In the realm of outdoor equipment, understanding the intricacies of your machinery is paramount. Proper care ensures longevity and optimal performance, allowing users to tackle a variety of tasks efficiently. This resource aims to equip enthusiasts with the necessary insights to navigate potential challenges.

Maintaining your equipment can be a straightforward process if approached systematically. With clear instructions and thorough guidance, you can resolve common issues and enhance the functionality of your device. Emphasizing preventive measures and routine checks can significantly reduce the likelihood of major breakdowns.

Whether you’re an experienced operator or a newcomer, having access to reliable resources fosters confidence in managing your tools. Dive into this comprehensive guide to uncover the ultimate tips and strategies for keeping your machinery in peak condition.

Understanding the John Deere Z445

This section explores a specific model in the realm of outdoor power equipment, focusing on its features, functionality, and maintenance aspects. This machine is designed for efficiency and durability, making it a popular choice among enthusiasts and professionals alike.

Key features of this model include:

- Robust engine performance

- Ergonomic design for operator comfort

- Advanced cutting technology for a clean finish

- Versatile attachments for various tasks

Proper upkeep is essential for optimal performance. Regular maintenance practices include:

- Frequent oil changes to ensure engine health

- Blade sharpening for effective cutting

- Inspection of belts and cables for wear

- Cleaning air filters to maintain airflow

By understanding the capabilities and care required for this equipment, users can maximize its longevity and efficiency, ensuring it remains a reliable tool for years to come.

Common Issues with Z445 Models

Owners of these popular lawn maintenance machines often encounter a range of challenges that can affect performance and efficiency. Understanding these frequent problems can help in troubleshooting and maintaining optimal functionality.

| Issue | Description | Possible Solution |

|---|---|---|

| Starting Problems | Difficulty in initiating the engine can be attributed to battery issues or faulty ignition components. | Check battery charge and connections; replace spark plug if necessary. |

| Uneven Cutting | A mower may produce an uneven cut due to dull blades or improper deck height. | Sharpen blades and adjust the cutting deck to the correct height. |

| Overheating | Engines may overheat if cooling fins are blocked or if the oil level is low. | Clean cooling fins and ensure proper oil levels are maintained. |

| Transmission Issues | Sluggish movement or difficulty in changing speeds can occur with the drive system. | Inspect the drive belt for wear and replace it if needed; check fluid levels. |

| Fuel System Problems | Fuel delivery issues can result from clogged filters or stale gasoline. | Replace fuel filters and use fresh fuel to ensure proper operation. |

Tools Needed for Repairs

When addressing maintenance tasks, having the right equipment is essential for efficiency and effectiveness. The proper tools not only facilitate the process but also ensure that the job is completed safely and correctly. A well-prepared toolkit can make a significant difference in the outcome of any mechanical work.

First and foremost, basic hand tools such as wrenches, sockets, and screwdrivers are crucial for disassembling components. Each of these items serves a specific purpose, enabling access to various parts of the machinery. Additionally, pliers and adjustable wrenches can provide the versatility needed for different tasks.

Furthermore, specialized tools may be required depending on the nature of the job. For instance, a torque wrench is essential for ensuring that fasteners are tightened to the manufacturer’s specifications. Similarly, diagnostic equipment can help identify issues more quickly, allowing for efficient troubleshooting.

Safety gear should also be included in your toolkit. Gloves, goggles, and hearing protection are important to shield yourself from potential hazards during work. Maintaining a safe working environment is just as vital as the tools themselves.

In conclusion, assembling a comprehensive set of tools tailored to the needs of your machinery will not only streamline the maintenance process but also enhance the longevity and performance of the equipment.

Step-by-Step Maintenance Guide

Regular upkeep of your outdoor equipment ensures optimal performance and longevity. This guide provides a systematic approach to maintaining your machine, focusing on essential tasks that enhance efficiency and prevent potential issues.

Essential Maintenance Tasks

- Check and change the oil regularly.

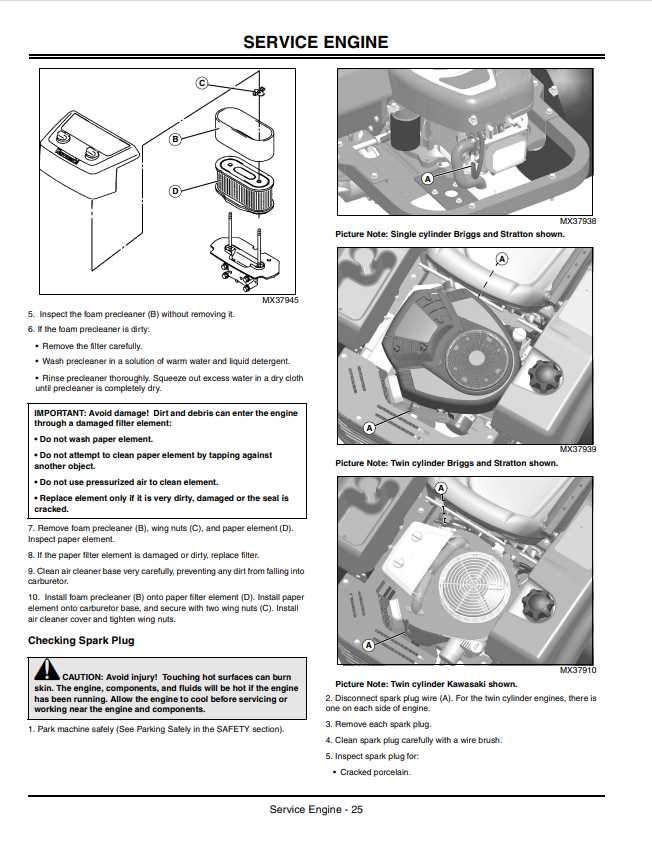

- Inspect air filters and replace if necessary.

- Sharpen blades to maintain cutting quality.

- Examine belts for wear and tear.

- Clean the deck and undercarriage to prevent buildup.

Step-by-Step Procedures

- Oil Change: Drain the old oil, replace the filter, and refill with fresh oil according to specifications.

- Air Filter Inspection: Remove the filter and clean or replace it to ensure proper airflow.

- Blade Sharpening: Safely detach the blades and use a sharpening tool to restore their edge.

- Inspecting Belts: Check for cracks or fraying and replace any damaged belts immediately.

- Cleaning: Use a brush or hose to clear grass clippings and debris from the equipment.

By following these steps, you can maintain your machinery effectively, ensuring it operates smoothly for years to come.

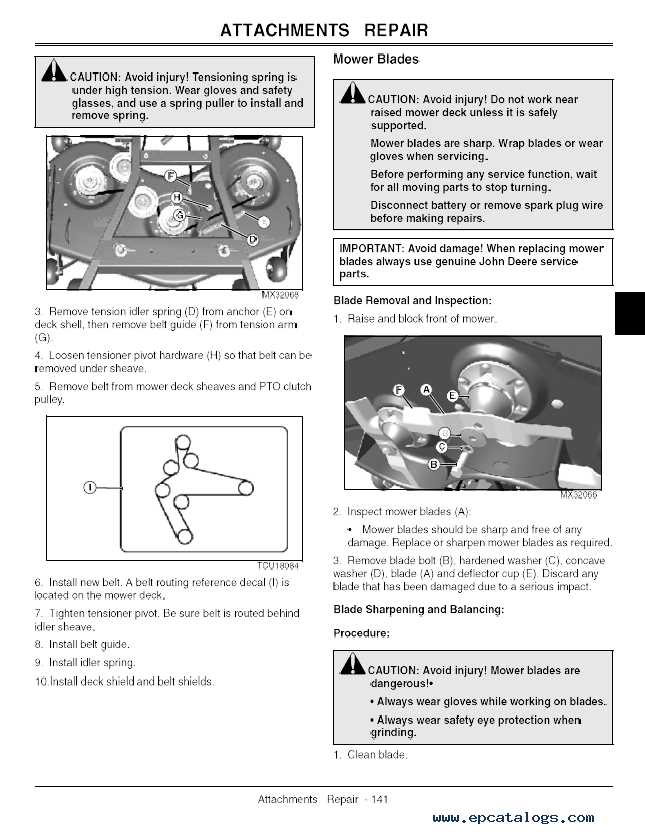

How to Replace the Blades

Replacing the cutting edges of your lawn care equipment is essential for maintaining optimal performance and achieving a clean, even cut. Over time, blades can become dull or damaged, impacting efficiency and the overall appearance of your lawn. This guide will walk you through the necessary steps to ensure a successful blade replacement.

Before starting the replacement process, gather the necessary tools and safety equipment. This typically includes a wrench, a socket set, safety gloves, and protective eyewear. Make sure your equipment is turned off and properly secured to prevent any accidents during the procedure.

| Step | Action |

|---|---|

| 1 | Disconnect the spark plug to eliminate the risk of accidental starts. |

| 2 | Lift the equipment securely using a jack or appropriate lifting device. |

| 3 | Remove the blade fastening hardware using the wrench or socket set. |

| 4 | Carefully take off the old blades, checking for any wear or damage on the mounting areas. |

| 5 | Install the new blades, ensuring they are oriented correctly and securely fastened. |

| 6 | Reconnect the spark plug and perform a safety check before starting the equipment. |

After completing the replacement, it’s important to regularly inspect the blades to ensure they remain in good condition. Keeping them sharp will not only enhance performance but also prolong the life of your equipment.

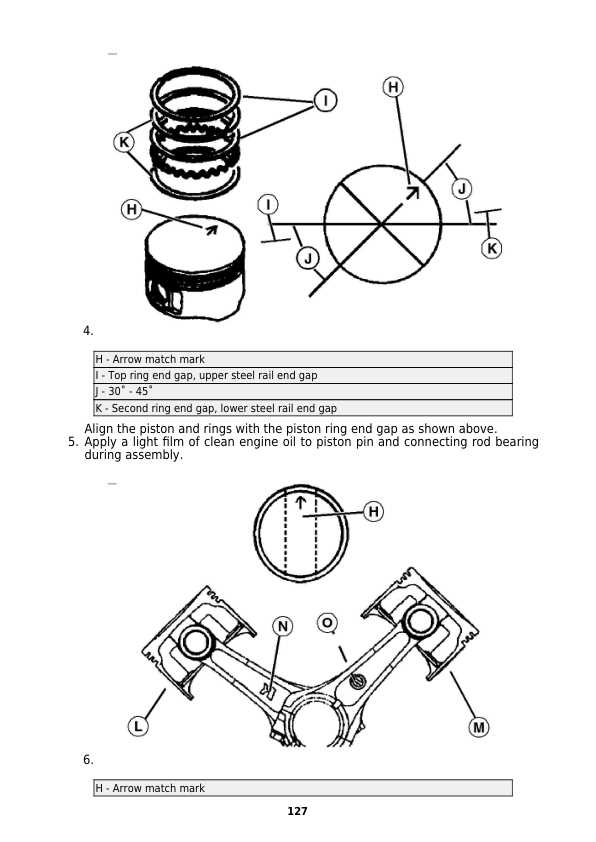

Engine Troubleshooting Techniques

Troubleshooting engine issues requires a systematic approach to identify and resolve problems effectively. Understanding the common symptoms and their potential causes can greatly aid in diagnosing issues. By following a logical sequence of checks, one can often pinpoint the underlying problem without unnecessary complications.

Start with Visual Inspection: Begin by examining the engine for any visible signs of damage or wear. Look for leaks, frayed wires, or loose connections. This initial step can reveal obvious problems that need addressing.

Check Fuel Supply: Ensure that the fuel system is functioning correctly. Inspect fuel lines for clogs or cracks, and verify that the fuel tank has an adequate supply. Contaminated fuel can also lead to engine performance issues, so consider testing or replacing the fuel if necessary.

Examine Electrical Components: A faulty ignition system can prevent an engine from starting. Test the spark plugs, ignition coil, and battery. Ensuring these components are in good condition is essential for reliable performance.

Monitor Engine Performance: Pay attention to how the engine runs. Listen for unusual noises and watch for irregular vibrations. These can be indicators of more significant problems, such as internal wear or misalignment.

Utilize Diagnostic Tools: Employing diagnostic equipment can simplify the troubleshooting process. Tools such as multimeters and compression testers provide valuable data that can guide further investigation into specific areas of concern.

Document Findings: Keeping a detailed record of the symptoms and actions taken can help in future troubleshooting efforts. This documentation can reveal patterns and assist in identifying recurring issues.

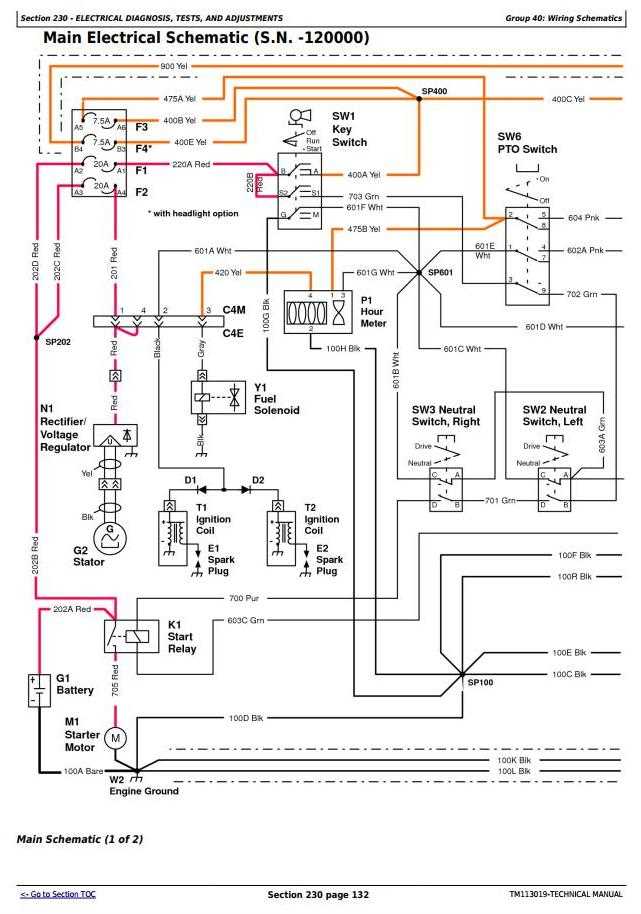

Electrical System Diagnostics

Understanding the functionality of the electrical components in a machine is crucial for efficient operation. This section will guide you through the essential steps for diagnosing issues within the electrical system, ensuring that all parts function harmoniously to maintain peak performance.

Common Electrical Issues

Several problems can arise within the electrical system. Here are some frequent issues to look out for:

- Dead or weak battery

- Faulty wiring connections

- Defective switches or relays

- Burned-out fuses

- Malfunctioning electrical components

Diagnostic Steps

To effectively diagnose electrical issues, follow these steps:

- Inspect the battery for corrosion and ensure a full charge.

- Check all wiring connections for signs of wear or damage.

- Test the functionality of switches and relays using a multimeter.

- Examine fuses for continuity; replace any that are blown.

- Utilize diagnostic tools to evaluate the performance of individual components.

By systematically addressing these aspects, you can identify and resolve electrical issues, thereby enhancing the reliability and functionality of your equipment.

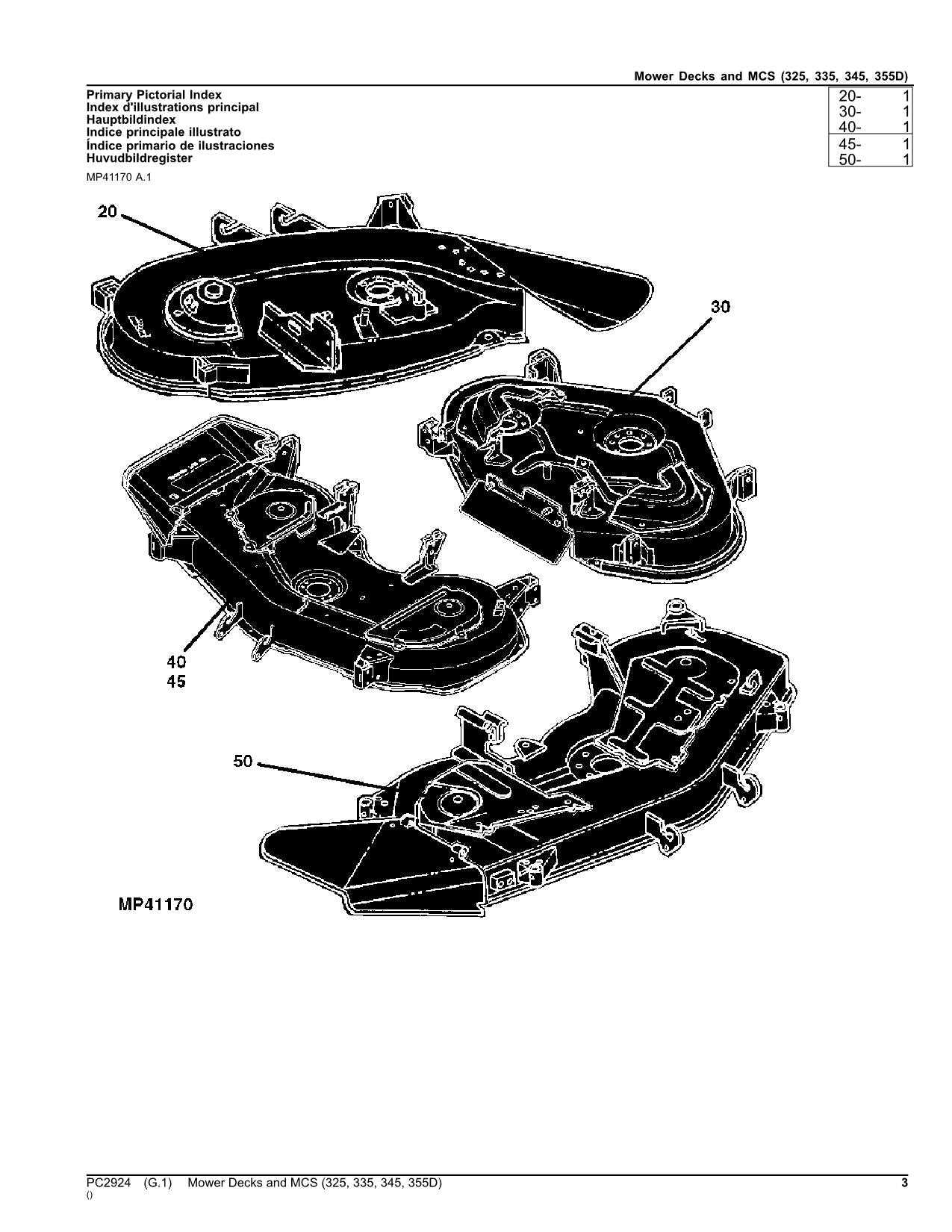

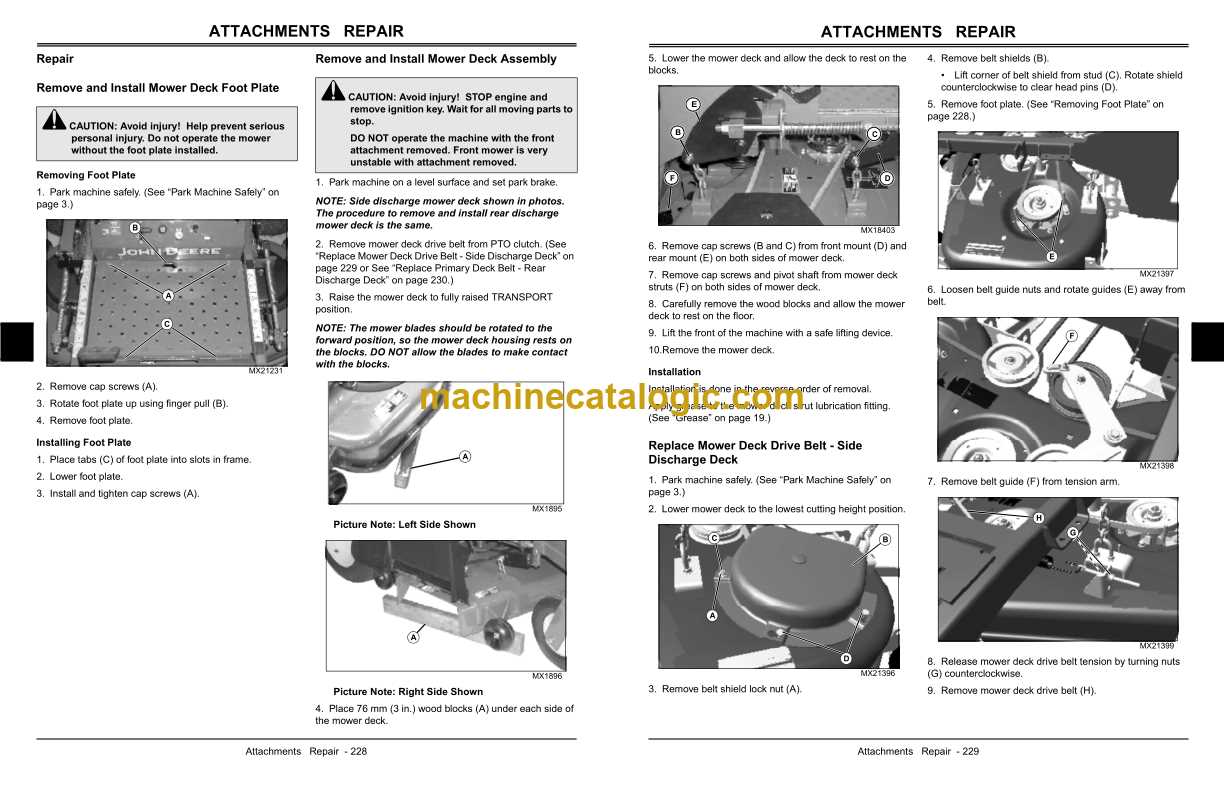

Adjusting the Deck Height

Setting the correct height of the cutting deck is essential for achieving an even and healthy lawn. Proper adjustments ensure that the mower performs optimally, reducing the risk of scalping and promoting robust grass growth. This section outlines the steps necessary to modify the deck height effectively.

Tools Needed

- Wrench or socket set

- Measuring tape

- Level surface

- Owner’s manual for reference

Steps to Adjust Deck Height

- Park the mower on a flat and level surface to ensure accurate measurements.

- Locate the adjustment mechanism, typically found near the front or side of the deck.

- Using the appropriate tool, loosen the lock nuts or bolts attached to the height adjustment brackets.

- Raise or lower the deck to the desired height, using a measuring tape to ensure precision.

- Once the desired height is set, tighten the lock nuts or bolts securely.

- Double-check the height on both sides of the deck to ensure uniformity.

- Test the mower on grass to confirm that the adjustment meets your requirements.

Regular checks and adjustments can help maintain optimal cutting performance throughout the mowing season.

Fuel System Care Tips

Maintaining the fuel system of your equipment is essential for optimal performance and longevity. Regular attention to this component helps prevent issues that can lead to inefficient operation or costly repairs. Here are some practical tips to ensure your fuel system remains in top shape.

Regular Inspection

Conduct frequent checks of fuel lines, filters, and connections to identify any signs of wear or leaks. Inspecting these components can prevent potential problems before they escalate. Look for cracks, swelling, or any signs of corrosion that might compromise the system’s integrity.

Quality Fuel Usage

Always use high-quality fuel that meets the manufacturer’s specifications. Contaminated or subpar fuel can lead to clogs and reduce efficiency. Additionally, consider adding a fuel stabilizer, especially if the equipment will sit unused for extended periods. This helps maintain fuel integrity and prevents degradation.

Recommended Lubrication Procedures

Proper maintenance of machinery is crucial for optimal performance and longevity. One of the key aspects of this upkeep involves the appropriate application of lubricants. Following specific guidelines for lubrication not only ensures smoother operation but also helps prevent wear and tear on critical components.

1. Select the Right Lubricant: It is essential to choose a lubricant that meets the manufacturer’s specifications. Look for products that offer excellent viscosity and protection against rust and corrosion.

2. Regular Inspection: Periodically check lubrication points for signs of wear or contamination. This proactive approach can help identify potential issues before they escalate.

3. Clean Surfaces: Before applying any lubricant, ensure that all surfaces are clean and free from debris. This step helps achieve better adhesion and effectiveness of the lubricant.

4. Apply in Appropriate Amounts: Use the correct amount of lubricant as recommended. Over-lubrication can lead to excess build-up, while under-lubrication may result in inadequate protection.

5. Follow a Schedule: Establish a routine lubrication schedule based on operating conditions and usage frequency. Adhering to this schedule can significantly enhance the lifespan of the equipment.

By implementing these lubrication procedures, operators can maintain the efficiency and reliability of their machinery, ensuring it continues to perform at its best.

Seasonal Maintenance Checklist

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. This seasonal maintenance checklist outlines key tasks that should be performed to keep your machinery in top condition throughout the year.

Spring Maintenance

- Inspect and clean the air filter to enhance engine efficiency.

- Check the spark plugs and replace them if necessary.

- Examine belts and hoses for signs of wear or damage.

- Change the oil and replace the oil filter for optimal lubrication.

- Sharpen or replace blades for effective cutting performance.

Fall Maintenance

- Drain fuel or add stabilizer to prevent degradation during storage.

- Clean the deck and remove any grass clippings or debris.

- Inspect tires for proper inflation and tread wear.

- Store equipment in a dry place to avoid rust and corrosion.

- Check battery condition and charge if necessary.

Finding Replacement Parts Easily

Locating the right components for your machinery can be a straightforward process if you know where to look. By utilizing various resources and methods, you can ensure that you find the necessary items without unnecessary delays. Understanding the options available to you can simplify the task and save you time and effort.

Online Resources

One of the best ways to find components is through online platforms. Here are some useful options:

- Manufacturer Websites: Often, the official websites provide detailed catalogs and ordering options.

- Parts Retailers: Numerous online retailers specialize in machinery parts and often feature user-friendly search functions.

- Forums and Community Groups: Engaging with fellow enthusiasts can lead to recommendations for reputable suppliers.

Local Options

In addition to online searches, local resources can be beneficial. Consider the following:

- Authorized Dealers: They can provide original components and expert advice.

- Salvage Yards: These places may have used parts at a fraction of the cost.

- Hardware Stores: Local stores often carry common components or can order them for you.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial for protecting both the individual performing the work and the machinery itself. Adhering to specific guidelines can significantly reduce the risk of accidents and enhance the efficiency of the process. Proper preparation, awareness of surroundings, and the use of appropriate protective gear are fundamental components of a safe working environment.

Essential Safety Gear

Before commencing any maintenance activities, it is imperative to equip oneself with the necessary protective equipment. This not only safeguards the individual but also promotes a culture of safety within the workspace.

| Gear Type | Purpose |

|---|---|

| Safety Glasses | Protects eyes from debris and harmful substances. |

| Gloves | Prevents cuts and abrasions while handling tools and components. |

| Steel-Toed Boots | Offers protection against heavy items that may fall. |

| Hearing Protection | Reduces exposure to loud machinery sounds. |

Work Area Safety Tips

Maintaining a clean and organized workspace is equally important. Clutter can lead to accidents and hinder efficient work. Furthermore, ensuring proper lighting and ventilation will create a safer environment, allowing for better visibility and air quality during tasks.