Maintaining outdoor machinery is essential for ensuring optimal performance and longevity. This guide serves as a valuable resource for those seeking to enhance their knowledge of upkeep and troubleshooting techniques. By familiarizing oneself with the intricacies of machinery, users can save time and resources while enjoying a well-kept garden or yard.

Understanding the core components and functionality of such devices is crucial for effective maintenance. With detailed insights and step-by-step instructions, even novice users can tackle common issues confidently. This approach not only simplifies the repair process but also empowers individuals to take control of their outdoor equipment.

Regular attention to maintenance can prevent minor issues from escalating into significant problems. By following structured guidelines and utilizing helpful resources, users can ensure their machinery operates smoothly and efficiently, ultimately enhancing the overall experience of yard care.

Understanding John Deere 160 Tractors

This section explores the features and functionalities of a popular model in the field of outdoor machinery. Designed for various landscaping and gardening tasks, this equipment combines efficiency with user-friendly operation. Owners benefit from a robust build and reliable performance, making it a preferred choice for many enthusiasts and professionals alike.

Key Features

- Powerful engine capabilities for efficient grass cutting.

- Ergonomic design ensuring comfort during prolonged use.

- Versatile attachments available for various tasks.

- Durable construction for long-lasting reliability.

Maintenance Tips

- Regularly check and change the oil to ensure optimal engine performance.

- Inspect and sharpen blades periodically for clean cuts.

- Clean the air filter to maintain proper airflow.

- Keep tires properly inflated for stability and control.

Common Issues with Lawn Tractors

Maintenance equipment often encounters various problems that can hinder their performance. Understanding these issues can help users effectively troubleshoot and maintain their machinery. Below are some frequently experienced challenges and their potential solutions.

Engine Problems

- Starting Difficulties: This is a common concern, often related to fuel delivery or battery issues.

- Overheating: Insufficient coolant or clogged air filters may lead to elevated temperatures.

- Excessive Noise: Unusual sounds might indicate worn-out components or insufficient lubrication.

Drive System Failures

- Slipping Gears: This can occur due to worn belts or improper adjustment.

- Vibration Issues: Unbalanced blades or misaligned parts can cause excessive shaking during operation.

- Stalling: A lack of fuel, air blockages, or malfunctioning ignition systems may result in stalling.

Addressing these issues promptly can prolong the lifespan of your equipment and ensure smooth operation. Regular checks and maintenance routines are essential in preventing these common problems.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and fixing tasks. The appropriate tools not only enhance efficiency but also ensure that the work is done correctly and safely. Below is a list of indispensable instruments that every enthusiast should consider having on hand for their maintenance activities.

- Wrenches: A set of combination wrenches is vital for loosening and tightening various nuts and bolts.

- Screwdrivers: Both flathead and Phillips screwdrivers in multiple sizes are essential for various fasteners.

- Socket Set: A quality socket set allows for easier access to hard-to-reach areas.

- Pliers: Needle-nose and slip-joint pliers are great for gripping and manipulating components.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

Additionally, certain other tools can make the process smoother:

- Multi-tool: Handy for unexpected situations, a multi-tool can provide several functions in one compact design.

- Jack and Stands: If elevating parts is necessary, having a reliable jack and stands is crucial for safety.

- Cleaning Supplies: Brushes, rags, and degreasers help keep components in optimal condition.

Equipping yourself with these fundamental tools will ensure that you are prepared for any task, promoting longevity and performance in your equipment.

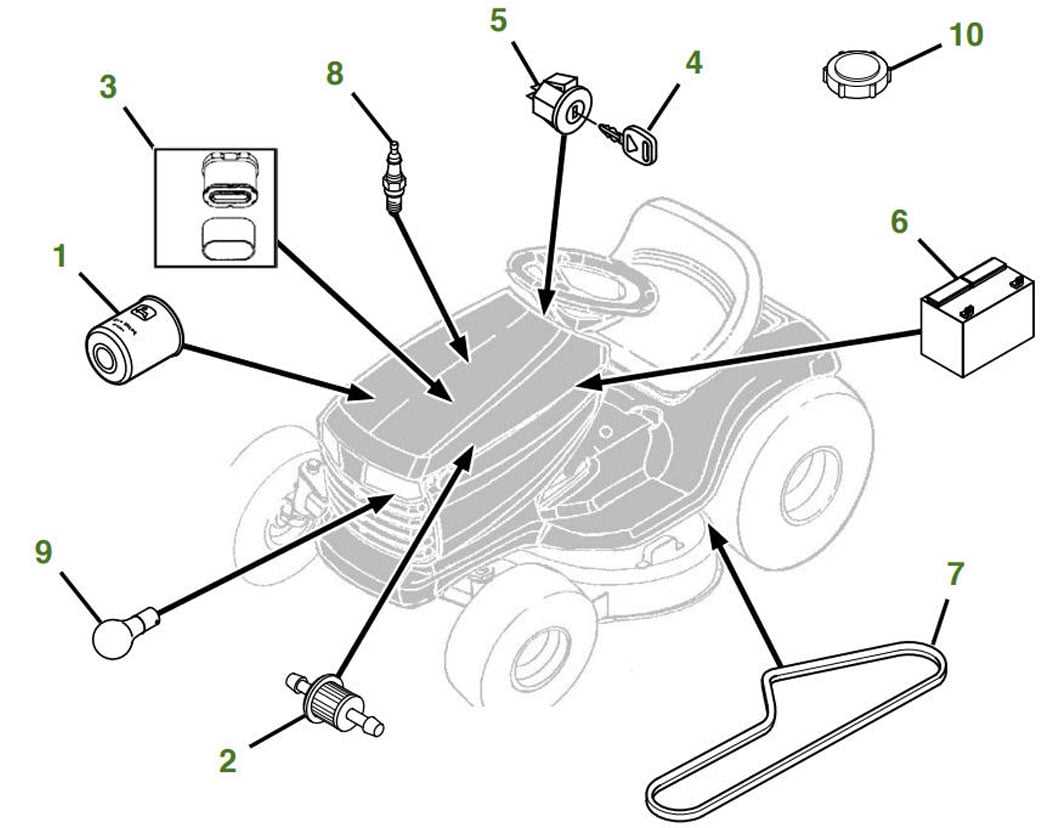

Step-by-Step Maintenance Guide

This guide provides a comprehensive approach to keeping your outdoor equipment in optimal condition. Regular upkeep ensures longevity and enhances performance, making it essential for any owner.

1. Check the Oil: Regularly inspect the oil level and quality. Change it as needed to maintain engine health.

2. Inspect the Air Filter: A clean air filter promotes efficiency. Replace or clean it if it appears dirty.

3. Sharpen the Blades: Dull blades can damage your lawn. Ensure they are sharp for a clean cut.

4. Clean the Undercarriage: Debris buildup can hinder performance. Regularly clear out grass and dirt.

5. Battery Maintenance: Check the battery connections and charge level. Replace the battery if it shows signs of wear.

6. Tire Pressure: Maintain the correct tire pressure for optimal traction and stability.

7. Fuel System Check: Inspect fuel lines and filters. Replace them if they show signs of wear or clogging.

8. Seasonal Preparation: Before winter, store your equipment properly and add stabilizer to the fuel.

Diagnosing Engine Problems

Identifying issues within an engine can be a challenging yet crucial task for maintaining optimal performance. By understanding common symptoms and applying systematic approaches, operators can effectively troubleshoot and resolve malfunctions. This section provides guidance on recognizing signs of distress and offers strategies for diagnosis.

Common Symptoms to Observe

Several indicators can suggest that an engine is not functioning correctly. Unusual noises, such as knocking or grinding, may signal internal wear or damage. Additionally, changes in power output, including stalling or reduced acceleration, often point to underlying issues. Other signs to consider include smoke from the exhaust, fluctuating temperatures, and abnormal vibrations.

Step-by-Step Diagnosis

To accurately diagnose engine troubles, follow a structured approach. Begin with a thorough visual inspection to check for leaks, worn belts, or loose connections. Next, assess the fuel system by ensuring that the fuel is clean and the lines are unobstructed. Testing the ignition components, such as spark plugs and coils, is also essential. If necessary, utilize diagnostic tools to evaluate electronic systems for error codes that can provide further insights.

By systematically addressing each potential problem area, one can effectively narrow down the source of the malfunction and implement appropriate corrective actions.

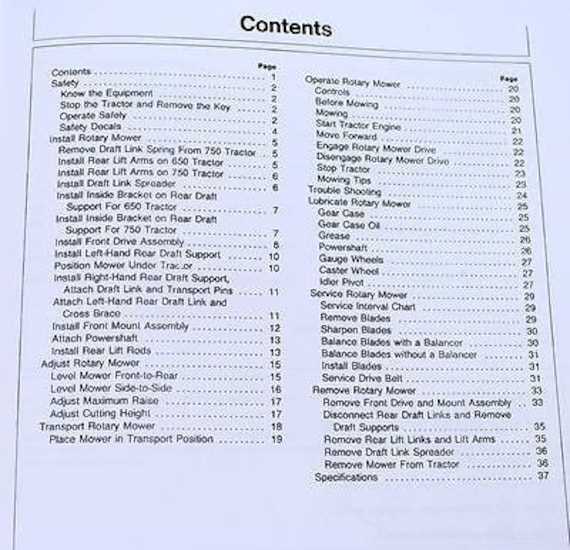

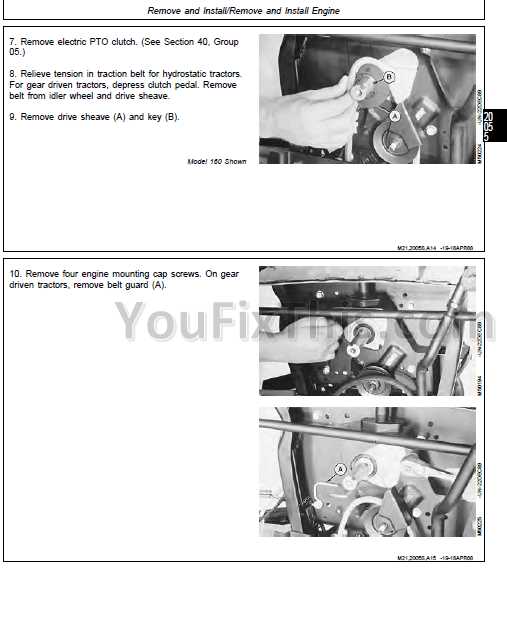

Replacing Blades: A How-To

Maintaining the sharpness and efficiency of cutting tools is essential for optimal performance. Replacing dull or damaged components not only improves results but also enhances safety. This guide provides a straightforward approach to switching out these crucial parts, ensuring your equipment runs smoothly.

Tools You Will Need

- Wrench or socket set

- Safety gloves

- Jack stands or ramps

- Replacement blades

- Grease or lubricant

Steps to Follow

- Ensure the machine is turned off and cool.

- Lift the unit using jack stands or ramps for easy access.

- Locate the fastening mechanisms securing the blades.

- Use the wrench to remove the bolts or nuts carefully.

- Take off the old blades and inspect the spindle for wear or damage.

- Position the new blades, ensuring they align properly with the spindle.

- Secure the blades in place with the fasteners, tightening them to the manufacturer’s specifications.

- Apply grease to moving parts as needed.

- Lower the unit and perform a test run to check the new blades.

Following these steps will help maintain the effectiveness of your equipment, ensuring a clean and efficient operation each time you use it.

Fuel System Troubleshooting Tips

Ensuring optimal performance of your machinery often hinges on the efficiency of its fuel system. Problems can arise due to various factors, and recognizing these issues early can save time and resources. This guide offers practical advice for diagnosing and resolving common fuel-related challenges.

Common Symptoms

Users may encounter several indicators that suggest fuel system malfunctions. These include inconsistent engine performance, difficulty starting, or unusual noises during operation. Identifying these signs early is crucial for effective troubleshooting.

Troubleshooting Steps

Begin by inspecting the fuel supply. Ensure there are no blockages in the lines, and check for any leaks that could affect performance. Examine the fuel filter as well; a clogged filter can restrict flow, leading to issues. If the fuel is old or contaminated, consider replacing it with fresh fuel. Additionally, evaluate the fuel pump to confirm it’s operating correctly, as a failing pump can drastically impact engine function.

Electrical System Overview

The electrical framework in outdoor machinery plays a crucial role in its overall functionality and performance. Understanding its components and how they work together is essential for troubleshooting and maintenance.

This system primarily consists of the following key elements:

- Battery: Provides the necessary power to start the engine and operates various electrical components.

- Starter Motor: Engages the engine and initiates its operation when power is supplied from the battery.

- Alternator: Recharges the battery while the engine runs, ensuring a consistent power supply.

- Wiring Harness: Connects all electrical components, facilitating communication and power distribution.

- Fuses and Relays: Protect the electrical system from overloads and control the flow of electricity to different parts.

Each component must function optimally to ensure smooth operation. Regular inspections and maintenance can prevent electrical failures and extend the lifespan of the machinery.

Transmissions: Maintenance and Repair

Proper upkeep of the transmission system is essential for ensuring optimal performance and longevity of any machine. This critical component is responsible for power transfer from the engine to the wheels, affecting speed and maneuverability. Regular maintenance and timely attention to potential issues can prevent costly failures and enhance the overall efficiency of the equipment.

Key maintenance practices include:

- Regular fluid checks and changes

- Inspection of belts and pulleys for wear

- Monitoring for leaks or unusual noises

When addressing problems, consider the following steps:

- Identify symptoms: Slipping gears or unusual sounds can indicate underlying issues.

- Consult the guidelines for specific adjustments and repairs.

- Use quality replacement parts to maintain performance standards.

By following these maintenance and troubleshooting tips, operators can ensure a smooth operation and extend the life of the transmission system.

Winterizing Your Lawn Tractor

Preparing your outdoor equipment for the colder months is essential to ensure its longevity and optimal performance. Proper maintenance during this transitional period can help prevent potential damage caused by freezing temperatures, snow, and ice.

Steps for Effective Preparation

- Clean Thoroughly: Remove all debris, grass clippings, and dirt from the exterior and undercarriage.

- Drain Fuel: If the equipment will be unused for an extended period, consider draining the fuel tank to avoid stale fuel issues.

- Change Oil: Replace the old oil with fresh oil to ensure that the engine components are well-lubricated.

- Inspect Battery: Clean the battery terminals and check the charge. If necessary, store the battery in a warmer location.

- Sharpen Blades: Ensure that cutting blades are sharp and in good condition for when they are needed again.

- Store Properly: Find a dry, sheltered location for storage to protect the equipment from harsh weather conditions.

Additional Tips

- Cover the equipment with a breathable tarp to prevent moisture buildup.

- Check tire pressure and inflate if necessary to avoid flat spots.

- Review the owner’s guidelines for any specific winterizing recommendations.

Where to Find Replacement Parts

Locating suitable components for your machinery can be a straightforward process if you know where to look. Whether you need a specific item or are exploring options for upgrades, several avenues exist to acquire high-quality parts.

Official Dealers

One of the most reliable sources is authorized dealers. They provide genuine components that ensure compatibility and performance. Visiting a local dealer not only offers access to original parts but also expert advice on installation and maintenance.

Online Retailers

Many online platforms specialize in selling spare parts. Websites dedicated to equipment supply often have extensive catalogs that allow for easy comparisons. Always check customer reviews and return policies to ensure a satisfactory purchase experience. Additionally, consider joining forums or communities where enthusiasts share their insights on the best online sources.