When it comes to ensuring optimal performance and longevity of agricultural machinery, having access to detailed instructions is crucial. This resource is designed to provide essential insights into the upkeep and troubleshooting of a specific model, enabling users to navigate common challenges effectively. Understanding the intricacies of these machines empowers operators to maximize efficiency and minimize downtime.

Maintenance plays a vital role in preserving the functionality and reliability of your machinery. By following a systematic approach, operators can address issues before they escalate, ensuring smooth operation during crucial farming activities. This guide outlines key procedures and techniques that every user should familiarize themselves with to maintain their equipment in peak condition.

In addition to regular upkeep, knowledge of potential issues and their solutions can significantly enhance productivity. This resource covers a variety of topics, from basic troubleshooting to more advanced interventions, providing a well-rounded understanding that supports informed decision-making. Whether you’re a seasoned professional or a newcomer to agricultural operations, this guide aims to equip you with the tools necessary for effective machine management.

Overview of John Deere 4200

This section provides an insightful look into a compact yet powerful agricultural machine designed for various tasks in farming and landscaping. Its design combines efficiency with versatility, making it a reliable choice for both professionals and enthusiasts.

Key Features

- Compact size suitable for tight spaces

- Robust engine providing excellent power

- Advanced hydraulic systems for optimal performance

- Multiple attachment options enhancing functionality

Applications

- Landscaping and lawn maintenance

- Soil tillage and preparation

- Snow removal and road maintenance

- General utility work on farms

Common Issues with John Deere 4200

Every machinery model comes with its own set of challenges that operators may encounter over time. Understanding these common problems can significantly aid in maintaining optimal performance and extending the lifespan of the equipment. Below are some frequent complications that users of this particular model might face.

- Engine Performance Issues:

- Difficulty starting

- Unusual noises during operation

- Overheating concerns

- Hydraulic System Failures:

- Leaking hydraulic fluid

- Poor lifting capabilities

- Erratic or slow response times

- Electrical Problems:

- Battery drainage

- Faulty wiring connections

- Malfunctioning lights or indicators

- Transmission Concerns:

- Difficulty shifting gears

- Unresponsive clutch

- Strange vibrations during operation

By staying informed about these issues, operators can proactively address them, ensuring that their equipment remains reliable and efficient in the long run.

Essential Tools for Repair

Having the right equipment is crucial for any maintenance task, ensuring efficiency and effectiveness. Whether addressing minor adjustments or significant issues, a well-equipped toolkit can make all the difference. This section outlines the key instruments that every technician should consider having on hand to facilitate successful interventions.

Basic Hand Tools

Essential hand tools include wrenches, screwdrivers, and pliers. These items are fundamental for loosening or tightening components and performing various adjustments. A good set of sockets and ratchets is also vital for accessing hard-to-reach fasteners. Quality hand tools not only save time but also prevent damage to parts, promoting a smooth workflow.

Diagnostic Equipment

In addition to hand tools, diagnostic devices play a critical role in troubleshooting. Multimeters, pressure gauges, and scanners help identify issues accurately. Utilizing these tools can significantly reduce the time spent on diagnostics, enabling quicker resolutions. Investing in reliable diagnostic equipment is essential for maintaining optimal performance.

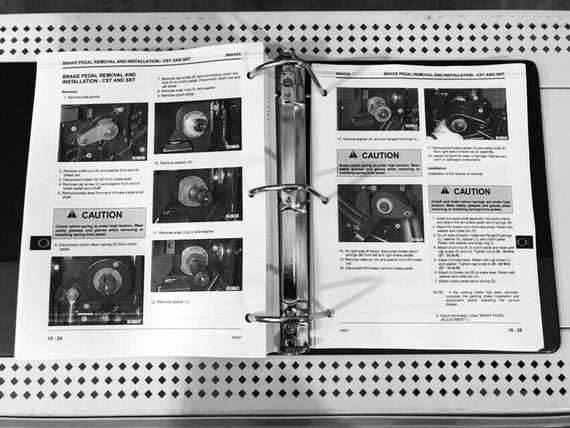

Step-by-Step Maintenance Guide

Proper upkeep of your equipment is crucial for ensuring its longevity and optimal performance. This section offers a detailed approach to routine care, helping you to maintain efficiency and prevent potential issues. Following a structured plan can make maintenance tasks more manageable and effective.

1. Daily Inspection: Before operating your machine, conduct a thorough visual check. Look for any signs of wear, leaks, or loose components. Addressing minor issues early can prevent larger problems down the line.

2. Fluid Levels: Regularly monitor and replenish fluid levels, including oil, coolant, and hydraulic fluids. Proper lubrication is essential for smooth operation and can reduce the risk of damage.

3. Filter Maintenance: Clean or replace air and fuel filters according to the manufacturer’s guidelines. Clogged filters can hinder performance and efficiency.

4. Battery Care: Inspect the battery terminals for corrosion and ensure connections are tight. Clean terminals as needed to maintain a reliable power source.

5. Tire Check: Examine tire pressure and tread wear. Properly inflated tires improve handling and fuel efficiency, while worn tires can pose safety risks.

6. Cleaning: Regularly clean the exterior and undercarriage to remove debris and dirt. This not only enhances appearance but also helps prevent rust and corrosion.

7. Scheduled Service: Adhere to the recommended service intervals for deeper maintenance tasks such as oil changes, greasing, and component replacements. Following a set schedule can prolong the life of your equipment.

8. Record Keeping: Maintain a log of all maintenance activities performed. This can help track when services are due and provide a history of the equipment’s care.

By following these guidelines, you can ensure that your machinery remains in peak condition, ready to tackle any task that comes its way.

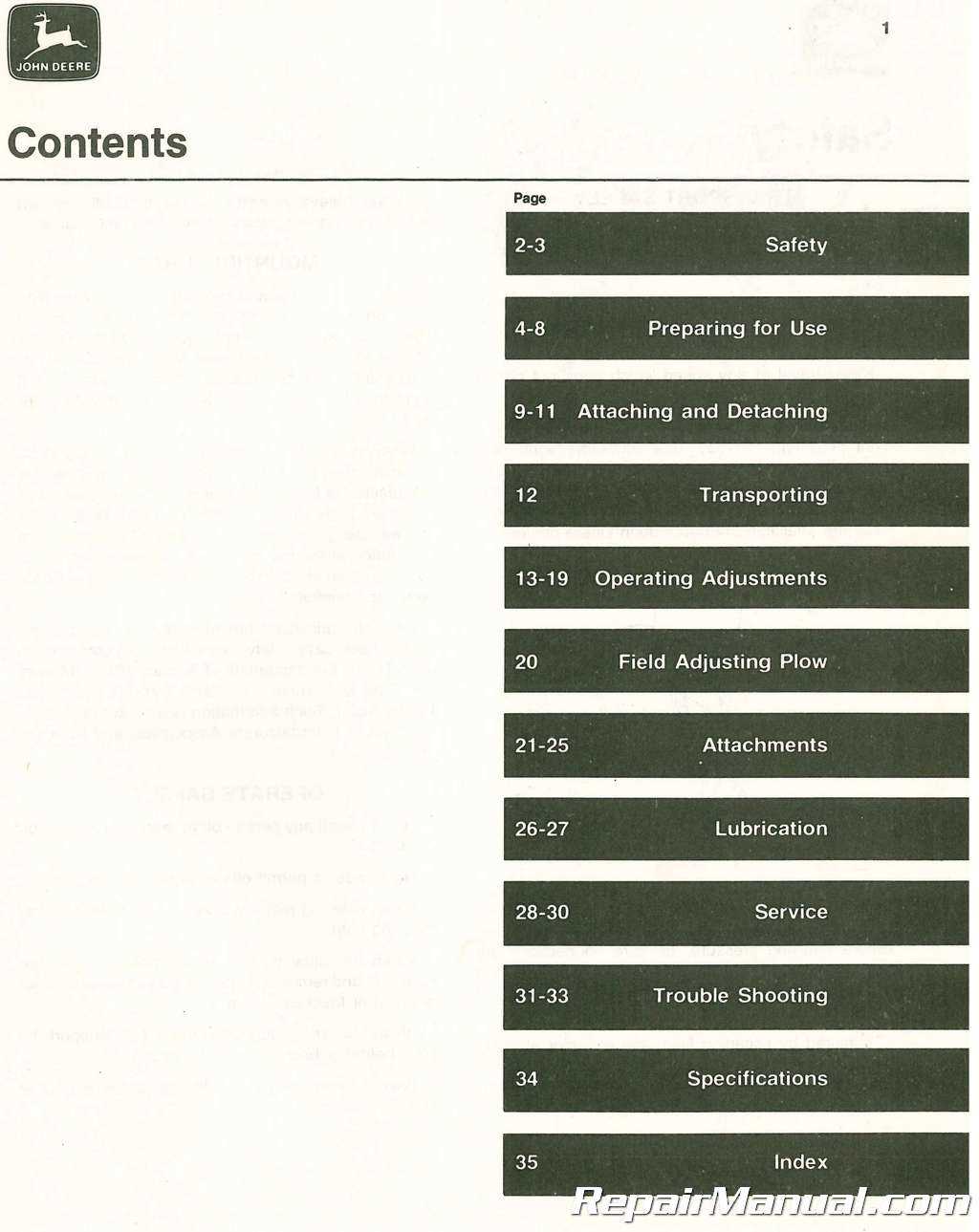

Understanding the Operator’s Manual

An operator’s guide serves as an essential resource for anyone who interacts with heavy machinery. This document is designed to provide critical information about the equipment’s features, functions, and maintenance requirements, ensuring safe and efficient operation.

Key Components of the Guide

Familiarizing yourself with the various sections of the guide can enhance your understanding and usage of the machinery. Here are some key components:

- Safety Information: Important precautions to prevent accidents and injuries.

- Operating Instructions: Step-by-step guidelines on how to use the equipment effectively.

- Maintenance Schedules: Recommended intervals for routine inspections and servicing.

- Troubleshooting Tips: Solutions for common issues that may arise during operation.

Benefits of Using the Guide

Utilizing the operator’s manual offers several advantages:

- Improves safety by ensuring users are aware of potential hazards.

- Enhances equipment longevity through proper maintenance practices.

- Increases efficiency by providing insights into optimal operating procedures.

- Facilitates troubleshooting, reducing downtime during operations.

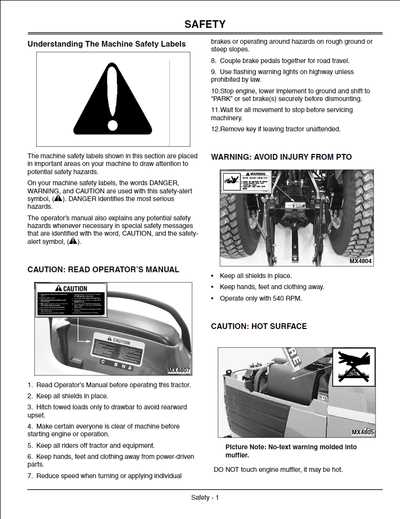

Safety Precautions During Repairs

When engaging in maintenance tasks, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions ensure a secure environment while allowing for efficient troubleshooting and fixing. Awareness of potential hazards and adherence to guidelines can significantly reduce risks associated with mechanical work.

Always wear appropriate personal protective equipment (PPE). This includes safety glasses, gloves, and sturdy footwear to shield yourself from debris and sharp objects. Proper attire can greatly mitigate the chance of injury during the process.

Ensure the work area is well-ventilated and organized. A clutter-free space allows for better focus and minimizes the risk of tripping or encountering hazards. Adequate airflow is essential, especially when using chemicals or tools that emit fumes.

Before beginning any task, disconnect power sources and ensure equipment is stable. This step is vital to avoid unintentional starts that could lead to serious accidents. Always follow the manufacturer’s guidelines regarding power disconnection and stabilization methods.

Familiarize yourself with the tools and components you will be working with. Understanding the operation and function of each element can help prevent misuse and enhance efficiency. Always use the correct tools for specific tasks to avoid damaging equipment or causing injury.

Finally, do not hesitate to seek assistance when uncertain about any step. Having a knowledgeable partner can provide support and additional safety during more complex tasks. Remember, taking the time to ensure safety is an investment in a successful and secure maintenance experience.

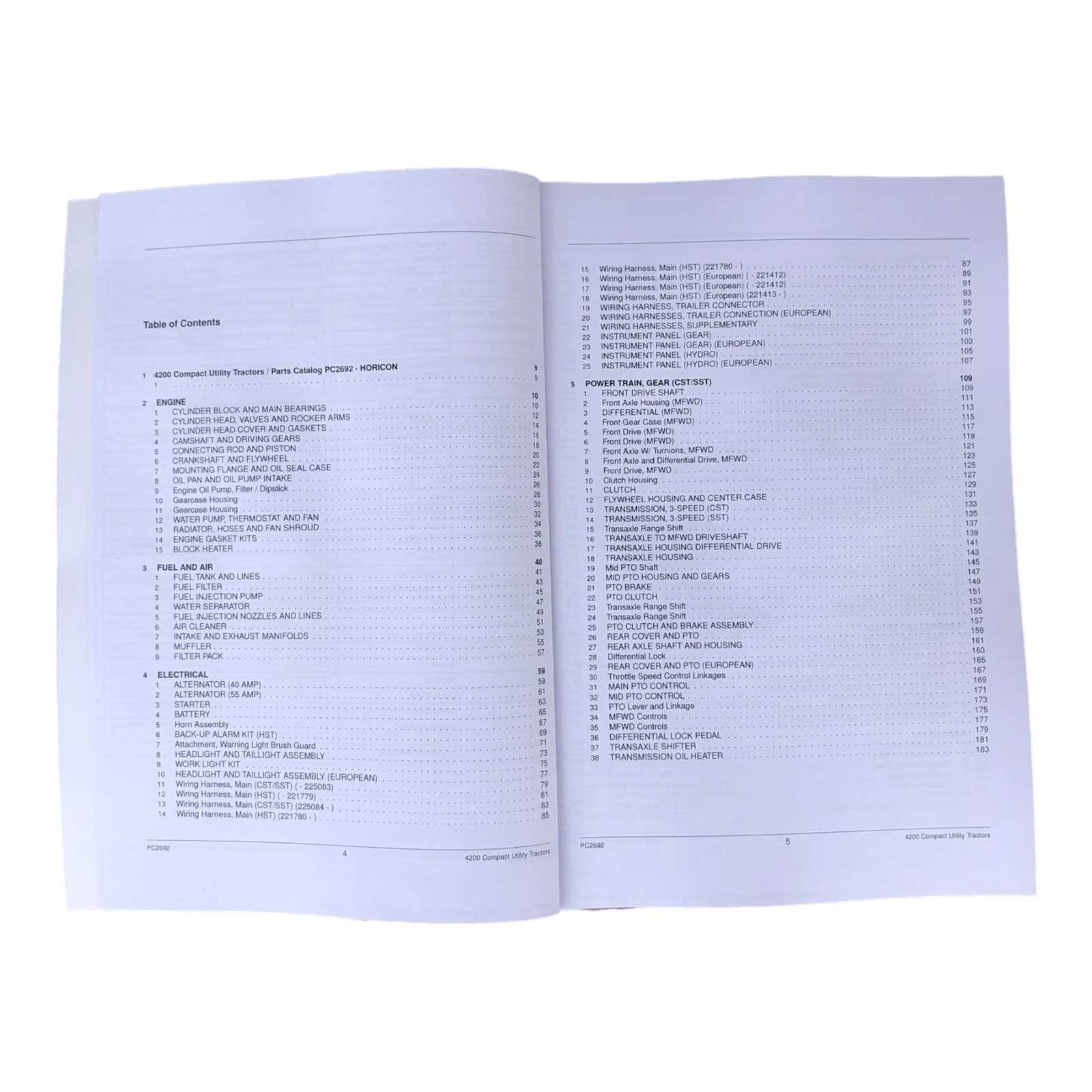

Parts and Components Identification

This section aims to assist users in recognizing and understanding the various parts and components of agricultural machinery. Proper identification is crucial for effective maintenance and troubleshooting, ensuring optimal performance and longevity of the equipment.

Key Components Overview

Below is a list of essential elements commonly found in this type of machinery:

- Engine

- Transmission

- Hydraulic System

- Electrical System

- Chassis

- Cab Assembly

- Attachment Points

Identifying Specific Parts

Familiarity with specific parts is beneficial for efficient operation. Here are some examples:

- Fuel System: Includes the fuel tank, filters, and injectors.

- Cooling System: Comprises the radiator, coolant reservoir, and hoses.

- Drive Train: Consists of gears, shafts, and differential components.

- Braking System: Features brake pads, discs, and hydraulic lines.

Understanding these components will facilitate better interaction with the machinery, leading to enhanced functionality and performance in the field.

How to Diagnose Mechanical Problems

Identifying mechanical issues requires a systematic approach to pinpoint underlying causes. By carefully observing symptoms and conducting thorough checks, one can effectively narrow down potential faults. Understanding the relationship between various components is crucial for accurate diagnosis.

Begin with Observation: Look for unusual sounds, vibrations, or performance irregularities. Take note of any warning indicators that may suggest malfunctioning parts.

Perform Basic Checks: Inspect fluid levels, filters, and connections. Regular maintenance can prevent larger issues and provide insight into existing problems.

Utilize Diagnostic Tools: Employ gauges and diagnostic equipment to gather data. These tools can help reveal inconsistencies and aid in locating the source of trouble.

Consult Documentation: Reference technical guidelines for specifications and troubleshooting steps. This resource can enhance your understanding and provide clarity in complex situations.

Seek Expert Assistance: If challenges persist, consider consulting a professional. Their expertise can offer invaluable insights and expedite the resolution process.

Electrical System Troubleshooting Tips

Identifying issues within the electrical framework of machinery can be a daunting task. However, with a systematic approach, operators can efficiently diagnose and rectify problems. This section provides essential strategies to tackle common electrical challenges, ensuring optimal performance of your equipment.

Start by checking for visible signs of wear and tear, such as frayed wires or corroded connectors. Utilize a multimeter to assess voltage levels at critical points, ensuring they meet specified requirements. Additionally, refer to the circuit diagrams to trace connections and pinpoint potential faults.

| Common Issues | Possible Causes | Troubleshooting Steps |

|---|---|---|

| Unresponsive components | Blown fuse, damaged wiring | Inspect fuses and replace if necessary; check wiring integrity |

| Fluctuating voltage | Faulty alternator, loose connections | Test alternator output; tighten any loose connections |

| Overheating | Excessive load, poor ventilation | Reduce load; ensure airflow is unobstructed |

By following these guidelines and being methodical in your approach, you can effectively address and resolve electrical issues, leading to improved functionality and longevity of your machinery.

Resources for Additional Support

When facing challenges with your equipment, having access to reliable resources can make all the difference. Various options are available to help you troubleshoot issues and enhance your understanding of machinery operation and maintenance.

- Online Forums: Engaging with community-driven platforms allows you to connect with fellow users who share their experiences and solutions. Look for dedicated groups or discussion boards focused on your specific model.

- Manufacturer’s Website: Official websites often provide downloadable documents, troubleshooting guides, and FAQs. These resources are tailored to address common concerns and offer insights into optimal usage.

- YouTube Tutorials: Video content can be particularly helpful, showcasing step-by-step procedures for various tasks. Search for channels that specialize in machinery maintenance to find relevant demonstrations.

- Local Repair Shops: Establishing a relationship with nearby service centers can provide hands-on assistance. Many technicians are willing to share tips and techniques based on their experiences.

- Technical Books: Reference literature can provide in-depth knowledge and methodologies. Check your local library or online retailers for comprehensive guides on similar equipment.

By utilizing these resources, you can enhance your understanding and efficiency when managing your machinery, ensuring a smoother operational experience.