Effective management of heavy machinery is crucial for optimal performance and longevity. This section serves as a resource for those seeking guidance on maintaining and troubleshooting a specific model of construction equipment. It encompasses essential practices and insights that can enhance the functionality and efficiency of your machinery.

Understanding the intricacies of equipment upkeep is vital for operators and technicians alike. By delving into the nuances of regular maintenance, users can ensure that their machinery remains in peak condition. This guide not only highlights common issues but also provides practical solutions to enhance operational reliability.

Equipped with the right knowledge and tools, users can navigate the complexities of machinery management with confidence. From routine inspections to addressing potential faults, this resource aims to empower operators, ensuring they can tackle challenges effectively and maintain their equipment’s performance.

Overview of John Deere 210C

This section provides a comprehensive look at a well-regarded machine in the construction and agricultural sectors. Known for its durability and efficiency, this equipment is designed to handle a variety of tasks, making it a popular choice among operators.

Key Features

- Robust engine performance for demanding jobs

- Ergonomic design enhancing operator comfort

- Versatile attachments suitable for multiple applications

- Reliable hydraulic system for smooth operation

Common Applications

- Excavation tasks

- Landscaping projects

- Material handling and transportation

- Site preparation for construction

With its reputation for reliability and versatility, this machine remains a top choice for professionals in various fields, ensuring efficiency and productivity on the job site.

Common Issues and Symptoms

When operating heavy machinery, various challenges may arise that can impact performance and efficiency. Recognizing these frequent problems and their associated signs is crucial for effective troubleshooting and maintenance. Awareness of these symptoms allows operators to address issues promptly, ensuring smooth functionality.

Engine Performance Problems

One of the primary areas of concern involves engine performance. Symptoms such as unusual noises, decreased power output, or difficulties in starting may indicate underlying mechanical issues. Additionally, fluctuations in idle speed or excessive exhaust smoke can suggest problems requiring immediate attention. Regular checks and diagnostics can help identify these complications early.

Hydraulic System Failures

Hydraulic systems are vital for the operation of various functions within the machinery. Common indicators of hydraulic issues include slow response times, leaks, or inconsistent pressure levels. If the hydraulic fluid appears discolored or has a burnt smell, it may signal contamination or overheating. Addressing these signs promptly can prevent more severe damage and costly repairs.

Maintenance Procedures for Optimal Performance

Ensuring the longevity and efficiency of your machinery requires a systematic approach to upkeep. Regular maintenance not only enhances performance but also prevents unexpected breakdowns, saving time and resources. By adhering to scheduled checks and implementing necessary procedures, operators can achieve peak functionality.

Begin with routine inspections of all critical components, including the engine, hydraulic systems, and electrical connections. Look for signs of wear, leaks, or corrosion that could affect operation. Changing fluids and filters at recommended intervals is essential to keep systems running smoothly and to avoid costly repairs down the line.

Additionally, lubrication is vital for moving parts. Regularly greasing joints and bearings minimizes friction and wear, extending the lifespan of mechanical elements. Pay attention to tire pressure and tread depth, as they impact traction and safety during operation.

Finally, maintaining cleanliness is crucial. Keeping the exterior and interior free of dirt and debris helps prevent overheating and improves visibility. By following these procedures diligently, you can ensure that your equipment operates efficiently and reliably for years to come.

Diagnostic Tools and Techniques

Effective troubleshooting requires the right tools and methods to accurately assess and resolve issues. Understanding various diagnostic instruments and techniques can significantly enhance the efficiency of the maintenance process.

- Multimeter: A versatile instrument for measuring voltage, current, and resistance. It helps identify electrical problems and verify circuit functionality.

- OBD II Scanner: Used for reading error codes from onboard systems. This tool assists in pinpointing faults related to the engine and emissions systems.

- Pressure Gauge: Essential for testing hydraulic systems. It measures fluid pressure, ensuring that systems operate within specified ranges.

- Infrared Thermometer: This non-contact tool helps identify overheating components by measuring surface temperatures, which can indicate issues in various systems.

- Fluid Analysis Kits: Utilized to assess the condition of fluids like oil and coolant. These kits provide insights into wear particles and contamination levels.

Incorporating these tools into routine checks can lead to early detection of potential failures, minimizing downtime and repair costs. Understanding how to effectively use each instrument is crucial for achieving accurate diagnostics.

Engine Troubleshooting Tips

Addressing issues with an engine can often be a daunting task, yet systematic approaches can lead to effective solutions. Understanding common symptoms and their underlying causes is crucial for efficient diagnostics and repair. This section provides essential strategies to identify and resolve engine-related problems.

1. Observe Symptoms: Begin by noting any unusual sounds, vibrations, or performance changes. Pay attention to indicators such as difficulty starting, excessive smoke, or poor acceleration, as these can reveal critical information.

2. Check Fluid Levels: Regularly inspect engine oil, coolant, and fuel levels. Low or contaminated fluids can lead to significant engine issues. Ensure all fluids meet manufacturer specifications for optimal performance.

3. Examine the Battery: A weak or faulty battery is a common cause of starting problems. Test the battery voltage and connections. Corrosion at the terminals can impede electrical flow, leading to unreliable starting.

4. Inspect Belts and Hoses: Worn or damaged belts and hoses can cause overheating or power loss. Regularly check for cracks, fraying, or leaks, and replace any components that show signs of wear.

5. Evaluate the Air Filter: A clogged air filter can restrict airflow, affecting engine performance. Check and clean or replace the air filter as needed to ensure proper combustion.

6. Monitor Exhaust Emissions: Unusual exhaust colors can indicate problems. Blue smoke may suggest oil burning, while black smoke often points to a rich fuel mixture. Investigate the cause to prevent further damage.

7. Utilize Diagnostic Tools: Employing diagnostic equipment can streamline the troubleshooting process. Scan tools can reveal error codes that provide insights into underlying issues, aiding in accurate diagnostics.

By following these guidelines, operators can effectively troubleshoot engine issues, leading to timely interventions and prolonged machinery life.

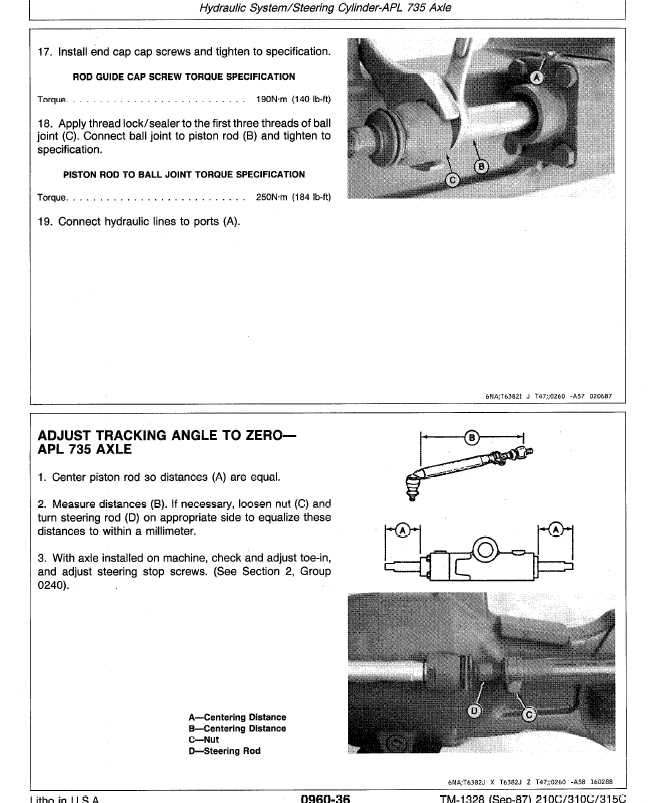

Hydraulic System Repairs Explained

The hydraulic system is a vital component in heavy machinery, relying on fluid power to facilitate movement and operation. Proper understanding and maintenance of this system are essential for ensuring efficiency and preventing costly downtime. This section provides insights into common issues and effective solutions related to hydraulic components.

Common Issues in Hydraulic Systems

Several challenges may arise within hydraulic systems, often manifesting as leaks, decreased pressure, or sluggish performance. Leaks can occur due to wear and tear on seals or hoses, while pressure drops may indicate issues with pumps or filters. Identifying these problems early can help mitigate further damage and ensure optimal functionality.

Effective Troubleshooting Techniques

To address hydraulic malfunctions, start with a thorough inspection of all components, including hoses, fittings, and pumps. Regular maintenance and monitoring of fluid levels can prevent many common issues. For repairs, always refer to comprehensive guidelines specific to the machinery in question to ensure proper techniques are employed. Keeping the hydraulic system in peak condition not only extends its lifespan but also enhances overall operational efficiency.

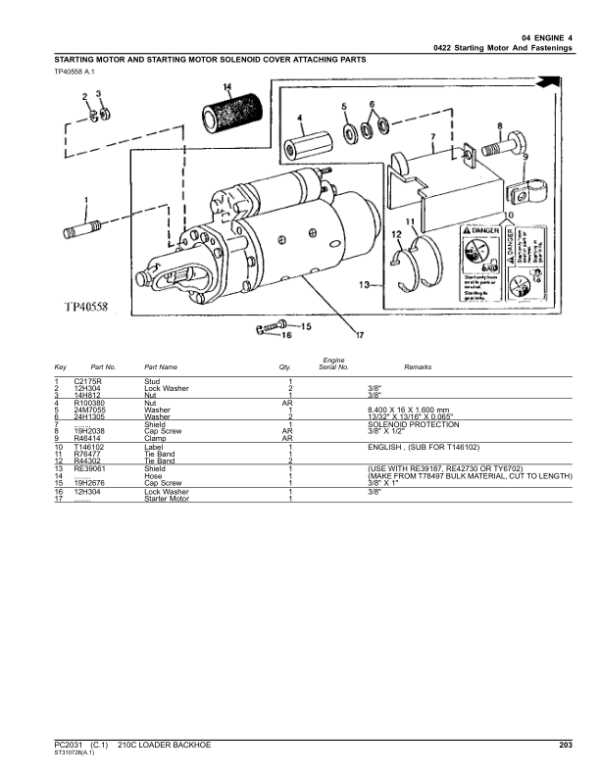

Electrical System Diagnostics

The ability to effectively troubleshoot and analyze the electrical system of machinery is crucial for ensuring optimal performance. A systematic approach to diagnostics can help identify issues early, minimizing downtime and repair costs. This section will outline key steps and techniques for assessing the electrical components and connections.

| Step | Description |

|---|---|

| 1 | Inspect Wiring: Check for frayed wires, loose connections, and signs of corrosion. |

| 2 | Test Voltage: Use a multimeter to measure voltage levels at critical points in the circuit. |

| 3 | Check Grounding: Ensure all ground connections are secure and functioning properly. |

| 4 | Examine Components: Assess fuses, relays, and switches for any signs of malfunction. |

| 5 | Perform Functional Tests: Test the operation of key electrical systems to confirm their functionality. |

By following these steps, operators can effectively pinpoint electrical faults and implement necessary corrections, enhancing the reliability and efficiency of the equipment.

Replacing Worn Components Effectively

Maintaining machinery involves timely substitution of degraded parts to ensure optimal functionality and longevity. Understanding when and how to replace these elements is crucial for efficient operation and performance enhancement.

Identifying wear and tear can often be done through regular inspections. Common signs include unusual noises, decreased performance, and visual damage. Once identified, effective replacement can restore the equipment to its original condition, preventing further issues down the line.

| Component | Signs of Wear | Replacement Tips |

|---|---|---|

| Filters | Reduced efficiency, clogged appearance | Replace regularly according to usage; choose high-quality filters. |

| Belts | Creaking sounds, fraying edges | Inspect tension regularly; replace if more than 50% worn. |

| Seals | Fluid leaks, visible cracks | Ensure proper alignment during installation; use appropriate sealants. |

| Bearings | Excessive vibration, noise | Lubricate regularly; replace in pairs to maintain balance. |

In summary, proactive identification and replacement of worn components can significantly enhance machinery reliability and performance. Regular maintenance checks and adherence to best practices will ensure continued efficiency in operations.

Safety Protocols During Repairs

Ensuring a secure working environment is paramount when conducting maintenance tasks on heavy machinery. Adhering to established safety measures not only protects the individual performing the work but also safeguards the equipment and surrounding personnel. Awareness of potential hazards and the implementation of precautionary steps are essential for a successful operation.

Before initiating any task, it is crucial to familiarize oneself with the equipment and its components. Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and hard hats. Additionally, maintaining a clean workspace reduces the risk of accidents.

| Safety Measure | Description |

|---|---|

| PPE | Always wear gloves, goggles, and hard hats to protect against injuries. |

| Workspace Organization | Keeps tools and materials neatly arranged to minimize tripping hazards. |

| Proper Training | Ensure that all personnel are trained in safe operation practices. |

| Lockout/Tagout | Implement procedures to ensure machinery is properly shut down before maintenance begins. |

Following these protocols not only enhances safety but also promotes efficiency during the maintenance process. Regularly reviewing and updating safety measures is essential to adapt to new challenges and maintain a secure working environment.

Resources for Parts and Service

Finding reliable sources for components and support is crucial for maintaining the functionality and longevity of your machinery. Accessing the right information can significantly enhance your repair experience and ensure that your equipment runs smoothly. Below are various resources that can assist you in sourcing parts and obtaining expert service.

Online Retailers

- Websites specializing in heavy equipment parts offer a vast selection of components at competitive prices.

- Many online marketplaces provide user reviews, which can help in selecting trustworthy sellers.

- Manufacturer websites often have sections dedicated to parts catalogs and ordering information.

Local Dealers and Service Centers

- Authorized dealerships can provide OEM (Original Equipment Manufacturer) parts, ensuring compatibility and quality.

- Local service centers often have trained technicians who are familiar with specific machinery models and can offer reliable repairs.

- Many dealers also offer maintenance services, which can be invaluable for routine check-ups.