Maintaining heavy machinery is essential for ensuring optimal performance and longevity. This section aims to provide comprehensive insights into the upkeep and troubleshooting processes for a specific model, enhancing the understanding of its components and functions.

Through careful examination of operational guidelines, users can effectively manage routine checks and resolve common issues. This knowledge not only saves time and resources but also empowers operators to maximize efficiency.

Understanding the intricacies of machinery operations is key to achieving the best results. By delving into detailed instructions, one can navigate the complexities of maintenance and make informed decisions.

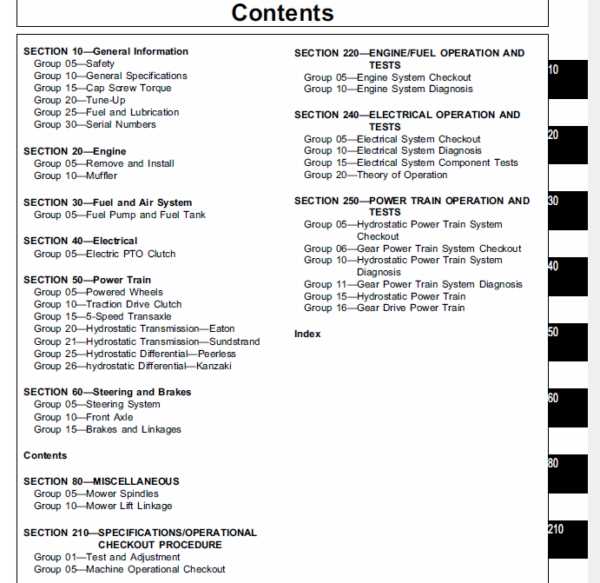

Understanding the John Deere 160

This section aims to provide a comprehensive overview of a popular model in the agricultural machinery sector. Focusing on its features, functionality, and maintenance, it serves as a valuable resource for users seeking to maximize performance and longevity.

The equipment is designed with robust engineering, ensuring reliability during various tasks. Its powertrain components work in harmony to deliver efficiency, making it suitable for both small and large-scale operations. Understanding the intricacies of this model allows operators to leverage its capabilities fully.

Regular upkeep and knowledge of essential functions are crucial for optimal operation. Familiarity with the various systems and parts enhances the user experience and minimizes downtime. This section will guide you through the core aspects necessary for effective management of this versatile machine.

Common Issues with the John Deere 160

When operating any type of agricultural machinery, encountering problems is a typical experience. Understanding these frequent challenges can help operators maintain efficiency and prolong the lifespan of their equipment. This section highlights some of the most prevalent issues faced by users of this particular model.

Mechanical Problems

Mechanical failures often stem from regular wear and tear or inadequate maintenance. Common concerns include issues with the engine, transmission, and other vital components. Below is a summary of typical mechanical problems:

| Issue | Symptoms | Possible Causes |

|---|---|---|

| Engine Overheating | Unusual temperature readings, smoke | Coolant leaks, clogged radiators |

| Transmission Slipping | Delayed engagement, loss of power | Low fluid levels, worn components |

| Poor Steering Response | Difficult maneuvering, vibrations | Fluid leaks, damaged steering gears |

Electrical Issues

Electrical problems can significantly impact performance and operational safety. These challenges may include faulty wiring, dead batteries, and malfunctioning lights. Operators should be aware of these common electrical failures:

| Issue | Symptoms | Possible Causes |

|---|---|---|

| Battery Drain | Inability to start, dim lights | Faulty alternator, parasitic draw |

| Malfunctioning Lights | Flickering or non-functioning lights | Wiring issues, blown fuses |

| Starter Problems | Clicking noise, no engine turnover | Weak battery, defective starter |

Tools Needed for Repairs

When tackling maintenance tasks, having the right instruments is essential for achieving optimal results. A well-equipped toolkit not only enhances efficiency but also ensures safety and precision in every procedure. Below is a list of must-have tools that can facilitate various tasks.

Basic Hand Tools

- Wrenches (adjustable and socket types)

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and regular)

- Hammer

- Tape measure

Specialized Equipment

- Torque wrench

- Diagnostic scanner

- Oil filter wrench

- Multimeter

- Grease gun

Equipping yourself with these tools will prepare you for a variety of maintenance tasks, helping to prolong the lifespan of your machinery and ensure smooth operation.

Step-by-Step Repair Process

This section outlines a detailed approach for addressing mechanical issues with your equipment. By following a systematic procedure, you can effectively diagnose and resolve problems, ensuring optimal functionality and longevity.

-

Assessment:

- Identify symptoms of malfunction.

- Gather relevant tools and materials.

- Consult documentation for specific guidance.

-

Disassembly:

- Carefully remove components, noting their arrangement.

- Use appropriate tools to avoid damage.

- Store parts in a labeled container for easy reassembly.

-

Inspection:

- Examine each component for wear and tear.

- Look for signs of corrosion or other damage.

- Test electrical connections and functionality.

-

Repair:

- Replace worn or broken parts with new equivalents.

- Use lubricants and cleaners as necessary.

- Ensure all fastenings are secure and correctly fitted.

-

Reassembly:

- Carefully reinstall all components in the reverse order of disassembly.

- Double-check alignment and connections.

- Refer to notes made during disassembly for accuracy.

-

Testing:

- Run the equipment to ensure proper functionality.

- Monitor for any unusual noises or performance issues.

- Make adjustments as necessary based on observations.

By adhering to this structured method, you can enhance your ability to troubleshoot and maintain your machinery, leading to better performance and reduced downtime.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your machinery requires consistent care and attention. By following a set of best practices, you can enhance performance, reduce the likelihood of unexpected failures, and maintain optimal functionality over time.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Oil Change | Every 50 hours of operation | Use high-quality oil and replace the filter simultaneously. |

| Air Filter Inspection | Every 25 hours | Clean or replace to ensure proper airflow and engine performance. |

| Tire Pressure Check | Weekly | Maintain recommended pressure to ensure even wear and improve fuel efficiency. |

| Belts and Hoses Inspection | Monthly | Look for signs of wear or damage and replace as necessary. |

| Battery Maintenance | Every three months | Clean terminals and check charge levels; replace if necessary. |

Implementing these routine checks can significantly extend the life of your equipment, ensuring it remains reliable for years to come. Regular maintenance not only prevents costly repairs but also enhances overall efficiency, making it a worthwhile investment for any operator.

How to Access the Repair Manual

Locating the necessary documentation for equipment maintenance is essential for effective troubleshooting and repair. This guide outlines the steps to find and utilize the appropriate resources to aid in the upkeep of your machinery.

Online Resources

- Visit the official website of the manufacturer.

- Navigate to the support or resources section.

- Utilize the search feature to enter the model number.

- Download the relevant documents in PDF format for convenience.

Physical Copies

- Check local equipment dealerships for printed versions.

- Inquire at repair shops; they may have spare copies.

- Consider contacting the manufacturer for additional options.

By following these steps, you can easily access the documentation needed for your equipment’s upkeep and ensure optimal performance.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is essential to prevent accidents and injuries. By adhering to specific guidelines, individuals can create a secure working environment and protect themselves and others.

- Wear Appropriate Personal Protective Equipment (PPE):

- Safety goggles to protect eyes from debris.

- Gloves to prevent cuts and abrasions.

- Steel-toed boots for foot protection.

- Ear protection when operating loud machinery.

- Maintain a Clean Workspace:

- Remove any unnecessary tools and materials.

- Keep pathways clear to avoid tripping hazards.

- Organize tools for easy access and safety.

- Understand the Equipment:

- Familiarize yourself with the machine’s features and controls.

- Consult available resources for guidance.

- Disconnect Power Sources:

- Always turn off and unplug equipment before starting any work.

- Ensure hydraulic systems are depressurized.

- Work with a Partner:

- Having a second person can enhance safety and efficiency.

- Ensure someone is present to assist in emergencies.

- Follow Proper Lifting Techniques:

- Bend at the knees, not the back, to lift heavy items.

- Use equipment like hoists or dollies for heavy loads.

By implementing these safety measures, individuals can significantly reduce the risk of accidents during maintenance tasks. Prioritizing safety not only protects the worker but also ensures that equipment remains in optimal condition for continued use.

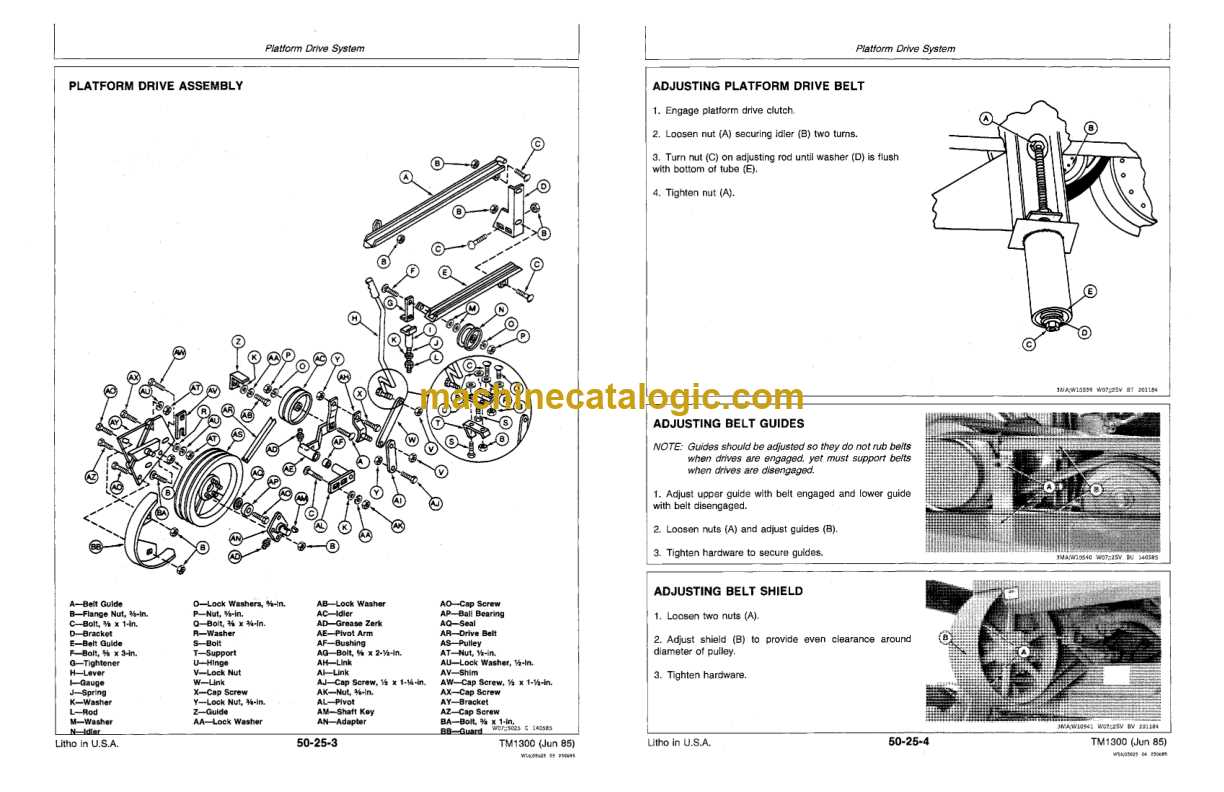

Replacing Key Components Effectively

Maintaining machinery involves the essential task of swapping out vital parts to ensure optimal performance and longevity. This process can significantly enhance efficiency and reduce the likelihood of breakdowns. Understanding how to approach these replacements with precision is crucial for successful maintenance.

When it comes to replacing components, it’s important to follow a structured methodology. Below is a table summarizing key steps and considerations for an effective replacement process:

| Step | Description | Tools Required |

|---|---|---|

| 1 | Identify the component that needs replacement | Inspection tools |

| 2 | Gather necessary tools and replacement parts | Wrenches, screwdrivers, new parts |

| 3 | Safely disconnect power source | Safety gloves, lockout tag |

| 4 | Carefully remove the faulty part | Appropriate tools for removal |

| 5 | Install the new component, ensuring a secure fit | Same tools used for removal |

| 6 | Reconnect power and conduct a functionality test | Test equipment |

Adhering to these steps not only streamlines the process but also minimizes potential risks associated with component replacement. Regular maintenance checks and timely part swaps can greatly enhance the reliability of your machinery.

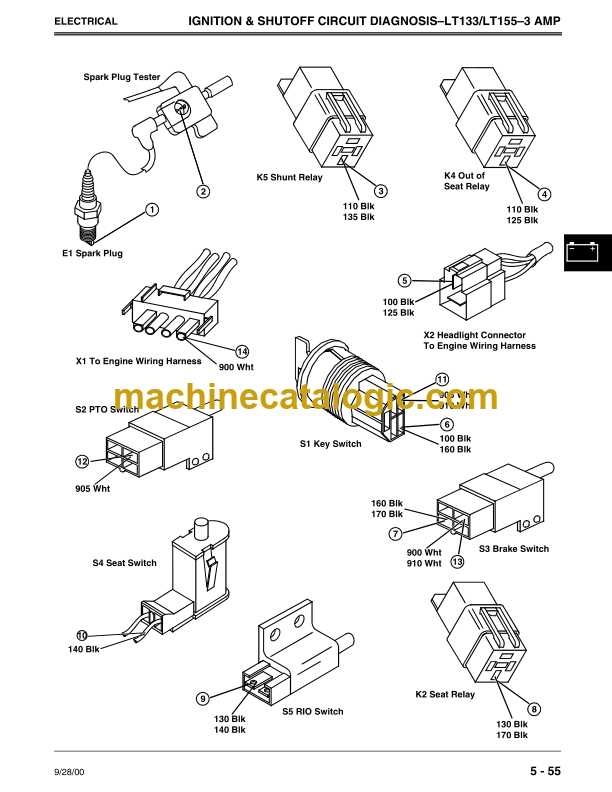

Troubleshooting Electrical Problems

Identifying and resolving electrical issues in machinery can be a daunting task. A systematic approach is essential to ensure all potential faults are examined. Understanding common symptoms and using diagnostic techniques will facilitate efficient troubleshooting, helping restore functionality.

Start by checking the power supply and ensuring that all connections are secure. Visual inspections can reveal loose wires or corroded terminals. If the machinery fails to operate, the following table outlines common symptoms and suggested solutions:

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| No power | Disconnected battery or blown fuse | Inspect connections; replace fuse |

| Inconsistent operation | Faulty switch or damaged wiring | Test switch functionality; replace damaged wiring |

| Overheating | Short circuit or overloaded circuit | Examine for shorts; reduce load |

| Lights dim or flicker | Weak battery or loose connections | Charge or replace battery; tighten connections |

Always ensure safety protocols are followed during troubleshooting to prevent accidents. If issues persist, consulting a professional may be necessary for more complex problems.

Hydraulic System Maintenance Tips

Maintaining the hydraulic system is crucial for ensuring optimal performance and longevity of your machinery. Regular attention to this component can prevent costly breakdowns and enhance efficiency. Here are some essential tips to keep your hydraulic system in excellent condition.

1. Regular Fluid Checks: Consistently monitor the hydraulic fluid level and quality. Low fluid levels can lead to increased wear and potential system failure. Additionally, check for contamination, as dirt and moisture can severely impact performance.

2. Change Filters: Hydraulic filters play a vital role in trapping contaminants. Replace these filters according to the manufacturer’s recommendations to ensure clean fluid circulation and protect the system’s components.

3. Inspect Hoses and Connections: Regularly examine all hoses and fittings for signs of wear, leaks, or damage. Promptly address any issues to prevent fluid loss and maintain system integrity.

4. Monitor Pressure Levels: Use a pressure gauge to check the hydraulic pressure regularly. Abnormal readings can indicate issues within the system that require immediate attention.

5. Clean the Reservoir: Keep the hydraulic fluid reservoir clean. Sediments can accumulate over time, affecting fluid quality. Clean it as needed to maintain optimal performance.

6. Follow Manufacturer Guidelines: Always refer to the manufacturer’s specifications for maintenance intervals and procedures. Adhering to these recommendations ensures that your hydraulic system operates effectively and reliably.

By implementing these maintenance practices, you can extend the life of your hydraulic system and ensure your equipment operates at peak efficiency.

Finding Replacement Parts Easily

Locating the right components for your machinery can often be a daunting task. However, with the right approach and resources, you can simplify the process significantly. Understanding where to look and what options are available can save you time and ensure that your equipment remains in optimal condition.

Here are some effective strategies to help you find the necessary parts quickly:

| Method | Description |

|---|---|

| Online Retailers | Websites specializing in parts sales provide a vast selection and often include customer reviews. |

| Local Dealers | Authorized distributors can offer genuine components and expert advice on compatibility. |

| Manufacturer’s Website | The official site often has a parts catalog and direct ordering options. |

| Community Forums | Online communities can provide valuable recommendations and tips from other users. |

| Salvage Yards | These locations can be treasure troves for hard-to-find or discontinued parts at reduced prices. |

By utilizing these resources, you can streamline your search and quickly find the components you need to keep your equipment running smoothly.

When to Seek Professional Help

Understanding when to enlist the expertise of a qualified technician can be crucial in maintaining equipment effectively. While many tasks can be managed independently, there are specific situations that warrant professional intervention to ensure safety and optimal performance.

Recognizing the signs that indicate a need for professional assistance is essential. Complex issues, unusual noises, or performance declines can suggest underlying problems that require specialized knowledge and tools. Additionally, attempting to resolve intricate matters without adequate expertise may lead to further complications.

| Situation | Reason to Seek Help |

|---|---|

| Persistent mechanical failure | Could indicate a serious underlying issue that needs expert diagnosis. |

| Electrical system malfunctions | Risk of safety hazards and requires specialized training. |

| Complex repairs | Often necessitate specific tools and knowledge beyond general skills. |

| Frequent breakdowns | May suggest deeper issues that need thorough investigation. |

| Unfamiliar symptoms | Indicates that the problem may be beyond basic troubleshooting. |

Ultimately, prioritizing safety and the longevity of your equipment should guide your decision to seek professional help. By recognizing your limitations and understanding the complexities involved, you can ensure that your machinery remains in top condition.