When it comes to maintaining outdoor machinery, having access to a thorough resource can make all the difference. Understanding the intricacies of your equipment ensures optimal performance and longevity. This section provides a detailed overview of essential practices and techniques for effective upkeep.

In addition to routine checks, it’s crucial to recognize the signs of wear and tear. Familiarizing yourself with common issues can empower you to address them swiftly, preventing minor concerns from escalating into significant challenges. This guide aims to equip you with the knowledge needed to tackle these tasks with confidence.

Whether you’re an experienced operator or a novice, having a structured approach to machinery care can enhance your skills. By following the outlined steps, you’ll be well-prepared to ensure your equipment operates smoothly for years to come. Embrace the journey of learning and maintenance, and watch your machinery thrive.

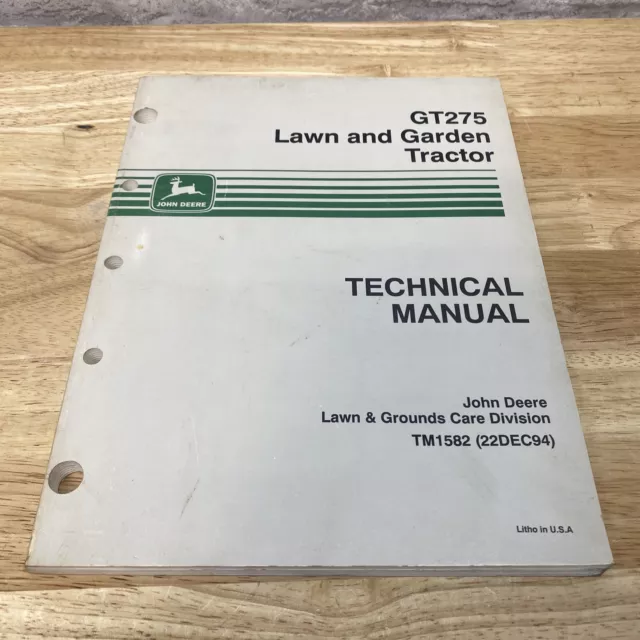

Overview of John Deere GT275

This section provides a comprehensive look at a versatile and efficient riding mower, renowned for its reliability and ease of use. It combines modern engineering with user-friendly features, making it a popular choice among homeowners and landscaping professionals alike. This machine is designed to deliver superior performance in various conditions, ensuring that lawn maintenance is both efficient and enjoyable.

Key Features

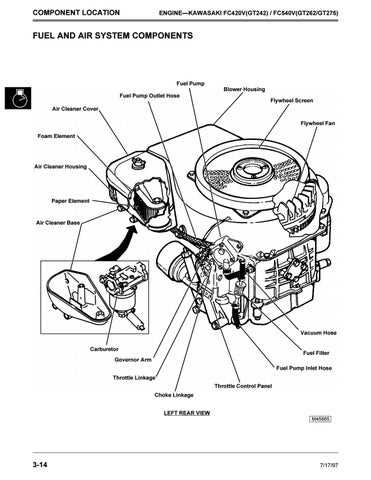

One of the standout characteristics of this riding mower is its robust engine, which offers ample power for tackling a variety of tasks. Additionally, the cutting deck is engineered for precision, allowing for an even and clean cut. Other notable features include ergonomic controls and adjustable seating, ensuring comfort during extended usage.

Specifications

| Feature | Description |

|---|---|

| Engine Type | Single-cylinder, air-cooled |

| Cutting Width | 42 inches |

| Transmission | Automatic |

| Fuel Capacity | 2 gallons |

| Weight | 500 lbs |

Overall, this riding mower exemplifies a blend of power and convenience, making it an excellent choice for maintaining any lawn with ease and efficiency.

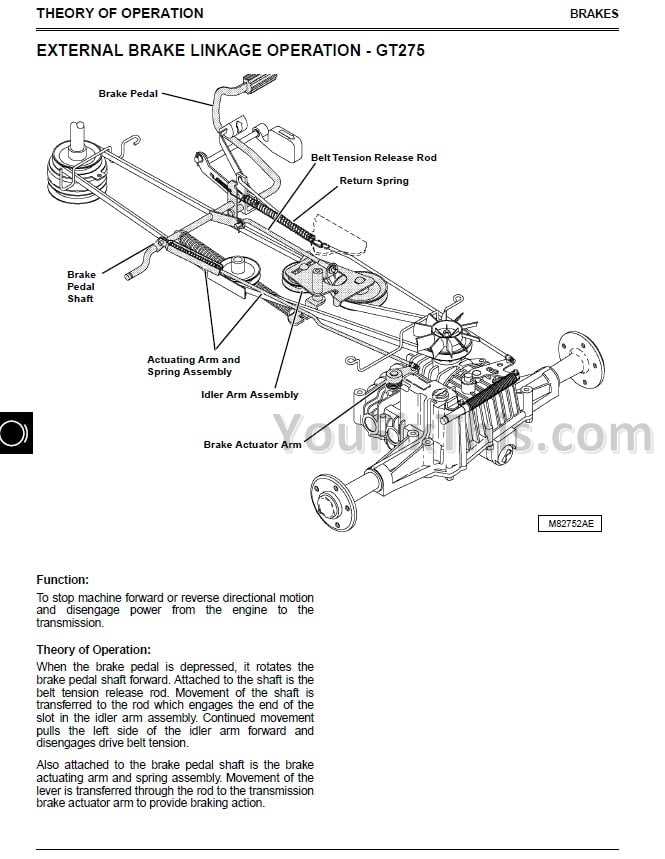

Common Issues with GT275 Tractors

Tractors of this model often experience a range of problems that can hinder their performance and efficiency. Understanding these common issues can help owners and operators address them proactively, ensuring smoother operation and longevity of the machinery.

Mechanical Failures

One frequent concern involves mechanical components that may wear out or fail over time. This can lead to decreased functionality and increased maintenance costs. Key areas to monitor include:

| Component | Issue | Symptoms |

|---|---|---|

| Engine | Overheating | Unusual noises, smoke |

| Transmission | Slipping gears | Difficulty shifting, loss of power |

| Hydraulic System | Fluid leaks | Reduced lifting capacity, visible drips |

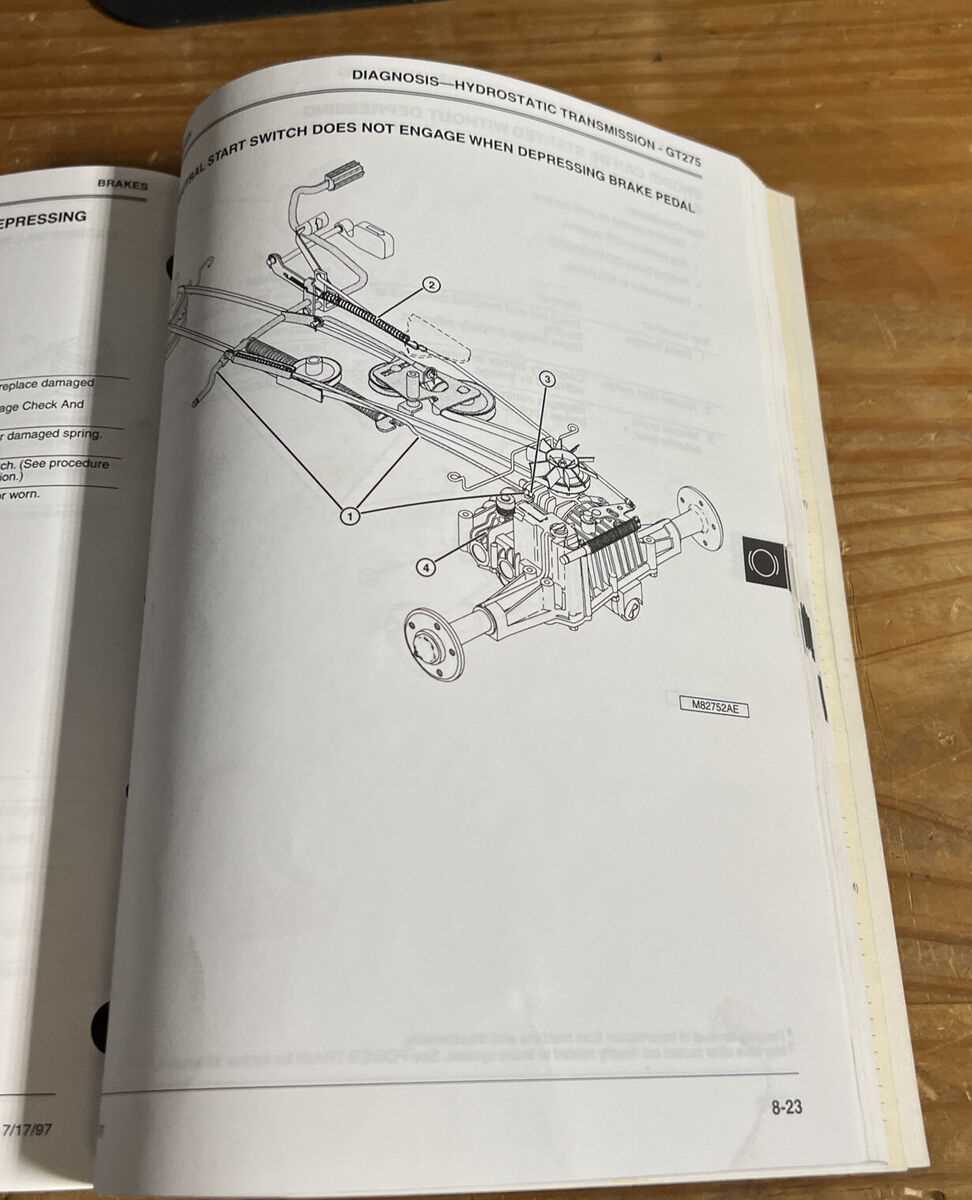

Electrical Issues

Another significant area of concern involves the electrical system, which can lead to starting problems and equipment malfunctions. Regular inspection of wiring and connections is essential to prevent these issues from escalating.

Essential Maintenance Tips for Owners

Proper upkeep is vital for ensuring the longevity and efficiency of your equipment. Regular attention to maintenance tasks not only enhances performance but also prevents costly repairs down the line. By adhering to a structured maintenance routine, you can enjoy smooth operation and reliability throughout the years.

Routine Checks

Conducting regular inspections is a key aspect of effective maintenance. This involves examining various components to identify potential issues before they escalate. Here are some essential areas to focus on:

| Component | Inspection Frequency | Notes |

|---|---|---|

| Oil Levels | Every 10 hours of use | Change if low or dirty |

| Filters | Every 50 hours of use | Replace to ensure clean operation |

| Tires | Weekly | Check pressure and tread wear |

| Batteries | Monthly | Clean terminals and check charge |

Seasonal Maintenance

Seasonal tasks are also crucial for optimal performance. Different weather conditions can affect your equipment in various ways. Here are some seasonal maintenance tips:

- Before winter, inspect the antifreeze levels and check for any leaks.

- In spring, thoroughly clean and lubricate moving parts to prevent rust.

- Summer checks should include cooling system inspections to avoid overheating.

By staying proactive with these maintenance strategies, you can ensure your machinery remains in top condition and ready for any task. Remember, a well-maintained machine is a reliable one.

Tools Needed for Effective Repairs

When it comes to maintaining and restoring machinery, having the right equipment is essential for achieving optimal results. Proper tools not only enhance efficiency but also ensure that tasks are performed safely and accurately. Understanding the types of instruments required can make the process smoother and more effective.

Below is a list of essential tools that can assist in the upkeep of machinery:

| Tool | Purpose |

|---|---|

| Wrench Set | Used for loosening and tightening bolts and nuts. |

| Screwdriver Set | Essential for fastening and unfastening screws of various types. |

| Pliers | Helpful for gripping, twisting, and cutting wire or other materials. |

| Socket Set | Ideal for accessing hard-to-reach bolts in tight spaces. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

| Multimeter | Used for measuring electrical voltage, current, and resistance. |

| Lubricants | Essential for reducing friction and preventing wear on moving parts. |

| Diagnostic Tools | Used to identify issues and monitor the performance of systems. |

Having these instruments readily available not only aids in tackling various maintenance tasks but also enhances the overall reliability and lifespan of the equipment.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to maintaining and troubleshooting your equipment. By following these detailed instructions, you can effectively address common issues, ensuring optimal performance and longevity. Each step is designed to be clear and actionable, allowing even those with limited experience to successfully navigate the process.

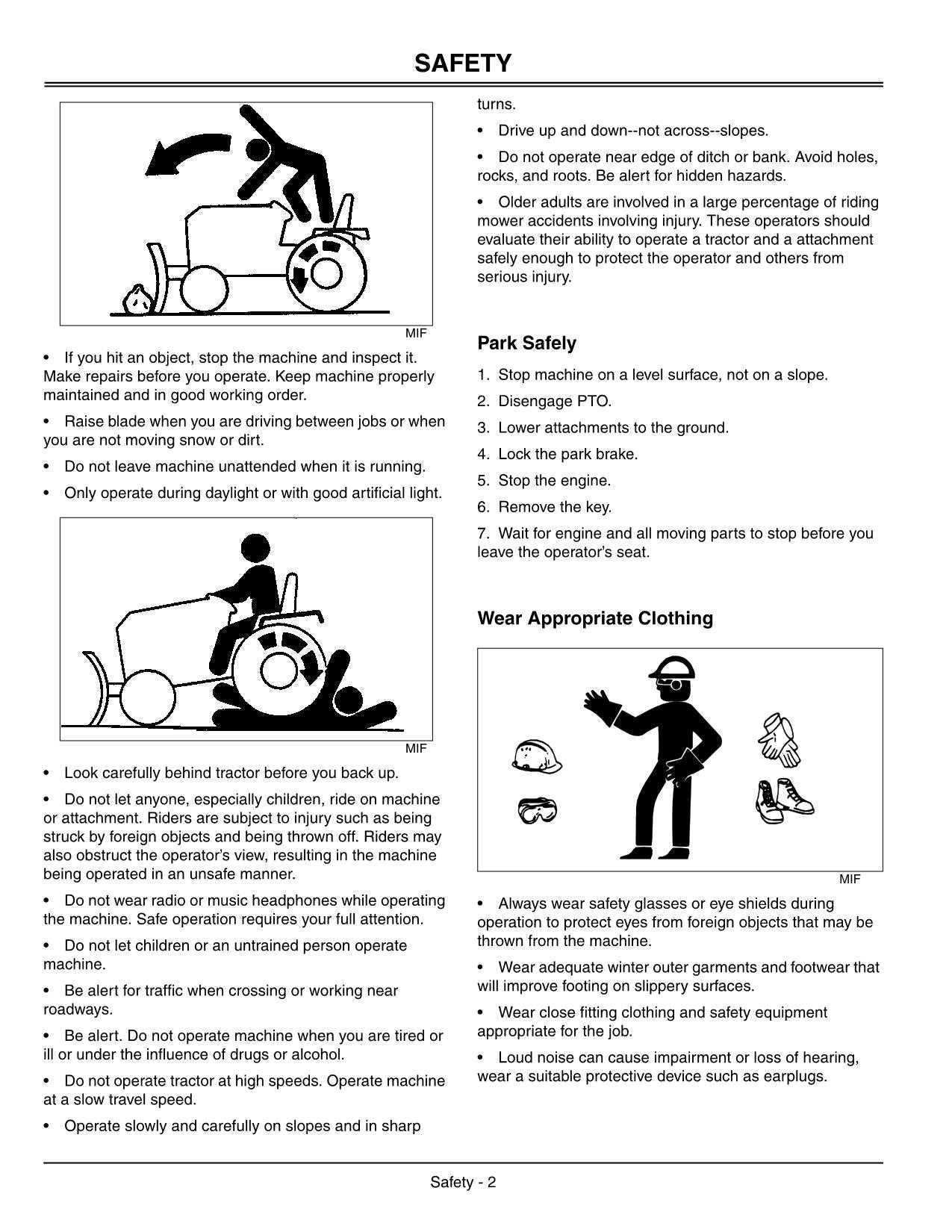

Preparation for Maintenance

Before starting any work, gather all necessary tools and components. Ensure you have a clean workspace to minimize the risk of losing parts. Familiarize yourself with the equipment’s layout and components to streamline the process. Always wear appropriate safety gear, including gloves and goggles, to protect yourself during maintenance activities.

Step-by-Step Instructions

Begin with the simplest tasks, such as checking fluid levels and inspecting belts for wear. Follow with more complex procedures, like replacing filters or adjusting settings. Always refer to specific guidelines for each task, ensuring that you complete all steps methodically. After each procedure, conduct a thorough test to confirm that the issues have been resolved and that the machinery is functioning correctly.

Understanding the Electrical System

The electrical framework of outdoor machinery plays a crucial role in its overall functionality and efficiency. This system is responsible for powering various components, enabling essential operations, and ensuring optimal performance. A thorough comprehension of its intricacies can significantly enhance maintenance practices and troubleshooting efforts.

The primary elements of this electrical system include the battery, wiring harness, ignition system, and various sensors. Each component works in harmony to deliver power where needed, facilitate communication between parts, and respond to operator commands. Understanding how these elements interact can help identify issues and improve the longevity of the equipment.

Regular inspection of connections, fuses, and components is vital to prevent malfunctions. Corrosion or loose connections can lead to power loss, affecting performance. Additionally, recognizing the signs of wear or damage allows for timely intervention, preventing further complications down the line.

Moreover, familiarity with the electrical schematics can assist in diagnosing problems more effectively. These diagrams illustrate how different parts are interconnected, providing valuable insights for repairs and upgrades. By investing time in understanding this system, operators can ensure their machinery remains reliable and efficient for years to come.

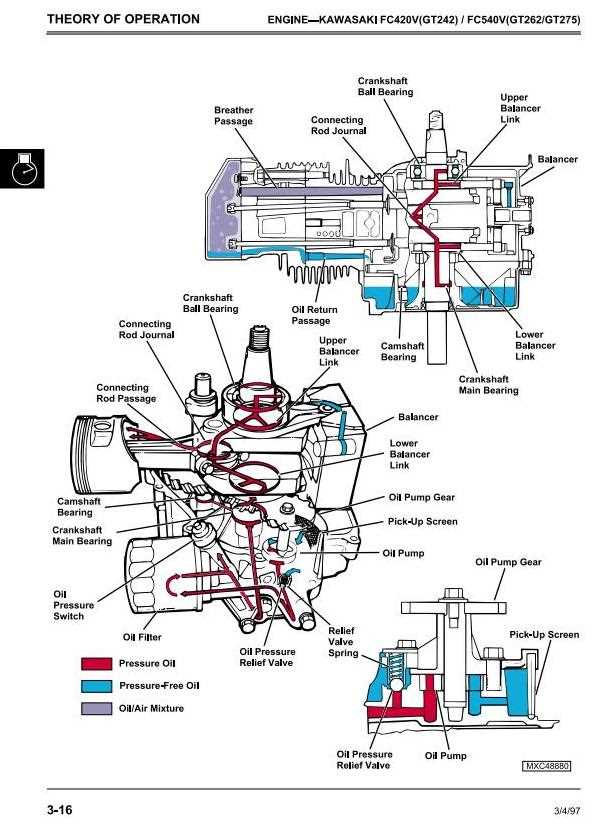

Engine Troubleshooting Techniques

Diagnosing issues within an engine can be a complex process, yet essential for maintaining optimal performance. Understanding common symptoms and employing systematic approaches can lead to effective solutions. This section explores practical methods for identifying and addressing engine-related problems.

Common Symptoms and Their Causes

| Symptom | Possible Cause |

|---|---|

| Engine won’t start | Faulty battery, ignition issues, or fuel supply problems |

| Overheating | Low coolant, a malfunctioning thermostat, or a damaged radiator |

| Excessive smoke | Oil leaks, worn piston rings, or a clogged air filter |

| Unusual noises | Lubrication issues, worn bearings, or loose components |

Step-by-Step Diagnostic Approach

To effectively troubleshoot, follow a structured process. Begin by observing the engine’s behavior and gathering relevant data. Next, inspect the system visually, checking for any obvious signs of wear or damage. Utilize diagnostic tools where applicable, and consult specifications to narrow down potential issues. Document your findings to track patterns and solutions over time.

Hydraulic System Insights and Fixes

The hydraulic system is a vital component of many outdoor equipment, providing the necessary force to operate various mechanisms efficiently. Understanding its intricacies can significantly enhance performance and longevity, while addressing issues promptly can prevent more severe complications down the line.

Common Issues and Their Symptoms

Identifying problems early is crucial. Some prevalent signs include leaks around connections, unusual noises during operation, and a lack of responsiveness in controls. These symptoms often indicate a need for immediate attention to ensure optimal functionality.

Maintenance Tips

Regular maintenance is essential for a healthy hydraulic system. Checking fluid levels routinely can help avoid overheating and pressure loss. Additionally, inspecting hoses and connections for wear and tear can prevent potential failures. Utilizing the correct type of hydraulic fluid as specified by the manufacturer ensures compatibility and efficiency.

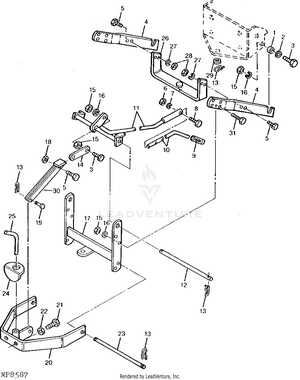

Finding Replacement Parts

Locating suitable components for machinery can be a challenging task, yet it is essential for maintaining optimal performance. Identifying reliable sources and understanding part specifications are crucial steps in the replacement process. This section provides guidance on effectively sourcing necessary items.

First, it’s important to know where to look for the right parts. Various options exist, from authorized dealers to online marketplaces. Each source has its advantages, such as availability, price, and authenticity.

| Source Type | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Guaranteed authenticity, expert advice | Potentially higher prices |

| Online Retailers | Wide selection, competitive pricing | Varied quality, need for careful vetting |

| Local Salvage Yards | Cost-effective options, unique finds | Inconsistent availability, potential wear |

| Manufacturer Websites | Direct access to original parts, detailed information | Shipping times may vary |

Additionally, always check the part number and compatibility before purchasing. Using the correct specifications ensures that the components will fit and function properly, minimizing future issues. By following these steps, you can efficiently find the parts needed for your equipment’s upkeep.

Resources for Technical Support

When dealing with maintenance and troubleshooting of machinery, having access to reliable resources is essential for effective resolution of issues. A variety of platforms and tools are available to assist users in their endeavors, ensuring they can find the help they need promptly and efficiently.

Here are some valuable sources to consider:

- Manufacturer’s Website: The official site often provides documentation, FAQs, and contact information for customer service.

- User Forums: Engaging with communities where users share experiences and solutions can yield practical insights.

- Technical Support Hotlines: Direct access to trained professionals who can guide you through specific problems.

- Video Tutorials: Visual aids can enhance understanding of complex repair procedures or maintenance tasks.

- Local Dealerships: Authorized dealers may offer in-person assistance and have access to specialized tools and parts.

Utilizing these resources can greatly enhance the troubleshooting process and lead to successful outcomes in machinery upkeep.