Effective upkeep of garden tools is essential for optimal performance and longevity. A well-maintained trimmer ensures that your outdoor spaces remain tidy and appealing, making your gardening tasks more efficient. Understanding the essential aspects of tool maintenance can significantly enhance your experience.

In this section, we will explore various techniques and tips that can aid in the smooth functioning of your trimming equipment. From addressing common issues to performing routine checks, you will find valuable insights that can save you time and effort in the long run. Regular attention to these details can prevent larger problems and improve the overall usability of your equipment.

Whether you’re a seasoned gardener or a novice, having access to comprehensive information is vital. This guide aims to equip you with the knowledge necessary to keep your gardening tools in peak condition, ensuring they serve you well for years to come. With the right approach, you can tackle any challenges that arise and enjoy a flourishing garden.

Understanding the typical challenges faced by users can greatly enhance the maintenance and performance of outdoor equipment. Various mechanical failures and operational difficulties may arise, impacting the overall efficiency and longevity of these tools.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Engine Won’t Start | Fuel blockage, spark plug failure, or air filter obstruction | Check fuel lines, replace spark plug, and clean the air filter |

| Excessive Vibration | Loose components or unbalanced attachments | Tighten screws and ensure attachments are properly balanced |

| Power Loss | Clogged exhaust or fuel mixture issues | Clean exhaust openings and adjust fuel mixture |

| Line Feed Problems | Incorrect line installation or worn spool | Reinstall line properly and replace spool if necessary |

Basic Maintenance for Longevity

Regular upkeep is essential to ensure the long-lasting performance of your gardening equipment. Implementing simple maintenance practices can significantly extend its lifespan and efficiency, preventing potential issues before they arise.

Routine Checks

- Inspect the device for any signs of wear or damage.

- Clean the exterior to remove debris and dirt.

- Check the power source and connections for any irregularities.

Periodic Servicing

- Replace the air filter regularly to ensure optimal airflow.

- Sharpen or replace cutting components as needed.

- Lubricate moving parts to reduce friction and wear.

Tools Needed for Effective Repair

Having the right equipment is essential for successful maintenance and troubleshooting of gardening tools. Proper tools not only simplify the process but also ensure that tasks are performed efficiently and safely. Below are the key items that can facilitate a smooth operation.

Essential Tools

- Screwdrivers: Both flathead and Phillips types are necessary for loosening and tightening screws.

- Wrenches: Adjustable wrenches can help with various nuts and bolts.

- Socket Set: Useful for accessing hard-to-reach areas and for more complex disassemblies.

Additional Equipment

- Pliers: For gripping, twisting, and cutting wire.

- Cleaning Supplies: Brushes and cloths to remove debris and ensure clear operation.

- Protective Gear: Gloves and safety goggles to protect against injury during maintenance tasks.

Troubleshooting Starting Problems

Starting difficulties can be a common issue with garden equipment. Identifying the root cause of these problems is essential for efficient operation. This section will guide you through the common factors that can affect ignition and how to address them effectively.

- Fuel Quality: Ensure that the fuel used is fresh and appropriate for the equipment. Stale or contaminated fuel can prevent proper ignition.

- Air Filter Condition: A clogged air filter can restrict airflow, making it hard for the engine to start. Regularly check and clean or replace the air filter as needed.

- Spark Plug Inspection: The spark plug plays a crucial role in ignition. Examine it for wear and carbon buildup. Replace it if it shows signs of damage or excessive wear.

- Starter Mechanism: If the starter mechanism is faulty, it may not engage properly. Inspect the pull cord and starter assembly for any obstructions or damage.

- Choke Position: Ensure that the choke is set correctly for starting. An improper choke setting can lead to starting issues.

By addressing these potential issues systematically, you can enhance the likelihood of successful ignition and maintain the performance of your equipment.

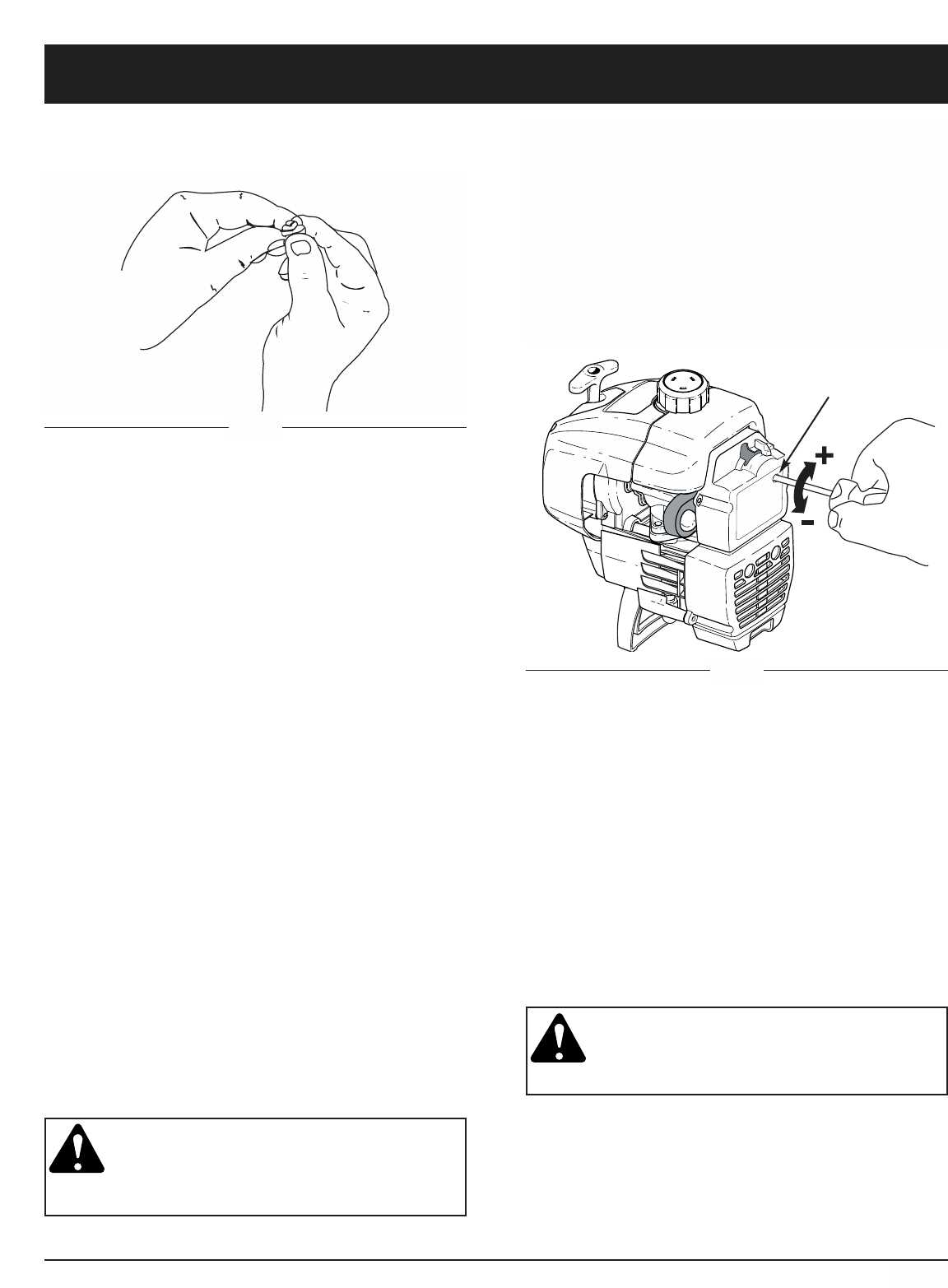

Replacing the Spark Plug Efficiently

Maintaining optimal performance in small engines often involves periodic tasks, one of which is changing the ignition component. This process ensures that the engine operates smoothly and efficiently, reducing the likelihood of issues during use. In this section, we will explore the steps to effectively replace this essential part.

Tools and Materials Needed

Before beginning the replacement, gather the necessary tools and components to ensure a smooth process. Below is a list of items you will need:

| Item | Purpose |

|---|---|

| Socket wrench | To remove the old component |

| New ignition component | To replace the old part |

| Gapping tool | To ensure correct spacing |

| Safety gloves | For protection during the process |

Step-by-Step Replacement Process

Follow these steps to ensure an efficient replacement:

- Start by disconnecting the power source to prevent accidental starts.

- Remove any coverings to access the component easily.

- Use the socket wrench to loosen and remove the old ignition part.

- Check the new part for proper spacing using the gapping tool.

- Install the new component by reversing the removal process, ensuring it is secured tightly.

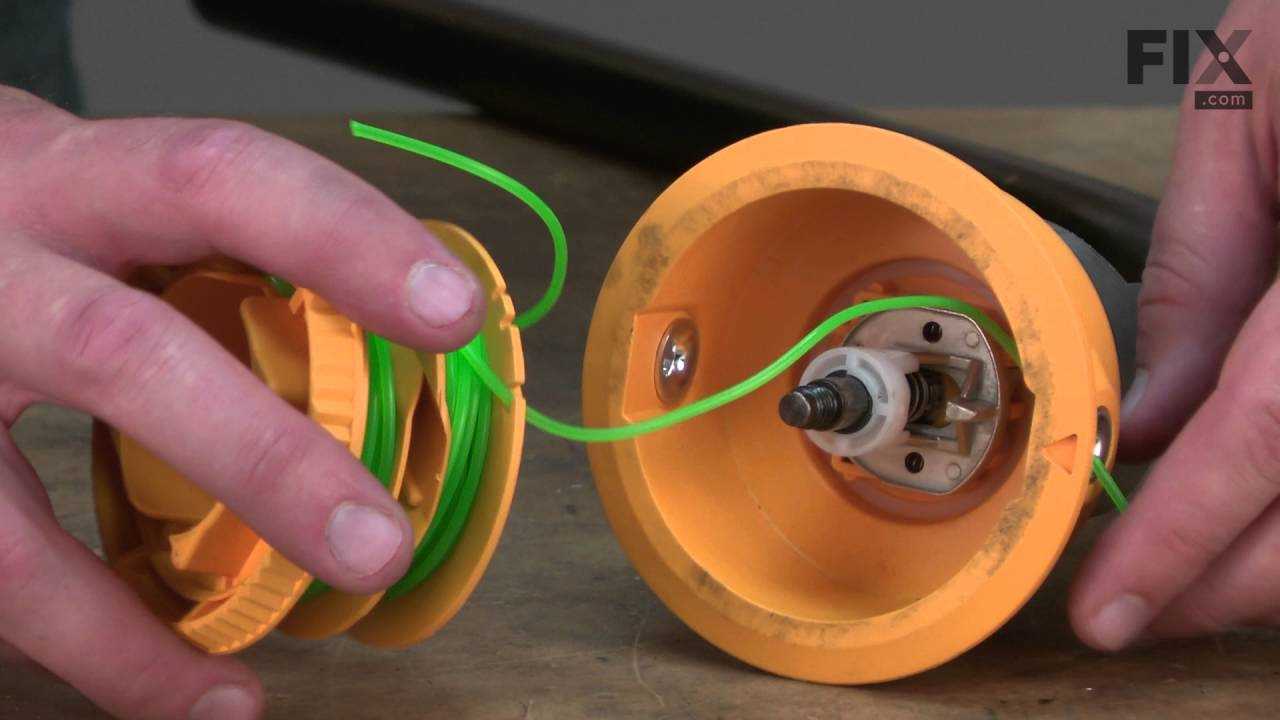

Fixing Line Feed Mechanism Issues

Line feed problems can hinder the efficiency of your trimming tool, leading to frustration during use. Understanding how to address these challenges will ensure optimal performance and longevity of your equipment.

Common Causes of Feed Issues

Several factors may contribute to malfunctioning line feed systems. Worn-out components, incorrect line installation, or debris buildup can all disrupt the smooth operation of the mechanism. Regular inspection of these elements is essential for preventing operational failures.

Steps to Resolve the Problem

Begin by examining the line spool for any signs of wear or damage. If necessary, replace it with a new spool designed for your device. Next, ensure that the cutting line is properly threaded through the feed holes, following the manufacturer’s guidelines. Clearing any obstructions from the mechanism will also improve functionality. Finally, test the tool to confirm that the line feeds correctly during operation.

Cleaning the Carburetor for Better Performance

Regular maintenance of the fuel delivery system is essential for optimal engine function. One of the key components, the fuel mixing device, often requires thorough cleaning to ensure efficient operation. Accumulated residue can lead to poor performance and difficulties in starting the engine. This section provides guidelines for effectively cleaning this crucial part, enhancing overall performance.

Tools and Materials Needed

| Item | Description |

|---|---|

| Cleaning Solution | Use a carburetor cleaner or a suitable solvent. |

| Brush | A small brush helps remove stubborn deposits. |

| Screwdriver | Necessary for disassembling the device. |

| Compressed Air | Useful for blowing out dirt from hard-to-reach areas. |

Step-by-Step Cleaning Process

To maintain efficiency, follow these steps:

- Disconnect the device from the power source.

- Remove the fuel mixing device carefully.

- Apply the cleaning solution generously, allowing it to soak for a few minutes.

- Use the brush to scrub all surfaces, focusing on jets and passages.

- Rinse with clean solvent and blow out any remaining debris with compressed air.

- Reassemble the unit and reconnect it to the power source.

Addressing Vibration and Noise Concerns

Excessive vibrations and noise during operation can significantly affect the overall performance and user experience of outdoor power tools. Identifying the underlying causes and implementing appropriate solutions can enhance comfort and efficiency while ensuring a longer lifespan for the equipment.

Common Causes of Vibration

Vibration may arise from several factors, including imbalanced components, loose fasteners, or wear and tear on internal parts. Regular inspections can help detect these issues early. Maintaining balance within the tool is crucial, as even slight imbalances can lead to increased vibration levels.

Noise Reduction Techniques

To minimize noise, consider using sound-dampening materials around components or implementing design modifications. Regular maintenance, such as lubricating moving parts and replacing worn-out components, can also help reduce operational noise. Ensuring that all parts are securely fastened will further decrease both vibration and noise levels.

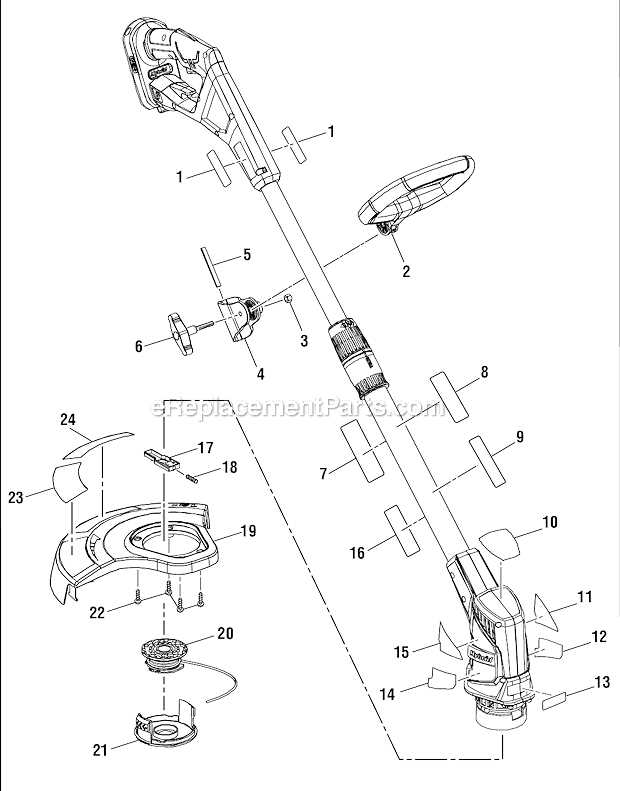

Repairing Damaged Trimmer Head Parts

Maintaining the functionality of the cutting apparatus is essential for effective lawn care. When components of the head become worn or broken, prompt attention is necessary to ensure optimal performance. This section outlines the key steps and considerations for restoring these critical parts.

| Component | Common Issues | Possible Solutions |

|---|---|---|

| Spool | Excessive wear, tangled line | Replace the spool or reline it carefully |

| Cover | Cracks, loose fitting | Use adhesive for minor cracks or replace if necessary |

| Line Feed Mechanism | Failure to advance line | Clean or replace the feed mechanism |

| Retaining Nut | Stripped threads | Replace with a new nut to secure components |

Addressing these issues promptly not only enhances performance but also extends the lifespan of the equipment. Regular inspections and maintenance practices can prevent more significant problems in the future.

Fuel System Maintenance and Repair

Proper upkeep of the fuel system is essential for optimal performance and longevity of your equipment. Regular attention to this area ensures efficient fuel delivery and prevents issues that can hinder operation. Understanding the components and their functions will aid in identifying potential problems early.

Begin by inspecting fuel lines for any signs of wear, cracks, or leaks. It is crucial to replace any damaged parts immediately to avoid fuel loss and ensure a steady supply. Additionally, regularly check the fuel filter and clean or replace it as needed to prevent blockages that could affect performance.

Cleaning the carburetor periodically is also vital. Remove any build-up of deposits that can restrict fuel flow. Ensure all gaskets and seals are intact to maintain pressure and prevent leaks. A well-maintained fuel system not only enhances efficiency but also promotes smoother operation and extends the lifespan of your machinery.

Final Tips for Safe Operation

Ensuring safe usage of garden trimming tools is essential for both efficiency and personal safety. Adhering to proper guidelines can significantly reduce the risk of accidents while enhancing overall performance.

Regular Maintenance: Conduct routine checks on your equipment to ensure all components are functioning properly. This includes inspecting the cutting mechanism and ensuring that all safety features are intact.

Protective Gear: Always wear appropriate safety gear, such as gloves, goggles, and sturdy footwear. This minimizes the risk of injury from debris and potential hazards during operation.

Environment Awareness: Before starting work, assess the surrounding area for potential obstacles, including people, pets, and flammable materials. Keeping a safe distance from these elements is crucial.

Clear Instructions: Familiarize yourself with the operation instructions specific to your equipment. Understanding how to handle and control the tool effectively will contribute to safer usage.

Emergency Preparedness: Always have a plan in case of emergencies. Know the location of the nearest first aid kit and keep a phone nearby to call for help if needed.