For those who take pride in their green spaces, understanding the intricacies of their lawn machinery is crucial. Proper upkeep not only extends the lifespan of these vital tools but also ensures optimal performance throughout the seasons. This section provides valuable insights into the techniques and processes involved in maintaining your equipment efficiently.

Whether you are a seasoned gardener or a novice, having access to comprehensive guidelines can significantly enhance your experience. From troubleshooting common issues to performing routine checks, the right information empowers users to tackle challenges with confidence. This resource aims to equip you with the necessary knowledge to handle maintenance tasks effectively.

In an environment where efficiency and reliability are paramount, knowing the specifics of your machinery can make all the difference. By familiarizing yourself with the operational aspects and care procedures, you can achieve better results and enjoy a thriving landscape. Embrace the journey of mastering your tools and discover the satisfaction that comes from a well-maintained garden.

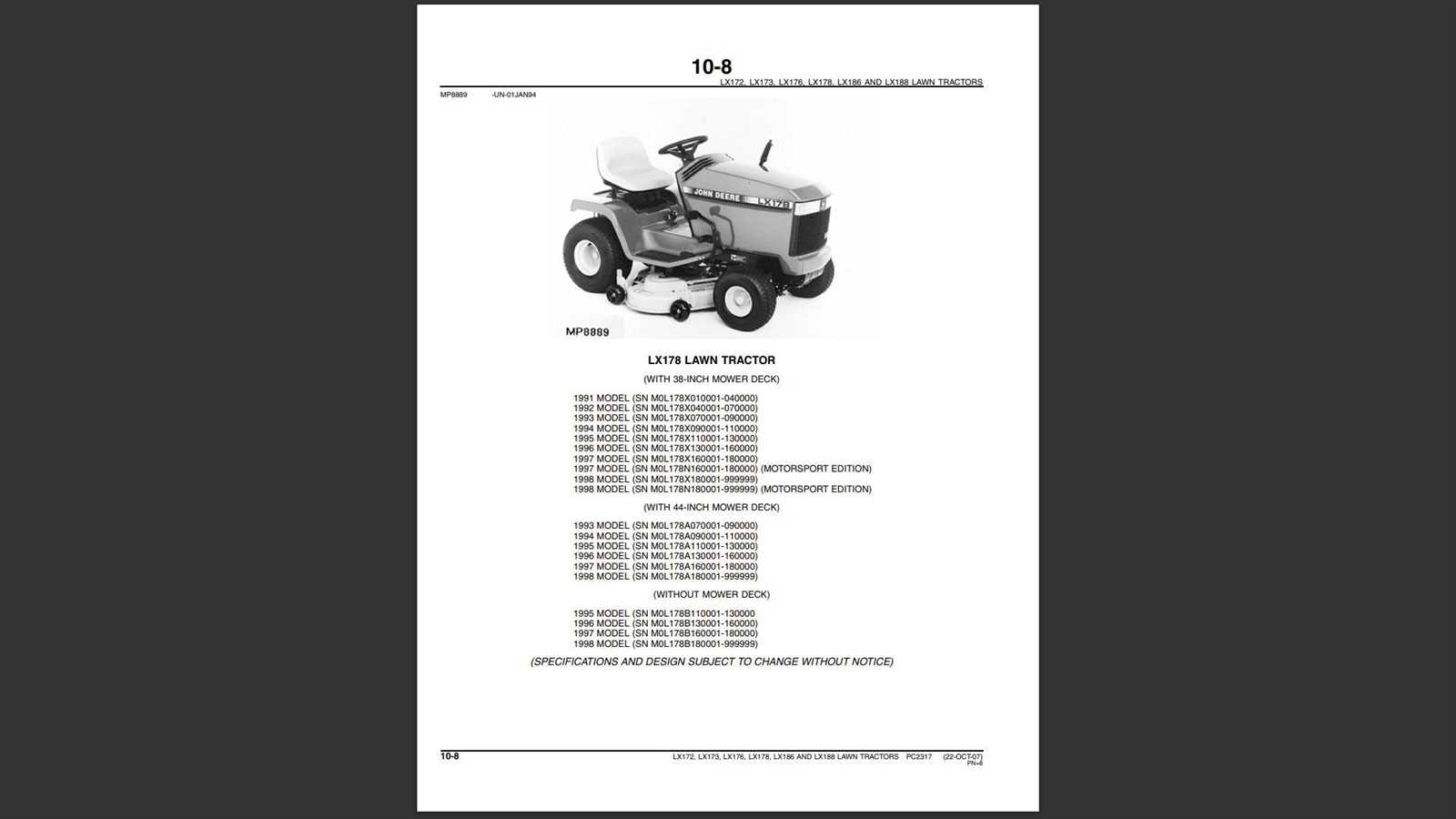

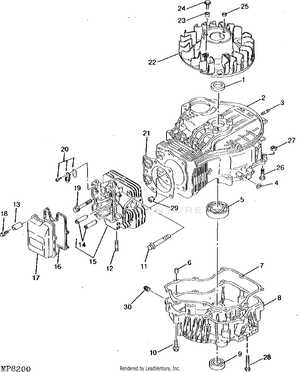

Understanding the John Deere LX176

This section aims to provide an in-depth look at a specific model of garden machinery, focusing on its features, functionality, and overall performance. A solid understanding of this equipment is crucial for users seeking to maintain or enhance its efficiency in various landscaping tasks.

Key Features

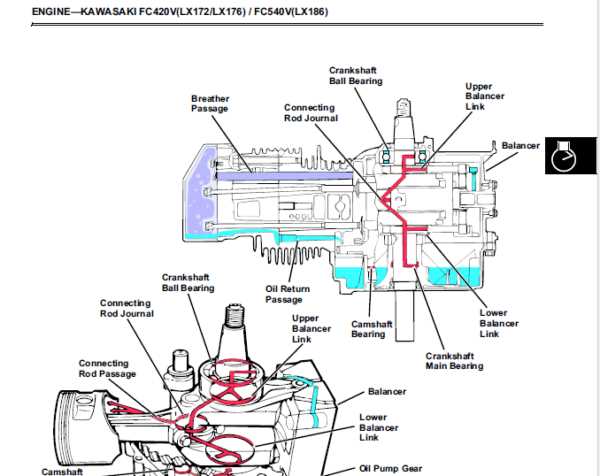

One of the standout attributes of this particular machine is its reliable engine, which ensures consistent power delivery for a variety of tasks. Additionally, the design emphasizes user comfort and ease of operation, making it suitable for both novice and experienced operators. The cutting system is engineered for optimal grass management, contributing to a well-manicured lawn.

Maintenance Considerations

To ensure longevity and peak performance, regular upkeep is essential. This includes routine checks of the engine components, cutting blades, and tires. Proper care can significantly extend the lifespan of the machinery. Furthermore, understanding the basic troubleshooting techniques can help users address minor issues before they escalate.

Common Issues with the LX176

The maintenance of outdoor equipment often reveals a variety of typical problems that can affect performance and usability. Understanding these common challenges can assist owners in addressing them promptly and effectively.

Engine Performance: One prevalent issue is related to the engine not starting or running inconsistently. This can stem from fuel-related problems, such as stale gasoline or clogged filters, which impede smooth operation.

Electrical Failures: Electrical components may occasionally malfunction, leading to difficulties with starting the machine or operating attachments. Issues such as a weak battery or corroded connections can contribute to these problems.

Cutting Quality: Many users report uneven cutting as a frequent concern. This can be caused by dull blades, incorrect deck height settings, or the buildup of grass clippings under the deck, which can hinder performance.

Transmission Issues: Another area that may require attention is the transmission. Problems such as slipping or difficulty shifting gears can arise, often due to low fluid levels or wear and tear on internal components.

Cooling System: Overheating can occur if the cooling system is not functioning properly. Blockages in the cooling fins or a malfunctioning fan can prevent adequate airflow, leading to potential engine damage.

Addressing these concerns early can enhance the longevity and reliability of the equipment, ensuring a smoother operation during use.

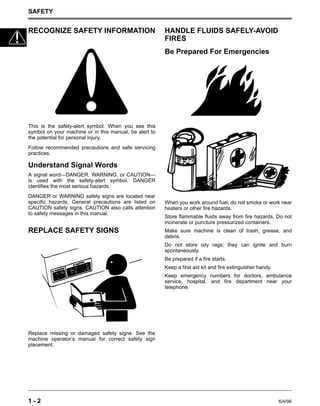

Essential Tools for Repairs

When it comes to maintaining and fixing outdoor machinery, having the right equipment is crucial. A well-equipped toolkit not only enhances efficiency but also ensures safety during various tasks. Understanding which instruments to keep on hand can make all the difference in managing routine upkeep and addressing unexpected issues.

Basic Hand Tools

Every technician should start with a set of fundamental hand tools. This includes wrenches, screwdrivers, and pliers. These items allow for the adjustment and tightening of various components, ensuring that everything operates smoothly. Additionally, an adjustable wrench can handle multiple sizes, making it a versatile choice for different jobs.

Specialized Equipment

For more complex tasks, specialized instruments become necessary. Items such as torque wrenches and multimeters can provide precise measurements essential for optimal functioning. A multimeter helps diagnose electrical issues, while a torque wrench ensures that fasteners are tightened to the correct specifications, preventing damage from over-tightening.

Step-by-Step Maintenance Guide

Regular upkeep is essential to ensure optimal performance and longevity of your equipment. By following a systematic approach, you can easily handle common tasks that will keep your machine running smoothly. This guide outlines key procedures for maintaining your vehicle effectively.

Essential Maintenance Tasks

- Check and replace the oil regularly.

- Inspect and clean the air filter to ensure proper airflow.

- Sharpen or replace the cutting blades as needed.

- Examine belts for wear and adjust tension accordingly.

- Clean the exterior and remove any debris from under the deck.

Seasonal Checklist

- Spring: Change oil, inspect battery, and check tire pressure.

- Summer: Clean air filter, check for leaks, and ensure cooling system is functioning.

- Fall: Prepare for storage, including fuel treatment and battery maintenance.

- Winter: Store in a dry place, cover, and disconnect the battery if needed.

By adhering to this maintenance guide, you will enhance the reliability and efficiency of your equipment, preventing costly repairs and ensuring a longer lifespan.

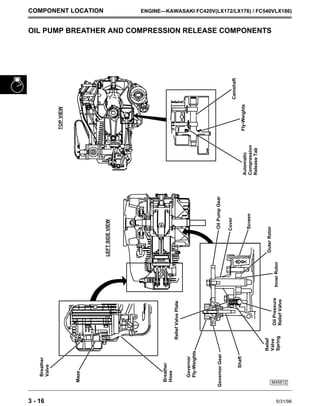

Engine Troubleshooting Tips

When dealing with performance issues in your machine’s power unit, it’s essential to follow a systematic approach. Identifying the root cause of a malfunction can save time and resources, ensuring efficient operation and longevity. This section provides key insights into common challenges and solutions that can help you get back on track.

Common Symptoms and Their Causes

Understanding the typical signs of engine trouble is the first step toward effective diagnosis. Here are some frequent indicators:

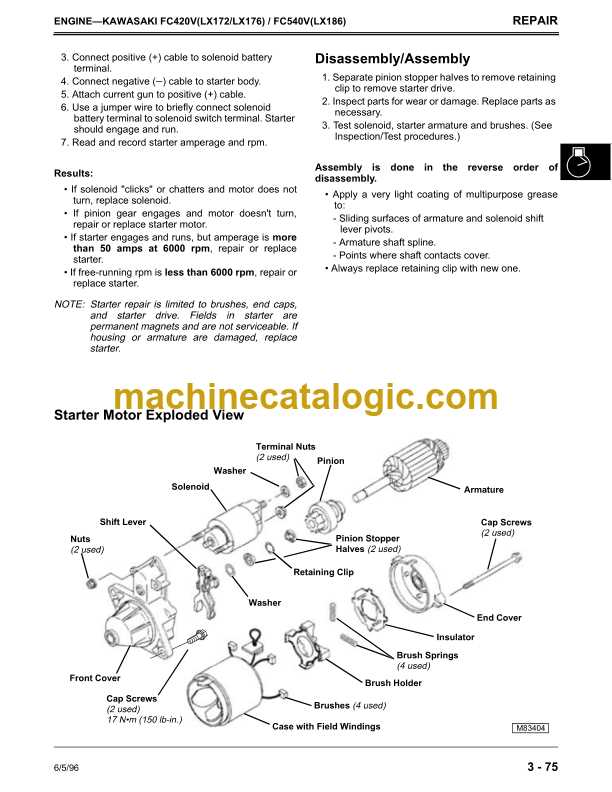

- Difficulty Starting: This may result from a weak battery, faulty ignition components, or fuel delivery issues.

- Overheating: Insufficient coolant levels, blocked air filters, or malfunctioning thermostats can lead to elevated temperatures.

- Unusual Noises: Rattling or knocking sounds might indicate internal wear or loose components.

Troubleshooting Steps

Once symptoms are identified, follow these troubleshooting steps:

- Check the Fuel System: Ensure that fuel is reaching the engine. Inspect the fuel lines, filter, and pump.

- Inspect Electrical Components: Examine the battery, starter, and wiring for any signs of wear or corrosion.

- Evaluate Cooling Systems: Verify that coolant levels are adequate and that there are no leaks in hoses or the radiator.

By systematically addressing these areas, you can often pinpoint the issue and implement appropriate corrective measures, leading to a smoother operation and enhanced reliability.

Electrical System Diagnostics

The electrical system of any machinery is crucial for its functionality and efficiency. Diagnosing issues within this system involves a systematic approach to identify faults and ensure proper operation. Understanding the components and their interactions is essential for effective troubleshooting.

Common Symptoms of Electrical Issues

- Inconsistent starting or failure to start

- Flickering lights or dimming

- Unusual sounds from the electrical components

- Unresponsive controls or instruments

Diagnostic Steps

- Check the battery voltage and connections.

- Inspect fuses for any signs of damage or failure.

- Examine wiring for wear, corrosion, or loose connections.

- Test relays and switches for proper operation.

- Utilize a multimeter to measure current and resistance in the circuit.

By following these guidelines, one can effectively pinpoint and resolve electrical problems, ensuring optimal performance of the equipment.

Transmission Problems and Solutions

Issues related to the transmission system can significantly impact the performance and efficiency of outdoor equipment. Understanding common challenges and their corresponding remedies is crucial for maintaining optimal functionality. This section explores prevalent transmission complications and offers practical solutions to ensure smooth operation.

1. Slipping Gears

If the gears tend to slip unexpectedly, it often indicates low fluid levels or contamination. Regularly check the transmission fluid and replace it if necessary. Additionally, inspect the filter for any obstructions that may hinder fluid flow.

2. Difficulty Shifting

Struggles with shifting can be caused by a range of factors, including worn cables or linkage issues. Examine the shift cable for fraying and ensure all connections are secure. Lubricating the linkage can also enhance smooth transitions between gears.

3. Overheating

An overheating transmission can lead to severe damage if not addressed promptly. Ensure that the cooling system is functioning correctly and check for any leaks in the cooling lines. Installing a transmission cooler may help in maintaining optimal temperature levels.

4. Unusual Noises

Unexplained noises during operation might signal internal problems within the transmission. Listen for grinding, whining, or clunking sounds. Regular maintenance and inspections can help identify and resolve issues before they escalate.

5. Fluid Leaks

Fluid leaks are a clear indication of potential problems within the transmission system. Inspect seals and gaskets for wear and replace them as necessary. Keeping an eye on fluid levels can help catch leaks early, preventing further damage.

Addressing these common transmission issues with timely interventions can lead to prolonged equipment life and improved performance. Regular maintenance checks and proactive measures are key to ensuring reliable operation.

Replacing Blades: A How-To

Maintaining optimal performance of your lawn care equipment involves regular upkeep, including the timely replacement of cutting components. This task ensures a clean cut, promoting healthier grass and a well-groomed appearance for your lawn. Here, we will guide you through the process of swapping out dull or damaged blades, ensuring safety and efficiency.

Gather Necessary Tools

Before you begin, it’s essential to assemble the right tools. You will need a socket wrench or a suitable screwdriver, safety gloves, and, ideally, a blade removal tool. Having these items ready will streamline the process and enhance your safety while working.

Step-by-Step Replacement Process

Start by ensuring the equipment is turned off and completely cool. Then, carefully tilt the machine to access the underside. Using your wrench, remove the fasteners securing the old blades. Take note of the orientation of the blades for proper installation of the new ones. Once removed, replace them with the new units, tightening the fasteners securely. Finally, lower the machine back to its operating position and test the functionality to confirm a successful installation.

Fuel System Care and Repair

The fuel system is crucial for the efficient operation of any machinery. Proper maintenance and timely attention to potential issues can enhance performance and prolong the lifespan of the engine. Understanding the components and their functions is key to ensuring optimal functionality.

Regular inspections should be part of your maintenance routine. Look for signs of wear or leaks, and ensure that all connections are secure. Keeping the fuel clean and free from contaminants is essential, as dirty fuel can lead to engine problems.

| Component | Care Tips | Common Issues |

|---|---|---|

| Fuel Filter | Replace regularly, especially after long usage. | Clogs leading to reduced engine performance. |

| Fuel Pump | Check for proper operation; listen for unusual noises. | Failure to deliver fuel causing engine stalling. |

| Fuel Lines | Inspect for cracks or leaks; replace if necessary. | Fuel leaks can lead to dangerous situations. |

| Carburetor | Clean periodically to prevent buildup. | Improper fuel-air mixture resulting in poor performance. |

Addressing these components with diligence can prevent minor issues from escalating into major repairs, ensuring the machine operates smoothly and efficiently.

Seasonal Maintenance Checklist

Regular upkeep is essential for optimal performance and longevity of your equipment. Adhering to a seasonal maintenance checklist helps ensure that all components function effectively and reduces the risk of unexpected breakdowns. This proactive approach not only enhances efficiency but also provides peace of mind throughout the year.

Spring Maintenance: Start by inspecting the battery and cleaning the terminals. Check the air filter and replace it if necessary. Inspect the tires for wear and ensure they are properly inflated. Also, examine the cutting blades for sharpness and replace them if needed.

Summer Maintenance: Keep an eye on fluid levels, including oil and coolant. Check the spark plugs for signs of wear and replace them if necessary. Ensure the belts and hoses are in good condition, and lubricate moving parts to reduce friction and wear.

Fall Maintenance: Clean the equipment thoroughly to remove any debris. Drain and replace fuel, and consider adding a fuel stabilizer. Inspect all electrical connections and wiring for signs of corrosion or damage. Store equipment in a dry, sheltered area to protect it from the elements.

Winter Maintenance: Conduct a comprehensive inspection of all systems. Verify that the battery is fully charged and, if possible, remove it for safe storage. Check and maintain tire pressure, and ensure all fluids are at appropriate levels. Cover the equipment to prevent dust accumulation and exposure to moisture.

Where to Find Replacement Parts

Finding suitable components for your equipment can be crucial for maintaining its functionality and longevity. Numerous sources are available, both online and offline, that offer a wide range of parts. Understanding where to look can save you time and ensure you obtain high-quality replacements.

Online Retailers

The internet is a treasure trove for parts procurement. Many dedicated websites specialize in providing components for various machinery. These platforms often feature search filters, allowing you to narrow down options based on your specific needs. Additionally, customer reviews can guide you in selecting reliable suppliers.

Local Dealerships and Stores

Your local dealerships and equipment stores can be invaluable resources. They often carry a selection of parts and may even assist you in finding what you need. Engaging with knowledgeable staff can provide insights into compatibility and installation, making the process smoother.