In any workspace where machinery is relied upon, having the right resources to understand upkeep and troubleshooting processes is invaluable. This guide introduces essential insights for maintaining compact machines efficiently and reliably.

For those who seek to extend the lifespan of their equipment, knowing how to identify and address common issues is crucial. With practical advice and clear instructions, this resource enables users to navigate a variety of technical challenges.

Detailed instructions and illustrative examples offer straightforward solutions to complex issues, helping readers to approach each situation with confidence. Whether you’re a beginner or experienced, this guide is crafted to assist at every step.

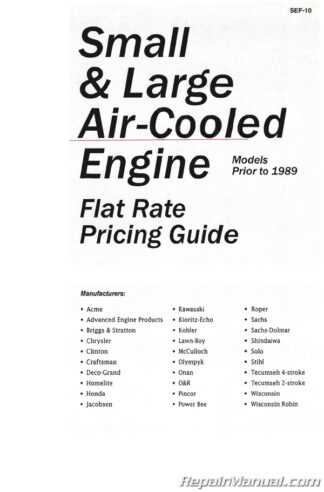

Top Guide for Compact Motor Maintenance

Understanding how to service compact machinery efficiently can be a crucial skill, especially when equipment starts showing signs of wear. A comprehensive guide provides essential insights into keeping these motors running smoothly, covering all facets from diagnostics to routine care.

Effective maintenance can significantly extend the life of machinery, reduce costs, and prevent downtime. With a reliable reference, enthusiasts and professionals alike gain detailed instructions, troubleshooting tips, and safety practices tailored for different models.

Whether tackling issues related to fuel systems, lubrication, or electrical connections, a thorough maintenance resource can be the key to navigating complex tasks. Clear step-by-step directions in these guides support users in restoring performance and optimizing functionality.

Comprehensive Guide to Small Engine Maintenance

Regular upkeep of compact power sources is essential for achieving reliable performance and extending equipment lifespan. By understanding fundamental care routines, users can ensure their machinery runs smoothly and avoid unexpected breakdowns. This section delves into essential practices, providing step-by-step guidance on maintaining your device in prime condition.

Key Maintenance Steps

Maintaining compact power systems involves various tasks that contribute to overall efficiency. Here are a few critical actions:

| Maintenance Task | Frequency | Purpose | ||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Oil Check and Change | Monthly or after every 20 hours of use | Ensures smooth operation and prevents wear | ||||||||||||||||||||||||||||||||||||||||

| Air Filter Cleaning | Every three months | Improves airflow, enhancing performance | ||||||||||||||||||||||||||||||||||||||||

S

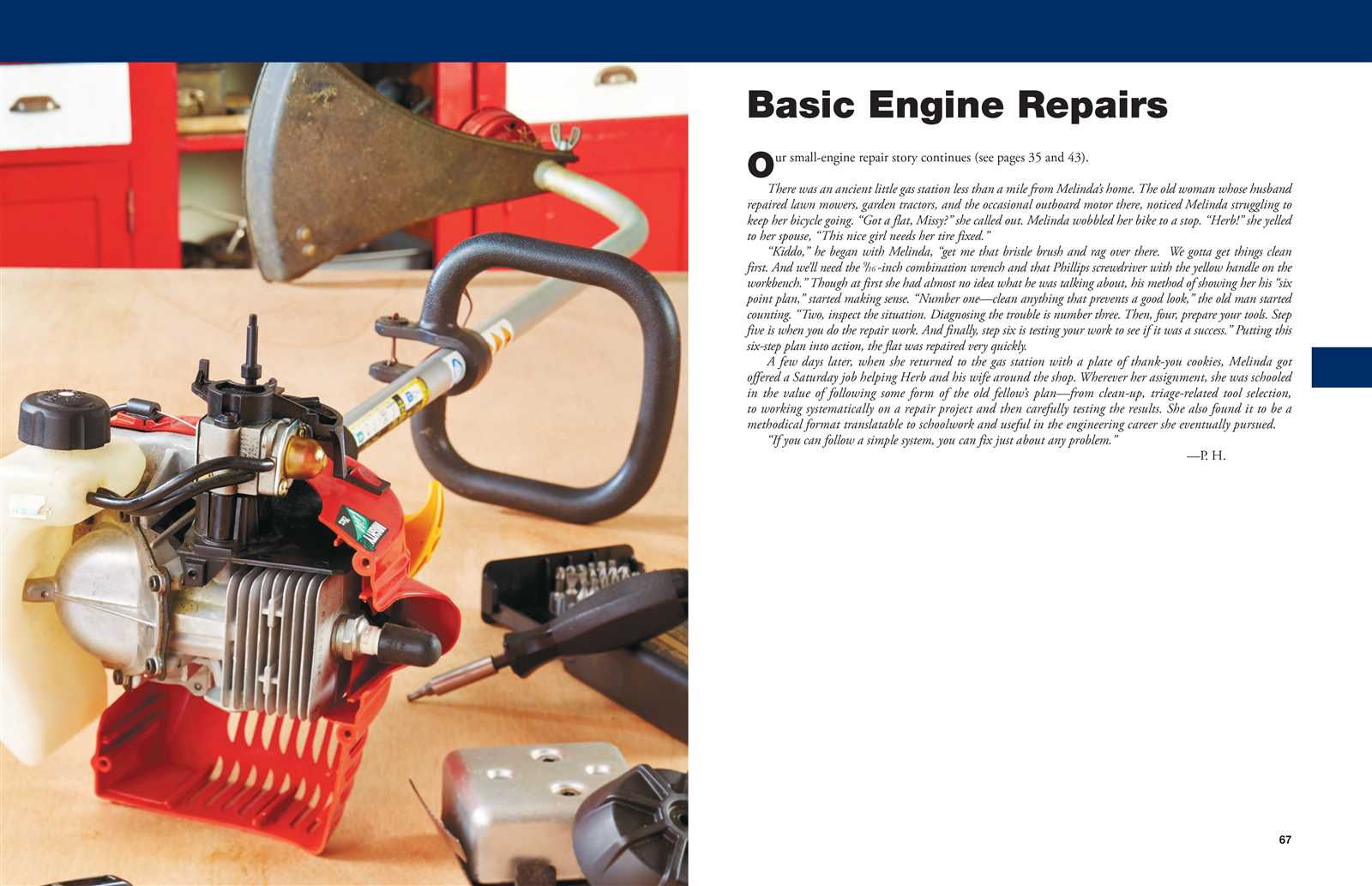

Choosing the Right Repair Tools

Effective maintenance starts with selecting appropriate tools. By ensuring you have the necessary instruments on hand, you can approach any technical task with precision and confidence. Selecting tools tailored to the task enhances efficiency and safety while reducing the chance of mistakes. Essential Hand Tools

For foundational work, certain hand tools are indispensable. These tools are versatile and allow for adjustments, disassembly, and routine upkeep with ease.

Specialized EquipmentFor more complex tasks, specialized equipment can simplify the process and ensure thoroughness. Consider these Troubleshooting Common Engine Problems

Diagnosing issues with machinery can be a straightforward process when equipped with a clear understanding of typical symptoms and causes. By carefully observing performance patterns and identifying warning signs, it becomes possible to narrow down the sources of mechanical troubles effectively. Identifying Power LossOne frequent concern is a noticeable reduction in power. This issue may stem from fuel flow interruptions, air intake obstructions, or worn-out internal components. Checking each element individually–starting with the fuel and air passages–can often reveal where performance is being compromised. Ensuring these systems are clear and functioning optimally is essential for restoring full efficiency. Resolving Unusual SoundsUnusual noises, such as knocking, sputtering, or grinding, may indicate deeper mechanical or operational issues. These sounds often arise from component misalignment, loose parts, Step-by-Step Engine Rebuilding Tips

Reassembling a complex machine system can seem daunting, but with a structured approach, each stage becomes manageable. This guide focuses on helping you navigate essential phases to restore parts to full functionality, ensuring durability and performance. 1. Prepare a Clean Workspace 2. Disassemble Methodically 3. Clean and Inspect Parts 4. Replace Worn Components Understanding Fuel and Oil RequirementsProper fuel and lubrication are essential for the optimal performance and longevity of any mechanical system. Knowledge of the specific needs for these vital components ensures efficient operation and helps prevent damage. By adhering to recommended guidelines, users can enhance functionality and reduce the likelihood of breakdowns. Importance of Correct Fuel TypeSelecting the appropriate type of fuel is crucial. Different machines may require specific grades or formulations to operate effectively. Here are some key points to consider:

Understanding Oil SpecificationsLubrication is equally vital for maintaining functionality. The right oil ensures smooth operation and protects internal components. Consider the following aspects:

Electrical Systems and Ignition RepairThe functionality of various mechanical devices heavily relies on their electrical frameworks and ignition mechanisms. A thorough understanding of these components is crucial for ensuring optimal performance and reliability. This section will explore the essential aspects of troubleshooting and enhancing these systems, providing insights into their operation and maintenance. Key Components of Electrical Systems Electrical systems comprise several vital elements, including wiring harnesses, batteries, and connectors. Each part plays a significant role in facilitating the smooth transmission of power throughout the device. Regular checks and maintenance of these components can prevent potential failures and ensure longevity. Ignition Mechanism Insights The ignition system is responsible for initiating the combustion process. Understanding its components, such as spark plugs, ignition coils, and timing mechanisms, is essential for effective troubleshooting. Issues like misfiring or hard starting can often be traced back to faults within these parts. Implementing systematic diagnostics will lead to better identification of issues, allowing for targeted solutions. Proper knowledge of electrical principles and ignition functionality empowers individuals to maintain and enhance the overall performance of their devices. Preventive Care for Longer Engine LifeMaintaining optimal performance and extending the lifespan of your machinery requires consistent attention and proactive measures. Regular maintenance practices play a crucial role in ensuring that vital components remain in excellent condition, ultimately preventing costly breakdowns and enhancing overall efficiency. Key Maintenance Practices

Implementing routine care can significantly impact longevity. Here are some essential practices to consider:

Benefits of Preventive CareInvesting time in preventive maintenance not only saves money but also boosts the reliability and efficiency of your machinery. By addressing potential issues early and keeping essential parts in top condition, you can enjoy a smoother operation and longer service life. Diagnosing Issues with Engine PerformanceUnderstanding the various factors that affect mechanical functionality is essential for ensuring optimal operation. Identifying potential complications can significantly enhance performance and extend the longevity of machinery. This section delves into common symptoms that indicate underlying problems and provides insights on how to approach troubleshooting effectively. Several symptoms may signal that a unit is not performing at its best. Observing changes in sound, vibration, or fuel efficiency can provide valuable clues. Addressing these issues promptly is vital to prevent further damage and costly repairs.

Safety Practices in Engine RepairEnsuring a secure environment while working on mechanical systems is paramount for any technician. Adhering to proper safety measures minimizes risks and promotes a more efficient workflow. It is essential to cultivate habits that prioritize personal well-being and the integrity of the machinery. Here are some fundamental practices to follow:

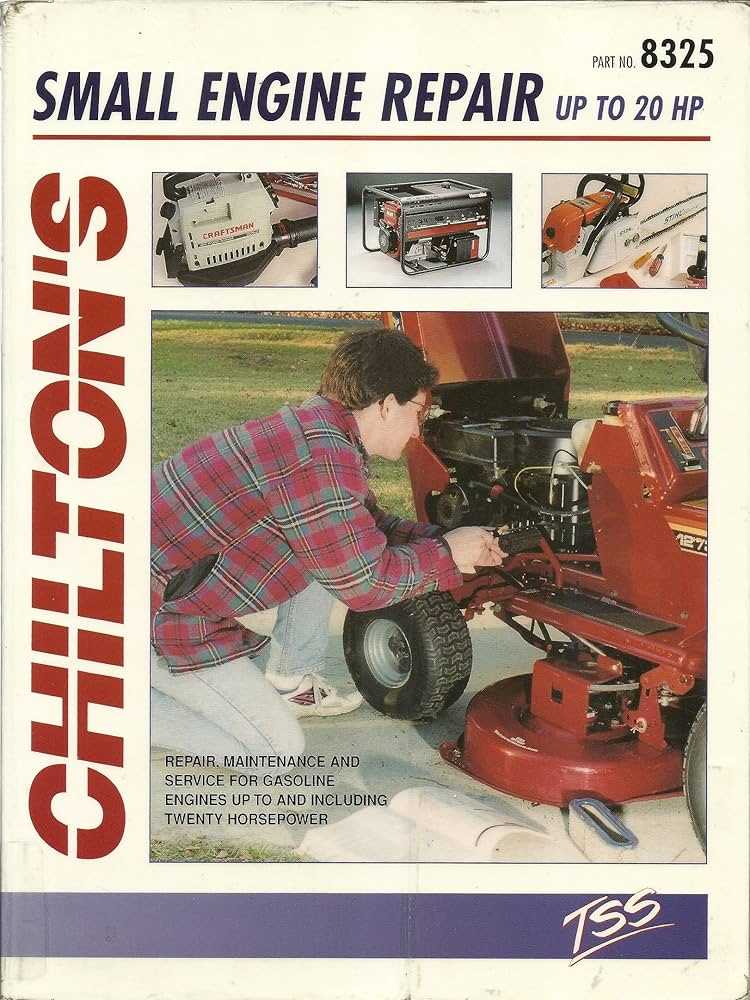

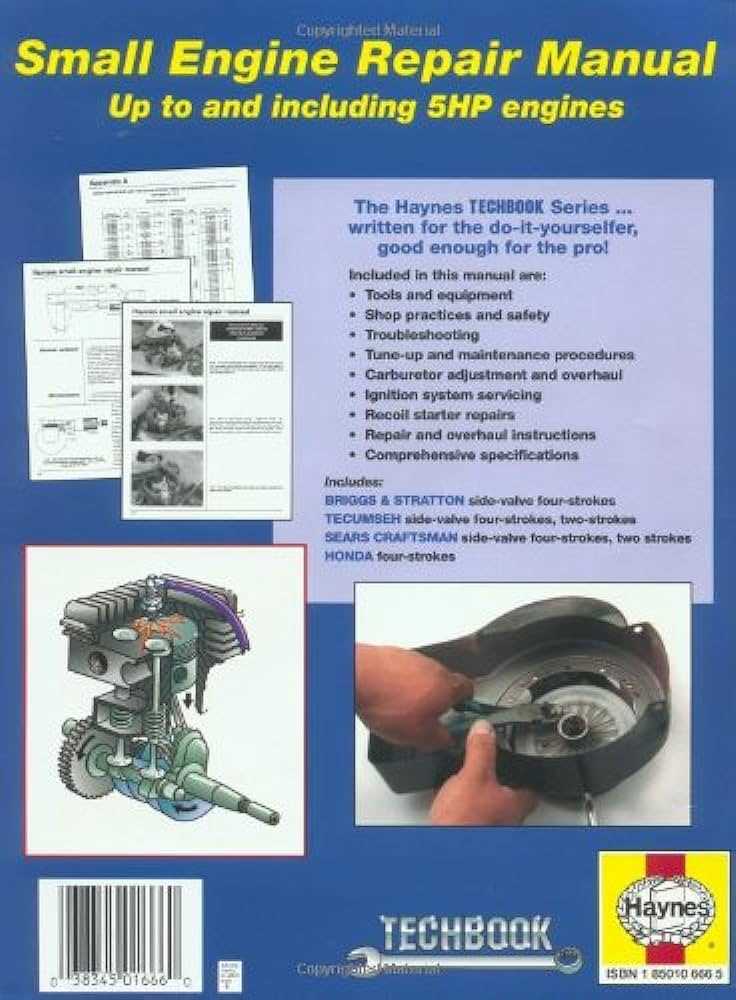

Implementing these practices fosters a culture of safety and enhances the overall quality of the work performed. Staying vigilant and proactive in maintaining a safe environment is essential for successful outcomes in mechanical tasks. Top Resources for Small Engine RepairFor individuals seeking to enhance their knowledge and skills in maintaining and fixing various mechanical devices, a variety of tools and materials are available. These resources can provide guidance, detailed instructions, and troubleshooting techniques essential for effective management of different types of machinery. Here are some valuable references to consider:

|