Maintaining agricultural machinery is crucial for optimal performance and longevity. This section provides valuable insights and guidance on troubleshooting and upkeep of your equipment, ensuring it remains efficient and reliable in various working conditions.

Understanding the intricacies of machinery not only helps in addressing common issues but also empowers operators to perform essential tasks independently. This knowledge is vital for maximizing productivity and minimizing downtime on the field.

Whether you are a seasoned professional or a novice in the world of farm equipment, having access to comprehensive resources enhances your ability to manage your machinery effectively. The following information will aid in navigating through common challenges and routine maintenance practices.

Overview of John Deere 4310

This section provides a comprehensive insight into a versatile agricultural machine designed for various tasks. Known for its robust build and efficiency, it serves as an essential tool for both professionals and hobbyists in the farming community.

With its reliable performance, this model excels in various applications, including landscaping, plowing, and hauling. Its adaptability makes it suitable for different terrains and conditions, ensuring that users can tackle a wide range of projects with confidence.

Features of this equipment include a powerful engine, efficient hydraulic system, and user-friendly controls, all contributing to an enhanced operational experience. The design emphasizes both functionality and ease of maintenance, ensuring longevity and reliability over time.

For those seeking a balance between power and versatility, this machine stands out in its class. Its ability to handle demanding tasks while remaining accessible to operators of all skill levels is a significant advantage.

Overall, this equipment represents a solid investment for anyone looking to improve their productivity and efficiency in agricultural endeavors.

Common Issues with John Deere 4310

Understanding the typical challenges faced by users of this popular agricultural machinery can help in maintaining its efficiency and longevity. Various factors may contribute to operational difficulties, which can often be addressed with timely interventions.

Frequent Mechanical Problems

Users often report issues related to the mechanical components of the equipment. These problems can arise from wear and tear or improper maintenance practices.

| Issue | Description | Potential Solutions |

|---|---|---|

| Engine Overheating | High temperatures can affect performance and damage internal parts. | Check coolant levels and radiator for blockages. |

| Transmission Difficulties | Shifting issues may hinder operation and efficiency. | Inspect fluid levels and filter condition. |

Electrical System Failures

Electrical issues can significantly impact functionality. Common symptoms include starting problems and erratic behavior of gauges.

| Issue | Description | Potential Solutions |

|---|---|---|

| Battery Drain | Unexpected power loss can lead to operational delays. | Check connections and battery health. |

| Faulty Wiring | Damaged wires may cause short circuits and malfunction. | Inspect for frayed wires and secure connections. |

Essential Tools for Repairs

When tackling maintenance tasks on agricultural machinery, having the right set of tools is crucial for efficiency and effectiveness. The proper equipment not only simplifies the process but also ensures that repairs are completed safely and correctly. Below are some fundamental implements every technician should consider.

Basic Hand Tools

- Wrenches: A variety of sizes, including adjustable, are essential for loosening and tightening bolts.

- Sockets and Ratchets: Useful for reaching fasteners in tight spaces.

- Pliers: Ideal for gripping, twisting, and cutting wires or other materials.

- Screwdrivers: Both flathead and Phillips types are necessary for various screws.

Specialized Equipment

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Multimeter: Essential for diagnosing electrical issues in machinery.

- Hydraulic Jack: Useful for lifting heavy components safely during maintenance.

- Oil Filter Wrench: Helps in the removal of stubborn oil filters.

Equipping yourself with these essential tools will significantly enhance your ability to perform maintenance tasks effectively and efficiently. Proper preparation is key to successful outcomes in any servicing endeavor.

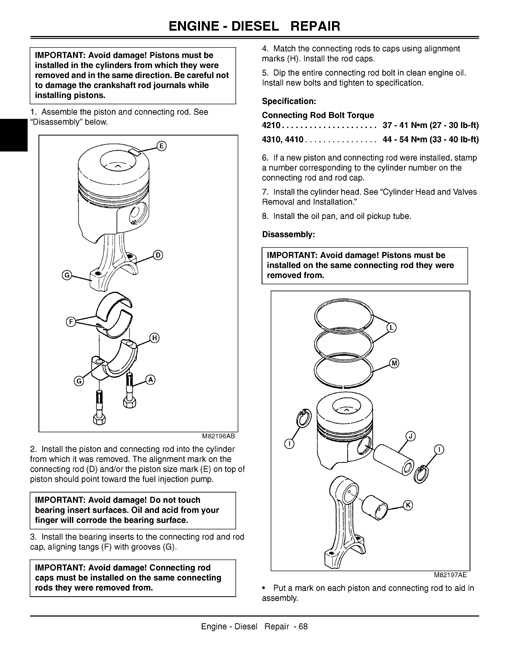

Step-by-Step Repair Procedures

This section provides a comprehensive guide to performing maintenance and troubleshooting tasks effectively. By following a systematic approach, you can address issues efficiently and ensure optimal functionality of your equipment.

Begin by gathering the necessary tools and materials specific to the task at hand. A clean and organized workspace will facilitate the process and minimize distractions. Always consult the specifications to understand the components involved and their functions.

Next, identify the problem accurately. Observing symptoms carefully will help in diagnosing the underlying cause. Document any unusual sounds, vibrations, or performance issues, as this information will be vital during the troubleshooting phase.

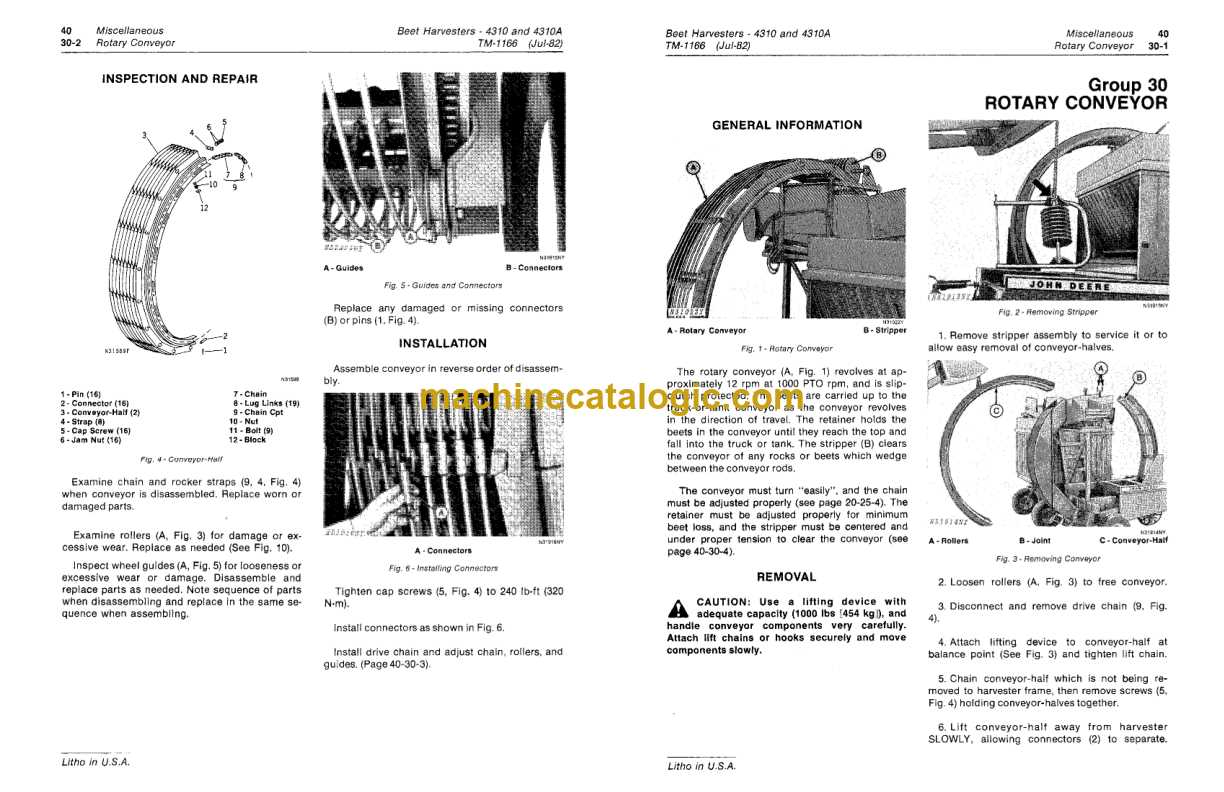

Proceed with disassembly as needed, taking care to note the sequence of parts removed. Label components or take photos to assist with reassembly. Utilize the appropriate methods for detaching and handling each part to prevent damage.

Once the problematic area is accessible, perform the necessary inspections or repairs. This could involve cleaning, replacing worn parts, or making adjustments. Ensure that all actions are executed with precision, adhering to safety guidelines throughout the process.

After completing the repairs, carefully reassemble the equipment, following the order noted during disassembly. Double-check all connections and fasteners to guarantee everything is secure before testing.

Finally, conduct a thorough test to confirm that the issue has been resolved. Monitor the equipment closely during initial operation to ensure it is functioning as intended. Regular maintenance checks following repairs will help prolong the lifespan of the machinery.

Understanding the Maintenance Schedule

A well-structured maintenance schedule is essential for the longevity and performance of any agricultural equipment. By adhering to recommended practices, operators can prevent unexpected breakdowns and ensure their machinery operates at optimal efficiency. This section delves into the key components of a maintenance schedule and emphasizes the importance of regular upkeep.

Key Components of a Maintenance Schedule

- Routine Inspections: Conducting regular checks helps identify wear and tear before it leads to major issues.

- Fluid Changes: Regularly replacing oils and fluids keeps the engine and hydraulic systems functioning smoothly.

- Filter Replacements: Air and fuel filters should be changed according to the specified intervals to maintain performance.

- Belts and Hoses: Inspecting and replacing worn belts and hoses prevents potential failures.

- Tire Maintenance: Regularly checking tire pressure and tread helps ensure safe operation and improves fuel efficiency.

Establishing a Maintenance Routine

Creating a consistent maintenance routine is vital for effective equipment management. Here are steps to help establish this practice:

- Review the manufacturer’s guidelines for specific maintenance intervals and procedures.

- Set reminders for key maintenance tasks to ensure they are not overlooked.

- Keep detailed records of maintenance activities to track performance and identify trends.

- Involve operators in the process, providing them with the knowledge and training necessary for basic upkeep.

By understanding and implementing a comprehensive maintenance schedule, operators can extend the life of their machinery and improve overall operational efficiency.

How to Troubleshoot Electrical Problems

Addressing electrical issues in machinery can seem daunting, but with a systematic approach, you can identify and resolve common faults effectively. This section outlines key steps to diagnose and fix electrical malfunctions, ensuring optimal performance.

Start by gathering the necessary tools, which may include a multimeter, wiring diagrams, and basic hand tools. Having these items ready will streamline the troubleshooting process.

- Inspect Visual Components:

- Check for any visible damage to wiring, connectors, and terminals.

- Look for signs of corrosion or loose connections.

- Test Battery and Power Supply:

- Use a multimeter to check the voltage of the battery.

- Ensure all connections to the battery are secure and clean.

- Examine Fuses and Relays:

- Locate the fuse box and inspect each fuse for continuity.

- Test relays to ensure they are functioning correctly.

- Check Switches and Controls:

- Test the operation of switches and control panels.

- Ensure that all controls are responsive and in the correct position.

- Conduct Wiring Tests:

- Perform continuity tests on wiring harnesses to detect breaks.

- Trace wires to ensure they are connected to the appropriate terminals.

After performing these checks, document your findings and any repairs made. This record can assist in future troubleshooting and maintenance efforts. If problems persist, consider consulting a professional for further diagnosis.

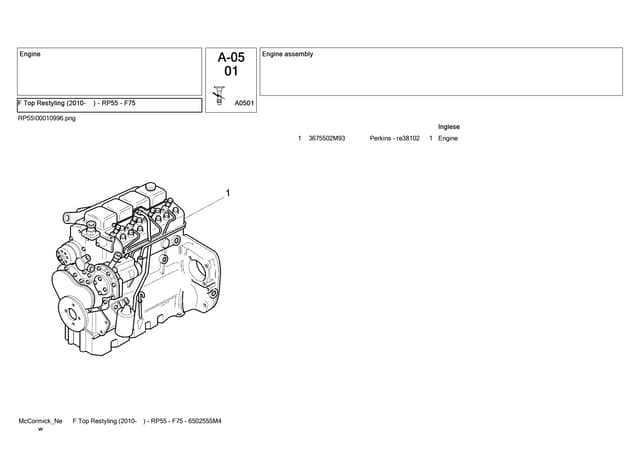

Engine Repair and Maintenance Tips

Maintaining optimal performance and longevity of your engine requires attention to detail and regular upkeep. Proper care not only enhances efficiency but also prevents potential issues that could lead to costly downtime. This section offers essential guidance on how to effectively manage your engine’s health.

| Task | Frequency | Notes |

|---|---|---|

| Check oil levels | Every 10 hours of operation | Ensure proper viscosity for optimal performance. |

| Change oil and filter | Every 100 hours | Use recommended oil type to maintain engine integrity. |

| Inspect air filter | Every 50 hours | Replace if dirty to ensure proper airflow. |

| Examine fuel system | Every 200 hours | Check for leaks and ensure clean fuel lines. |

| Inspect belts and hoses | Every 100 hours | Look for wear and tear; replace as needed. |

| Check coolant levels | Every 50 hours | Maintain proper coolant to prevent overheating. |

Following these guidelines will help ensure your engine operates smoothly and efficiently. Regular maintenance minimizes the risk of unexpected failures and extends the overall life of your machinery.

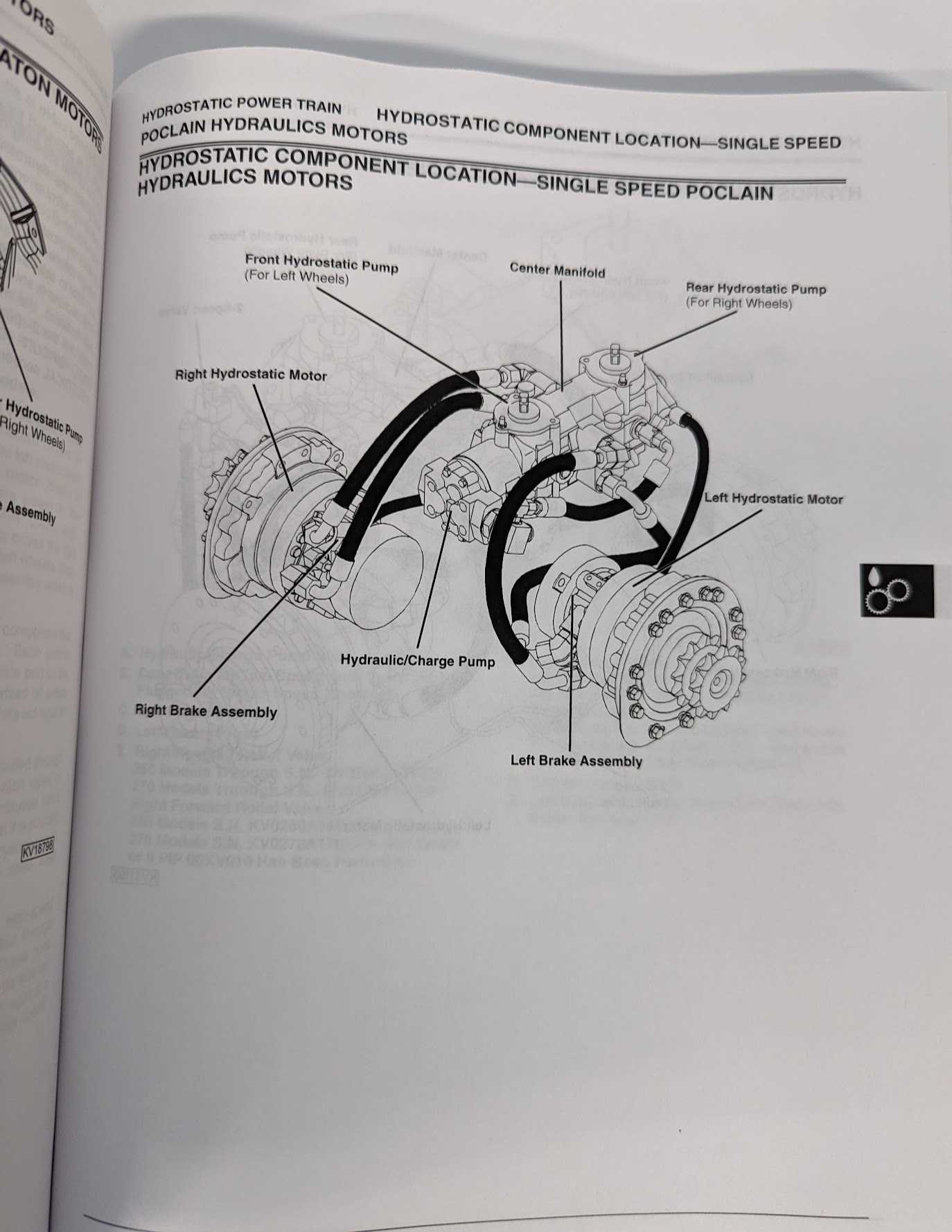

Hydraulic System Diagnostics

Effective analysis of hydraulic systems is crucial for maintaining optimal performance in various machinery. Understanding the components and their interactions allows operators and technicians to identify issues that may impede functionality. Regular assessment not only enhances efficiency but also prolongs the lifespan of the equipment.

Common Issues and Symptoms

Several signs indicate potential problems within the hydraulic system. These may include unusual noises, inconsistent fluid levels, or diminished power in hydraulic functions. Additionally, leaks or visible wear on hoses and fittings can signal the need for immediate attention. Recognizing these symptoms early can prevent more severe damage and costly repairs.

Diagnostic Procedures

Conducting a thorough diagnostic procedure involves checking fluid levels, inspecting for leaks, and testing pressure gauges. Using specialized tools, technicians can assess the performance of hydraulic pumps and cylinders. Regular monitoring and maintenance practices are essential to ensure all components are functioning correctly and to facilitate timely interventions when necessary.

Replacing Filters and Fluids

Maintaining optimal performance in agricultural machinery requires regular attention to the various filters and fluids that ensure efficient operation. These components play a crucial role in protecting the engine and enhancing overall functionality. Neglecting to replace them can lead to decreased efficiency, increased wear, and potential breakdowns.

When it comes to fluid replacement, it is essential to adhere to the manufacturer’s specifications regarding types and intervals. This includes engine oil, hydraulic fluid, coolant, and fuel. Each of these fluids serves a distinct purpose, contributing to the smooth operation and longevity of the equipment.

Filters, on the other hand, are integral for removing contaminants from fluids. Regularly replacing oil filters, air filters, and hydraulic filters can significantly improve the performance and reliability of the machinery. It’s advisable to inspect these components frequently and replace them according to the recommended schedule.

In conclusion, consistent maintenance of filters and fluids not only enhances performance but also extends the lifespan of the equipment, ensuring it remains a reliable asset in agricultural operations.

Upgrading Parts for Better Performance

Enhancing the capabilities of your machinery often requires attention to its components. By selecting high-quality or specialized parts, operators can achieve significant improvements in efficiency, power, and longevity. Understanding the impact of these upgrades not only maximizes performance but also ensures a smoother operational experience.

Benefits of Upgraded Components

Investing in superior parts can yield numerous advantages. Enhanced durability, reduced maintenance needs, and improved energy consumption are just a few outcomes that can result from strategic upgrades. Additionally, modern parts may incorporate advanced technology, offering better adaptability to various tasks.

Key Components to Consider

| Component | Upgrade Options | Expected Improvement |

|---|---|---|

| Engine | Performance chips, aftermarket air filters | Increased horsepower and torque |

| Transmission | High-performance clutches, synthetic fluids | Smoother shifting and better efficiency |

| Suspension | Upgraded shock absorbers, reinforced springs | Enhanced stability and handling |

| Hydraulics | High-flow pumps, performance hoses | Faster response and increased lifting capacity |

Safety Precautions During Repairs

When undertaking maintenance tasks, it is crucial to prioritize safety to prevent accidents and ensure a secure working environment. Proper precautions can help mitigate risks associated with machinery and tools, ultimately leading to a more efficient and successful process.

Essential Safety Gear

Wearing appropriate personal protective equipment (PPE) is vital when working on machinery. This includes items such as gloves, goggles, and steel-toed boots. Each piece of equipment serves to protect you from potential hazards that may arise during servicing.

| Safety Gear | Purpose |

|---|---|

| Gloves | Protect hands from sharp objects and chemicals |

| Goggles | Shield eyes from debris and harmful substances |

| Steel-toed Boots | Prevent foot injuries from heavy equipment |

Work Area Organization

Keeping the workspace tidy and organized is essential for maintaining safety. Ensure that tools and materials are stored properly, and remove any unnecessary items from the area to reduce tripping hazards. A clear workspace enhances focus and minimizes distractions.