of power and efficiency, catering to various driving needs. Users appreciate its responsiveness, making it suitable for both city commuting and highway cruising.

In summary, this specific power unit exemplifies a successful fusion of technology and functionality, appealing to both manufacturers and consumers seeking reliability and performance in their vehicles.

Common Issues with 2AZ-FE Engines

When dealing with certain automotive power units, several recurring problems can arise, impacting overall performance and longevity. Understanding these typical complications can aid in effective troubleshooting and maintenance, ensuring optimal functionality and reliability over time.

Overheating is a frequent concern, often caused by coolant leaks, faulty thermostats, or malfunctioning radiators. If the temperature gauge consistently rises above normal levels, it is crucial to address this promptly to prevent severe damage.

Another common problem involves oil consumption. Many users report excessive oil usage, which can stem from worn piston rings or valve seals. Regular checks and timely oil changes can mitigate this issue, promoting smoother operation.

Misfiring can also occur, resulting from issues with ignition components or fuel delivery systems. If the vehicle exhibits a rough idle or loss of power, it may indicate a need for diagnostic checks on spark plugs and fuel injectors.

Finally, timing chain noise can be indicative of wear or improper tension. Attention to this aspect is vital, as neglecting it may lead to more significant mechanical failures. Regular inspections can help detect these noises early, preventing costly repairs down the line.

Essential Tools for Engine Repair

When undertaking the complex task of overhauling a vehicle’s power unit, having the right equipment is crucial. The appropriate tools not only facilitate the process but also ensure precision and safety. This section outlines the fundamental implements necessary for successful disassembly and assembly tasks.

Basic Hand Tools

- Wrenches: Various sizes to accommodate different bolt types.

- Screwdrivers: Both flathead and Phillips for diverse fasteners.

- Plier Sets: Useful for gripping and bending components.

- Torque Wrench: Essential for applying the correct tension to bolts.

Specialized Equipment

- Compression Tester: Evaluates cylinder pressure effectively.

- Oil Filter Wrench: Simplifies the removal of oil filters.

- Timing Light: Assists in setting ignition timing accurately.

- Diagnostic Scanner: Identifies electronic faults and codes.

Equipping yourself with these essential tools will enhance your capability to handle various tasks with confidence and skill, ultimately leading to better outcomes in your mechanical endeavors.

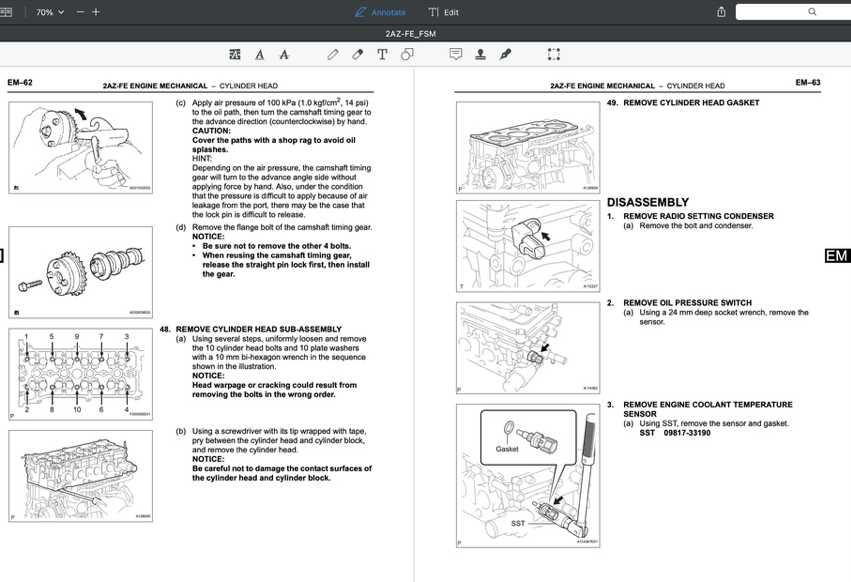

Step-by-Step Disassembly Guide

This section outlines a detailed approach to systematically dismantling the internal components of a specific vehicle system. Following this guide will help ensure that each part is carefully removed, reducing the risk of damage and facilitating easier reassembly.

- Preparation:

- Gather necessary tools such as wrenches, screwdrivers, and pliers.

- Ensure you have a clean workspace with adequate lighting.

- Disconnect the battery to prevent any electrical issues.

- Remove External Covers:

- Unscrew and take off any protective covers or shields.

- Keep all fasteners organized for reinstallation.

- Drain Fluids:

- Carefully drain any remaining fluids to avoid spills.

- Use appropriate containers for collection.

- Detach Components:

- Start with the air intake system and exhaust components.

- Proceed to remove additional assemblies like the fuel system and wiring harnesses.

- Remove Core Parts:

- Loosen bolts and take out major components one at a time.

- Label each part for easy identification during reassembly.

- Final Checks:

- Inspect all removed parts for wear or damage.

- Document the disassembly process for future reference.

By adhering to this structured approach, you can effectively dismantle the system while minimizing the risk of complications during the reassembly phase.

Identifying Engine Components

Understanding the various parts of a power unit is crucial for effective maintenance and troubleshooting. Each component plays a vital role in the overall functionality, contributing to performance, efficiency, and longevity. Familiarizing oneself with these elements allows for informed decisions during diagnostics and service tasks.

Key Components Overview

The core components of a power unit can be categorized into several groups, each serving distinct functions. Recognizing these parts helps in identifying potential issues and facilitates better communication during repair processes.

| Component | Function |

|---|---|

| Cylinder Head | Houses the intake and exhaust valves, as well as the combustion chamber. |

| Pistons | Move up and down within the cylinders, converting fuel energy into mechanical power. |

| Crankshaft | Transforms the linear motion of the pistons into rotational motion to drive the vehicle. |

| Timing Belt | Synchronizes the movement of the crankshaft and camshaft for precise valve operation. |

| Oil Pan | Holds lubricating oil that minimizes friction between moving parts. |

Importance of Component Identification

Accurate identification of these parts is essential for diagnosing issues, performing maintenance, and executing upgrades. Knowledge of each component’s location and purpose aids in efficient inspections and repairs, ultimately enhancing the performance and reliability of the system.

Rebuilding vs. Replacing Parts

When faced with the choice of refurbishing components or opting for new replacements, several factors come into play. Both strategies have their merits and drawbacks, which can significantly influence the decision-making process. Understanding the nuances of each approach helps in making an informed choice that aligns with specific needs and circumstances.

Advantages of Rebuilding

Refurbishing existing components can often be a cost-effective solution. It allows for retaining original parts that may have been specifically designed for the application, ensuring compatibility. Furthermore, rebuilding can extend the lifespan of these components when done correctly, reducing waste and promoting sustainability.

Benefits of Replacing

On the other hand, opting for new parts guarantees the latest technology and enhancements. Replacements often come with warranties, providing peace of mind regarding their performance and durability. This approach can also minimize the risk of recurring issues associated with older components, thereby ensuring reliability and efficiency.

| Criteria | Rebuilding | Replacing |

|---|---|---|

| Cost | Generally lower | Often higher |

| Compatibility | Maintains original design | May require adjustments |

| Longevity | Extended with proper care | New parts typically last longer |

| Warranty | Usually limited | Often includes warranty |

Ultimately, the choice between refurbishing and replacing hinges on individual circumstances, budget, and long-term goals. Evaluating these factors thoroughly will lead to a decision that best suits one’s requirements.

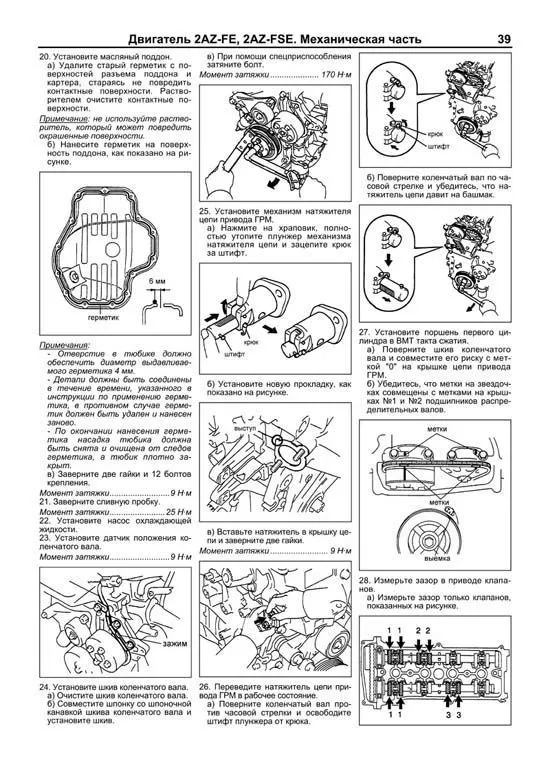

Torque Specifications and Measurements

This section focuses on the importance of accurate torque settings during the assembly and maintenance of automotive components. Proper tightening ensures optimal performance, safety, and longevity of parts. Each fastener plays a crucial role in maintaining structural integrity, making it essential to adhere to specified values.

Torque refers to the rotational force applied to a fastener, typically measured in units such as foot-pounds or Newton-meters. Accurate measurement of this force is vital, as both under-tightening and over-tightening can lead to component failure or damage. To achieve the desired torque, it is recommended to use calibrated tools, such as torque wrenches, which provide precise readings.

When working with various components, it is important to follow the manufacturer’s guidelines for torque values. These specifications are determined based on the material, size, and application of the fastener. Always consult the relevant documentation to ensure that you are applying the correct settings for each specific part.

Additionally, consider the sequence in which fasteners are tightened. Following a specific order helps distribute stress evenly across the assembly, reducing the risk of warping or misalignment. This is particularly important in multi-fastener assemblies, where a systematic approach is key to achieving proper fit and function.

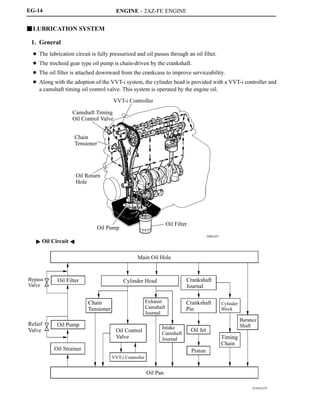

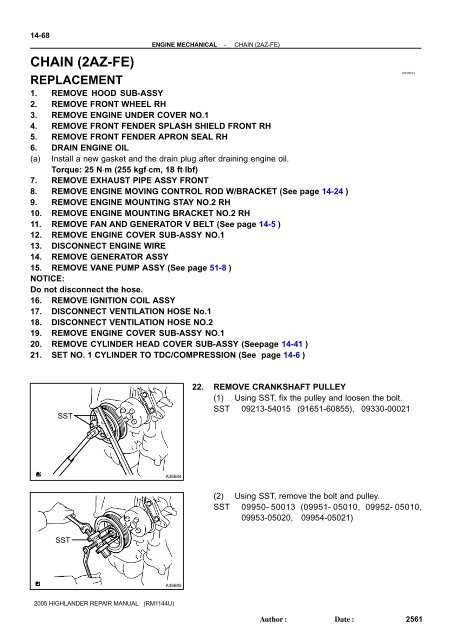

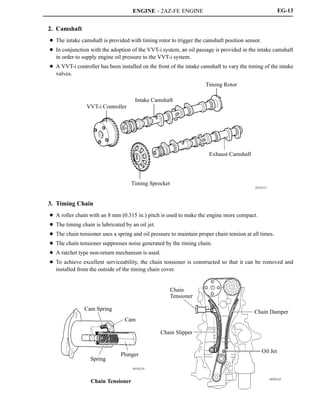

Engine Timing and Synchronization

The precise coordination of moving parts within a power unit is crucial for optimal performance and longevity. This section focuses on the importance of aligning various components accurately to ensure efficient operation. Proper synchronization reduces wear, enhances fuel efficiency, and maximizes power output, making it essential for any successful maintenance effort.

Understanding Timing Mechanisms

Timing mechanisms play a vital role in controlling the sequence of operations. These systems often consist of gears, belts, and chains that must be positioned correctly. Any deviation can lead to significant performance issues, including misfires and reduced efficiency. Maintaining correct alignment is paramount to avoiding costly repairs and ensuring reliable function.

Steps for Effective Synchronization

To achieve effective synchronization, one must first verify the condition of all related components. Regular inspections for wear and tear can help identify potential problems early on. Following a systematic approach during adjustments will ensure that everything remains in harmony. For instance, utilizing the correct tension and following manufacturer specifications can greatly enhance the overall functionality of the system.

In conclusion, mastering the art of timing and synchronization is essential for anyone seeking to enhance the efficiency and reliability of their machinery. Adhering to best practices in this area will lead to improved performance and longevity.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your vehicle’s mechanical components requires consistent care and attention. Adopting a proactive approach to upkeep can significantly enhance performance and reliability, preventing costly issues down the line. Here are essential practices to follow for optimal functioning and durability.

| Tip | Description |

|---|---|

| Regular Oil Changes | Frequent replacement of lubricant helps maintain smooth operation and reduces wear on moving parts. |

| Monitor Fluid Levels | Keep an eye on coolant, brake fluid, and transmission fluid to ensure proper functioning and prevent overheating. |

| Check Air Filters | Clean or replace filters regularly to improve airflow and efficiency, which can lead to better fuel consumption. |

| Tire Maintenance | Inspect tire pressure and tread depth frequently to ensure safety and optimal traction, enhancing overall handling. |

| Routine Inspections | Conduct periodic assessments of all systems to catch potential issues early and avoid major failures. |

By following these guidelines, you can foster a reliable performance and extend the lifespan of vital components, ensuring a smoother and more efficient driving experience.

Testing After Repairs

Ensuring optimal performance following maintenance is crucial for any mechanical system. This phase involves a series of evaluations designed to confirm that all components function harmoniously and meet required specifications. Proper assessment helps identify potential issues early, thereby preventing future complications.

Initial Checks: Begin with a visual inspection of all replaced or adjusted parts. Look for any signs of leaks, improper fittings, or unusual wear. Ensure that all connections are secure and that the surrounding areas are clean.

Functional Tests: Conduct a series of operations to gauge performance under various conditions. This may include idle tests, acceleration tests, and observing system responsiveness. Monitor for any unusual sounds or vibrations that could indicate underlying problems.

Diagnostic Tools: Utilize appropriate diagnostic equipment to analyze the system’s performance. Scan tools can provide valuable data, highlighting any error codes or irregularities that need addressing. Pay close attention to fluid levels, pressure readings, and temperature ranges.

Road Testing: After stationary checks, take the vehicle on a test drive. Evaluate handling, braking, and overall driving experience. Ensure that all gauges function correctly and monitor for any performance discrepancies.

Final Evaluation: After completing all tests, compile the data and compare it against the expected outcomes. If everything aligns with specifications, the maintenance can be considered successful. If issues persist, further investigation may be necessary to rectify them.

Common Upgrades and Modifications

When it comes to enhancing performance and efficiency, there are numerous modifications enthusiasts can consider. These upgrades not only improve power output but can also enhance reliability and driving experience. From simple tweaks to more complex installations, the options are plentiful for those looking to elevate their vehicle’s capabilities.

Performance Enhancements

Many vehicle owners choose to start with performance enhancements that provide noticeable improvements. Common options include upgrades to the intake and exhaust systems, which can significantly increase airflow and reduce back pressure. Additionally, reprogramming the electronic control unit (ECU) can optimize fuel delivery and ignition timing, leading to better overall performance.

Suspension and Handling Modifications

To complement the increased power, modifications to suspension and handling are essential. Upgrading to performance shocks and struts can improve stability and cornering ability. Lowering springs can also enhance the vehicle’s stance and aerodynamics, resulting in a more aggressive look and improved handling dynamics.

| Upgrade Type | Description | Benefits |

|---|---|---|

| Cold Air Intake | Replaces factory air intake with a high-flow system | Increased horsepower and throttle response |

| High-Performance Exhaust | Upgraded exhaust system for better flow | Improved sound and power |

| ECU Tune | Software adjustments to optimize performance | Enhanced fuel efficiency and power |

| Suspension Upgrade | Performance shocks and springs | Better handling and ride quality |

Resources for Further Learning

Expanding your knowledge in the field of automotive mechanics can significantly enhance your skills and understanding. This section provides a variety of resources that can aid in deepening your expertise, whether you are a beginner or an experienced enthusiast.

Books and Publications: Numerous texts are available that cover the fundamentals as well as advanced techniques. Look for titles that focus on mechanical systems, troubleshooting, and maintenance practices. These resources often include diagrams and step-by-step instructions, making complex concepts more accessible.

Online Courses: Various platforms offer comprehensive courses ranging from introductory to specialized topics. These interactive lessons often include videos, quizzes, and forums for discussion, allowing for a more engaging learning experience.

Community Forums: Participating in online communities can provide invaluable insights. Forums allow you to connect with fellow enthusiasts, share experiences, and seek advice on specific issues you may encounter. Engaging with others in the field can foster collaboration and the exchange of knowledge.

YouTube Channels: Many content creators focus on automotive topics, providing tutorials, reviews, and walkthroughs. Visual demonstrations can clarify processes that might be difficult to understand through text alone, making them an excellent supplement to your studies.

Workshops and Classes: Local technical schools and community colleges often offer hands-on workshops. These practical sessions allow you to gain firsthand experience under the guidance of professionals, enhancing your skills and confidence in real-world applications.

Utilizing these resources can empower you to build a robust understanding and hone your practical skills, ensuring you are well-prepared for any challenge in the automotive field.