This section aims to provide essential insights into the upkeep and troubleshooting of specialized gardening machinery. With a focus on ensuring optimal performance, users can learn effective strategies to address common issues and enhance the longevity of their equipment.

Understanding the intricacies of machinery is vital for anyone looking to maintain their tools efficiently. By familiarizing oneself with various components and functions, users can empower themselves to tackle challenges with confidence. This guide serves as a valuable resource for those eager to gain knowledge and practical skills.

Through detailed explanations and systematic approaches, this content seeks to simplify the maintenance process. By applying the techniques outlined here, individuals can ensure their equipment operates smoothly and remains in peak condition throughout the seasons.

Maintaining outdoor machinery is essential for ensuring longevity and optimal performance. Regular care can prevent significant issues and enhance efficiency. This section outlines fundamental practices that every owner should adopt to keep their equipment in top condition.

| Heading | Description |

|---|---|

| Routine Inspections | Conduct regular checks to identify any potential problems early on. |

| Cleaning the Equipment | Ensure that debris and grass clippings are removed after each use. |

| Checking Fluid Levels | Regularly monitor oil, fuel, and coolant levels for optimal performance. |

| Sharpening Blades | Keep cutting edges sharp for efficient and clean cuts. |

| Battery Maintenance | Check and maintain battery health to prevent starting issues. |

| Tire Pressure | Maintain proper tire inflation for improved traction and stability. |

| Belts and Cables | Inspect and replace worn belts and cables to ensure safety. |

| Seasonal Storage | Prepare equipment for off-season storage to prevent deterioration. |

| Owner’s Manual Review | Regularly consult the manual for specific maintenance recommendations. |

| Professional Servicing | Schedule periodic professional inspections for comprehensive care. |

Common Issues and Solutions

This section addresses frequent problems encountered with garden maintenance equipment, providing practical solutions for each. Understanding these common challenges can help users troubleshoot effectively and enhance the longevity of their machines.

Engine Starting Problems

If the engine fails to start, check the fuel level and ensure it is fresh. Additionally, inspect the battery connections for corrosion and tightness. Regular maintenance of spark plugs can also prevent ignition issues.

Uneven Cutting Performance

When the cutting is inconsistent, the blades may be dull or damaged. Sharpening or replacing them can improve performance. Ensure the deck is level, as an unbalanced deck can lead to uneven results.

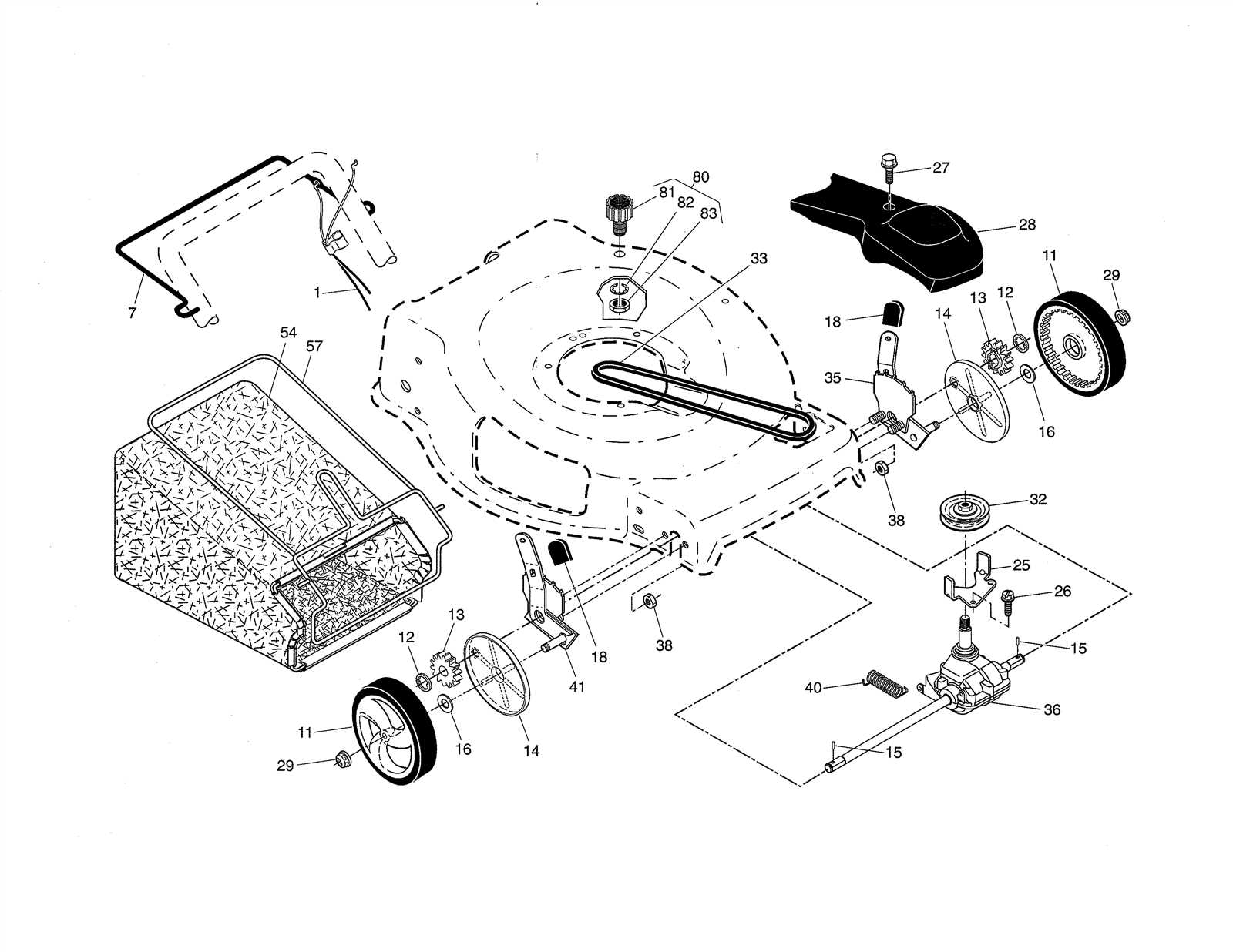

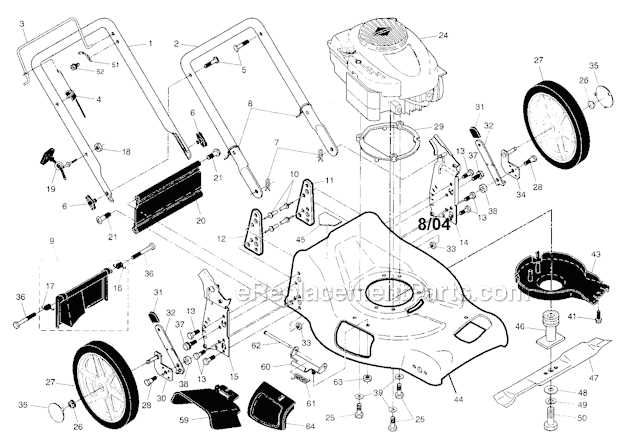

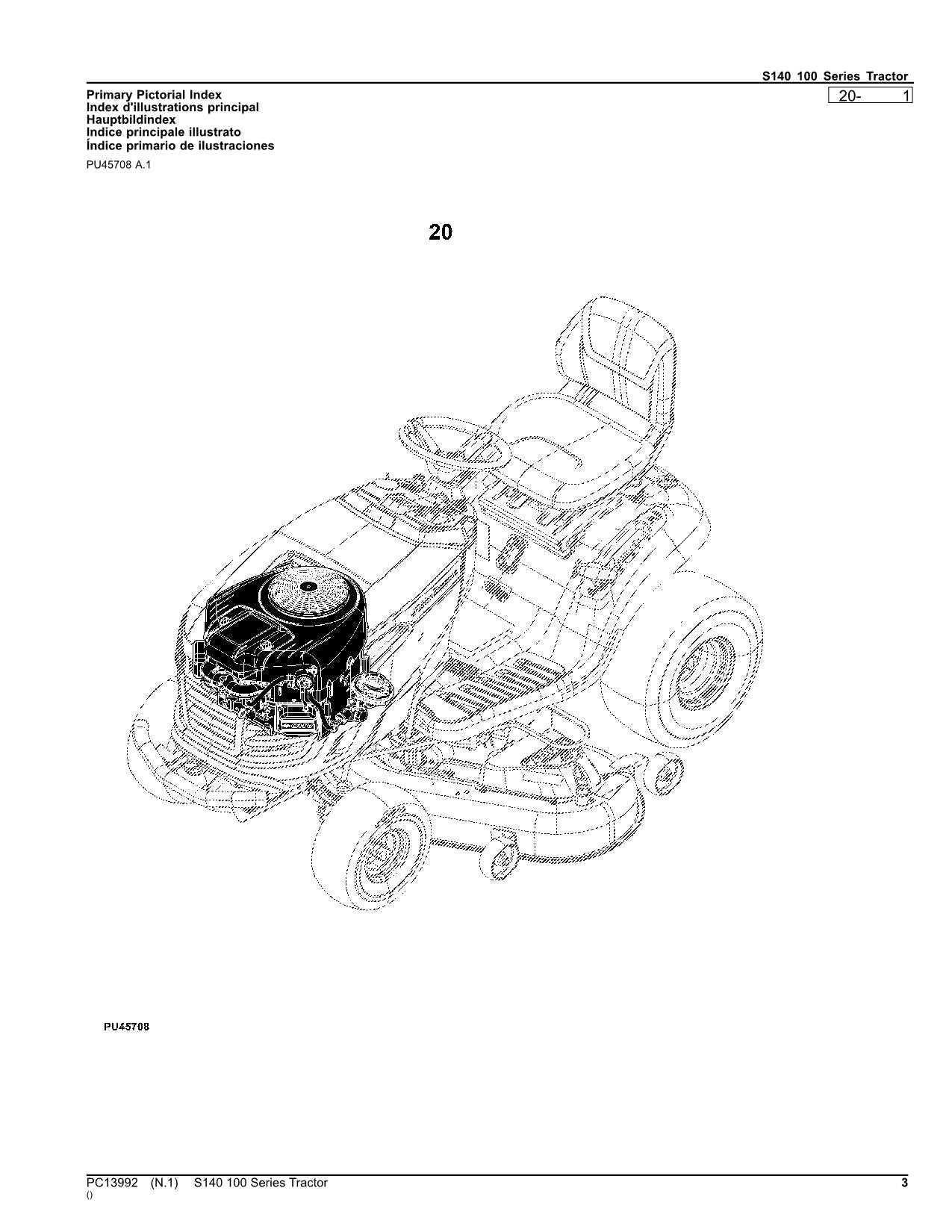

Parts Identification and Replacement

Understanding the various components of your equipment is crucial for effective maintenance and functionality. Properly identifying each part allows for timely replacements, ensuring smooth operation and longevity of the machine.

When examining the elements, it’s beneficial to familiarize yourself with the specific functions and locations of each component. Below is a table summarizing common parts, their descriptions, and indications for when they may need to be replaced.

| Part | Description | Replacement Indicators |

|---|---|---|

| Blade | Sharp metal attachment used for cutting. | Worn edges or signs of damage. |

| Battery | Power source for starting and operating. | Difficulty starting or electrical failures. |

| Fuel Filter | Removes impurities from the fuel. | Clogs causing performance issues. |

| Belt | Transfers power from the engine to other components. | Cracks or fraying visible on the surface. |

| Tires | Provide traction and stability. | Worn tread or noticeable air loss. |

Regular inspection of these components can prevent unexpected malfunctions and enhance the overall efficiency of your machine. If any parts show signs of wear, prompt action should be taken to replace them to maintain optimal performance.

Safety Precautions During Repairs

Ensuring a secure environment while performing maintenance tasks is essential for preventing accidents and injuries. Following proper guidelines helps safeguard both the individual and the equipment being worked on.

Before initiating any service, consider these crucial safety measures:

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Ensure the engine is turned off and completely cool to avoid burns or unexpected starts.

- Disconnect the battery to prevent electrical shocks or shorts during the process.

- Work in a well-ventilated area to minimize exposure to fumes and ensure proper airflow.

- Keep tools organized and within reach to avoid accidents caused by reaching or stretching.

Following these guidelines will promote a safer working atmosphere, allowing for efficient and effective service tasks.

Tools Needed for Effective Repairs

Having the right instruments at your disposal is crucial for ensuring successful maintenance and troubleshooting of your equipment. The following list outlines essential tools that can facilitate efficient and effective work.

- Wrenches: A variety of sizes will allow you to handle different fasteners easily.

- Screwdrivers: Both flathead and Phillips types are necessary for removing and securing components.

- Socket Set: These can provide better torque and access to hard-to-reach areas.

- Pliers: Useful for gripping, twisting, and cutting wires or small parts.

- Hammer: Helpful for gently tapping components into place or removing stuck parts.

- Diagnostic Tools: Such as multimeters, for troubleshooting electrical issues.

Investing in quality tools can greatly enhance your efficiency and ease during the maintenance process, leading to better outcomes and prolonged equipment lifespan.

Step-by-Step Repair Procedures

This section outlines a systematic approach to addressing common issues encountered with your outdoor equipment. Following these detailed instructions will help ensure that you can effectively diagnose and resolve problems, enhancing the longevity and performance of your machinery.

Initial Assessment

Begin by examining the unit for any visible signs of wear or damage. Pay close attention to essential components, ensuring that all parts are securely attached and functioning properly. Identifying issues early can prevent more significant complications down the line.

Component Replacement

If a specific part is found to be faulty, proceed to remove it carefully. Replace it with a compatible alternative, ensuring all connections are tight and secure. Following the manufacturer’s guidelines during this process is crucial for optimal performance and safety.

Understanding the Engine Components

The internal mechanisms of a power unit play a crucial role in its overall functionality. Each segment is designed to work in harmony, ensuring that the device operates efficiently and effectively. Familiarizing oneself with these elements is essential for optimal performance and maintenance.

The core elements of the power unit include the cylinder, piston, and crankshaft. The cylinder serves as the chamber where fuel combustion occurs, generating the necessary power. The piston moves within this chamber, converting the energy produced into mechanical motion. Meanwhile, the crankshaft translates this motion into rotational energy, driving the system forward.

Understanding these components not only aids in recognizing their individual functions but also highlights the importance of regular upkeep. Ensuring that each part is in proper working condition can significantly enhance the longevity and efficiency of the entire system.

Seasonal Maintenance Checklist

Regular upkeep of your equipment ensures optimal performance and longevity. Adhering to a seasonal checklist can help prevent issues and keep everything in prime condition throughout the year.

Here are essential tasks to consider during each season:

-

Spring:

- Inspect and clean air filters to ensure proper airflow.

- Check and sharpen cutting blades for efficient operation.

- Change the oil and replace the oil filter if applicable.

- Examine belts and cables for signs of wear or damage.

-

Summer:

- Monitor tire pressure and adjust as needed.

- Clean the undercarriage to prevent grass buildup.

- Check fuel levels and replace old fuel if necessary.

- Inspect safety features to ensure they are functioning correctly.

-

Autumn:

- Prepare for storage by cleaning and inspecting all components.

- Change the oil again to keep the engine in good condition.

- Store fuel in a safe manner to avoid degradation.

- Remove batteries and store them in a cool, dry place.

-

Winter:

- Cover the equipment to protect it from harsh weather.

- Perform a thorough inspection for any needed repairs.

- Ensure all fluids are at appropriate levels to prevent freezing.

- Review the checklist for any missed tasks from the previous seasons.

By following this seasonal checklist, you can ensure that your equipment remains in excellent working order and ready for use when needed.

Troubleshooting Electrical Problems

Identifying and resolving issues related to the electrical system is crucial for ensuring optimal performance of the equipment. Various factors may contribute to malfunctions, and understanding these can help in efficient diagnostics and solutions.

Common signs of electrical difficulties include failure to start, inconsistent operation, or unexpected shutdowns. A systematic approach can assist in pinpointing the exact cause of these problems.

| Issue | Possible Cause | Solution |

|---|---|---|

| No power | Disconnected battery or faulty wiring | Check connections and replace damaged wires |

| Engine won’t start | Defective ignition system | Inspect and replace ignition components as needed |

| Intermittent function | Loose connections or corrosion | Tighten connections and clean corroded terminals |

| Electrical overload | Excessive load on the circuit | Reduce load or upgrade circuit components |

Regular inspections and maintenance of the electrical components can help prevent these issues from occurring. Being proactive ensures a longer lifespan and reliable operation.

Regular Cleaning and Care Practices

Maintaining the functionality of outdoor equipment is essential for optimal performance and longevity. Implementing consistent cleaning and care routines ensures that machinery operates smoothly, reducing the likelihood of malfunctions and enhancing efficiency.

Importance of Routine Maintenance

Regular upkeep not only prolongs the life of your equipment but also guarantees a cleaner working environment. By addressing dirt and debris promptly, you can prevent buildup that may lead to mechanical issues. Make it a habit to inspect and clean your machine after each use.

Effective Cleaning Techniques

Utilize a soft brush or cloth to remove dust and grass clippings from the surface. For stubborn dirt, a gentle wash with water and mild soap can be effective. Ensure that all components, especially those exposed to the elements, are thoroughly dried to prevent rust and corrosion. Additionally, checking and clearing air filters will promote proper airflow, which is vital for performance.

Upgrading and Modifying Your Mower

Enhancing and customizing your equipment can significantly improve its performance and efficiency. Whether you are looking to boost power, increase durability, or tailor functionality to better suit your needs, various modifications can be implemented. These upgrades not only optimize operation but also provide a more enjoyable experience while using the equipment.

Performance Enhancements: One of the most common upgrades involves improving the engine’s output. This can be achieved through various means such as installing a more efficient air filter or tuning the carburetor. Additionally, considering fuel additives may lead to better combustion and increased horsepower.

Comfort and Usability: Enhancing user comfort is another vital aspect. Adding a more ergonomic seat or incorporating additional controls can make the experience more pleasant. Furthermore, implementing accessories such as cup holders or storage compartments can significantly improve usability.

Durability and Maintenance: To prolong the lifespan of your equipment, consider upgrading components that are subject to wear and tear. Replacing standard blades with high-performance alternatives or using heavy-duty tires can enhance durability. Regular maintenance and inspection after modifications are essential to ensure optimal performance.