Maintaining the efficiency and longevity of an engine is crucial for optimal performance. This guide provides essential insights into understanding common issues, conducting preventative measures, and executing effective solutions. Whether you’re a novice or an experienced mechanic, having access to comprehensive information can make all the difference.

Through careful examination and troubleshooting, you can identify the root causes of various operational problems. This resource offers a detailed approach to diagnosing faults, replacing components, and ensuring that your engine runs smoothly. By following the guidelines presented, you will enhance your skills and confidence in handling engine-related tasks.

Ultimately, this guide serves as a valuable tool for anyone looking to improve their knowledge and practical abilities in engine care. With a focus on clear explanations and step-by-step procedures, it aims to empower you to tackle challenges effectively and maintain your machinery in peak condition.

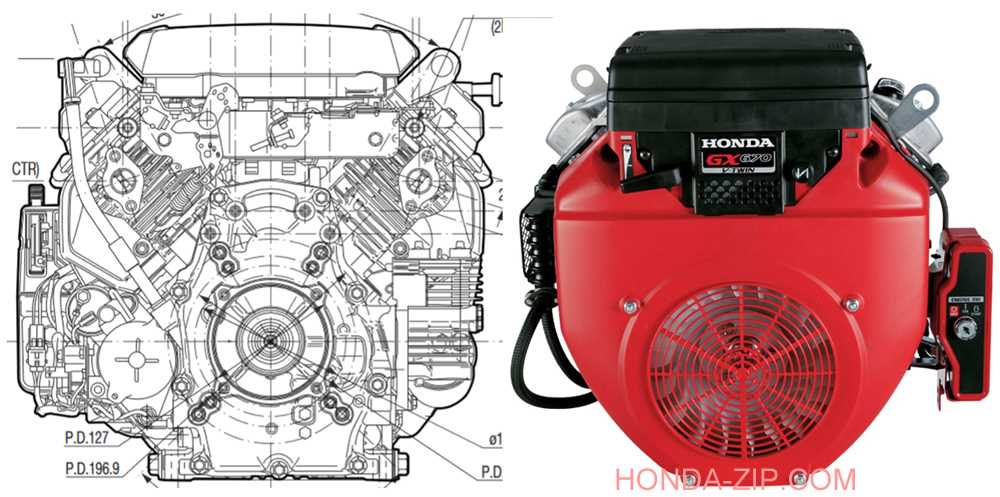

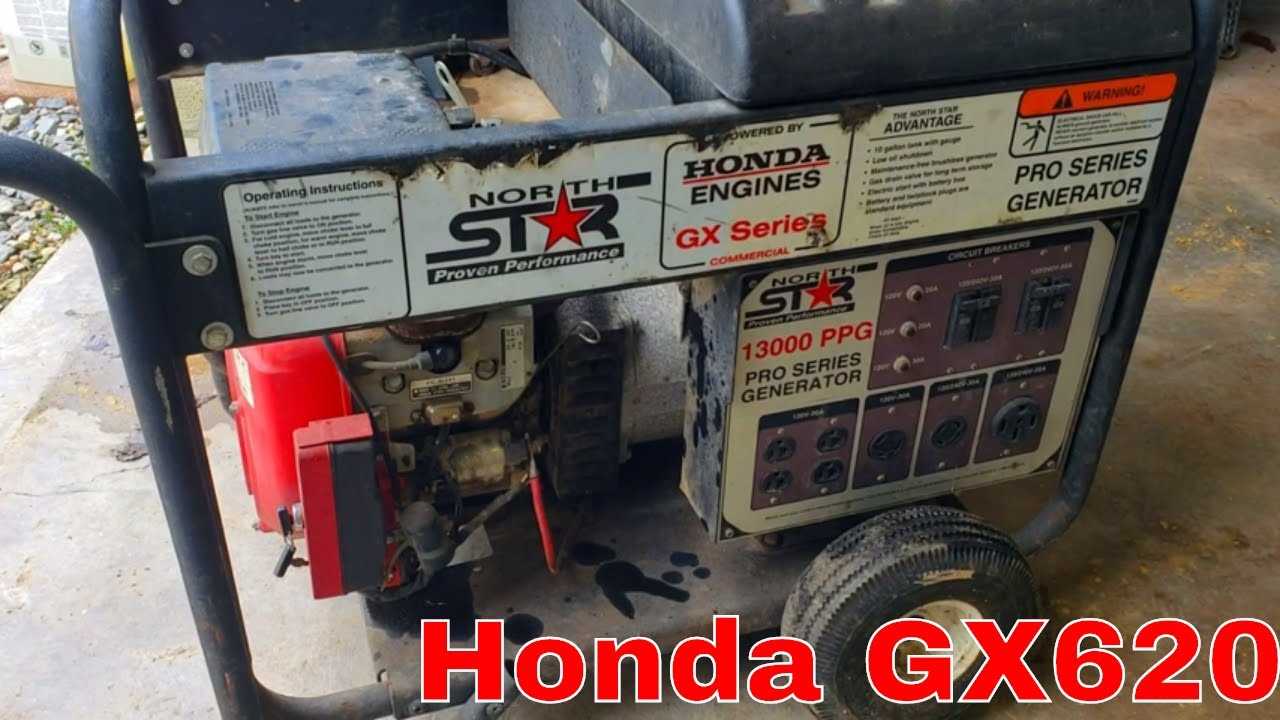

Understanding the Honda GX620 Engine

The engine in question is a robust and reliable power source designed for various applications. Known for its efficiency and durability, it caters to a wide range of tasks, making it a popular choice among enthusiasts and professionals alike. This section delves into its key features and specifications, helping users gain a comprehensive understanding of its capabilities.

| Feature | Description |

|---|---|

| Cylinder Configuration | V-twin layout for enhanced performance and balance. |

| Displacement | Approximately 614 cc, providing ample power for demanding tasks. |

| Power Output | Produces around 20.0 HP, ensuring effective operation across various equipment. |

| Cooling System | Air-cooled design that maintains optimal operating temperatures. |

| Fuel Type | Operates on regular gasoline, promoting accessibility and convenience. |

| Starting System | Equipped with an electric starter for effortless ignition. |

This power unit stands out due to its versatile nature, making it suitable for lawn care, construction, and various industrial applications. Understanding its specifications helps users maximize its potential, ensuring efficient and reliable performance.

Common Issues with GX620 Models

The engine units in this category are known for their reliability, but like any machinery, they can encounter problems over time. Identifying these common challenges early can help ensure optimal performance and longevity. Below are some frequently reported concerns that users may face.

Starting Difficulties: One of the prevalent issues is trouble with ignition. Users may find that the engine struggles to start or does not start at all. This can often be traced back to a faulty battery, ignition components, or fuel delivery problems.

Overheating: Another significant concern is overheating. Insufficient coolant, a malfunctioning thermostat, or a blocked radiator can lead to this problem. Regular checks of the cooling system can prevent severe damage.

Fuel System Issues: Clogs in the fuel filter or issues with the fuel pump can affect engine performance. Poor fuel quality or improper fuel can also lead to hesitation during operation. Maintaining the fuel system is crucial for smooth functionality.

Oil Leaks: Oil leakage is a common issue that can result from worn gaskets or seals. Addressing any leaks promptly is essential to avoid low oil levels, which can cause significant engine damage over time.

Vibration and Noise: Excessive vibrations or unusual sounds can indicate underlying mechanical problems. This could stem from loose parts, misaligned components, or wear and tear on internal parts. Regular inspections can help identify and rectify these issues early.

By being aware of these common challenges, operators can take proactive measures to maintain their engine’s performance and reliability.

Essential Tools for Repairs

When tackling maintenance tasks, having the right equipment is crucial for achieving optimal results. A well-equipped workspace enhances efficiency and ensures that projects are completed safely and effectively. This section will highlight the fundamental instruments necessary for any repair undertaking.

First and foremost, a comprehensive set of hand tools, including wrenches, pliers, and screwdrivers, forms the backbone of any toolkit. These versatile items allow for a variety of adjustments and disassemblies. Additionally, power tools such as drills and saws can significantly expedite tasks, making them invaluable for more extensive projects.

Safety gear cannot be overlooked; items like gloves, goggles, and ear protection are essential to ensure personal safety during any hands-on work. Furthermore, having a reliable work surface, such as a sturdy bench or table, can provide stability and facilitate a more organized approach.

Lastly, specialized tools tailored to specific tasks, such as torque wrenches or compression testers, can enhance precision and ensure that each job is performed to the highest standard. Equipping yourself with these essential tools will pave the way for successful and efficient project completion.

Step-by-Step Maintenance Guide

Proper upkeep of small engines is crucial for ensuring longevity and optimal performance. Following a systematic approach to maintenance can help prevent potential issues and enhance efficiency. This guide outlines essential steps to keep your equipment in excellent working condition.

1. Regular Oil Changes: Change the oil every 50 hours of operation or at least once a season. Use the recommended type of lubricant to ensure smooth functioning.

2. Air Filter Inspection: Examine the air filter regularly. Clean or replace it as needed to prevent dirt and debris from entering the engine, which can affect performance.

3. Spark Plug Maintenance: Check the spark plug for wear and carbon buildup. Replace it if necessary to ensure easy starting and efficient combustion.

4. Fuel System Care: Regularly check the fuel lines and filter for leaks or clogs. Drain old fuel at the end of the season to avoid engine problems.

5. Cooling System Check: Inspect the cooling fins and ensure they are clean. Overheating can lead to serious damage, so keep them free from debris.

6. Battery Maintenance: For electric start models, check the battery condition regularly. Keep terminals clean and ensure a secure connection to avoid starting issues.

7. Belts and Cables Inspection: Regularly examine belts for wear and tension, and check cables for fraying or damage. Replace as necessary to maintain optimal function.

By adhering to these straightforward steps, you can significantly enhance the lifespan and reliability of your machinery. Consistent attention to maintenance not only prevents unexpected breakdowns but also contributes to better overall performance.

Identifying Engine Noises and Solutions

Understanding unusual sounds from an engine is crucial for maintaining optimal performance and preventing further damage. Recognizing these noises can help diagnose potential issues early, ensuring longevity and reliability. This section will guide you through common sounds, their meanings, and suggested remedies.

- Knocking or Pinging:

This sound often indicates improper fuel combustion. It may arise from low-quality fuel or incorrect timing.

- Check fuel quality and consider switching to a higher octane.

- Inspect the ignition timing and adjust if necessary.

- Hissing or Whistling:

A hissing sound can point to a vacuum leak or a problem with the exhaust system.

- Examine hoses and connections for wear or damage.

- Inspect the exhaust for leaks or loose fittings.

- Grinding:

Grinding noises may suggest worn bearings or internal components that need attention.

- Check oil levels and quality; replace if contaminated.

- Consult a technician to assess internal components if necessary.

- Rattling:

This sound could be caused by loose parts or components that are not securely fastened.

- Inspect all external components and tighten any loose bolts.

- Listen for changes in sound when the engine is revved; this can indicate specific areas to check.

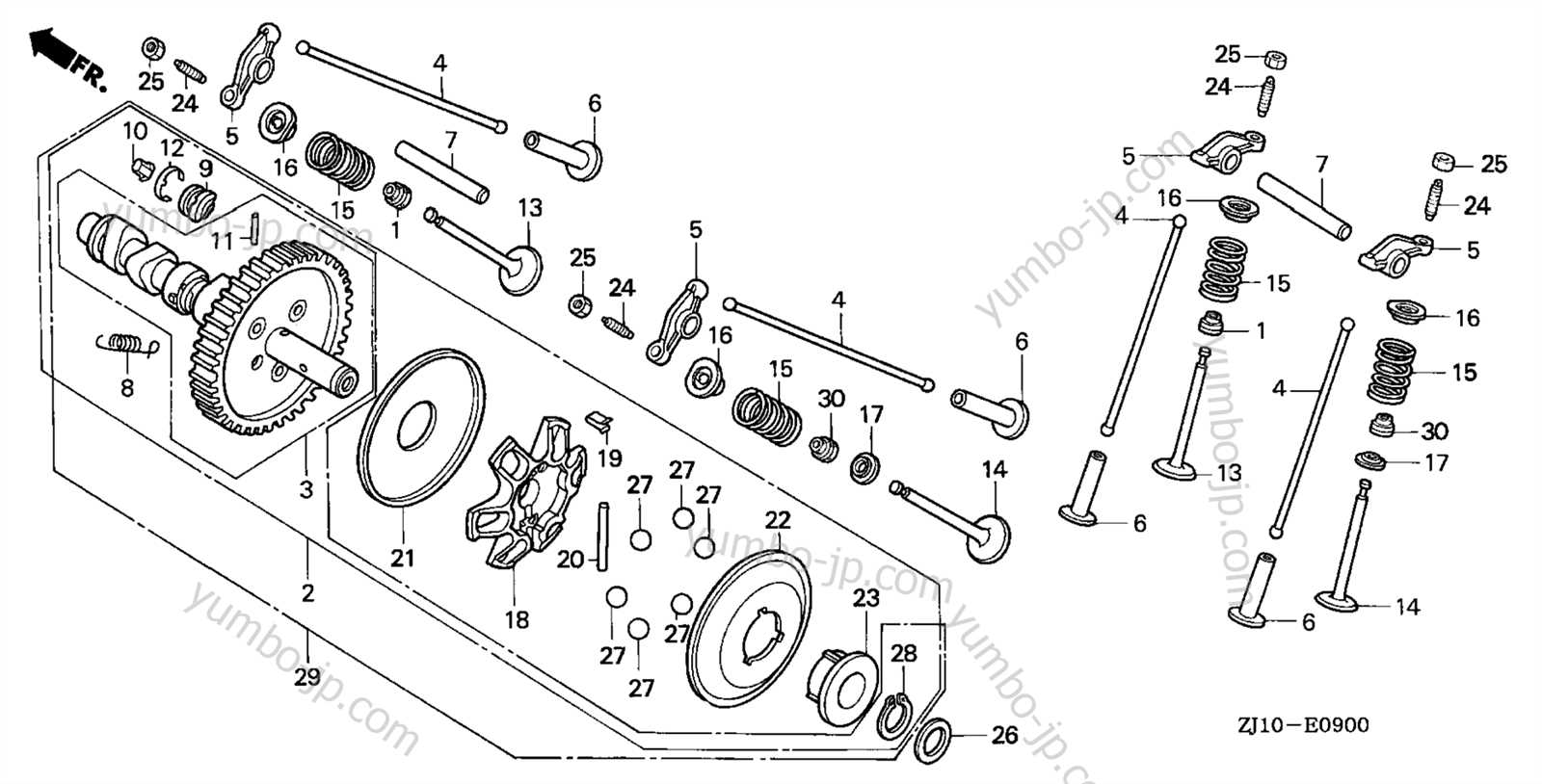

- Ticking:

A ticking noise might be linked to valve clearance or insufficient lubrication.

- Check the oil level and change if it is low or dirty.

- Adjust valve clearance as per specifications if necessary.

phpCopy code

By being attentive to these sounds and their implications, you can take proactive measures to address issues before they escalate, ensuring a smoother and more efficient operation.

Replacing Spark Plugs: A Quick Guide

Changing spark plugs is an essential maintenance task that can significantly improve engine performance. This procedure ensures that your engine runs smoothly, providing better fuel efficiency and reducing emissions. Following a systematic approach will make the process straightforward and effective.

Tools and Materials Needed

- New spark plugs

- Socket wrench

- Torque wrench

- Spark plug gap tool

- Anti-seize compound (optional)

Steps to Replace Spark Plugs

- Ensure the engine is cool before starting the replacement process.

- Locate the spark plug wires or coils and carefully remove them.

- Using the socket wrench, loosen and remove the old spark plugs.

- Inspect the old plugs for wear and deposits, which can indicate engine issues.

- Prepare the new plugs by checking the gap with a gap tool and adjusting as necessary.

- Apply a small amount of anti-seize compound to the threads of the new plugs if desired.

- Insert the new plugs and tighten them to the manufacturer’s specified torque using the torque wrench.

- Reconnect the spark plug wires or coils securely.

By following these steps, you can enhance the performance and longevity of your engine, ensuring it runs at its best for years to come.

Fuel System Troubleshooting Techniques

Diagnosing issues within the fuel system is essential for optimal performance and longevity of the engine. Understanding the common symptoms and implementing effective techniques can help identify and resolve problems efficiently. This section outlines various methods to troubleshoot fuel system complications.

Begin with a systematic approach to assess the situation:

- Visual Inspection:

- Check for leaks in fuel lines and connections.

- Examine the condition of fuel filters for blockages.

- Inspect the fuel tank for debris or contamination.

- Fuel Quality Assessment:

- Ensure the fuel used is appropriate and fresh.

- Look for signs of water or sediment in the fuel.

- Pressure Testing:

- Use a pressure gauge to evaluate the fuel pump’s performance.

- Check for consistent pressure in the fuel lines.

- Component Functionality Check:

- Test the fuel pump operation for proper activation.

- Verify the functionality of injectors or carburetor components.

By following these troubleshooting techniques, you can effectively identify and address fuel system issues, ensuring smooth operation and enhancing engine reliability.

Cooling System Maintenance Tips

Proper upkeep of the cooling system is essential for optimal engine performance and longevity. Ensuring that this system functions effectively prevents overheating and maintains the ideal operating temperature. Regular inspections and timely interventions can significantly enhance reliability and efficiency.

Start by checking the coolant level frequently. Low coolant can lead to severe overheating issues. If the level is low, replenish it with the appropriate mixture of coolant and water, adhering to the manufacturer’s specifications. Additionally, inspect for leaks around hoses and connections, as even small leaks can compromise the system’s performance.

It’s also crucial to flush the cooling system periodically. This process removes any sediment or rust that may have accumulated, which can hinder heat transfer. Follow the recommended flushing intervals and use high-quality flushing agents to ensure a thorough cleanse.

Another key aspect is examining the radiator for any obstructions. Dirt and debris can block airflow, leading to inefficient cooling. Regularly cleaning the exterior of the radiator, especially in dusty environments, helps maintain optimal airflow.

Lastly, pay attention to the thermostat and water pump. Ensure they are functioning correctly, as a faulty thermostat can disrupt temperature regulation, and a malfunctioning water pump may prevent coolant circulation. Replacing these components as needed will help ensure the cooling system operates smoothly.

Battery and Electrical System Checks

Regular inspection of the battery and electrical components is crucial for ensuring optimal performance and longevity of the machinery. A thorough assessment can help identify potential issues early, preventing costly repairs and downtime. This section outlines essential checks to maintain the electrical system’s reliability.

Battery Inspection

Start by examining the battery for any signs of corrosion, leaks, or physical damage. Ensure that the terminals are clean and securely connected. A weak or discharged battery can lead to starting difficulties and operational failures.

Electrical System Assessment

Next, evaluate the entire electrical system, including wiring and connections. Look for frayed wires, loose connections, or any other irregularities. It is also important to check the fuses and relays for continuity and proper functionality.

| Component | Check Method | Expected Result |

|---|---|---|

| Battery Terminals | Visual Inspection | No corrosion, tight connections |

| Battery Voltage | Multimeter Measurement | 12.6V or above |

| Wiring | Visual Inspection | No frays or breaks |

| Fuses | Continuity Test | Fuse intact |

Transmissions: Common Problems and Fixes

Transmissions are essential components that facilitate power transfer from the engine to the wheels. Issues in this system can lead to significant performance degradation, making it crucial to identify and address them promptly. Understanding common challenges and their solutions can help maintain optimal functionality and extend the lifespan of the equipment.

Common Issues

- Slipping Gears: This problem often manifests as difficulty in maintaining gear engagement, causing sudden changes in speed.

- No Response: A complete lack of movement when the throttle is applied may indicate a failure in the transmission system.

- Fluid Leaks: Observing fluid puddles underneath the equipment can signal leaks that need immediate attention.

- Unusual Noises: Grinding or whining sounds can indicate internal wear or damage within the transmission.

Potential Solutions

- Check and Replace Fluid: Ensuring that the transmission fluid is at the correct level and is free from contaminants can prevent many issues.

- Inspect for Leaks: Identifying the source of any leaks and sealing them can prevent further damage.

- Adjust Linkages: Properly aligning and adjusting the transmission linkages can resolve issues with slipping gears.

- Professional Assessment: In cases of unusual noises or no response, consulting a specialist for a thorough examination is recommended.

Lubrication: Importance and Methods

Proper lubrication is crucial for the longevity and efficiency of any engine. It reduces friction between moving parts, minimizes wear, and helps in dissipating heat. By ensuring that components are adequately lubricated, one can enhance performance and prevent potential failures, thereby extending the lifespan of the machinery.

Importance of Lubrication

Effective lubrication plays several vital roles:

- Friction Reduction: It creates a film between surfaces, reducing direct contact and wear.

- Heat Dissipation: Lubricants carry away heat generated during operation, preventing overheating.

- Contaminant Removal: Lubricants can help trap and carry away debris and contaminants from surfaces.

- Corrosion Prevention: Many lubricants contain additives that protect against rust and corrosion.

Methods of Lubrication

There are various methods to ensure adequate lubrication:

- Manual Lubrication: This involves periodically applying lubricant to specific points as recommended by the manufacturer.

- Automatic Lubrication Systems: These systems provide a continuous supply of lubricant to critical areas, reducing the need for manual intervention.

- Splash Lubrication: In this method, moving parts dip into a reservoir of lubricant, distributing it as the components move.

- Pressurized Lubrication: This method uses pumps to deliver lubricant to various parts under pressure, ensuring thorough coverage.

Regular maintenance and proper lubrication techniques are essential for maintaining peak performance and avoiding costly repairs.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is essential to prevent accidents and injuries. Following proper guidelines not only protects the individual performing the work but also preserves the integrity of the equipment being serviced. Awareness of potential hazards and adherence to safety measures can significantly reduce risks.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is crucial in minimizing exposure to potential dangers. This includes wearing gloves, goggles, and masks, which serve as barriers against harmful substances and debris.

Workspace Organization

Maintaining a tidy and organized workspace contributes to safety. Ensuring tools are stored properly and walkways are clear helps prevent trips and falls, while a well-lit area enhances visibility during tasks.

| Type of Equipment | Recommended PPE |

|---|---|

| Power Tools | Gloves, Goggles, Ear Protection |

| Chemicals | Gloves, Masks, Protective Clothing |

| Heavy Machinery | Steel-Toed Boots, Hard Hats |

Where to Find Genuine Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. Genuine parts provide reliability and compatibility that aftermarket alternatives may not match.

Here are some reliable sources for finding original components:

- Authorized Dealers: Visit official dealerships that specialize in your brand. They typically stock a comprehensive range of genuine parts and have knowledgeable staff to assist you.

- Manufacturer’s Website: Many manufacturers offer online catalogs where you can browse and order parts directly. This ensures you receive the right components for your model.

- Specialty Retailers: Look for stores that focus on equipment and machinery. These retailers often carry a selection of genuine parts and can provide expert advice.

- Online Marketplaces: Websites dedicated to parts sales can be a good resource. Ensure that the sellers have a solid reputation for providing authentic items.

- Local Repair Shops: Some repair shops may sell genuine parts or can order them for you. They often have strong connections with suppliers.

By choosing genuine components, you can maintain the integrity and performance of your machinery, ultimately leading to better efficiency and reduced downtime.