In the world of agricultural machinery, ensuring optimal performance and longevity is essential. This section provides valuable insights into the upkeep of your equipment, focusing on essential procedures and best practices. Whether you are a seasoned operator or a new user, understanding the intricacies of your machine can greatly enhance its efficiency.

Maintaining your equipment requires attention to detail and a commitment to following established guidelines. By adhering to recommended protocols, you can avoid common issues that may arise during operation. This guide will cover crucial aspects such as routine checks, necessary adjustments, and troubleshooting techniques, all designed to keep your machinery running smoothly.

Investing time in learning about your equipment not only prolongs its lifespan but also improves overall productivity. This guide emphasizes the significance of proactive maintenance and empowers users to address minor problems before they escalate. With the right knowledge and tools, you can ensure that your machine remains a reliable partner in your agricultural endeavors.

Overview of John Deere 5520

This section provides a comprehensive look at a well-regarded agricultural machine, highlighting its key features and specifications. Designed for efficiency and versatility, this equipment is ideal for various farming tasks, ensuring optimal performance in diverse conditions.

Built with a focus on reliability, the vehicle boasts a robust engine that delivers excellent power and torque. Its ergonomic design enhances user comfort, while the intuitive controls facilitate ease of operation. Additionally, advanced technology integrated into the system contributes to improved productivity, making it a valuable asset for any agricultural endeavor.

Overall, this machine represents a blend of innovation and tradition, catering to the needs of modern farmers while maintaining the quality expected from trusted manufacturers.

Common Issues and Troubleshooting

This section addresses frequent problems encountered with agricultural machinery, focusing on identifying symptoms and providing practical solutions. Understanding these challenges can significantly enhance the efficiency and longevity of the equipment.

Engine Performance Problems

One of the most common issues involves irregular engine operation. Symptoms may include difficulty starting, stalling, or reduced power output. To troubleshoot, check the fuel system for clogs, ensure the air filter is clean, and examine the spark plugs for wear. Regular maintenance of these components can prevent many performance-related issues.

Hydraulic System Malfunctions

Another prevalent concern is hydraulic system failure, which may manifest as slow or unresponsive movements. Begin troubleshooting by inspecting hydraulic fluid levels and looking for leaks in hoses or connections. Additionally, ensure that filters are not obstructed, as this can hinder fluid flow. Timely detection and resolution of these issues can restore functionality and prevent further damage.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring that your machinery operates at its best. By implementing a few straightforward practices, you can enhance efficiency, prolong the lifespan of components, and prevent potential issues. This section outlines effective strategies for maintaining your equipment and achieving optimal functionality.

Routine Inspections

Conducting frequent checks on various systems is crucial. Look for signs of wear, leaks, or unusual noises that may indicate underlying problems. Early detection can save time and resources in the long run. Make it a habit to inspect filters, belts, and fluids regularly to keep everything running smoothly.

Proper Lubrication

Lubrication plays a vital role in reducing friction and preventing wear. Ensure that all moving parts are adequately lubricated according to the manufacturer’s recommendations. Using the right type of lubricant can significantly enhance performance and minimize the risk of breakdowns. Remember to check lubrication levels frequently and replenish as needed.

Essential Tools for Repair Work

Having the right equipment is crucial for any maintenance task, ensuring efficiency and effectiveness. Various instruments can simplify complex procedures, allowing for accurate adjustments and timely resolutions to issues. This section highlights the necessary tools that contribute to successful service activities, regardless of the specific machinery involved.

Basic Hand Tools

Every technician should possess a range of basic hand tools, such as wrenches, screwdrivers, and pliers. These instruments are fundamental for disassembling components and making essential modifications. Quality hand tools enhance grip and leverage, minimizing the risk of damage to parts during operation.

Diagnostic Equipment

In addition to standard hand tools, diagnostic equipment plays a pivotal role in identifying underlying issues. Tools like multimeters and pressure gauges provide vital information regarding the functionality of various systems. Utilizing advanced diagnostic tools can lead to quicker assessments and more informed decisions regarding necessary interventions.

Step-by-Step Repair Procedures

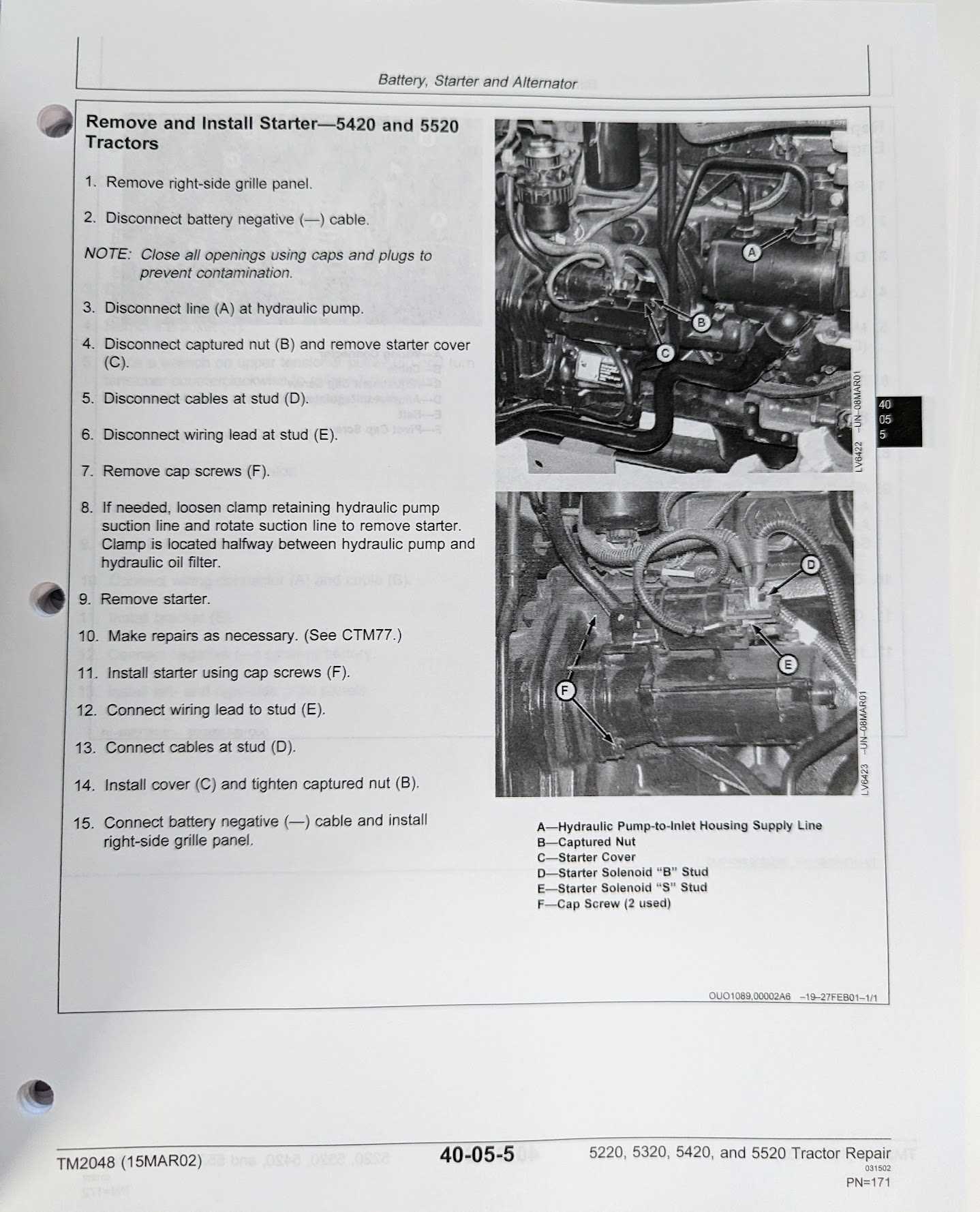

This section outlines a comprehensive approach to addressing common issues in agricultural machinery. Following a systematic method can enhance efficiency and ensure optimal performance of the equipment. Detailed instructions will guide you through the necessary actions, allowing you to restore functionality effectively.

| Step | Description |

|---|---|

| 1 | Begin by identifying the specific problem affecting the equipment. Conduct a thorough inspection to determine any visible signs of wear or damage. |

| 2 | Gather the necessary tools and replacement parts required for the procedure. Ensure that all items are compatible with the machinery. |

| 3 | Disconnect the power source to ensure safety during the maintenance process. This step is crucial to prevent accidental activation of the machinery. |

| 4 | Carefully dismantle the affected components according to the guidelines. Keep track of each part to facilitate reassembly. |

| 5 | Replace any damaged or worn-out components with new ones. Verify that all replacements meet the required specifications. |

| 6 | Reassemble the machinery, ensuring that each component is securely fitted and properly aligned. |

| 7 | Reconnect the power source and conduct a thorough test to ensure that the equipment operates smoothly and efficiently. |

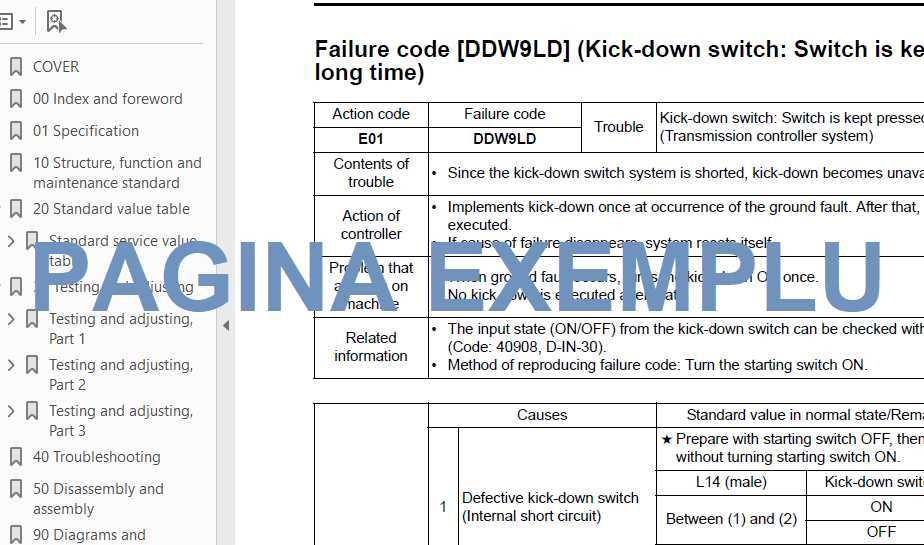

Understanding the Electrical System

The electrical system plays a crucial role in the overall functionality of machinery, providing the necessary power to various components. This system encompasses a network of wiring, batteries, and electronic elements that work in tandem to ensure smooth operation. Understanding how these components interact can greatly enhance troubleshooting and maintenance efforts.

Power Source: At the heart of the electrical setup lies the power source, which supplies energy to the entire system. Regularly checking the battery’s condition and connections is essential to prevent performance issues.

Wiring and Connections: Proper wiring and secure connections are vital for efficient energy distribution. Inspecting for frayed wires or loose terminals can help identify potential problems before they escalate.

Control Panel: The control panel acts as the central hub for monitoring and managing electrical functions. Familiarity with its layout and indicators aids in quick diagnostics and ensures that operators can respond to alerts effectively.

Safety Precautions: Understanding the electrical system also involves recognizing safety protocols. Ensuring that all components are in good working order and adhering to safety guidelines can prevent accidents and damage.

In summary, gaining insight into the electrical components of machinery not only facilitates better performance but also empowers users to conduct more effective maintenance and troubleshooting.

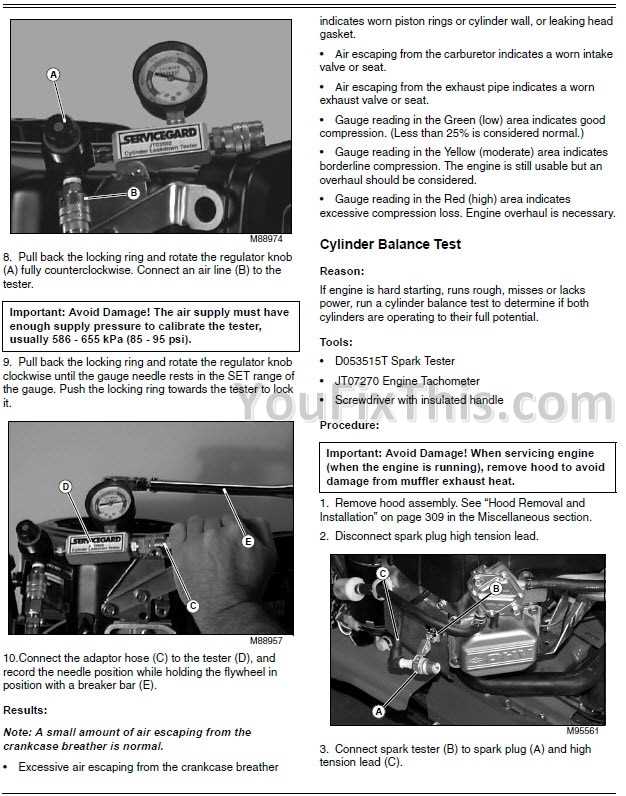

Hydraulic System Diagnostics

Effective troubleshooting of hydraulic systems is essential for ensuring optimal performance and longevity of machinery. Understanding the various components and their functions allows for a systematic approach to identifying issues that may arise within the system. Regular diagnostics can help prevent major failures and enhance operational efficiency.

Begin the diagnostic process by visually inspecting the hydraulic system for any signs of leaks or physical damage. Check connections and hoses for wear, ensuring that all fittings are secure. A pressure gauge can be used to assess system pressure, confirming whether it meets the manufacturer’s specifications. Abnormal readings may indicate potential issues that require further investigation.

Listening for unusual noises during operation is another critical aspect of diagnostics. Sounds such as whining or grinding can signal problems with the hydraulic pump or motor. Additionally, examining fluid quality is vital; contaminated or degraded fluid can severely affect system performance. Replacing the fluid may be necessary if it appears discolored or contains particulates.

Employing diagnostic tools, such as flow meters and electronic testers, can provide deeper insights into the system’s functionality. These tools help in analyzing flow rates and identifying inefficiencies. Following a comprehensive assessment, any identified issues should be addressed promptly to maintain the integrity and efficiency of the hydraulic system.

Engine Performance Enhancements

Improving the efficiency and power of an engine can significantly enhance overall machinery performance. Various techniques can be employed to achieve this goal, ranging from mechanical modifications to software tuning. These enhancements aim to optimize fuel consumption, increase torque, and improve responsiveness, ultimately leading to a more productive operation.

Key Enhancements

- Air Intake Modifications: Upgrading the air intake system can improve airflow, allowing the engine to breathe better and perform more efficiently.

- Exhaust System Improvements: A high-performance exhaust system can reduce back pressure, enhancing engine efficiency and increasing power output.

- Fuel System Tuning: Adjusting fuel delivery and mixture can lead to optimal combustion, resulting in better engine performance.

- ECU Remapping: Modifying the engine control unit settings can optimize performance parameters, tailoring them to specific operational needs.

Maintenance Considerations

- Regular Inspections: Frequent checks can help identify potential issues early, ensuring that enhancements continue to function effectively.

- Quality Parts: Utilizing high-quality components for upgrades can enhance durability and reliability.

- Performance Monitoring: Keeping track of engine performance metrics can provide insights into the effectiveness of enhancements and guide future modifications.

Parts Replacement Guidelines

Ensuring the longevity and optimal performance of machinery often involves the timely substitution of worn or damaged components. This section provides essential information to assist users in identifying when replacements are necessary and how to carry out the process effectively.

Identification of Worn Components

Regular inspections are vital for detecting signs of wear or malfunction in various parts. Look for indicators such as unusual noises, decreased efficiency, or visible damage. Keeping a maintenance log can also aid in recognizing patterns that suggest impending issues.

Replacement Process

When it becomes necessary to replace a component, begin by consulting the specifications to ensure compatibility with the machinery. Always utilize high-quality parts to maintain performance and safety standards. Follow the manufacturer’s guidelines for installation, taking care to secure all fittings and connections properly. For complex replacements, consider seeking professional assistance.

Safety Precautions During Repairs

When performing maintenance tasks on machinery, ensuring safety is paramount. Proper precautions can help prevent accidents and injuries while working. Understanding potential hazards and following recommended practices is essential for anyone engaged in this kind of work.

Before starting any task, it’s crucial to familiarize yourself with the equipment and tools involved. Wearing appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear, is vital. This protective gear can safeguard against various risks, including sharp objects, chemicals, and falling debris.

Additionally, maintaining a clean and organized workspace can significantly reduce the likelihood of accidents. Keeping tools in designated areas and ensuring that pathways are clear will help create a safer environment. It’s also advisable to turn off and disconnect machinery from power sources before conducting any work to prevent unintended activation.

Lastly, always stay aware of your surroundings and any potential hazards that may arise during the process. Having a well-thought-out plan and being prepared for unexpected situations can enhance safety and efficiency during maintenance tasks.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and troubleshooting for agricultural machinery. Here, users can find valuable information that assists in resolving typical issues, enhancing performance, and ensuring longevity of the equipment.

What are the signs of potential issues?

Several indicators may suggest that the machinery requires attention. Unusual noises, decreased efficiency, and warning lights on the dashboard are primary signals that maintenance may be necessary. Regular checks can help in identifying these concerns early.

How often should routine checks be performed?

It is advisable to conduct routine inspections periodically, typically every few months or after significant usage. Following the manufacturer’s guidelines can help maintain optimal performance and prevent unexpected breakdowns.