Ensuring optimal performance of large format printing devices is essential for achieving high-quality results and extending the lifespan of the equipment. This section provides a comprehensive overview of essential maintenance practices and troubleshooting techniques, enabling users to keep their machines running smoothly. By understanding the intricacies of these printers, owners can prevent common issues and improve overall efficiency.

With a focus on user-friendly approaches, this guide emphasizes the importance of regular checks and timely interventions. By familiarizing oneself with the inner workings of the printer, individuals can identify potential problems before they escalate, ensuring consistent output and minimizing downtime. Proper care not only enhances functionality but also contributes to the longevity of the device.

Whether you are an experienced operator or new to large format printing, having access to reliable information is invaluable. This resource aims to empower users with the knowledge necessary to address challenges effectively and maintain their equipment in peak condition. Embracing proactive maintenance habits can significantly improve the performance and reliability of your printing technology.

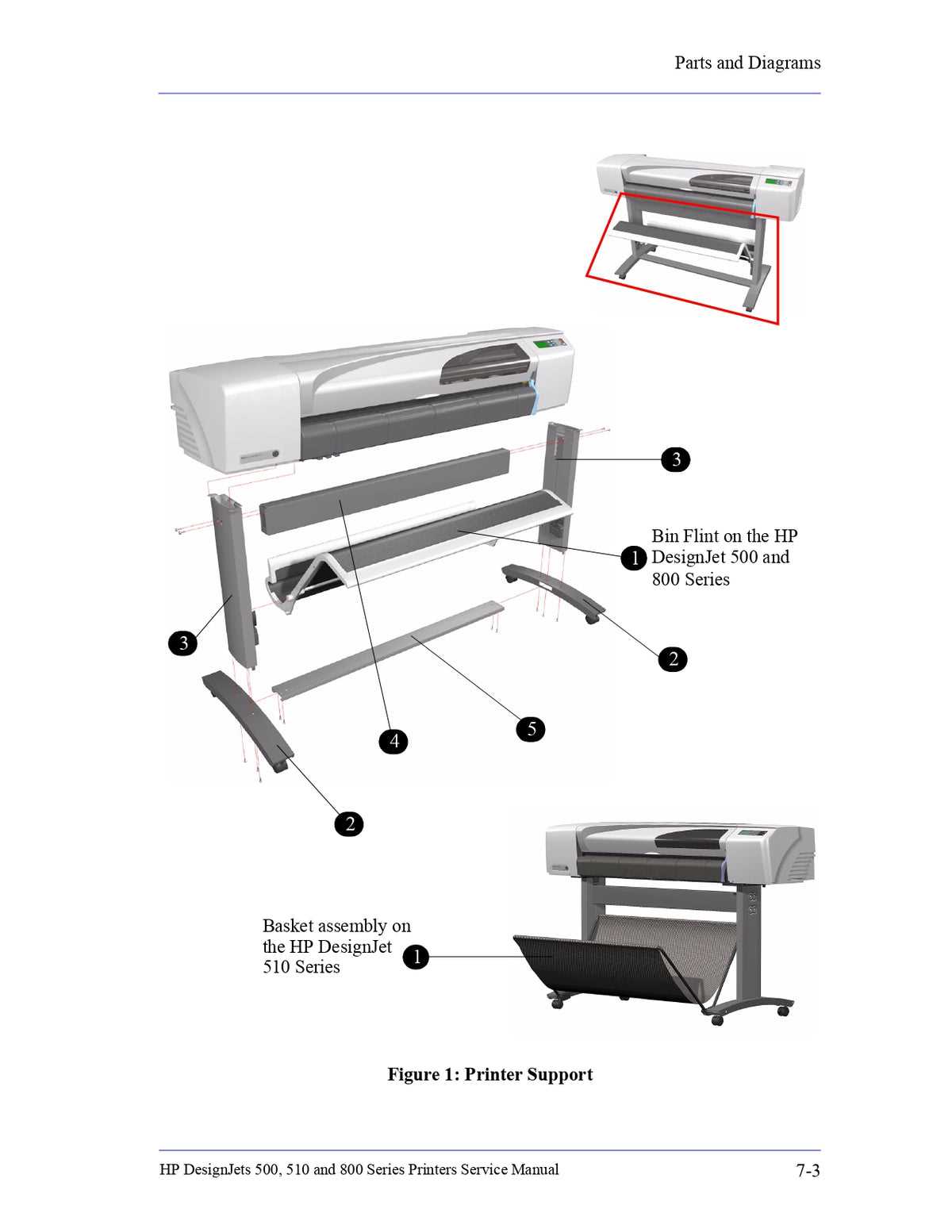

Overview of HP DesignJet 500

This section provides an insight into a series of wide-format printers designed for professional use, focusing on their capabilities and features. These devices are engineered to produce high-quality prints, making them ideal for applications in various fields, including architecture, engineering, and graphic design.

Key Features: The printers in this lineup are known for their precision and reliability. They offer a range of printing technologies that ensure vibrant colors and sharp details. The models cater to different media types, allowing users to print on everything from simple sheets to large-format rolls.

Performance: These printers are built for efficiency, capable of handling large volumes of work without compromising on quality. Their speed and output consistency make them a valuable asset in fast-paced environments, where time is often of the essence.

Connectivity Options: Designed with modern workflows in mind, these printers include various connectivity options, facilitating seamless integration with different devices and networks. This enhances productivity by allowing multiple users to access the printer from various locations.

Maintenance and Support: Maintaining optimal performance is crucial, and these models come with built-in features that simplify upkeep. Regular servicing and user-friendly troubleshooting guides are essential for ensuring longevity and peak functionality.

Common Issues with DesignJet 500

This section addresses frequent challenges faced by users of large-format printing devices. Understanding these problems can help in identifying solutions and improving overall functionality. Regular maintenance and awareness of common faults are essential for ensuring optimal performance.

Frequent Printing Errors

Users may encounter various printing errors that affect output quality. These can include misalignment, streaks, or faded prints. Such issues often stem from clogged nozzles, incorrect media settings, or calibration problems.

Connectivity Problems

Another common challenge is related to connectivity. Users might face difficulties in establishing a stable connection between their device and the computer. Issues can arise from outdated drivers, network disruptions, or incorrect settings.

| Issue | Possible Cause | Solution |

|---|---|---|

| Print Misalignment | Calibration issues | Perform recalibration |

| Clogged Nozzles | Infrequent use | Run the cleaning cycle |

| Faded Prints | Low ink levels | Replace ink cartridges |

| Connection Failure | Outdated drivers | Update software |

Tools Needed for Repair

Effective maintenance and troubleshooting of printing devices require specific equipment and instruments. Having the right tools on hand not only streamlines the process but also enhances the likelihood of successful interventions. Below is a detailed overview of the essential items necessary for effective service and upkeep.

Essential Equipment

The following tools are critical for addressing common issues and performing routine maintenance:

| Tool | Purpose |

|---|---|

| Screwdriver Set | To access internal components by removing screws. |

| Tweezers | For handling small parts and delicate components. |

| Cleaning Cloths | To wipe down surfaces and remove debris. |

| Multimeter | To check electrical connections and voltage. |

| Vacuum | For removing dust and particles from the interior. |

Specialized Tools

In addition to general equipment, some tasks may require specialized tools:

| Tool | Purpose |

|---|---|

| Calibration Tools | To ensure accurate color reproduction and alignment. |

| Heat Gun | For softening adhesive materials or components. |

| Chip Reset Tool | To reset ink levels and monitor usage. |

| Diagnostic Software | For troubleshooting and performance analysis. |

Step-by-Step Troubleshooting Guide

This guide provides a structured approach to identifying and resolving common issues that may arise during the operation of large-format printing devices. By following these steps, users can effectively diagnose problems and implement solutions to ensure optimal performance.

Identifying Common Issues

Begin by observing the device for any obvious signs of malfunction. Common problems include poor print quality, paper jams, or error messages on the display. Check the basics first, such as ensuring that the machine is powered on and all connections are secure. If there are visible signs of wear, like frayed cables or damaged components, these should be addressed immediately.

Troubleshooting Steps

1. Assess Print Quality: If prints are faded or streaked, inspect the ink cartridges for clogs. Running a cleaning cycle may resolve this issue.

2. Examine Paper Path: For paper jams, carefully open access panels and remove any obstructions. Ensure that the paper is loaded correctly and that the feed rollers are clean.

3. Review Error Codes: If the device displays an error message, refer to the user documentation to interpret the code and follow the recommended steps to rectify the issue.

By systematically addressing these aspects, users can often resolve issues independently, enhancing their overall experience with the device.

Replacing Printer Ink Cartridges

Maintaining optimal print quality requires regular attention to the ink supply of your printing device. When the ink levels drop, it is essential to replace the cartridges to ensure consistent performance and vibrant results. This section outlines the process for swapping out old cartridges for new ones effectively and safely.

Steps to Replace Cartridges

Follow these straightforward steps to successfully change your printer’s ink cartridges:

- Power on the printer and open the cover to access the cartridge compartment.

- Wait for the cartridges to move to the replacement position.

- Gently remove the old cartridge by pressing the release tab.

- Unpack the new cartridge and remove any protective covers.

- Insert the new cartridge firmly into its designated slot until it clicks into place.

- Close the printer cover and allow it to reset.

Cartridge Compatibility

Using compatible cartridges is crucial for the longevity of your device. Below is a comparison table to help identify suitable options:

| Brand | Compatible Models | Cartridge Type |

|---|---|---|

| Brand A | Model X, Model Y | Standard |

| Brand B | Model Z | High Yield |

| Brand C | Model W, Model V | Photo |

Always check the specifications to ensure the best match for your printing device. Following these guidelines will help maintain print quality and prolong the life of your printer.

Maintaining Print Quality

Ensuring optimal output requires regular attention to various factors that influence the performance of printing equipment. Consistent maintenance not only prolongs the lifespan of the machine but also guarantees that printed materials meet high standards of clarity and precision.

Regular Cleaning: Dust and ink residue can accumulate and affect the quality of prints. Implement a routine cleaning schedule for the print heads and other internal components. Using appropriate cleaning solutions will help prevent clogs and ensure smooth operation.

Check Ink Levels: Monitoring ink levels is crucial. Low ink can lead to streaks and faded prints. Replace cartridges promptly and opt for high-quality inks that are compatible with your device to achieve vibrant colors and sharp details.

Paper Quality: The choice of media plays a significant role in print results. Always use paper that matches the specifications recommended by the manufacturer. This not only enhances color fidelity but also minimizes issues such as smudging and paper jams.

Calibration: Regularly calibrate the equipment to align colors and ensure accurate reproduction. Calibration tools or software provided by the manufacturer can help maintain consistent quality across different print jobs.

Environmental Factors: Keep the printing environment stable in terms of temperature and humidity. Extreme conditions can adversely affect both the machine and the printed output. Aim for a controlled environment to enhance overall performance.

Cleaning Printer Components

Maintaining the cleanliness of printer parts is essential for optimal performance and longevity. Regularly addressing dirt and debris can enhance print quality and prevent mechanical issues.

Essential Components to Clean

- Print Heads

- Rollers

- Ink Cartridges

- Exterior Surfaces

Cleaning Steps

- Power off the printer and unplug it for safety.

- Gently remove ink cartridges and set them aside.

- Use a lint-free cloth to wipe down the exterior.

- Clean the rollers with a damp cloth, ensuring no moisture drips.

- For print heads, follow the manufacturer’s recommended cleaning solution.

- Reassemble the components and plug the printer back in.

Updating Firmware and Drivers

Keeping your printing device updated is crucial for optimal performance and enhanced functionality. Regular updates ensure compatibility with various software, improve efficiency, and can introduce new features. This section will guide you through the essential steps to update the necessary components.

Before proceeding with updates, consider the following:

- Check the current version of your firmware and drivers.

- Identify the latest versions available from the manufacturer’s website.

- Ensure a stable internet connection to avoid interruptions during the update process.

To update the firmware, follow these steps:

- Visit the official website of the manufacturer.

- Navigate to the support or downloads section.

- Locate the firmware update specific to your model.

- Download the update file to your computer.

- Connect the printer to your computer via USB or ensure it is connected to the same network.

- Run the downloaded update file and follow the on-screen instructions.

For driver updates, you can follow a similar procedure:

- Access the manufacturer’s website.

- Find the drivers section and select your device model.

- Download the latest drivers compatible with your operating system.

- Install the drivers by running the downloaded file and following the prompts.

After completing these updates, it is advisable to restart your device to ensure all changes take effect. Regular maintenance of firmware and drivers will contribute significantly to the longevity and performance of your printing equipment.

Safety Precautions During Repairs

Ensuring a secure environment is essential when performing maintenance tasks on complex machinery. Adhering to proper safety measures can prevent accidents and damage to the equipment. Understanding potential hazards and taking proactive steps is crucial for both the technician and the device involved.

Always disconnect power sources before beginning any work. This simple step mitigates the risk of electrical shocks and accidental activations. Ensure that all capacitors are discharged if applicable, as they can retain charge even when unplugged.

Utilize appropriate personal protective equipment (PPE) such as gloves and safety goggles. This protects against sharp components and potential chemical exposure. It’s important to select gear that suits the specific tasks at hand.

Maintain a clean and organized workspace to minimize hazards. Clutter can lead to tripping or misplacing tools, which may result in injuries or delays. Ensure that all tools are in good condition and appropriate for the job to avoid malfunctions.

Be aware of your surroundings and ensure proper ventilation when working with materials that may emit harmful fumes. If necessary, use respirators or other filtration devices to protect your respiratory health.

Follow the manufacturer’s guidelines closely, as they provide critical information regarding safe handling and troubleshooting of the equipment. Being informed about the specific model can enhance safety and effectiveness during the maintenance process.

By implementing these precautions, you can create a safer environment for both yourself and the equipment, ensuring that all tasks are completed efficiently and without incident.

Where to Find Replacement Parts

Locating components for your equipment can be a straightforward process if you know where to look. Various sources offer both new and refurbished items, ensuring you can find what you need without hassle. Below are some reliable options to consider when searching for necessary replacements.

| Source | Description | Advantages |

|---|---|---|

| Manufacturer’s Website | The official site often has a dedicated section for parts. | Authenticity and quality assurance. |

| Online Retailers | Platforms like Amazon or eBay provide a wide selection. | Competitive pricing and user reviews. |

| Local Supply Stores | Physical stores specializing in electronics and components. | Immediate availability and personal assistance. |

| Third-party Vendors | Specialized companies that offer compatible parts. | Cost-effective alternatives to original items. |

| Forums and Community Groups | Online communities where users share resources. | Insights from experienced users and potential leads. |

By exploring these options, you can efficiently source the components required to keep your equipment functioning optimally.