This section provides essential insights into the upkeep and problem-solving techniques for a popular utility vehicle. Understanding the intricacies of its operation can enhance performance and longevity.

Within this guide, users will find detailed instructions on various aspects, from routine checks to more complex diagnostics. Familiarity with the machinery’s components is crucial for effective maintenance and optimal functionality.

Engaging with this resource will equip operators with the knowledge to tackle common issues, ensuring reliable performance in various conditions. By following the outlined procedures, users can achieve efficient and safe operation of their equipment.

Overview of Agricultural Equipment

This section provides an insight into a specific model of agricultural machinery designed for versatility and efficiency in various farming tasks. These machines are known for their robust construction and ease of use, making them suitable for both professional farmers and hobbyists.

Key features include:

- Powerful engine options for enhanced performance.

- Advanced transmission systems for smooth operation.

- Compact design allowing for maneuverability in tight spaces.

Users benefit from:

- Enhanced productivity through innovative technology.

- Reliability in diverse working conditions.

- Ease of maintenance and serviceability, ensuring long-term usability.

This equipment serves as a reliable partner in various agricultural applications, from tilling to hauling, making it a valuable asset for optimizing farm operations.

Common Issues and Troubleshooting

This section highlights frequent problems encountered with certain agricultural machinery and provides practical solutions for effective resolution. Understanding these issues can enhance the longevity and efficiency of the equipment.

Several common challenges may arise during operation:

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine won’t start | Dead battery or faulty ignition system | Check battery connections and replace if necessary. |

| Overheating | Low coolant level or blocked radiator | Inspect coolant levels and clear any obstructions. |

| Poor performance | Clogged fuel filter or dirty air filter | Replace fuel and air filters to restore functionality. |

| Unusual noises | Worn bearings or loose components | Examine and tighten loose parts; replace worn bearings. |

Maintenance Guidelines for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of any machinery. Adhering to a consistent maintenance schedule not only enhances performance but also minimizes the risk of unexpected breakdowns. Understanding key practices can significantly contribute to the effective operation of your equipment.

Here are some important aspects to consider during maintenance:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Fluid Checks | Weekly | Inspect all fluid levels, including oil, coolant, and hydraulic fluids to ensure optimal functioning. |

| Filter Replacements | Every 200 hours | Change air, fuel, and oil filters regularly to prevent contamination and maintain efficiency. |

| Tire Inspection | Monthly | Check tire pressure and tread wear to ensure safe and efficient movement. |

| Battery Maintenance | Every 6 months | Inspect battery terminals for corrosion and ensure proper charge levels. |

Implementing these guidelines will lead to enhanced performance and extended service life for your machinery. Staying proactive with maintenance is key to avoiding costly repairs and ensuring smooth operation.

Essential Tools for Repairs

Having the right instruments is crucial for effective maintenance and troubleshooting of machinery. A well-equipped toolkit not only enhances efficiency but also ensures that tasks are performed safely and accurately. Below are some fundamental tools that every technician should have at their disposal.

| Tool | Purpose |

|---|---|

| Wrench Set | Used for loosening or tightening bolts and nuts. |

| Screwdriver Set | Essential for driving screws in various sizes. |

| Pliers | Handy for gripping, twisting, and cutting wire. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

| Multimeter | Used for measuring electrical values such as voltage and resistance. |

| Socket Set | Allows for easier access to fasteners in tight spaces. |

Engine Specifications and Care

This section provides an overview of the essential characteristics and maintenance practices for optimal engine performance. Understanding these aspects ensures longevity and reliability, enhancing the overall efficiency of the machinery.

Specifications

The engine is equipped with advanced features that contribute to its power and efficiency. Key specifications include:

- Displacement: X liters

- Cylinders: X

- Horsepower: X HP

- Torque: X Nm

Maintenance Practices

Regular care is vital for sustaining engine health. Recommended practices include:

- Frequent oil changes to maintain lubrication

- Inspection and replacement of air filters

- Monitoring coolant levels

- Checking belts and hoses for wear

By adhering to these guidelines, users can ensure their engine operates smoothly and efficiently over time.

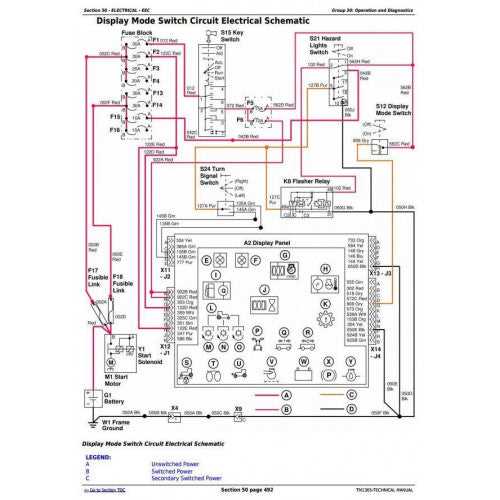

Electrical System Diagnostics

Diagnosing issues within the electrical framework of machinery is essential for maintaining optimal performance and reliability. This process involves a systematic approach to identifying faults, ensuring that all components function correctly, and pinpointing areas that may require attention or repair.

Initial steps typically include checking the battery’s condition and ensuring proper voltage levels. Utilizing diagnostic tools, technicians can assess the integrity of wiring and connectors, identifying potential short circuits or breaks in the circuit. Regular monitoring of fuses and relays also plays a crucial role in troubleshooting electrical problems.

In addition to physical inspections, employing advanced diagnostic equipment can provide valuable insights into system performance. Scanning for error codes and analyzing data from various sensors helps in understanding the root cause of electrical failures. This proactive approach not only aids in swift repairs but also enhances the longevity of the equipment.

Hydraulic System Maintenance Tips

Proper upkeep of hydraulic systems is essential for ensuring optimal performance and longevity of machinery. Regular maintenance not only enhances efficiency but also helps in preventing costly repairs and unexpected downtimes. Implementing a consistent maintenance routine can significantly extend the life of hydraulic components.

Routine Inspections

Conducting frequent inspections is crucial for identifying potential issues before they escalate. Check for leaks, wear, and damage in hoses, fittings, and seals. Make it a habit to inspect fluid levels and quality; dirty or low fluid can lead to system failures.

Fluid Maintenance

Maintaining the right hydraulic fluid is vital for the system’s functionality. Regularly replace the fluid according to the manufacturer’s recommendations. Ensure that the fluid is compatible with your system and that it meets specified performance standards. Additionally, keep the hydraulic reservoir clean to prevent contamination.

Implementing Safety Protocols

Establishing effective safety measures is crucial in any operational environment involving machinery. These protocols are designed to minimize risks and ensure the well-being of all personnel involved in the task at hand.

Prioritizing safety begins with comprehensive training for operators, enabling them to recognize potential hazards and respond appropriately. Regular drills and simulations can reinforce this knowledge, ensuring readiness in emergency situations.

Additionally, maintaining clear communication among team members is essential. This can involve the use of signaling systems or visual aids to convey important information quickly and efficiently.

Regular inspections and maintenance of equipment play a vital role in preventing accidents. By identifying wear and tear early, operators can address issues before they escalate into dangerous situations.

Lastly, fostering a culture of safety encourages all team members to take personal responsibility for their own safety and that of their colleagues. This collective mindset can significantly reduce the likelihood of incidents occurring on-site.

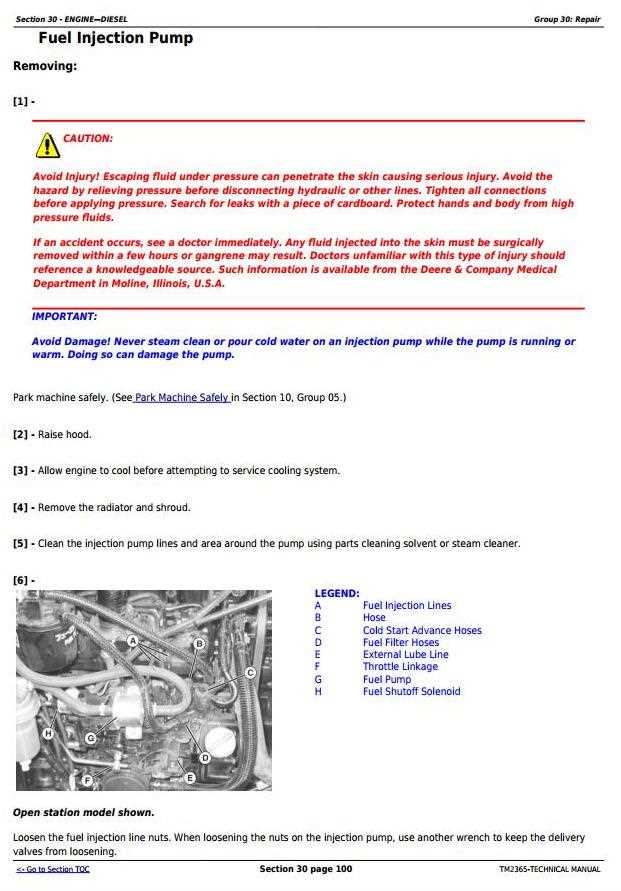

Parts Replacement Procedures

This section outlines essential steps for efficiently replacing components within machinery, ensuring optimal performance and longevity. Following the correct protocols is crucial for maintaining the integrity of the system and avoiding potential issues during operation.

Preparation Steps

Before beginning the replacement process, it is important to gather all necessary tools and components. Ensure that the workspace is clean and organized. Reviewing the specifications of the new parts will help confirm compatibility with existing equipment.

Replacement Process

Start by carefully disconnecting power sources and any attachments that may interfere with the replacement. Follow the designated sequence for removing the old part to prevent damage to surrounding components. Install the new part securely, ensuring all connections are tight and aligned correctly. Finally, conduct a thorough inspection and test the machinery to confirm successful installation.

Service Intervals and Schedules

Maintaining optimal performance of machinery requires adherence to specific intervals for servicing and inspections. Regular upkeep ensures longevity and efficiency, helping to prevent unexpected breakdowns and costly repairs.

The following guidelines outline essential service intervals:

- Daily Checks:

- Inspect fluid levels

- Examine tires for wear

- Check safety equipment

- Every 50 Hours:

- Change engine oil

- Replace oil filter

- Inspect air filter

- Every 100 Hours:

- Grease fittings

- Check battery connections

- Inspect hydraulic system

- Every 500 Hours:

- Replace fuel filter

- Examine belts and hoses

- Test coolant system

Adhering to these schedules enhances reliability and performance, ensuring that the equipment operates smoothly throughout its lifespan.

Upgrades and Modifications

This section explores various enhancements and adjustments that can improve the performance and functionality of your equipment. By incorporating specific upgrades, operators can achieve better efficiency, increased durability, and tailored features that meet their specific needs.

Performance Enhancements

Upgrading certain components can significantly boost overall performance. Consider the following modifications:

- Improved engine components for higher power output

- Enhanced transmission systems for smoother operation

- Upgraded hydraulic systems for increased lifting capacity

Comfort and Usability Improvements

In addition to performance, enhancing comfort and usability can greatly improve the operator experience. Some options include:

- Advanced seating options for better ergonomics

- Upgraded control systems for easier handling

- Enhanced lighting systems for improved visibility

| Upgrade Type | Benefits |

|---|---|

| Engine Modifications | Higher power and efficiency |

| Transmission Upgrades | Smoother gear shifts |

| Hydraulic Enhancements | Greater lifting capabilities |

| Comfort Features | Improved operator experience |

Resources for Further Assistance

Accessing additional resources can significantly enhance your troubleshooting capabilities and provide deeper insights into equipment maintenance. Various platforms offer guidance, community support, and expert advice that can help you effectively resolve issues and optimize performance.

Online Forums and Communities

Engaging with online forums allows you to connect with fellow enthusiasts and professionals. These communities often share valuable experiences, tips, and solutions to common challenges. Participating in discussions can broaden your understanding and provide practical advice tailored to specific situations.

Official Documentation and Guides

Consulting official documentation and instructional guides is essential for comprehensive knowledge. These resources typically include detailed specifications, operational procedures, and maintenance protocols. Utilizing these materials ensures you have access to accurate information and can follow recommended practices effectively.