Owning a robust vehicle involves not just the thrill of driving but also the responsibility of its upkeep. Understanding the intricacies of your automobile can significantly enhance its longevity and performance. This section delves into the essential practices for maintaining a specific model, offering insights and guidance to ensure optimal operation.

From routine inspections to addressing specific issues, effective maintenance is paramount. It encompasses everything from understanding the fundamental components to troubleshooting common problems that may arise over time. By following systematic procedures and utilizing the right resources, owners can navigate their vehicle’s needs with confidence.

Equipping oneself with the necessary knowledge not only empowers owners but also fosters a deeper connection with their automobile. Whether you’re a novice or an experienced enthusiast, this comprehensive guide serves as an invaluable resource, enabling you to tackle maintenance tasks efficiently and effectively.

Overview of 1998 Chevrolet Blazer

This section provides a comprehensive examination of a versatile vehicle known for its robust performance and reliable design. It combines practicality with a touch of style, making it a popular choice among enthusiasts and everyday drivers alike. This model exemplifies a blend of functionality and comfort, appealing to a wide range of users.

| Feature | Description |

|---|---|

| Engine Options | Available with various engine configurations, delivering a balance of power and efficiency. |

| Transmission | Equipped with both manual and automatic transmission options for enhanced driving experience. |

| Interior Comfort | Designed with spacious seating and quality materials, ensuring comfort during long journeys. |

| Safety Features | Incorporates multiple safety systems aimed at providing peace of mind on the road. |

| Off-Road Capability | Offers features that enhance its ability to navigate rough terrains effectively. |

This vehicle’s reputation for durability and versatility has secured its place as a favorite among users who require both capability and style in their driving experience.

Common Issues and Solutions

This section addresses frequent challenges encountered by vehicle owners and provides effective resolutions. Understanding these typical problems can help ensure optimal performance and longevity of your automobile.

Electrical System Troubles

Electrical malfunctions can significantly impact vehicle functionality. Symptoms may include dimming lights, non-responsive accessories, or starting difficulties. These issues often stem from battery depletion, corroded connections, or faulty alternators.

Cooling System Failures

Overheating is a common concern, often caused by a malfunctioning radiator, thermostat issues, or coolant leaks. Addressing these problems promptly can prevent severe engine damage.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Electrical Failure | Dead battery, corroded terminals | Check connections, replace battery if necessary |

| Overheating | Coolant leaks, faulty radiator | Inspect for leaks, replace thermostat or radiator |

| Transmission Problems | Fluid leaks, worn components | Check fluid levels, consult a technician for repairs |

Essential Tools for Repairs

Having the right equipment is crucial for performing effective maintenance and fixing any issues that may arise. The following tools are fundamental for anyone looking to undertake mechanical tasks, ensuring efficiency and safety during the process.

1. Wrenches: A variety of wrenches, including adjustable and socket types, are essential for loosening or tightening bolts and nuts of different sizes. Having a complete set allows for greater flexibility and ease when tackling various components.

2. Screwdrivers: A selection of screwdrivers, both flathead and Phillips, is necessary for working on different screws. Magnetic tips can enhance convenience, preventing dropped screws from getting lost in hard-to-reach areas.

3. Pliers: Pliers are versatile tools used for gripping, twisting, and cutting. A good pair of needle-nose pliers can be particularly useful for accessing tight spaces, while standard pliers provide strength for larger tasks.

4. Jack and Stands: A reliable jack is critical for lifting vehicles, enabling access to the undercarriage. Pairing this with sturdy stands ensures safety while working beneath the vehicle, preventing accidental collapses.

5. Diagnostic Tools: Investing in diagnostic equipment, such as OBD-II scanners, aids in identifying issues within the vehicle’s systems. This technology streamlines the troubleshooting process, allowing for quicker resolutions.

6. Safety Gear: Personal protective equipment, including gloves, goggles, and ear protection, is vital. These items safeguard against injuries while working on mechanical tasks, promoting a safe working environment.

Equipping yourself with these essential tools prepares you for a variety of tasks, enhancing your ability to maintain and improve vehicle performance effectively.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring optimal performance and longevity of your vehicle. By following a systematic process for upkeep, you can enhance reliability and prevent potential issues before they arise. Regular attention to various components not only keeps your ride smooth but also saves on costly repairs down the line.

| Task | Frequency | Notes |

|---|---|---|

| Check oil level | Monthly | Ensure oil is at the recommended level; replace if dirty. |

| Inspect tires | Monthly | Look for wear and maintain proper pressure. |

| Replace air filter | Every 12,000 miles | Improves engine efficiency; replace sooner if driving in dusty conditions. |

| Check brakes | Every 6,000 miles | Inspect pads and rotors for wear; replace if necessary. |

| Flush coolant | Every 30,000 miles | Prevents overheating; use the manufacturer’s recommended fluid. |

| Inspect battery | Every 3 months | Check terminals for corrosion; ensure charge is adequate. |

By adhering to this structured schedule, you will not only enhance your vehicle’s performance but also ensure safety during your travels. Taking the time to regularly check and maintain various systems will yield long-term benefits and reliability.

Understanding Engine Specifications

This section delves into the essential characteristics and parameters that define an engine’s performance and efficiency. By examining these specifications, one can gain valuable insights into how an engine operates, its capabilities, and its limitations. Understanding these elements is crucial for both maintenance and enhancement of vehicle functionality.

Key Components and Their Functions

Engines are complex systems comprised of various components, each serving a specific role in overall operation. The cylinder configuration, for instance, determines the engine’s power output and smoothness of operation. Additionally, the displacement directly influences the torque and horsepower available, which are critical for performance. Knowledge of these components aids in troubleshooting and optimizing engine functionality.

Performance Metrics

Performance metrics such as horsepower and torque are vital indicators of an engine’s capabilities. Horsepower reflects the engine’s ability to perform work over time, while torque measures the rotational force available for acceleration. Together, these metrics provide a comprehensive view of the vehicle’s performance, helping enthusiasts make informed decisions regarding upgrades or modifications.

Transmission Troubleshooting Techniques

Addressing issues related to the shifting mechanism can often be challenging. Understanding the symptoms and employing systematic methods can significantly aid in identifying the root cause of the problem. This section outlines effective approaches to diagnose common complications that may arise in the transmission system.

Initial Inspection: Begin by examining fluid levels and condition. Low or contaminated fluid can lead to inadequate performance and shifting problems. Check for leaks around the transmission casing and hoses, as well as any signs of damage or wear.

Diagnostic Tools: Utilize diagnostic equipment to retrieve error codes from the onboard computer. These codes can provide valuable insights into electronic issues or sensor failures affecting the transmission’s operation.

Test Drive: Conduct a test drive to observe shifting behavior under various conditions. Pay attention to any unusual noises, slipping, or delayed engagement when changing gears. This firsthand experience can help pinpoint specific issues.

Check Electrical Connections: Inspect wiring and connectors related to the transmission control module. Corroded or loose connections can disrupt communication, leading to malfunctioning systems.

Component Evaluation: If issues persist, consider assessing individual components such as the solenoids, clutch packs, and valve body. Testing these parts for proper operation can reveal underlying faults that need to be addressed.

By applying these troubleshooting techniques, one can effectively narrow down the causes of transmission problems and take appropriate corrective actions to ensure optimal performance.

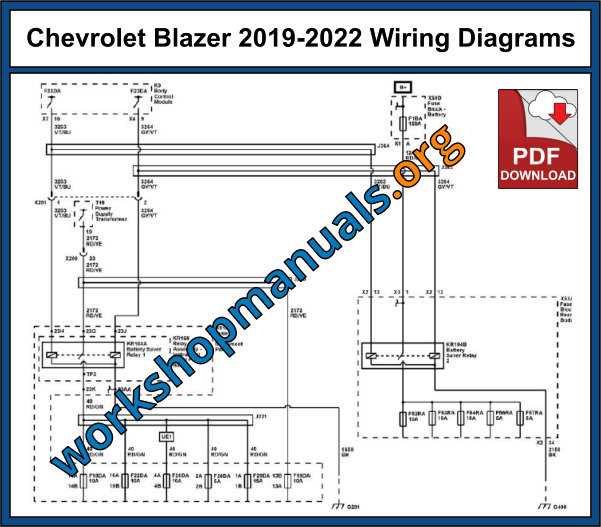

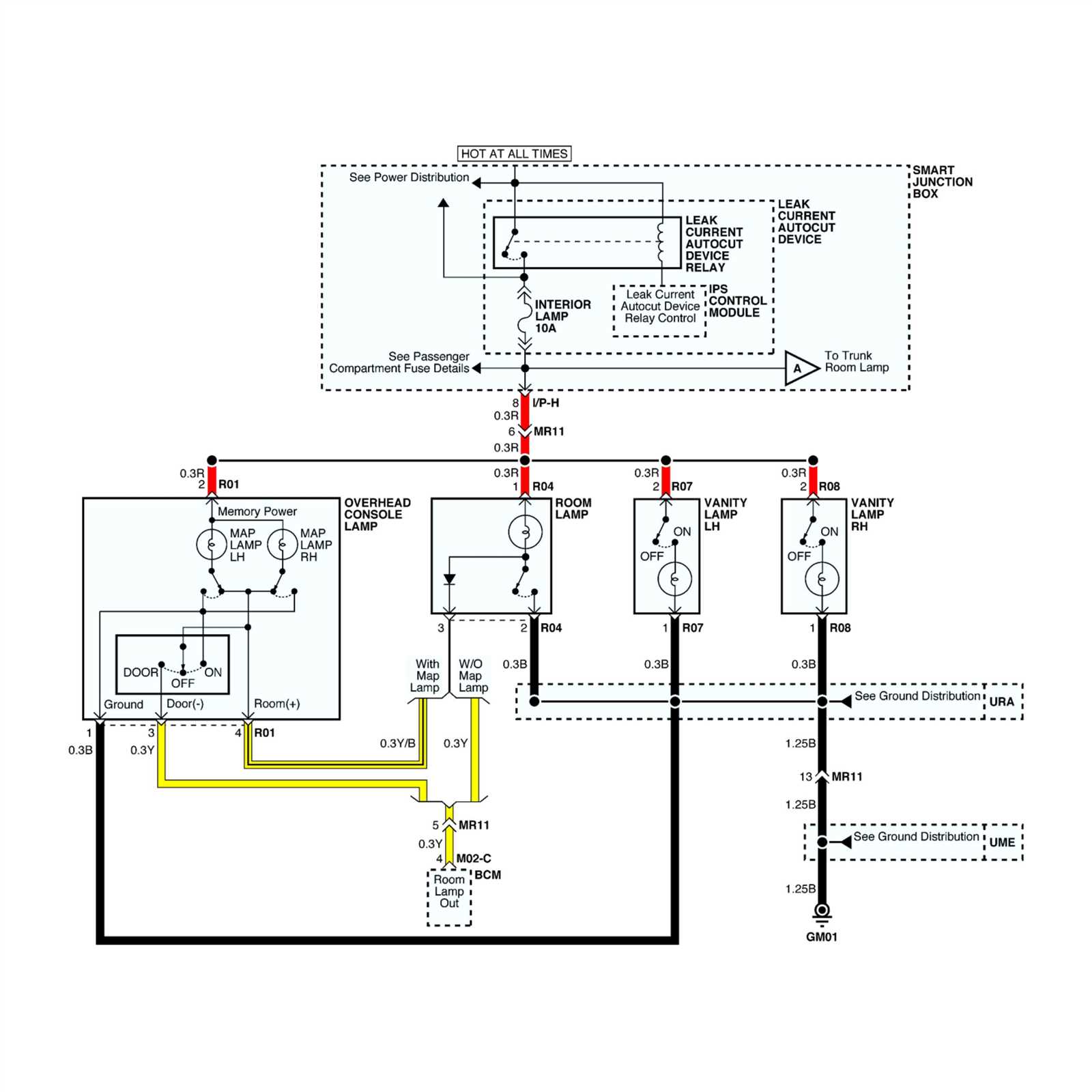

Electrical System Diagnostics

Diagnosing electrical issues is crucial for maintaining optimal vehicle performance. This process involves identifying and troubleshooting problems within the electrical network that can lead to malfunctions or inefficiencies. A systematic approach ensures that issues are addressed effectively, minimizing downtime and repair costs.

Common Electrical Problems

Several frequent issues may arise within the electrical system. These can include faulty wiring, blown fuses, or malfunctioning components. Identifying these problems often requires a thorough inspection and the use of diagnostic tools. Testing the battery and alternator performance is essential, as these components are vital for the overall function of the system.

Diagnostic Procedures

To effectively diagnose electrical issues, follow these procedures: begin with a visual inspection of the wiring and connections for signs of wear or damage. Next, utilize a multimeter to check voltage levels and continuity. Systematic testing of individual components can pinpoint the source of the malfunction. Documenting findings throughout the process is recommended for reference and further analysis.

Suspension and Steering Insights

The suspension and steering systems are vital components that significantly influence vehicle handling and comfort. Understanding their intricacies can enhance performance and prolong the lifespan of the vehicle. This section explores essential elements, maintenance tips, and common issues associated with these systems.

Key Components

- Shocks and Struts: Responsible for absorbing road impacts, these elements maintain ride quality and stability.

- Control Arms: These provide the connection between the vehicle body and the suspension system, allowing for proper wheel movement.

- Steering Rack: This component converts the rotational motion of the steering wheel into lateral movement of the wheels.

- Ball Joints: These pivot points allow for flexible movement and support the weight of the vehicle.

Maintenance Tips

- Regular Inspections: Periodically check for signs of wear and tear, such as leaks or unusual noises.

- Tire Alignment: Ensure wheels are aligned correctly to prevent uneven tire wear and enhance handling.

- Fluid Levels: Keep an eye on power steering fluid levels and top up as necessary to ensure smooth operation.

- Replace Worn Parts: Address any worn components promptly to maintain optimal performance and safety.

Braking System Maintenance Tips

Ensuring the longevity and effectiveness of your vehicle’s stopping mechanism is crucial for safety and performance. Regular upkeep not only enhances braking efficiency but also prevents costly repairs down the line. Here are some essential guidelines to maintain optimal functionality.

Regular Inspections: Routinely check the brake components, including pads, rotors, and calipers. Look for signs of wear or damage, as early detection can save you from more significant issues.

Fluid Checks: Monitor the brake fluid level frequently. Low fluid can indicate leaks or worn components, and maintaining the correct level is vital for the system’s efficiency.

Brake Pad Replacement: Replace brake pads when they show signs of thinning or when a squeaking noise occurs. Keeping fresh pads ensures maximum grip and minimizes rotor wear.

Clean Components: Periodically clean brake parts to remove dust and debris. This helps prevent build-up that can lead to reduced performance or premature wear.

Professional Servicing: Consider having a professional technician perform a complete system check periodically. Their expertise can identify underlying problems that may not be visible during a casual inspection.

Adhering to these maintenance tips will help keep your vehicle’s stopping system in top condition, ensuring safe and reliable performance on the road.

Resources for Parts and Accessories

Finding the right components and add-ons for your vehicle can enhance both performance and aesthetic appeal. Whether you are looking for replacement parts or upgrades, a variety of sources are available to meet your needs. Exploring different options will ensure you find quality items at competitive prices.

Online Retailers

Numerous online platforms offer a wide selection of parts and accessories. Websites specializing in automotive supplies often provide detailed catalogs, allowing you to search for specific items easily. Look for vendors with customer reviews to gauge the reliability of their products and services. Additionally, many sites offer competitive pricing and frequent discounts, making it an economical choice.

Local Auto Parts Stores

Visiting local suppliers can be beneficial for immediate needs. Brick-and-mortar stores typically carry a range of components and accessories, and the advantage of in-person shopping allows for personal assistance. Knowledgeable staff can help you identify the right items for your vehicle. Moreover, purchasing locally supports the community and may offer a chance for convenient returns or exchanges.