Maintaining outdoor equipment is crucial for ensuring longevity and optimal performance. This guide offers essential insights into addressing common issues that may arise during operation. By understanding the intricacies of your equipment, you can enhance its efficiency and reliability.

In this resource, you will discover various techniques for diagnosing problems and executing repairs effectively. Whether you are facing minor glitches or more significant malfunctions, our detailed instructions aim to empower you with the knowledge needed to tackle challenges confidently.

With a focus on practical solutions, this guide emphasizes the importance of regular upkeep and preventive measures. By implementing the strategies outlined here, you can ensure that your equipment remains in peak condition, ready to assist you in all your outdoor tasks.

Understanding the Ryobi SS30 Model

This section provides insights into a versatile outdoor power tool designed for efficiency and ease of use. Users often seek a reliable solution for various yard maintenance tasks, and this particular device meets those demands with a blend of power and convenience.

Key Features: One of the standout characteristics of this model is its lightweight design, which enhances maneuverability. This aspect allows for comfortable operation over extended periods, making it suitable for both casual gardeners and professional landscapers alike.

Performance: Equipped with a robust engine, this tool delivers sufficient power to handle tough vegetation. Its cutting capabilities ensure that users can achieve a clean and precise finish, contributing to the overall aesthetics of the outdoor space.

Maintenance: Regular upkeep is essential for optimal performance. Understanding the basic components and their functions will aid in troubleshooting and prolonging the lifespan of the tool. Familiarity with the operating principles can enhance user experience and efficiency.

Overall, this power tool stands out in the market for its practicality and effectiveness, making it a preferred choice for those looking to maintain their gardens or lawns with ease.

Common Issues with Ryobi SS30

When operating a versatile outdoor tool, users may encounter a variety of challenges that can hinder performance. Understanding these common problems can help in diagnosing and resolving them efficiently.

Here are some frequent issues faced by users:

- Starting Difficulties: Many users report trouble getting the device to start, which may stem from fuel-related issues or spark plug malfunctions.

- Power Loss: A significant drop in power during operation can occur due to clogged filters or a malfunctioning carburetor.

- Excessive Vibration: Unusual shaking can indicate an imbalance in the cutting attachment or worn-out components.

- Overheating: Extended use without proper cooling can lead to overheating, often caused by blocked air vents.

- String Feed Problems: Issues with the line feeding mechanism may arise, leading to frustrating interruptions during work.

Identifying these problems early can facilitate quicker solutions and ensure optimal functionality during use.

Essential Tools for Repair

Having the right instruments on hand is crucial for maintaining and restoring outdoor equipment effectively. A well-equipped toolkit not only simplifies the process but also enhances the outcome of any maintenance tasks. Understanding which tools are essential can make a significant difference in efficiency and success.

Basic Hand Tools are fundamental for most tasks. A quality set of screwdrivers, wrenches, and pliers is indispensable. These tools allow for easy assembly and disassembly, enabling quick access to various components. Investing in a reliable toolbox will keep everything organized and readily available.

Power Tools can also be beneficial, especially for more extensive projects. A cordless drill or impact driver can significantly speed up the process, making it easier to handle stubborn screws and bolts. Ensure you have the appropriate bits and attachments to match the tasks at hand.

Safety Equipment should never be overlooked. Items like gloves, goggles, and ear protection are essential for personal safety. Working with machinery can pose risks, and being prepared with the right protective gear is a vital part of any task.

Lastly, having a multimeter or diagnostic tool is invaluable for troubleshooting electrical issues. These devices can help identify problems quickly, allowing for efficient corrections and minimizing downtime.

Equipped with these essential instruments, tackling any maintenance challenge becomes a more manageable and rewarding experience.

Step-by-Step Disassembly Guide

This section provides a comprehensive procedure for dismantling a garden tool effectively. Following these instructions will ensure that each component is accessed safely, allowing for thorough inspection or maintenance. Careful attention to detail during this process can prevent damage and facilitate reassembly.

Tools Required

| Tool | Description |

|---|---|

| Screwdriver | A flat-head and a Phillips screwdriver are essential for removing screws. |

| Wrench | A set of wrenches will help in loosening nuts and bolts. |

| Pliers | Used for gripping and pulling components apart. |

| Safety Gloves | To protect your hands from sharp edges and debris. |

Disassembly Steps

Begin by ensuring the device is disconnected from any power source. Remove any attachments or accessories that may interfere with disassembly. Next, locate the screws or fasteners that hold the outer casing together and carefully unscrew them using the appropriate screwdriver. Once the casing is removed, inspect internal components for additional screws or clips that may require removal. Take note of the order of disassembly, as this will aid in reassembly later. After all necessary parts are freed, gently detach them, ensuring no components are damaged in the process. Finally, place all removed parts in an organized manner for easy access during reassembly.

Inspecting the Fuel System

Evaluating the fuel system is essential for ensuring optimal performance and reliability of small engine equipment. This process involves checking various components that deliver fuel from the tank to the combustion chamber. A thorough inspection can help identify potential issues that may affect efficiency or cause operational failures.

Start by examining the fuel tank for any signs of contamination or leaks. Ensure the tank is clean and free from debris that could obstruct fuel flow. Next, inspect the fuel lines for cracks, wear, or blockages, as these can restrict fuel delivery. Replacing any damaged lines is crucial for maintaining proper functionality.

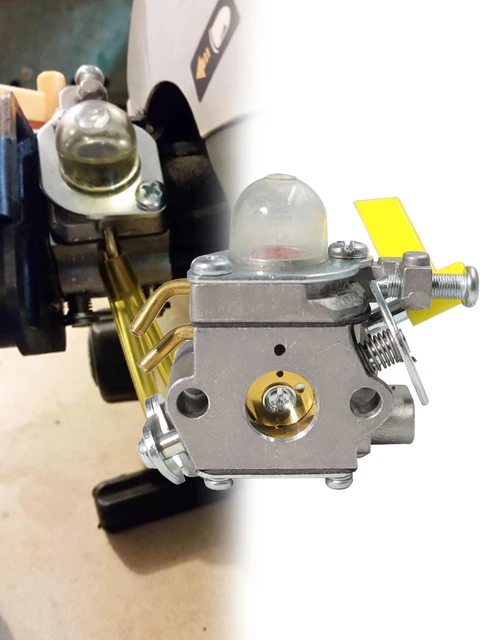

Don’t forget to assess the fuel filter, as a clogged filter can hinder performance. If necessary, clean or replace it to ensure a steady flow of fuel. Additionally, check the carburetor for any signs of dirt or residue that could disrupt the mixture of air and fuel. Proper maintenance of these components can lead to smoother operation and extend the lifespan of the equipment.

How to Replace the Spark Plug

Replacing the spark plug is an essential maintenance task that ensures optimal performance of your outdoor equipment. A worn or faulty spark plug can lead to difficulties in starting the engine and decreased efficiency. This guide will walk you through the steps needed to successfully change the spark plug, enhancing the reliability and longevity of your machine.

Before you begin, gather the necessary tools and materials. You will need a new spark plug, a spark plug socket or wrench, a gap gauge, and possibly a torque wrench for proper installation. Ensure that your equipment is turned off and cooled down before starting the procedure.

| Step | Description |

|---|---|

| 1 | Locate the spark plug. It is typically found on the engine’s cylinder head, often covered by a boot. |

| 2 | Remove the boot carefully to expose the spark plug. Take care not to damage any surrounding components. |

| 3 | Use the spark plug socket or wrench to unscrew the old spark plug. Turn counterclockwise to remove it. |

| 4 | Check the gap on the new spark plug using the gap gauge. Adjust if necessary to meet the manufacturer’s specifications. |

| 5 | Install the new spark plug by hand to avoid cross-threading, then tighten it securely with the socket or wrench. |

| 6 | Reattach the boot, ensuring a snug fit to establish a good connection. |

By following these steps, you can easily replace the spark plug and improve the functionality of your equipment. Regular checks and replacements will contribute to smoother operation and extend the life of your machine.

Maintaining the Cutting Head

Proper upkeep of the cutting head is essential for ensuring optimal performance and longevity of your equipment. Regular attention to this component can enhance cutting efficiency and minimize wear and tear, ultimately saving time and resources. This section outlines key practices to keep your cutting apparatus in top condition.

Cleaning the Cutting Head

Regular cleaning is crucial for maintaining functionality. Dirt and debris can accumulate, affecting performance. Follow these steps for effective cleaning:

- Turn off the equipment and disconnect the power source.

- Remove any grass clippings or debris from the cutting head.

- Use a soft brush or compressed air to clear hard-to-reach areas.

- Inspect for any signs of damage or wear while cleaning.

Inspecting and Replacing Blades

Keeping blades sharp is vital for efficient cutting. Dull blades can strain the motor and reduce effectiveness. Consider the following:

- Check the sharpness of the blades regularly.

- Replace blades that show signs of significant wear or damage.

- Ensure proper alignment of the blades during installation to prevent uneven cuts.

- Store replacement blades in a dry place to avoid rust.

By adhering to these maintenance practices, you can prolong the life of the cutting head and maintain high performance standards in your equipment.

Troubleshooting Electrical Components

This section aims to assist users in identifying and resolving issues related to the electrical parts of their device. Understanding the common problems and their solutions can enhance performance and ensure longevity.

Identifying Common Issues

When encountering difficulties, the first step is to examine the power source. Check connections, ensuring they are secure and free from corrosion. Additionally, inspect the cables for any signs of damage or wear. These basic checks can often reveal the root cause of the malfunction.

Testing Electrical Parts

Utilize a multimeter to assess the functionality of various components. By measuring voltage and continuity, you can determine if the elements are operational. If a part fails to meet the specified readings, it may require replacement. Always consult the specifications to ensure compatibility with the existing setup.

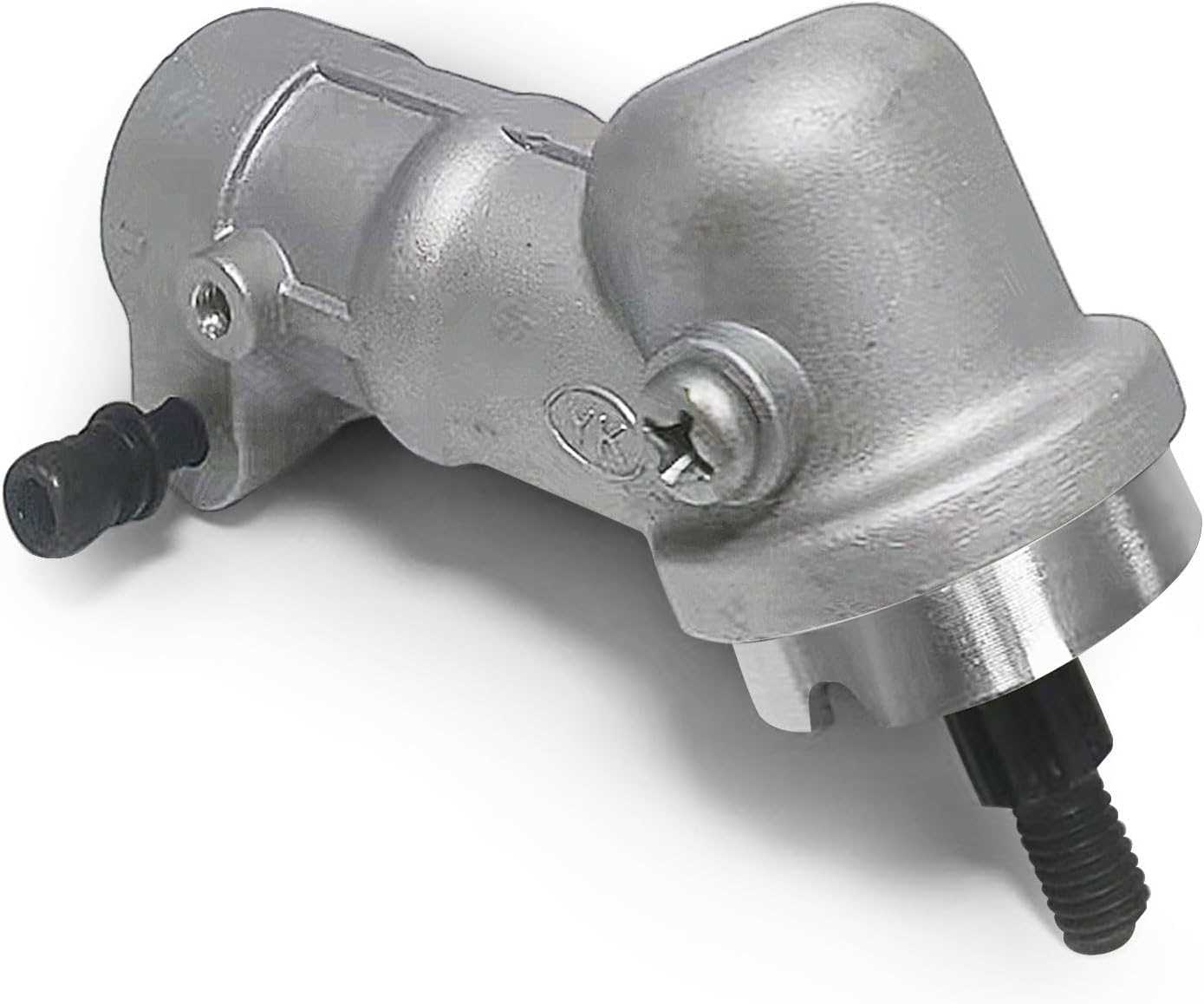

Reassembling the Ryobi SS30

Reassembly of this device requires careful attention to detail to ensure optimal functionality. Following a systematic approach will facilitate a smoother process and help avoid common pitfalls.

Begin by gathering all the components and tools necessary for the task. It is essential to have a clean workspace to keep track of all parts. Here’s a step-by-step guide:

- Start with the main housing and ensure all internal components are properly aligned.

- Secure any loose parts with appropriate fasteners, making sure not to overtighten.

- Reattach any covers or protective elements, ensuring they fit snugly.

- Reinstall any external accessories, checking for compatibility.

- Finally, conduct a thorough inspection to confirm everything is in place and functioning correctly.

After reassembling, it’s advisable to perform a test run to verify that the device operates as intended. This ensures all components are correctly positioned and the unit is ready for use.

Testing After Repairs

Once modifications have been made to the equipment, it is crucial to ensure that everything is functioning correctly. This phase involves a series of assessments to verify that all adjustments have been successful and that the device operates as intended. Comprehensive testing not only guarantees performance but also enhances safety and reliability for future use.

Initial Functionality Check

The first step in the testing process involves conducting a basic functionality assessment. This includes checking the power supply and ensuring that all components are responding appropriately. Pay attention to any unusual sounds or behaviors, as these may indicate underlying issues that require further investigation.

Performance Evaluation

After the initial check, proceed to evaluate the performance of the device under normal operating conditions. This involves running the equipment for an extended period while monitoring its efficiency and effectiveness. Any discrepancies from expected performance standards should be addressed immediately to prevent potential failures.

Preventative Maintenance Tips

Regular upkeep is essential to ensure optimal performance and longevity of your equipment. By following a few simple practices, you can minimize the risk of breakdowns and enhance efficiency.

1. Clean After Use: Always remove debris and dirt from the device after each use. This prevents buildup that can hinder operation.

2. Check and Replace Filters: Periodically inspect filters for dirt accumulation. Replacing them when necessary can improve airflow and functionality.

3. Lubricate Moving Parts: Apply suitable lubricant to all moving components to reduce friction and wear, enhancing overall performance.

4. Inspect Cables and Connections: Regularly examine electrical connections and cables for signs of wear or damage, ensuring safe operation.

5. Store Properly: Keep the device in a dry and secure location when not in use. Proper storage can prevent unnecessary damage.

Implementing these practices can significantly extend the lifespan and reliability of your equipment.

Where to Find Replacement Parts

Locating suitable components for your equipment can significantly enhance its performance and longevity. Whether you are in need of specific parts due to wear or damage, there are various resources available to assist you in this endeavor.

Authorized Dealers: One of the most reliable sources for parts is authorized dealers. These establishments often stock genuine components, ensuring compatibility and quality.

Online Retailers: Numerous online platforms offer a wide range of parts for various models. Searching these sites can yield quick results, along with user reviews to gauge quality.

Local Repair Shops: Visiting local repair shops can also be beneficial. Experienced technicians may have spare parts or can direct you to trustworthy suppliers.

Manufacturer’s Website: The official website of the manufacturer often features a section dedicated to parts and accessories. This can be a convenient way to access necessary items directly.

Using these resources will help ensure you find the appropriate components to keep your equipment functioning effectively.