Maintaining the integrity of your vehicle’s shifting system is crucial for optimal performance and longevity. This segment delves into the intricate components and functions that ensure smooth transitions between gears, providing an overview of common issues and solutions. By grasping the fundamental principles, you can better appreciate the mechanics at play.

Comprehending the mechanics behind your vehicle’s power delivery system is essential for anyone looking to enhance their automotive knowledge. This exploration will guide you through various challenges that may arise, offering insights into troubleshooting and effective techniques for restoring functionality. Understanding these principles empowers vehicle owners to take informed actions.

Moreover, an emphasis on preventive measures can significantly reduce the likelihood of future complications. By familiarizing yourself with the signs of wear and tear, you can proactively address potential problems before they escalate. This proactive approach not only saves time and money but also contributes to a safer driving experience.

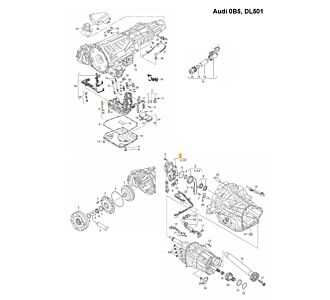

Understanding the 0B5 Transmission

The 0B5 system represents a sophisticated engineering achievement that combines efficiency and performance. Designed for modern vehicles, it is known for its ability to deliver smooth power transfer while enhancing fuel economy. This section delves into its components, functionality, and common issues, providing insights for enthusiasts and professionals alike.

Key features of this advanced mechanism include:

| Feature | Description |

|---|---|

| Design | Optimized for lightweight materials to improve performance. |

| Shifting Mechanism | Employs advanced hydraulic systems for seamless gear changes. |

| Control Module | Incorporates intelligent software for adaptive driving experiences. |

| Durability | Built to withstand various driving conditions, enhancing longevity. |

Understanding these characteristics is essential for effective maintenance and troubleshooting. A clear grasp of how this system operates will lead to more informed decisions regarding upkeep and potential modifications.

Common Issues with the 0B5 Transmission

When dealing with modern automotive gear systems, several challenges can arise, affecting overall performance and reliability. Understanding these frequent problems can help in identifying symptoms early and preventing more severe complications.

- Shifting Difficulties: Many users report issues with gear engagement, including hard or delayed shifts. This can stem from low fluid levels or contamination.

- Fluid Leaks: One of the most common concerns is leaking fluid. This may indicate worn seals or gaskets that require immediate attention.

- Overheating: Excessive heat can lead to operational failures. Poor cooling or a malfunctioning cooler often causes this issue.

- Unusual Noises: Grinding or whining sounds during operation can signal internal damage or inadequate lubrication.

- Warning Lights: Dashboard alerts may indicate electronic issues, which could affect system functionality.

By being aware of these potential pitfalls, owners can take proactive measures to maintain their vehicle’s functionality and extend its lifespan.

Step-by-Step Repair Process

This section outlines a systematic approach to addressing issues within the specified system. Following a clear sequence of actions is crucial for ensuring effective troubleshooting and resolution.

-

Assessment: Begin by identifying the symptoms. Gather information on any unusual noises, performance issues, or warning indicators.

-

Preparation: Assemble the necessary tools and components. Ensure you have safety gear and an organized workspace.

-

Disassembly: Carefully remove external covers and components. Keep track of screws and parts to facilitate reassembly.

-

Inspection: Examine internal parts for wear, damage, or irregularities. Note any components that require replacement.

-

Replacement: Install new parts as needed, ensuring proper fit and alignment. Follow manufacturer specifications for torque settings.

-

Reassembly: Carefully reattach all components in the reverse order of disassembly. Double-check that everything is secure.

-

Testing: Conduct a thorough test to verify that the system functions correctly. Monitor for any abnormal behavior during operation.

-

Final Review: Document the process and any changes made. Ensure that all tools are accounted for and the workspace is clean.

Essential Tools for Transmission Repair

Having the right set of instruments is crucial for anyone looking to work on complex automotive systems. A well-equipped toolkit not only enhances efficiency but also ensures precision during the disassembly and assembly processes. Here, we explore some fundamental tools that are indispensable for this type of work.

| Tool | Purpose |

|---|---|

| Socket Set | Essential for loosening and tightening bolts of various sizes. |

| Torque Wrench | Ensures that bolts are tightened to the manufacturer’s specifications. |

| Screwdriver Set | Used for various screws, providing versatility in tasks. |

| Pliers | Useful for gripping, twisting, and cutting wires or components. |

| Fluid Pump | Facilitates the transfer of fluids, making it easier to manage hydraulic systems. |

| Oil Catch Pan | Collects old fluid during servicing to prevent mess and environmental hazards. |

| Measuring Tools | Allows for precise measurements of components for accurate fitting. |

| Lift or Jack | Raises the vehicle, providing necessary access to the undercarriage. |

Equipped with these essential instruments, technicians can tackle complex tasks with confidence, ensuring both safety and effectiveness throughout the process.

Diagnosing Transmission Problems

Identifying issues within a vehicle’s power transfer system is essential for maintaining optimal performance and safety. Recognizing the signs of malfunction early can prevent further damage and costly repairs. This section will guide you through the common indicators and methods for assessing potential faults.

One of the primary symptoms of trouble is unusual noises. If you hear grinding, whining, or clunking sounds, these could indicate mechanical wear or insufficient lubrication. Additionally, erratic shifting–such as slipping gears or delayed engagement–can signal deeper issues within the internal components.

Another critical aspect to monitor is fluid condition. Discoloration, a burnt smell, or the presence of particles in the fluid can reveal underlying problems. Regular checks of the fluid level and quality are vital for early detection.

Electronic diagnostics play a significant role in troubleshooting. Many modern vehicles are equipped with onboard systems that can provide error codes, which help pinpoint the source of the malfunction. Utilizing a diagnostic tool can streamline the identification process.

Ultimately, systematic observation and regular maintenance can significantly enhance the lifespan of your vehicle’s drivetrain. If you notice any concerning symptoms, seeking professional assistance is advisable to ensure accurate diagnosis and appropriate action.

Replacing Transmission Fluid: Best Practices

Regularly changing the fluid in your vehicle’s gearbox is essential for maintaining optimal performance and extending its lifespan. This process helps ensure that all internal components function smoothly, reducing wear and preventing potential issues down the line. Understanding the best practices for this task can help you achieve the best results and maintain your vehicle’s reliability.

Before you begin, it’s important to gather the necessary tools and materials. Here’s a checklist of what you will need:

| Tools | Materials |

|---|---|

| Wrench set | Fresh fluid |

| Fluid pump | New filter (if applicable) |

| Drain pan | Sealing gasket |

| Funnel | Cleaning rags |

Start by locating the drain plug and ensuring that the vehicle is level. Place the drain pan underneath to catch the old fluid as it drains out. Remove the plug carefully, allowing the fluid to flow out completely. While the old fluid is draining, inspect the condition of the filter and replace it if necessary. A clean filter contributes significantly to the longevity of the system.

Once the old fluid has fully drained, replace the drain plug securely. Using the pump, fill the system with the appropriate new fluid through the designated fill hole. Be sure to follow the manufacturer’s specifications regarding fluid type and quantity. After filling, check the level using the dipstick and add more fluid if needed.

Finally, run the engine for a few minutes while monitoring the fluid level again. This step ensures that the new fluid circulates properly. Always dispose of the old fluid responsibly, following local regulations for hazardous materials.

Electrical Components and Their Functions

The intricate network of electrical components plays a vital role in the overall performance of any automotive system. Each part serves a specific function, contributing to the efficiency, reliability, and safety of the vehicle’s operation. Understanding these components is essential for effective diagnostics and troubleshooting.

- Control Module: Acts as the brain of the system, processing data from various sensors and making real-time decisions to optimize performance.

- Sensors: Monitor critical parameters such as temperature, pressure, and speed, providing data necessary for the control module to function effectively.

- Wiring Harness: Serves as the nervous system, connecting all electrical components and ensuring seamless communication between them.

- Relays: Function as switches that control high-current circuits, allowing the control module to manage power distribution without direct involvement.

- Actuators: Convert electrical signals into mechanical movement, enabling adjustments to various systems based on commands from the control module.

Each of these components is crucial for maintaining optimal functionality. Regular checks and maintenance of these parts can prevent potential issues and enhance the longevity of the system.

- Ensure all connections are secure to prevent electrical failures.

- Inspect sensors periodically for accuracy and proper operation.

- Replace any damaged wiring to maintain signal integrity.

- Test relays for responsiveness to ensure reliable operation.

- Monitor actuators for smooth operation and responsiveness to commands.

By prioritizing the upkeep of these electrical components, one can ensure a smooth and efficient performance in automotive systems.

Preventive Maintenance Tips

Regular upkeep is essential for ensuring the longevity and optimal performance of your vehicle’s components. By following a few simple guidelines, you can significantly reduce the risk of unexpected failures and maintain a smooth driving experience.

Routine Inspections

- Check fluid levels regularly, including oil, coolant, and brake fluid.

- Inspect belts and hoses for signs of wear and tear.

- Examine the condition of the tires, ensuring proper inflation and tread depth.

Scheduled Services

- Follow the manufacturer’s recommended service intervals for essential maintenance tasks.

- Replace filters, such as air and fuel filters, at suggested intervals to ensure optimal function.

- Consider professional inspections periodically to catch potential issues early.

By implementing these preventive measures, you can enhance the reliability of your vehicle and extend its lifespan, providing peace of mind on the road.

Identifying Warning Signs of Failure

Recognizing early indicators of malfunction is crucial for maintaining the performance of your vehicle’s system. By being aware of specific symptoms, you can take proactive measures to prevent further damage and costly fixes. This section highlights key signs that may suggest underlying issues.

Unusual Noises: Listen for any strange sounds such as grinding, whining, or clunking. These noises often signal that components are not functioning as they should.

Slipping: If you experience unexpected changes in power transfer or a delay in response when accelerating, this could indicate a problem with the internal mechanisms.

Fluid Leaks: Any noticeable fluid pooling under your vehicle may point to leakage. Check for reddish or brown fluid, as this can indicate a serious issue.

Warning Lights: Pay attention to dashboard alerts. If the check engine light or any specific indicator illuminates, it is essential to investigate further.

Unresponsive Shifting: Difficulty in changing gears or experiencing jerky transitions can be a sign that the system is not operating smoothly. Regularly monitor how your vehicle behaves during gear changes.

By staying vigilant for these warning signs, you can address potential problems before they escalate, ensuring the longevity and reliability of your vehicle’s essential systems.

Transmission Control Module Overview

The control module serves as the brain for managing the intricate functions of gear shifting within vehicles. This essential component ensures optimal performance by processing various inputs and executing commands that enhance driving experience and efficiency.

Key Functions

- Monitoring vehicle speed and engine performance

- Adjusting gear shifts based on driving conditions

- Communicating with other vehicle systems for coordinated operation

Importance of Proper Functioning

A well-functioning control module is crucial for:

- Ensuring smooth gear transitions, which affects overall drivability.

- Maximizing fuel efficiency by optimizing engine performance.

- Preventing mechanical wear and potential failures through timely adjustments.

Understanding the role of this component is vital for maintaining the overall health of the vehicle’s powertrain system.

Cost Factors in Repair Services

When addressing mechanical issues, several elements influence the overall expenses associated with the restoration process. Understanding these variables can provide clarity for vehicle owners contemplating necessary interventions.

Labor Costs: One of the primary components is the expense related to skilled technicians. Rates can vary significantly based on geographic location, expertise, and the complexity of the tasks required. Higher labor rates may reflect a shop’s reputation and the proficiency of its staff.

Parts Quality: The choice between original equipment manufacturer (OEM) parts and aftermarket alternatives can greatly affect the final bill. While OEM components might be pricier, they often ensure better compatibility and durability, potentially leading to lower long-term costs.

Diagnostic Fees: Accurate identification of the underlying issues is crucial. Some service providers charge a fee for diagnostic assessments, which can be deducted from the total if repairs are completed. Understanding this aspect helps in anticipating upfront costs.

Extent of Damage: The severity of the malfunction plays a vital role in determining expenses. Minor fixes typically require less time and fewer resources, whereas significant problems may necessitate extensive work and higher financial outlay.

Warranties and Guarantees: Some shops offer warranties on their services and parts, which can provide peace of mind. However, such guarantees might come at a premium. Weighing the benefits of added security against initial costs is essential for informed decision-making.

By considering these factors, vehicle owners can make better choices and manage their budgets effectively while ensuring their vehicles receive the attention they require.

Choosing a Reliable Repair Shop

Finding a trustworthy service center for your vehicle is essential for ensuring its longevity and performance. When it comes to addressing complex issues, selecting a competent establishment can make all the difference. In this section, we will explore key factors to consider when making your choice.

Research and Recommendations

Start by gathering information from various sources. Online reviews, ratings, and testimonials from previous customers can provide valuable insights into the quality of service. Additionally, seek recommendations from friends, family, or colleagues who have had similar experiences. A well-regarded shop often has a strong reputation within the community.

Certifications and Experience

Look for establishments that employ certified technicians with extensive experience. Qualifications from recognized organizations signify that the staff is trained and knowledgeable in their field. Moreover, a shop with a solid track record in handling various mechanical challenges is more likely to deliver satisfactory results. Pay attention to the types of vehicles they specialize in and ensure they have the expertise relevant to your needs.

Ultimately, making an informed decision requires careful consideration of all these elements. Investing time in selecting the right facility will help safeguard your vehicle’s health and enhance your driving experience.